Bringing together structural design and thermal performance!

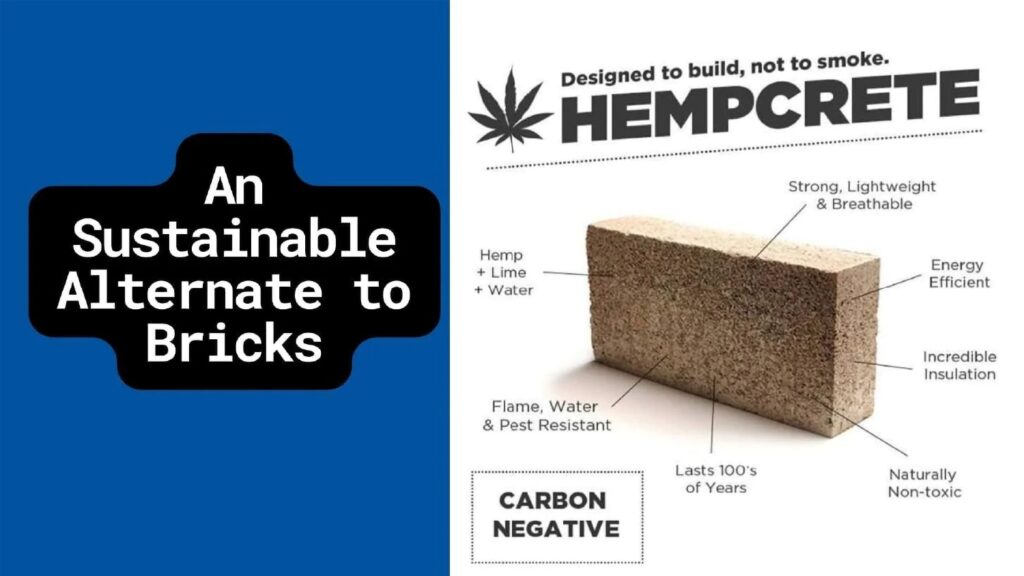

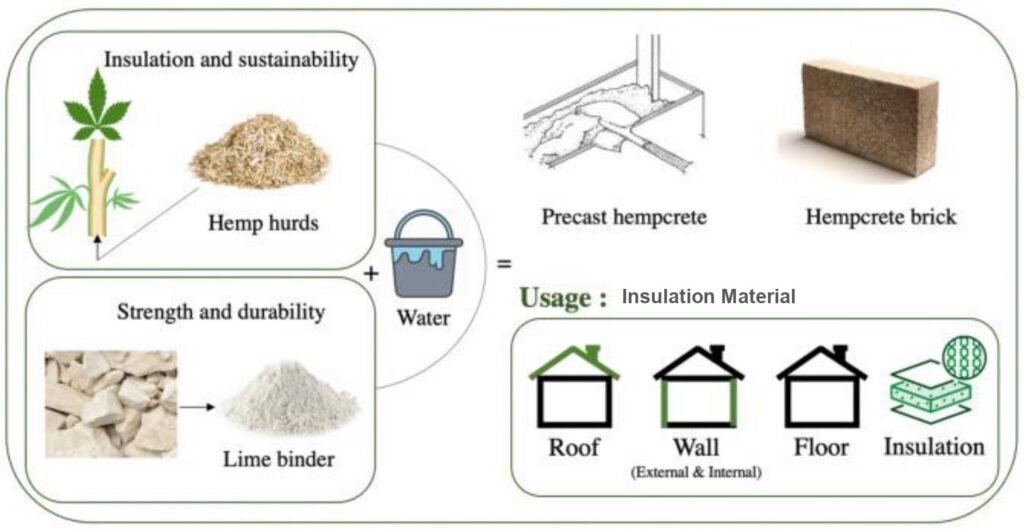

Section 1 : Introduction to Hempcrete

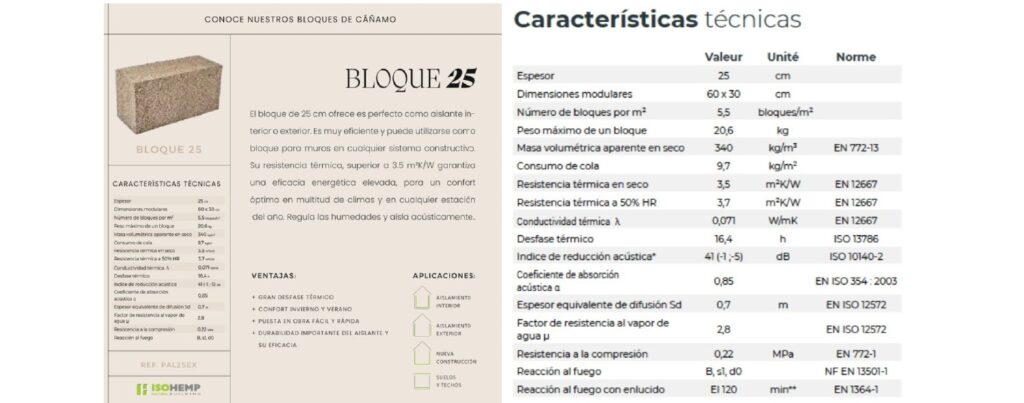

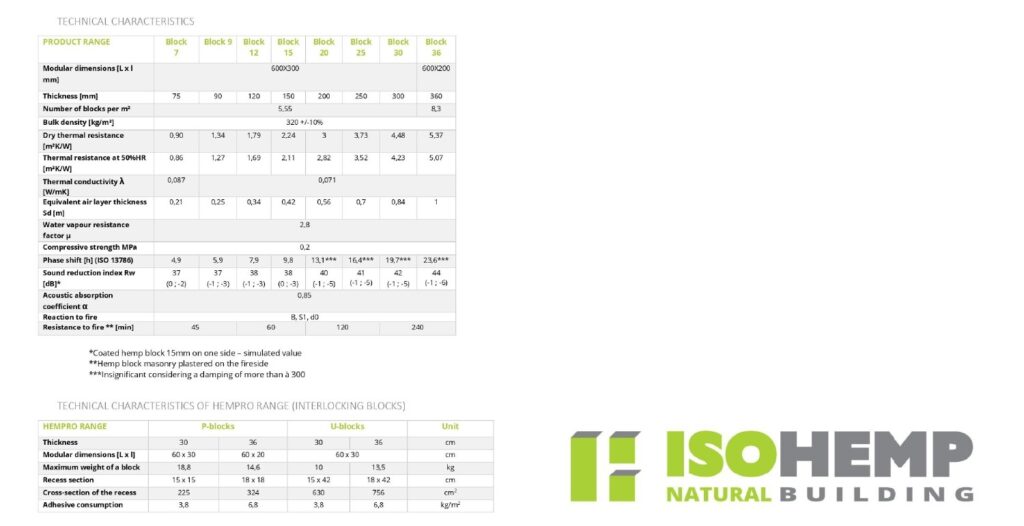

Hempcrete has excellent insulating properties, providing thermal regulation by allowing the building to breathe and reduce moisture build-up. The thermal conductivity of hempcrete is typically in the range of 0.06 to 0.07 W/mK, which is about half the thermal conductivity of concrete.

One of the primary advantages of hempcrete is its sustainability. Hemp sequesters carbon dioxide from the atmosphere during its growth, making it a carbon-negative material.

The 25 cm block is perfect as interior or exterior insulation, it is highly efficient and can be used as a wall block in any construction system. Its thermal resistance of more than 35 m²K/W guarantees high energy efficiency, for optimum comfort in multitude of climates and in any season of the year. It regulates humidity and insulates acoustically.

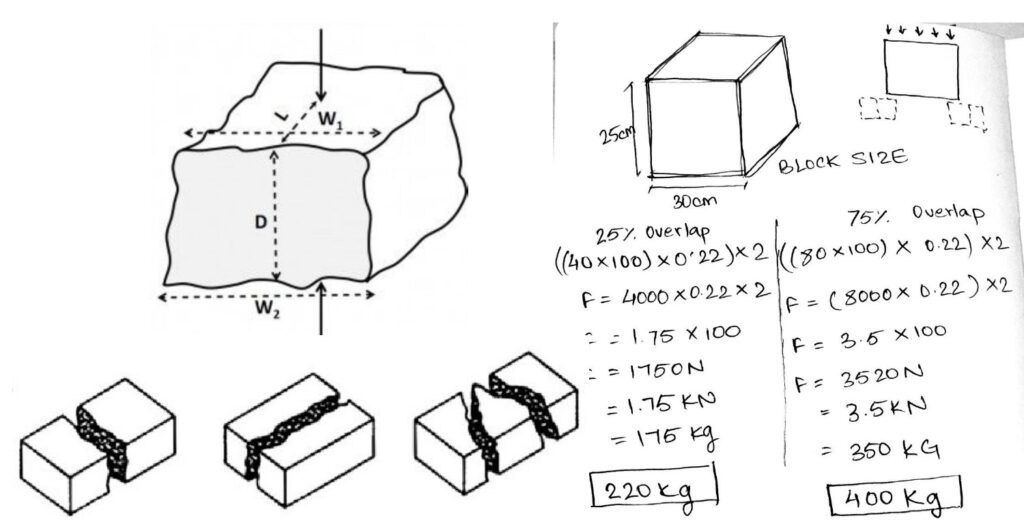

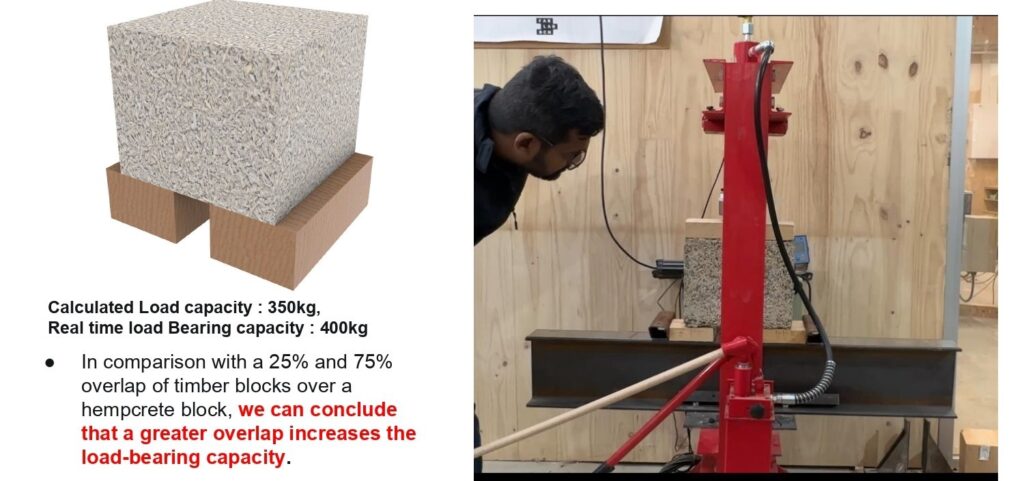

Section 2 : Compression Test and Load bearing Capacity

Calculated Load capacity : 175kg , Real time load Bearing capacity : 220kg

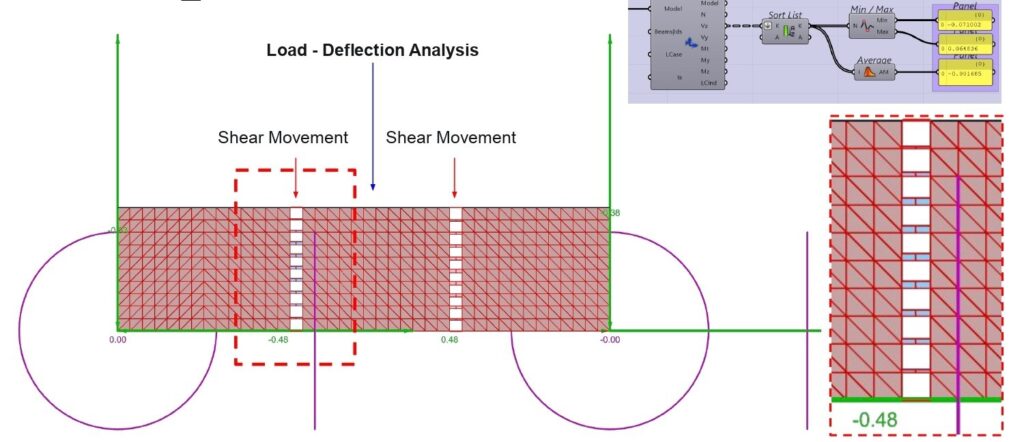

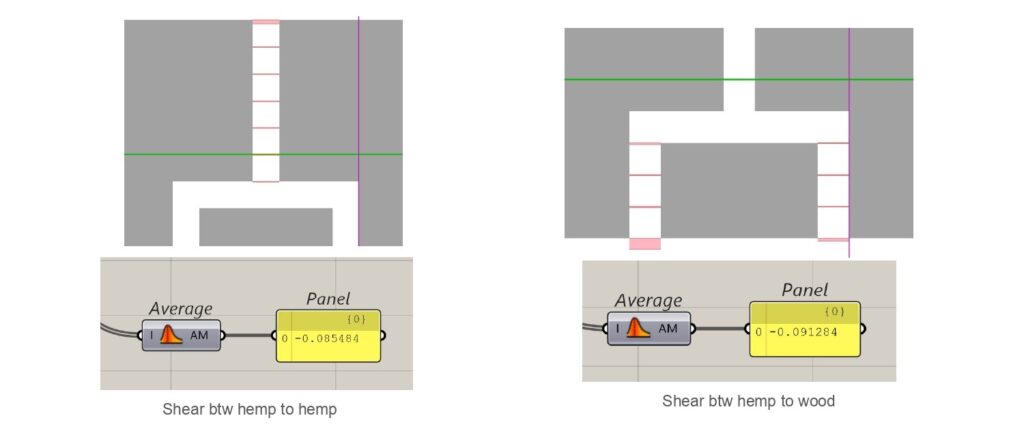

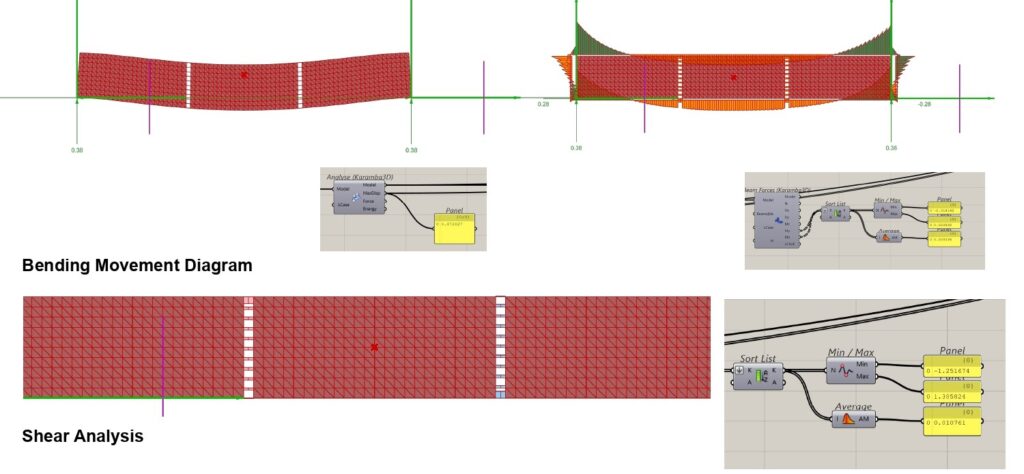

Section 3 : Shear Test – Karamba Analysis

Maximum Load Application on the Hempcrete Block in order to check movement of block.

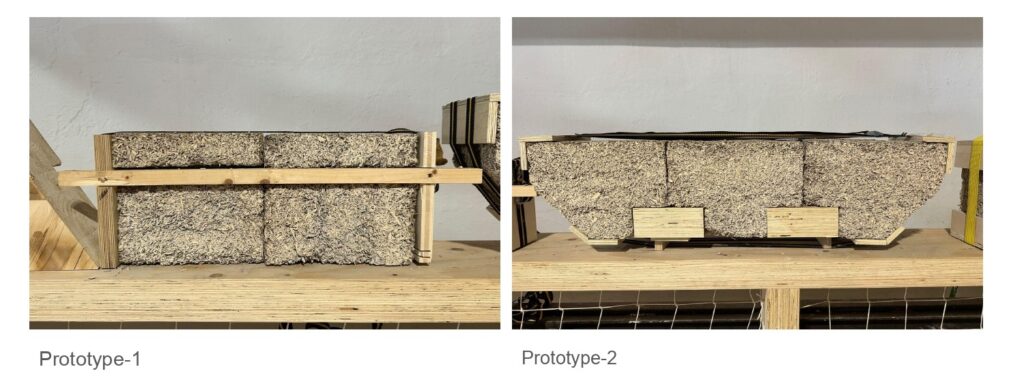

Section 4 : Shear Test – Real Time Scenario

Smooth Surface, Without Post tension ( Through wedges ) – 6kgs

With Post tension ( Through wedges ) – 55 to 60 kgs

Rough Surface, Without Post tension ( Through wedges ) – 9kgs

With Post tension ( Through wedges ) – 80 to 85 kgs

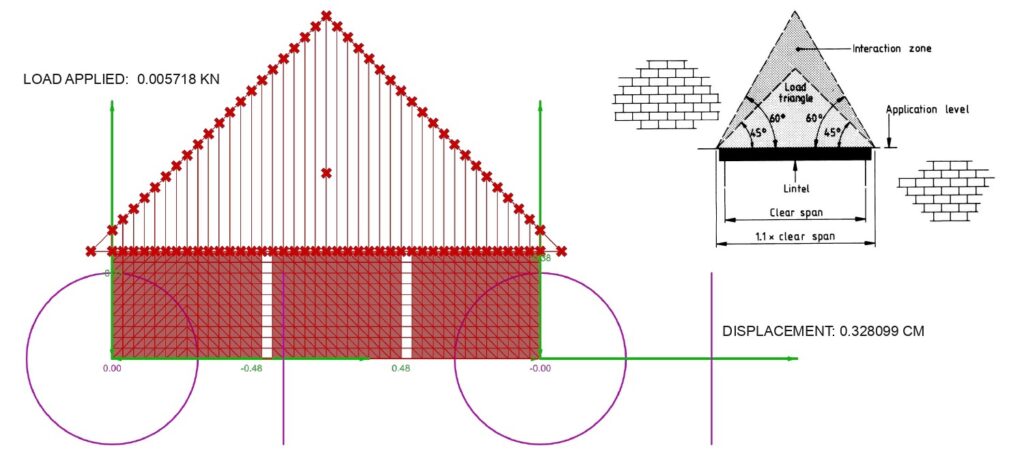

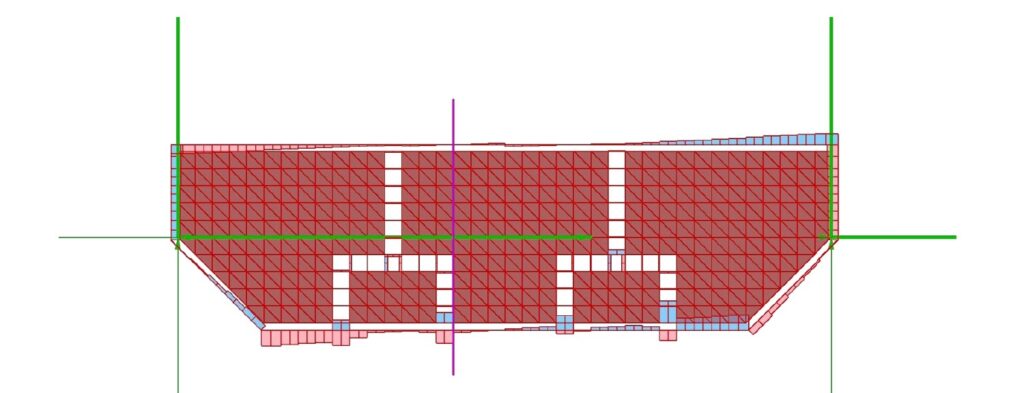

Section 5 : Beam Iterations and Designs

DISPLACEMENT (WITH HEMP BLOCKS ONLY) :1.178602 CM

DISPLACEMENT (WITH HEMP AND TIMBER BLOCKS) : 0.793855 CM

UNDERSTANDINGS

Rough over smooth Surface

To not Scrape/ cut Hempcrete block – Use in its whole form

Pre stress to be applied to create friction

Post tension to be applied to allow shear between Hemp-hemp, Hemp-wood

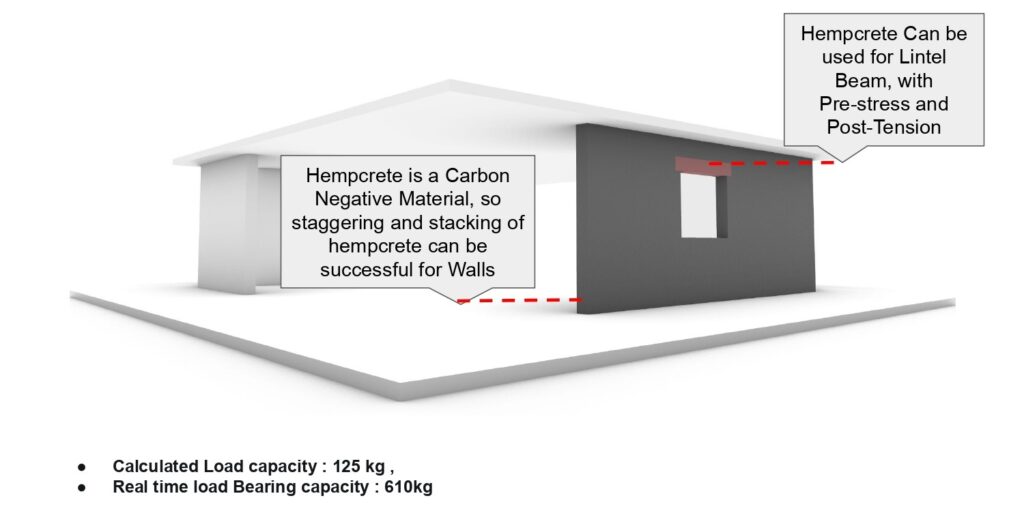

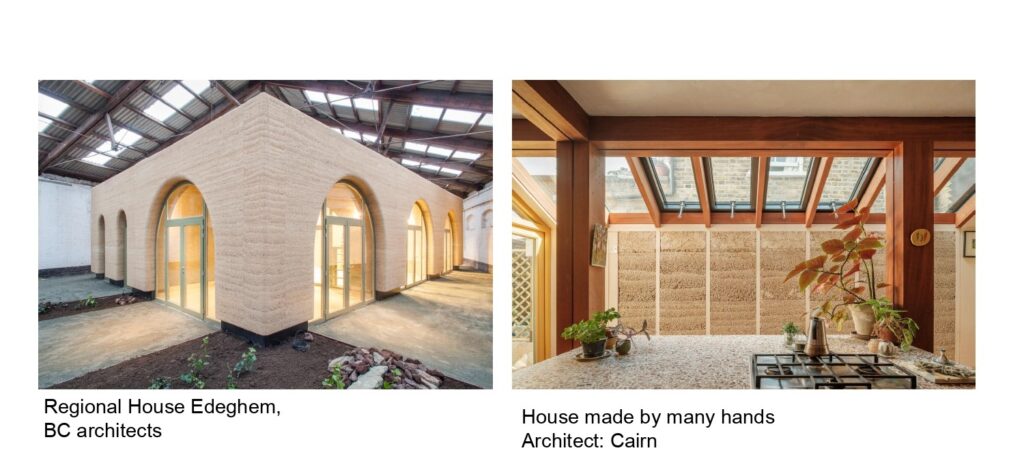

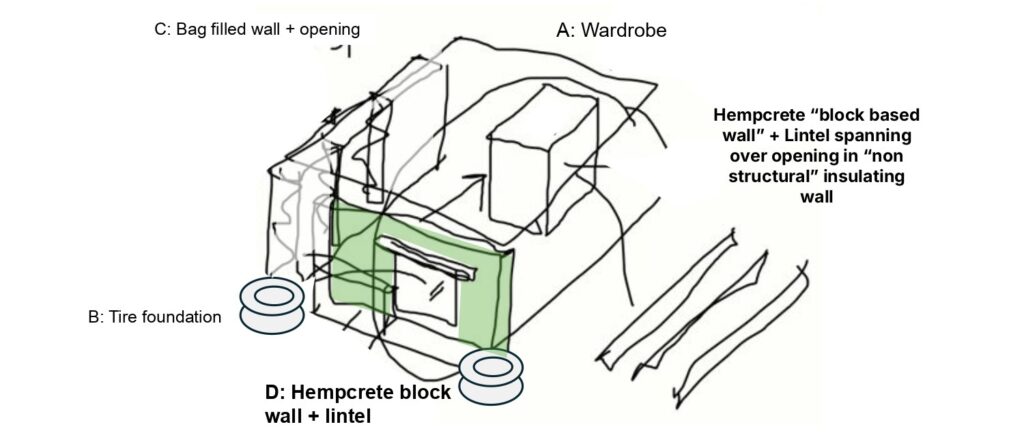

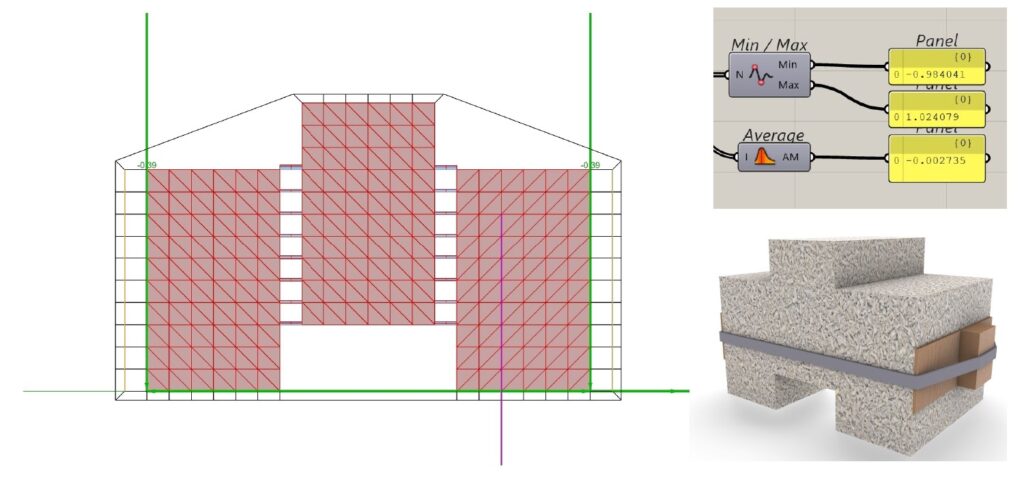

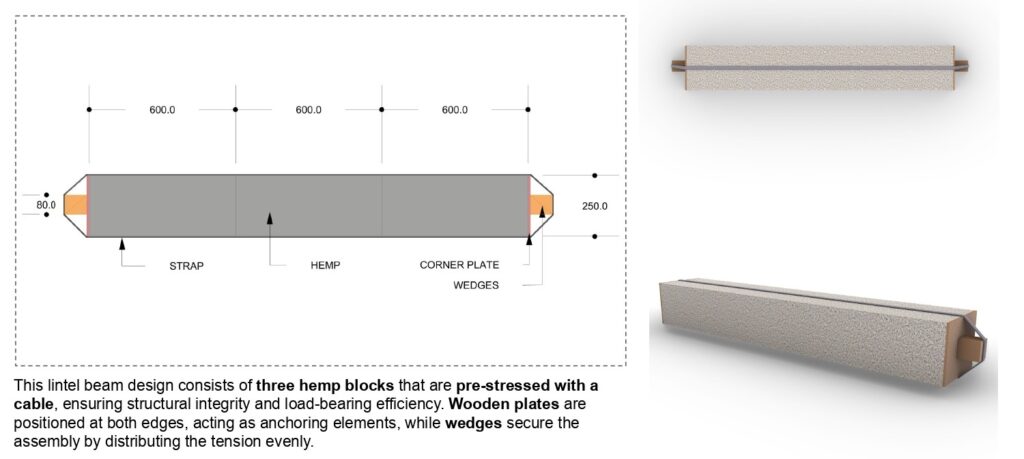

Section 6 : Proposed Design

Section 7 : Proposed Beam Test Results

Calculated Load capacity : 125 kg , Real time load Bearing capacity : 250kg

Calculated Load capacity : 125 kg , Real time load Bearing capacity : 610kg

Section 8 : Conclusion