Photo Credit : Mariana Diaz Leites

Some Statistics

- According to the circularity gap report 2022, only 8.6% of the global economy is circular.

- By 2050, the population on the earth is likely to reach 9bn people and means that we will require 3 times more resources that we currently use. If we are to meet the needs of a population of nine billion effectively, then we need a different operating system for our entire economy.

- Buildings are responsible for more than 40% of global energy use and one third of global greenhouse gas emissions, both in developed and developing countries.

The global Construction & demolition waste market is estimated to be USD 26.6 billion in 2021 and is projected to reach USD 34.4 billion by 2026, at a CAGR of 5.3% from 2021 to 2026.

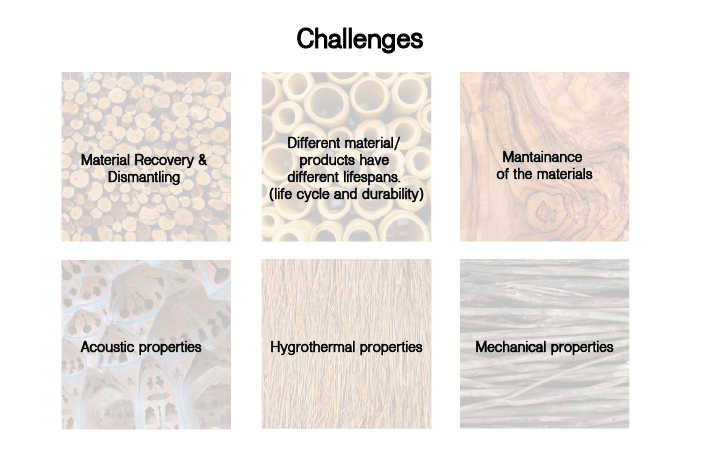

Challenges

Photo Credit : Mariana Diaz Leites

Solutions

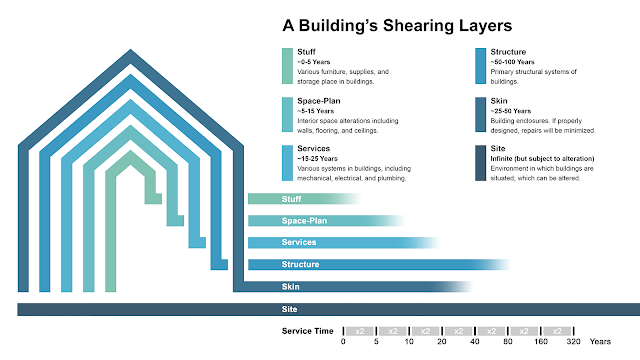

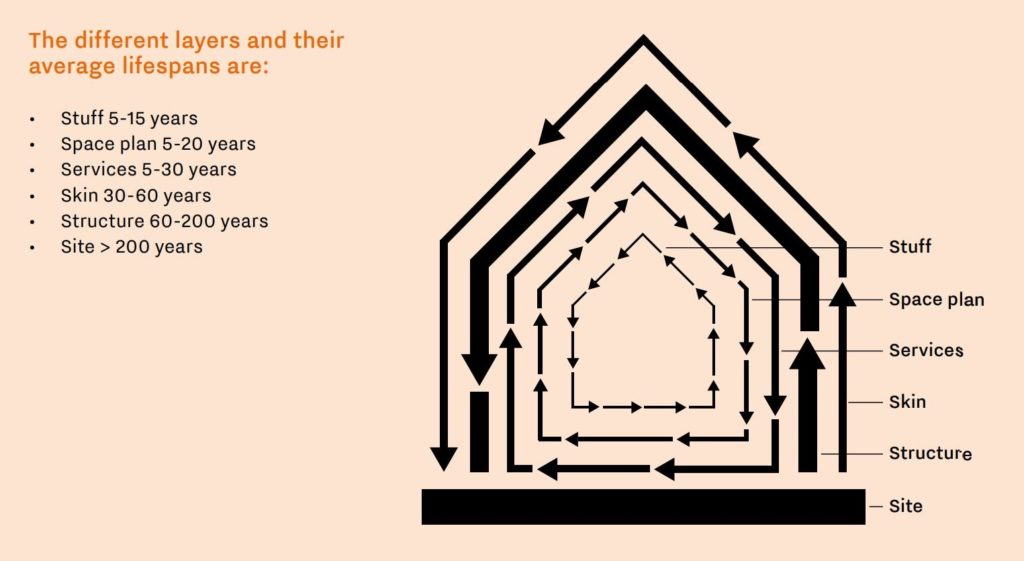

The Shearing layers – A concept by Architect Frank Duffy, Which was elaborated by Steward Brand in his book “How Buildings learn: What Happens After They’re Built”

The idea is that there are processes in nature that live in different time scales which result in no or least amount of transfer of energy.

A better understanding of these different layers can help us increase the potential of circularity of a building from the planning stage itself

All these layers have different longevity and operate at different timeline

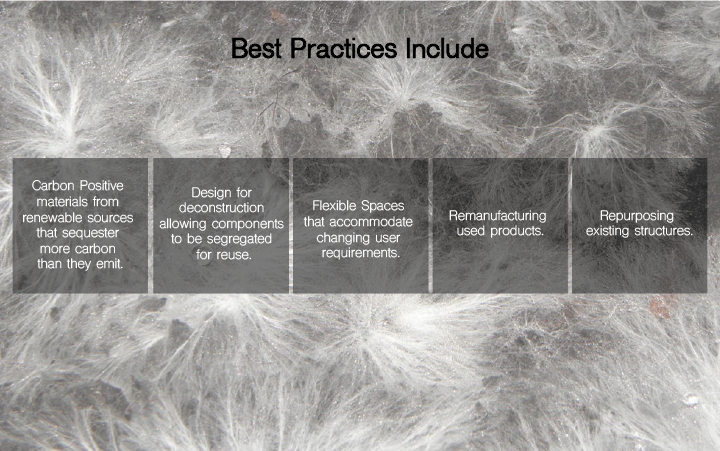

Biobased materials can be reabsorbed by the planet as biological feedstock within a timeframe that corresponds to the service life and without leaving toxic traces behind or other forms of pollution

Design for disassembly: is a holistic design approach where the intention is to make any given product easy to disassemble into all its individual components.

Allows the different components to fit into a closed material cycle, where they can be reused, reassembled and recycled to new products of similar or higher quality Because the product is easier to assemble, simpler and cheaper to produce.

Photo Credit : Sanjana Chaganti

Material Passport

Material passport ensures the ability to gain access to all relevant information describing the characteristics and quality of a component or material in a product. It is not necessarily a collected database integrated in BIM.

Relevant information must be collected for each component in the construction:

- The initial, characteristics of the component as delivered from the supplier or manufacturer

- The actual, characteristics and conditions of the component after use

- Chemical and technical specification

- Environmental impact during production and lifetime

- Description of quality assurance and relevant certificates

- Instructions for assembly, disassembly, maintenance, reconstruction and reuse

- Unique code to identify exact location in the construction

The passport will represent the current state of the building and materials. It can be regularly updated after assessment through physical inspection or by simple physical tests.

But to identify the exposure during the entire lifetime of the component, monitoring kits will be required.

Case Studies

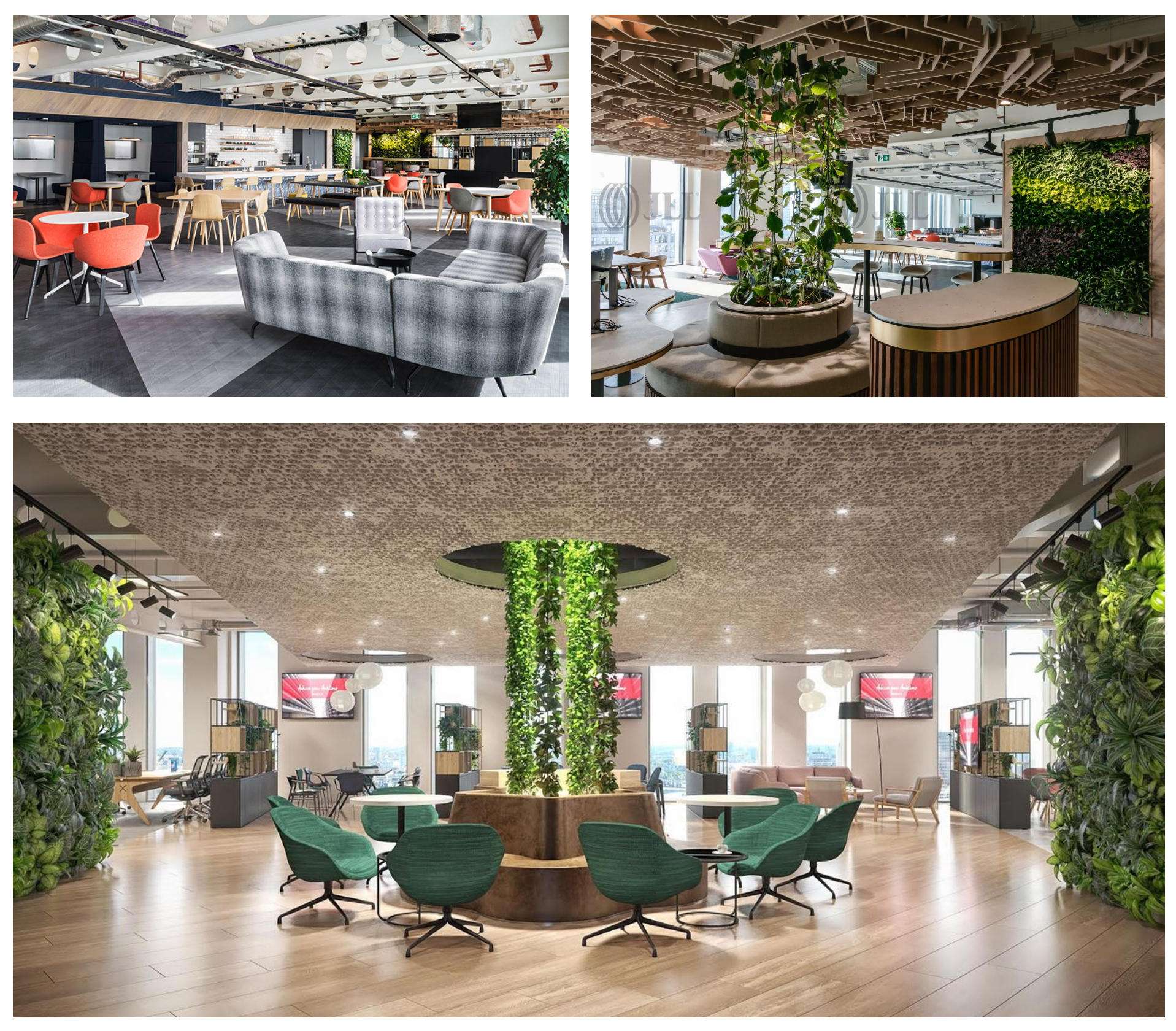

JLL Landmark Office Manchester

Project Type: Fit-Out Office

Circular Principles :

- Flexible fit-out design used low tack adhesives which allow moving elements

- High recycled content which meets the lifecycle requirements of the project

- Use of upcycled materials

- Reused AV equipment and table frames from its previous office and repurposed glass table tops

- New AV equipment was procured through a leasing model. The provider will maximized the value of the AV asset at the end of the lease.

- The old furniture from the previous office were donated.

- Achieving reuse on over 90% of the products from the previous office.

“JLL’s Office Fit Out Is Leading the Way in Wellbeing.”

Overbury,

www.overbury.com/case-studies/jll-manchester.

Margent farm: flat house, Cambridgeshire

Project Type: New Build House

Film director Steve Barron realised that it was high time to respond to the environmental crisis

Circular Principles :

- Prefabrication construction system

- Use of hemp-based materials – it sequesters carbon better than commercial forestry

- Hemp has long tap roots which is good for soil to channel water deeper and to hold the soil structure in plan

- Main body of the house is constructed out of ‘Hempcrete – a mixture of hemp shiv and lime

- Easily disassembled at the end of life and either reused or mulched or composed back into the soil.

- Internal finish – Clay paint

- External cladding – Corrugated composite material made from hemp fibre grown on site that is thermally compressed with sugar-based resin made entirely from agricultural waste

- This corrugated cladding requires 2.6 times less energy than bitumen plastic and 1.5 times less energy than galvanized steel cladding

“Hemp Is Used on the Inside and Out of Cambridgeshire’s Flat House.”

Dezeen, 9 Jan. 2020,

www.dezeen.com/2020/01/09/flat-house-hempcrete-practice-architecture-margent-farm.

Tideway: Thames Tunnel

Project Type: Interception Tunnel, London

1379 tonnes of carbon avoided through circular design changes

Circular Principles :

- Reducing the amount of carbon embodied in material by prioritizing low carbon materials and redesign of assets.

- Reduce the lining thickness – led to a 16% saving on the volume of concrete used across the 12.6km central section of the tunnel

- maximized the volume of cement replacement using waste products from industrial processes with Pulverized fuel ash (PFA) and ground granulated blast furnace slag (GGBS).

Jacobs,

www.jacobs.com/projects/thames-tideway-tunnel.

Case Study Sources : “Advancing Circular Construction” by Business in the Community, https://www.bitc.org.uk/wp-content/uploads/2020/09/BITC_Casestudiesdoc_AdvancingCircularConstruction_September2020.pdf

Dry stacking of bricks

Bricks have a longer life span compared to concrete. But during demolition at the end of the lifespan of concrete, bricks also tend to get categorized as waste. Also the separation of brick from mortar is a hectic process. Here the mortar joints are replaced by plastic units.

StoneCycling, 1 Nov. 2021, www.stonecycling.com/news/drystack-demountable-facades.

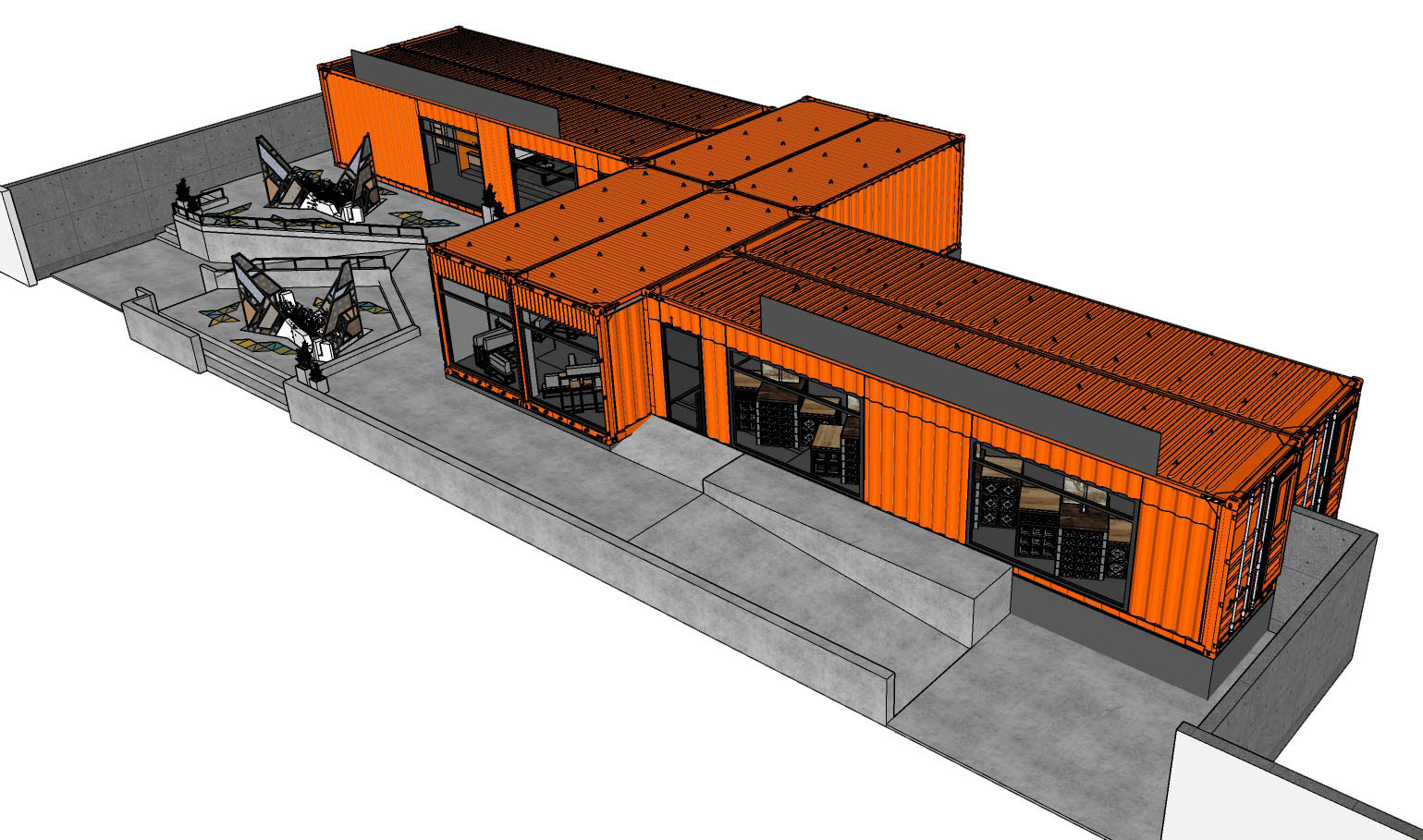

Container Showroom, Al Tasnim Group

Project Type: Showroom, Muscat, Oman

Asset management & circular procurement

Circular Principles :

- At the end of an asset’s lifespan, high-quality recycling and reuse of materials can address the huge amounts of construction and demolition waste, resource scarcity, and environmental impact associated with material production.

- Excess materials from building construction sites are repurposed to be used in another construction project.

- For this project, old containers are repurposed for the showroom and the samples of excessive building materials are displayed for client selection.

Photo Credit : Ahmed Faizal

Photo Credit : Ahmed Faizal

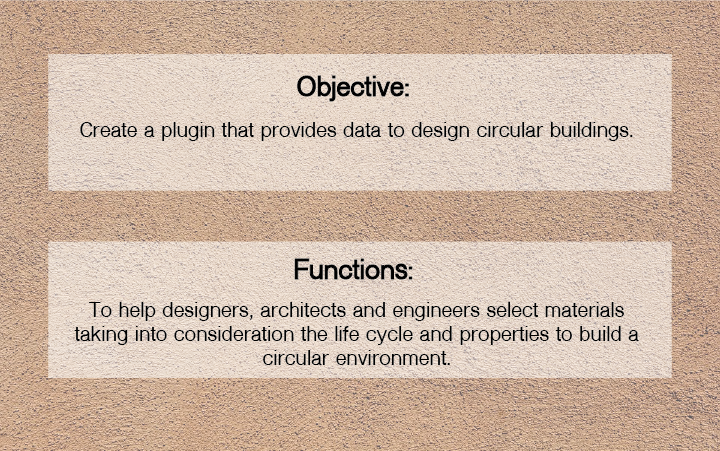

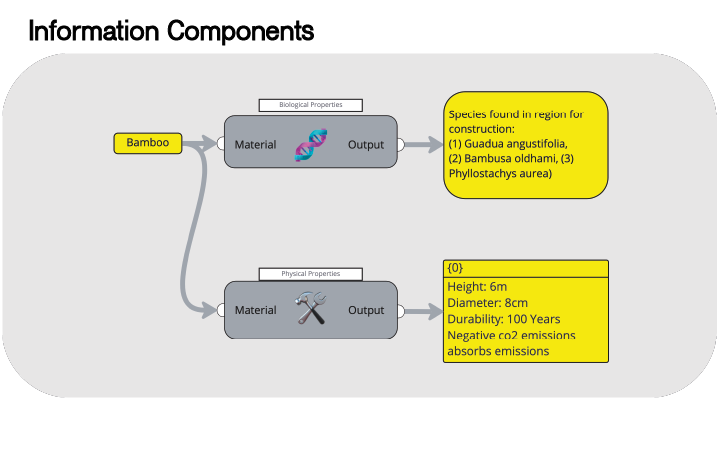

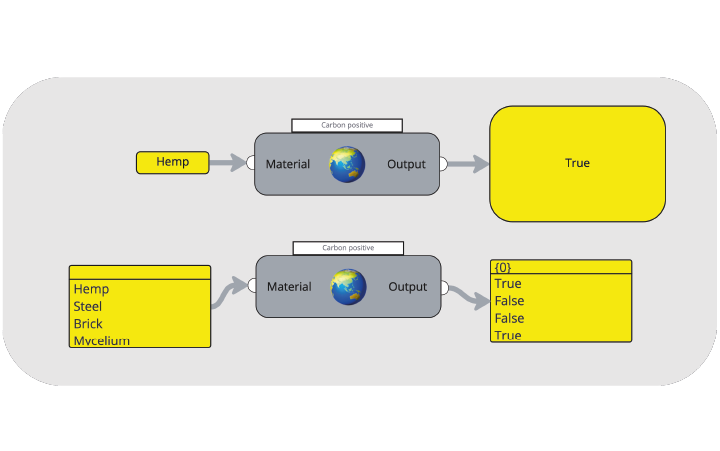

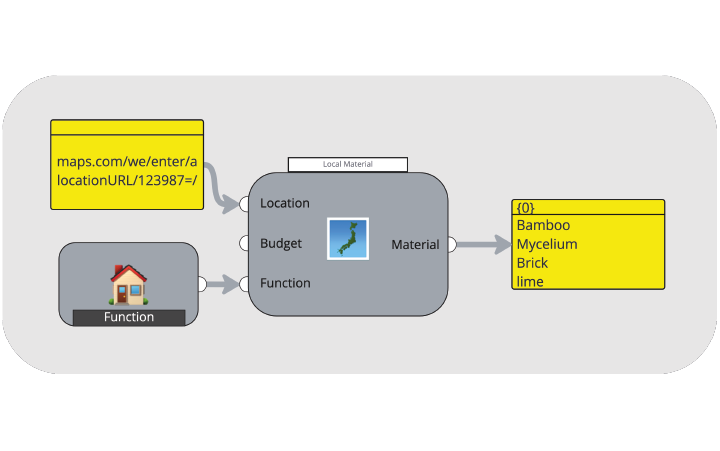

Plug-in for Circular Buildings or Material Passport

Credit : Sanjana Chaganti

Credit : Sanjana Chaganti

Credit : Sanjana Chaganti

Credit : Sanjana Chaganti

Grasshopper Plug-in Component Examples

Input the location – Output the locally found material

Input the material – Output the species (in case of timber)

Input the material – Output the transportation time & cost of the material

Input the material – Output the materials with similar life cycle/ durability, Combination of material use

Ladybug can be used to define the material’s response to weather (daylight, radiance, wind, water)

After defining the material, Karamba3D is used to define structural forces depending on the chosen material.

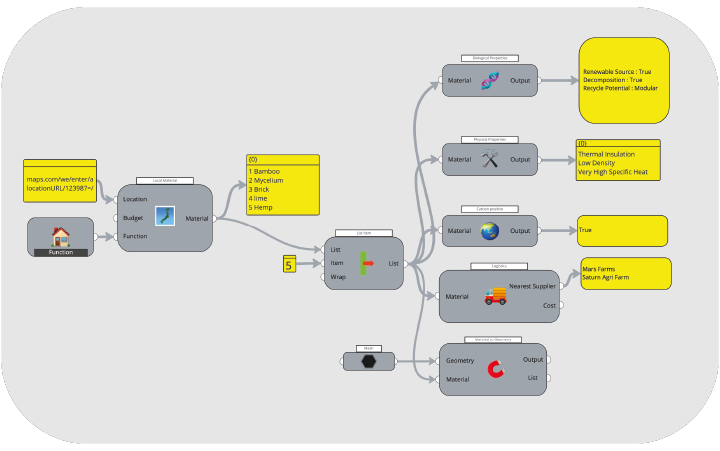

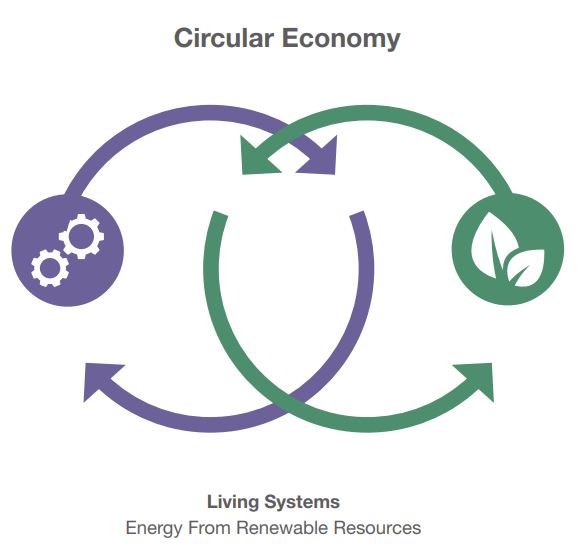

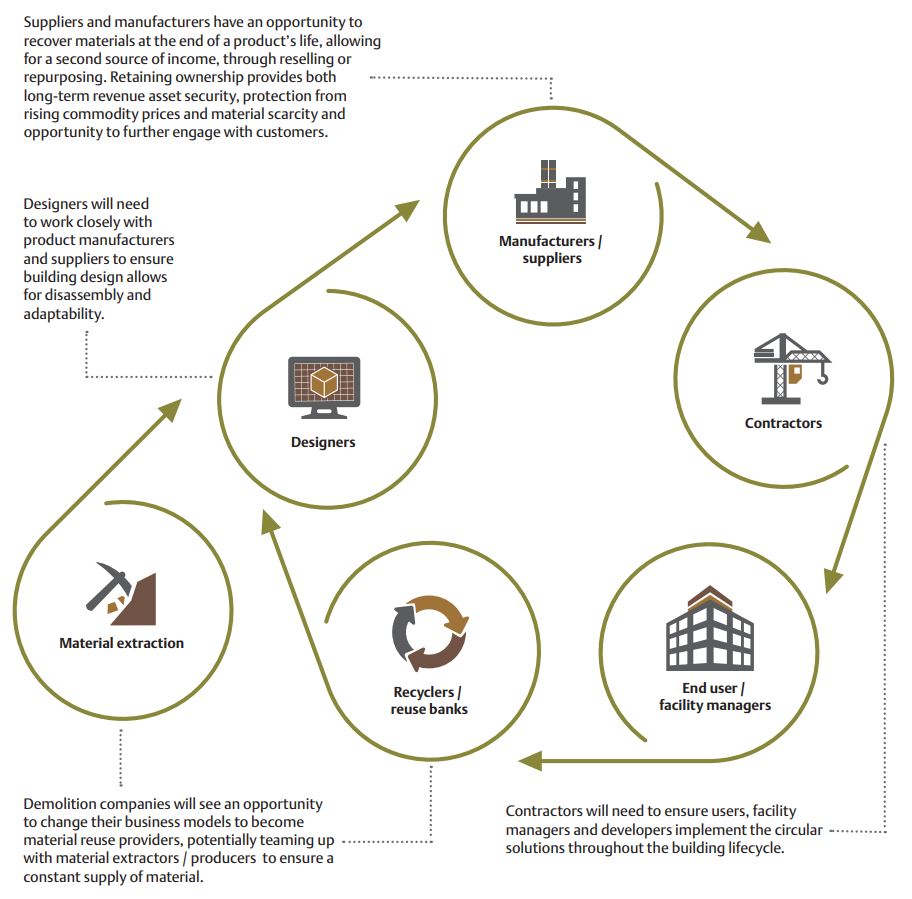

Circular Business Models

The key to a circular economy is closing the loop of products and raw materials, keeping them in use as intensively and as long as possible, preventing wastage and waste as much as possible (along the Ladder of Circularity).

A circular building’s economy

Circular economy principles can help solve building sector challenges in several ways. Circular design pre-integrates lifespan considerations, and future reuse of materials and structures at every stage of the project.

- Asset management

- Recycling and reuse of materials

- Use of renewable and bio-based materials, such as timber, hemp, and elephant grass.

- Digital technologies such as material passports or digital logbooks can track the journeys of products, components, and materials.

- Digital solutions and sustainable business models and services (e.g. products-as-service) will not only dematerialize our economies and make them less dependent on primary resources.

- Developing methods to measure circularity is essential to make informed decisions.

- Circular procurement

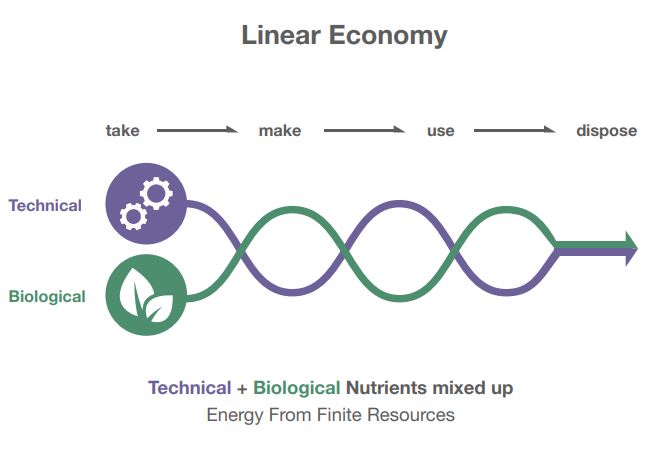

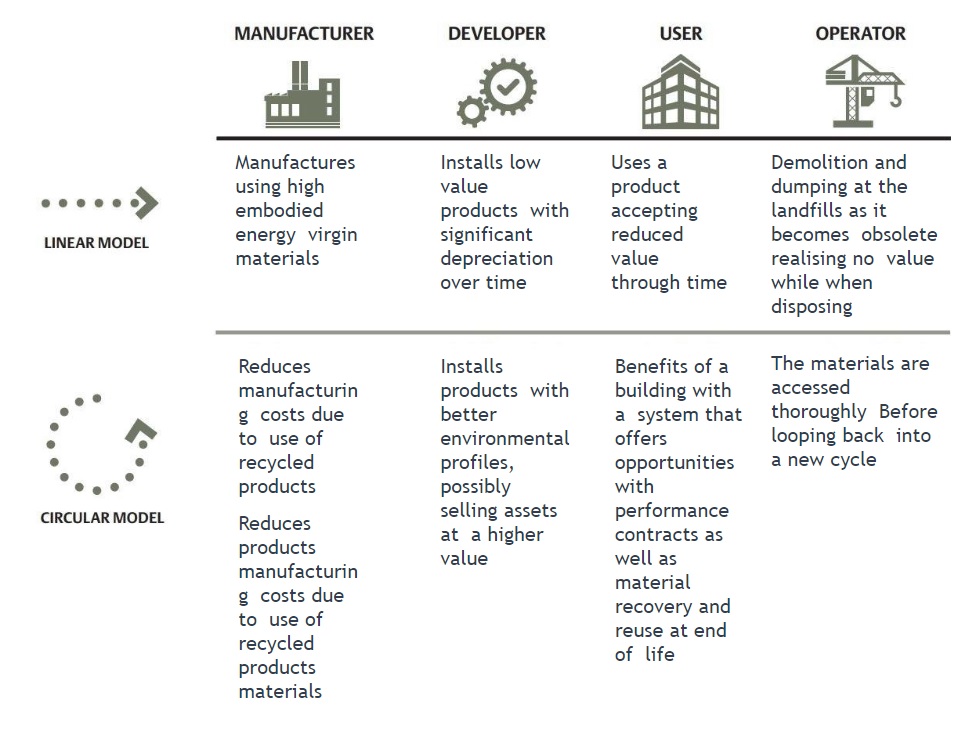

The Built Environment: from Linear to Circular

The built environment is under increasing pressure to minimize its impact. A circular approach could help the sector to reduce its environmental footprint, and to avoid rising costs, delays, and other consequences of volatile commodity markets.

By adopting circular economy business models, the focus will shift to sourcing sustainably, maintaining material productivity over the lifecycle of developments, and reducing losses of non renewable materials. This will produce financial, social and environmental benefits.

The ReSOLVE framework

The ReSOLVE framework is a key output of the Ellen MacArthur Foundation’s research. It outlines six actions to guide the transition towards a circular economy.

The six elements can be applied to products, buildings, neighborhoods, cities, regions, or even to entire economies. The framework is used to illustrate how the circular economy can be applied in the built environment.

Circular Value Chain

Benefits of Circular Business Models

References

“Shearing Layers of Change – Seeking Higher Ground.” Shearing Layers of Change – Seeking Higher Ground, ifma.foleon.com/white-paper/seeking-higher-ground/shearing-layers-of-change. Accessed 1 Jan. 2023.

“Advancing Circular Construction” by Business in the Community, https://www.bitc.org.uk/wp-content/uploads/2020/09/BITC_Casestudiesdoc_AdvancingCircularConstruction_September2020.pdf

“JLL’s Office Fit Out Is Leading the Way in Wellbeing.” Overbury, www.overbury.com/case-studies/jll-manchester. Accessed 1 Jan. 2023.

Levy, Natasha. “Hemp Is Used on the Inside and Out of Cambridgeshire’s Flat House.” Dezeen, 9 Jan. 2020, www.dezeen.com/2020/01/09/flat-house-hempcrete-practice-architecture-margent-farm.

“Thames Tideway Tunnel.” Jacobs, www.jacobs.com/projects/thames-tideway-tunnel. Accessed 1 Jan. 2023.

“Drystack: Making Demountable Facades With StoneCycling.” StoneCycling, 1 Nov. 2021, www.stonecycling.com/news/drystack-demountable-facades.

“18 Eco-Friendly Building Materials That Help You Save Energy and the Earth.” Barbulianno Design, 16 Oct. 2020, www.barbuliannodesign.com/post/eco-friendly-building-materials-list.

“About Bamb – BAMB.” BAMB, www.bamb2020.eu/about-bamb. Accessed 1 Jan. 2023.

Thorns, Ella. “8 Biodegradable Materials the Construction Industry Needs to Know About.” ArchDaily, 2 May 2018, www.archdaily.com/893552/8-biodegradable-materials-the-construction-industry-needs-to-know-about.

“Circular Economy in the Built Environment – Arup.” Circular Economy in the Built Environment – Arup, www.arup.com/en/perspectives/publications/research/section/circular-economy-in-the-built-environment. Accessed 4 Jan. 2023.

“Circular Business Models for the Built Environment.” Circular Business Models for the Built Environment – Arup, www.arup.com/en/perspectives/publications/research/section/circular-business-models-for-the-built-environment. Accessed 4 Jan. 2023.

Circular Buildings: constructing a sustainable future 3 Content. (n.d.). https://circulareconomy.europa.eu/platform/sites/default/files/nl-branding-circular-buildings.-f.pdf

“9042_Misfah_ATNMCP_Container Showroom” Al Tasnim Enterprises.