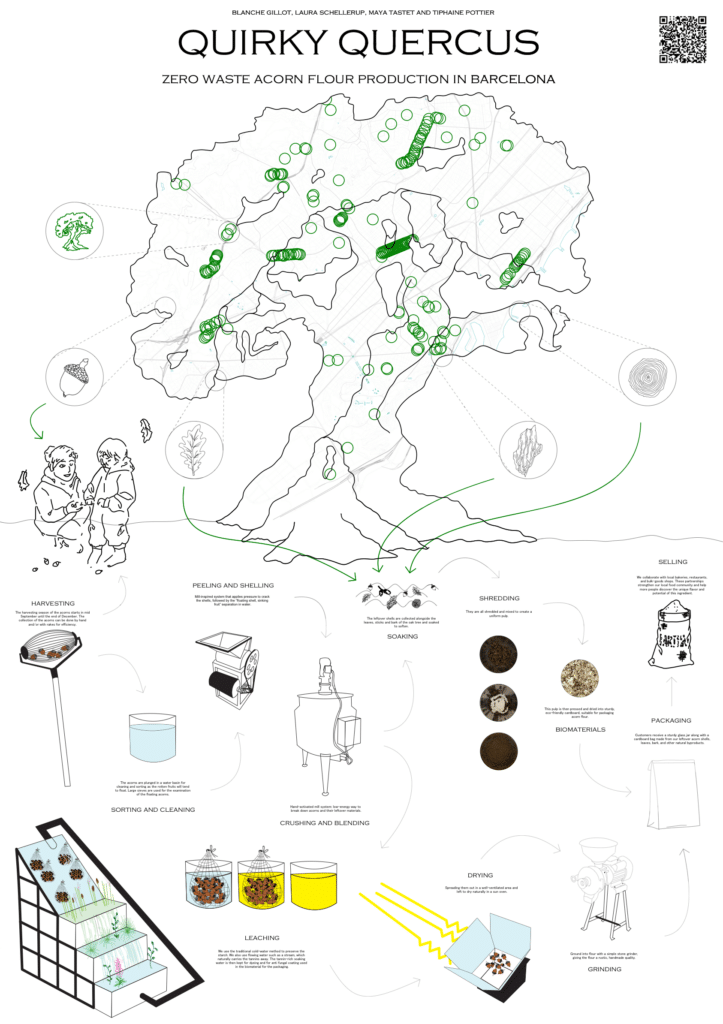

Zero waste acorn flour production in Barcelona

Quirky Quercus is a cottage industry aiming to transform locally collected acorns fallen from the parks of Barcelona into flour. The product is designed to use all parts of the tree, including the acorn shells, leaves, and oak bark to make a biomaterial packaging. This project strengthens connections between the city and its natural spaces, inviting the community to rediscover the value of what is often overlooked and seen as waste.

Harvesting

The harvesting season of the acorns starts in mid September until the end of December. During this time, we partner with primary schools for a simple and educational program. The children from the schools collect acorns alongside fallen leaves, sticks and bark used later for the biomaterial of the packaging. They get to learn about local trees and sustainable foraging. In the afternoon, they visit our workshop to help make acorn pancakes from the leftover acorn flour. The collection of the acorns can be done by hand for the younger kids, and with rakes for the older ones. The rakes allow for an efficient and fast collection of the acorns while still keeping it entertaining and fun for the kids.

Sorting and cleaning

The acorns are plunged in a water basin for cleaning and sorting. The rotten fruits will tend to float because of the fermentation process happening inside the shell resulting in the formation of air pockets. The floating acorns can be removed for further examination and discarded. Large sieves are used for the human driven examination of the floating acorns, to remove the rotten acorns, the insects, and the dirt. Only satisfactory specimens are to be left from the process.

Peeling and shelling

After collection, the acorns arrive at our small shelling station. We use a simple, mill-inspired system that applies pressure to crack the shells, followed by the “floating shell, sinking fruit” separation in water. This low-cost universal-nutcracker setup works well for our scale. The shells and peels float and are gathered for the packaging biomaterial, while the acorns sink and are used for the next step. A professional sheller exists, but at around €3,000 and is needed only a few times a year which is far beyond our budget. Instead, we’re exploring the creation of an Acorn Association of Spain, allowing small producers to share or rent the machine, or even offer shelling as a communal service. Either way, anything we can’t upcycle goes straight to compost, keeping the process clean, circular, and waste-free.

Crushing and blending

To keep our process simple and accessible, we’re developing a hand-activated mill system. A small funnel feeding two gears turned by a crank. It’s an easy, low-energy way to break down acorns and their leftover materials. Even the byproducts find a purpose. Some batches can be lightly roasted to create a rich, “acorn coffee,” while the rest goes to compost.

Leaching

Once shelled, the acorns are leached to remove their natural bitterness. We use the traditional cold-water method which is longer than hot leaching, but ideal for flour because it preserves the starch. The acorns are soaked in cool water and the water is changed several times a day until it runs clear, a process that takes a couple of days. When possible, we use flowing water such as a stream, which naturally carries the tannins away without manual changes. The tannin-rich soaking water is then kept for dyeing and for anti fungal coating used in the biomaterial for the packaging. After boiling it for at least an hour to deepen the pigments, it produces a soft brown pigment which can shift into a deep grey with an iron mordant.

Drying and grinding

After leaching, the acorns are spread out in a well-ventilated area and left to dry naturally in the sun. This slow, gentle drying prevents mold and preserves the acorns’ flavor and starch. We simply check them daily until they reach the expected dryness, firm, light, and ready for grinding. Once fully dried, the acorns are ground into flour. We can keep things traditional with a simple stone grinder, giving the flour a rustic, handmade quality. Alternatively, we tighten the gears on our small crushing mill for a finer, more consistent grind.

Biomaterial packaging

To make the biomaterial, a separate process must be done. After the acorns were shelled, the leftover shells are collected alongside the leaves, sticks and bark of the oak tree. They are all soaked, shredded and mixed to create a uniform pulp before being dried into the desired shape. This pulp is then pressed and dried into sturdy, eco-friendly cardboard, suitable for packaging acorn flour. For wholesale, we offer our acorn flour in bulk. Customers receive a sturdy glass jar along with a biomaterial bag made from our leftover acorn shells, leaves, bark, and other natural byproducts. This biomaterial cardboard can be used for packaging acorn flour or other dry goods, turning what would be waste into a sustainable, eco-friendly solution. It keeps the flour fresh while showcasing the full-circle approach of our cottage industry.

Selling

We also collaborate with local bakeries, restaurants, and bulk-goods shops to showcase the versatility of acorn flour. Together, we organize small baking workshops where people can learn how to use acorn flour in breads, pastries, and everyday recipes. These partnerships strengthen our local food community and help more people discover the unique flavor and potential of this ingredient.