Overview

Every geographical location has its native construction material. Some of these materials may be used in their raw state or they can be mixed with other natural materials in order to improve their performance. Understanding Earth as a construction material and its compositions requires a technical study: deciphering the various soils and their individual components by performing tests on the materials under different states is quintessential.

Sedimentation Test

Sedimentation test is the result of settling the various sizes of particles according to their weights when dissolved in an excessive amount of water. Different soil samples were contained in the same size of glass bottles, kept undisturbed for a week. The results showed the percentage of gravel/ sand/ silt/ clay after settling as per their respective weights: the heaviest particles being settled at the bottom of the bottle, and the lightest particles of the organic matter (if any) floating at the water surface.

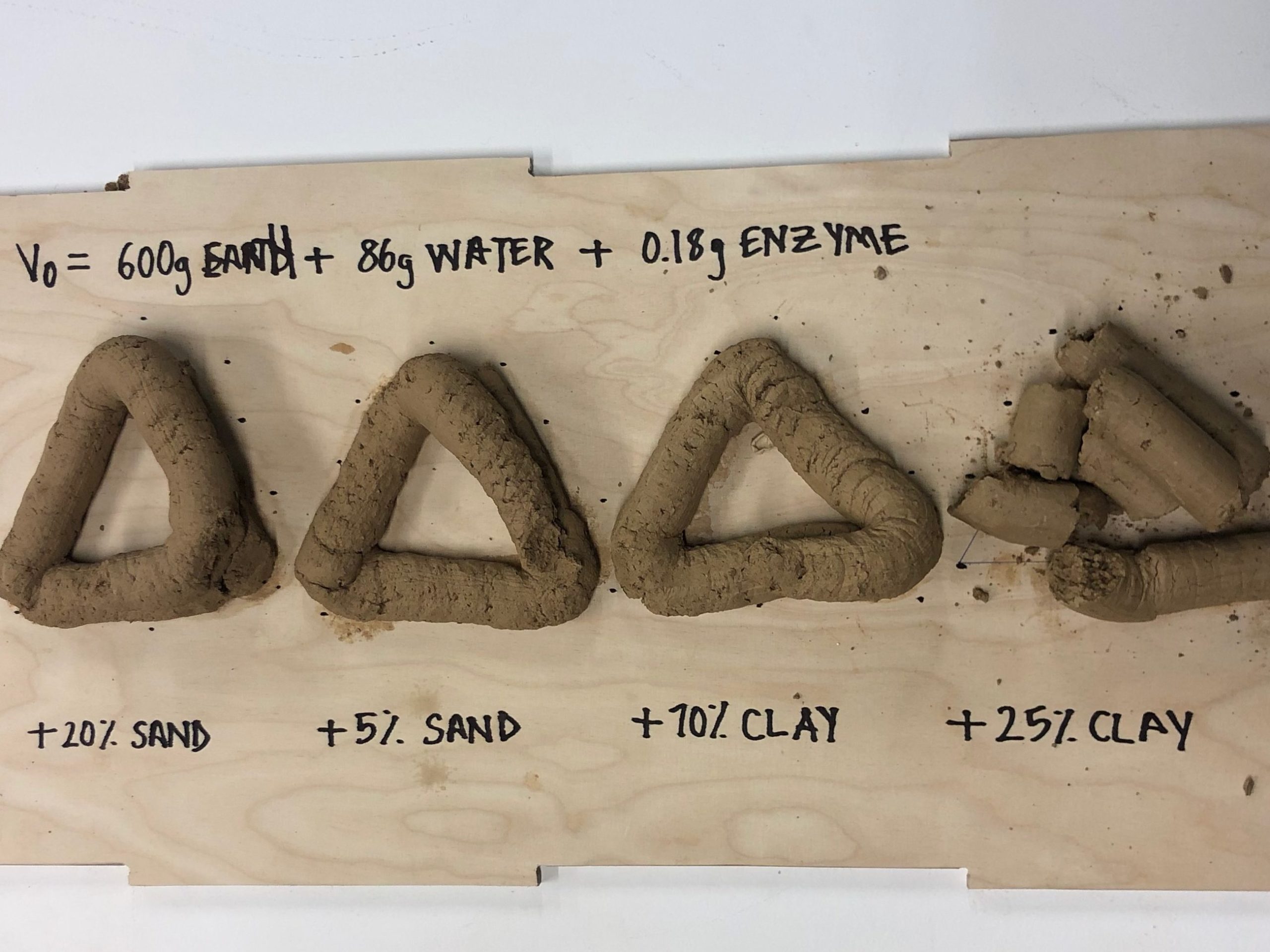

Clay-Sand Matrix

Four different samples with their respective predefined proportions were mixed with the given quantity or just enough water to be able to be extruded smoothly. Manually extruded samples in a triangular form of side 12 cm each, were observed for its ease of extrusion. Each group proposed a modified mix (5th sample) after understanding the extrusion results. All the samples were documented after drying to note the shrinkages. The dried samples were later broke by applying a constant force repetitively to understand the tensile strength of each mix sample

Water Research

Further tests were performed by changing the water proportion of the earth samples from the Clay-Sand-Matrix test. The samples were extruded in a triangular form of side 12 cm each. Water proportion in the earth mix plays a significant role, as the consistency of the final mix defines the state of the material. It is observed that the ideal state for extrusion is the viscous state. The following test results show that various types of earths require varying amounts of water in order to be able to extrude.

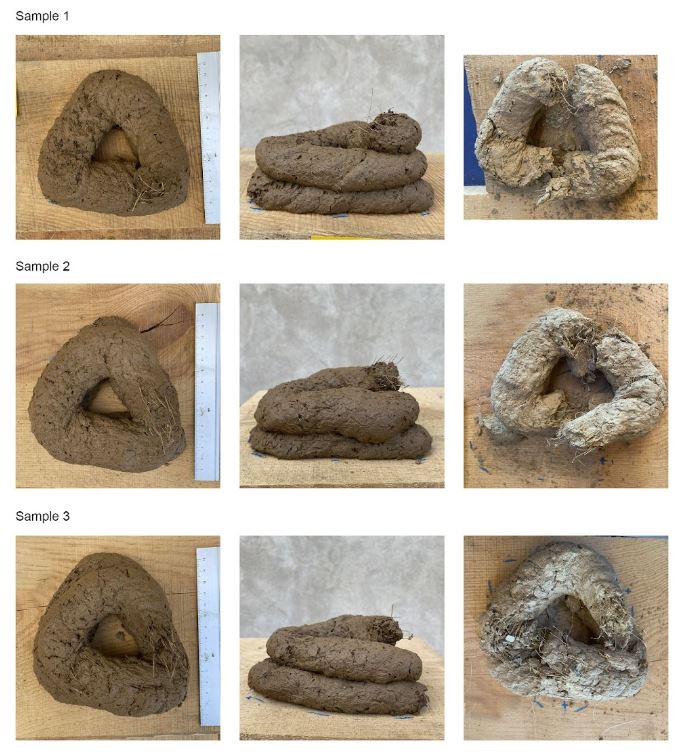

Fibers Matrix

Addition of fibers to the earth mix further improves the quality of the earth mix, as fibers not only help to prevent the shrinkage cracks but also supports the geometry in its wet state during the printing process. It is essential to monitor the quantity of fibers as excessive amounts of fibers not only absorb the water from the mix and make it not viscous enough to extrude, but also reduce the binding between the earth components. The amount and size of the fibers also depends upon the size of the extruder nozzle, as excessive amounts might result in blocking the nozzle mouth during printing.

It was observed that, less amount of fibers could not provide the desired strength to the sample and excessive amount of fiber addition made the samples fragile due to lack of adhesion and excessive water absorption by the fibers.

Carazas Test

Carazas test is one of the most important tests to understand the required state of earth mix to be able to be extruded smoothly. Various samples were molded by pouring, hand compacting, and ramming methods. Each sample showed a diverse behavior due it’s inherent binding properties or presence of the quantity of the binder in the mix. The samples were molded in their dry, humid, plastic, viscous and liquid states.

The sample types were extremely varying in its behavior. The samples of clay and sand showed opposite results due to their inherent properties. Clay being a binder, resulted into a compact core even in its dry poured state whereas sand couldn’t hold its particles when poured dry into the mold. Also, with the natural moisture content, the clay particles form glue-like properties due to surface tension behaving opposite to the nature of sand. The organic soil samples had average binding due to the presence of clay. The adherence percentage was different due to varying percentages in each soil type.

Finishes

One of the integral parts of the earth construction is the finishes, as it provides necessary protection against the erosion due to water. Two samples were tested for each type of finishing material. The first sample was prepared by adding the finishing material in the earth mix, whereas the second sample was molded by adding water and the finishing material was applied on the surface of the sample after it was completely dry. Both the samples were placed under a container with water and a tap at a height of 2.50 m. The tap was opened and the drops of water fell at the center of the sample at a high speed of one.

The samples with the finishing coat applied to the surface showed better results than adding the finishing material to the mix. Among the provided finishing materials, egg white, linseed oil and black soap performed better against erosion and penetration when kept under water dripping conditions.

Drying & Documentation

The samples were observed for its shrinkage after drying. It was observed that the amount of clay and water plays an important role in the shrinkage percentage. More the percentage greater shrinkage cracks were observed in the samples.