This hypothetical study aims to reduce CO2 emissions in the construction sector by incorporating cutting-edge technologies during the foundational stage. Our focus is on ensuring 100% renewable energy usage and optimizing energy consumption.

Our focus

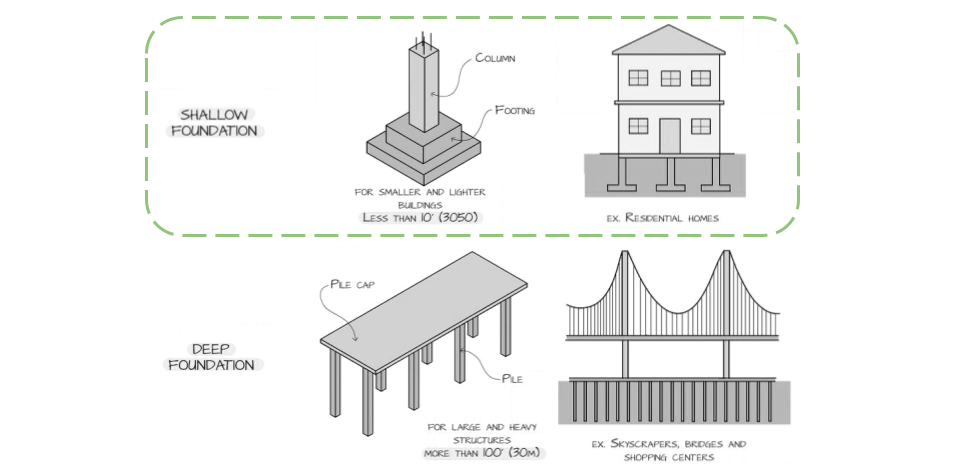

Addressing all foundation types and their associated components and processes would be too broad for us to effectively handle. To narrow our focus, we chose to concentrate on shallow foundations, which typically involve fewer processes and less machinery.

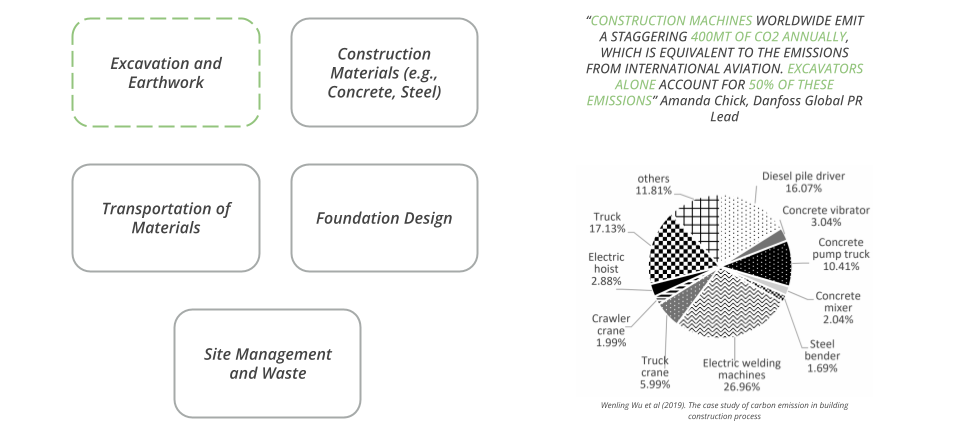

Through our research, we identified the most polluting phases during foundation construction, ranked as follows: construction material, excavation and earthwork, transportation, site management and waste, and foundation design. Given our background and expertise, we opted to zero in on excavation and earthwork.

Specifically, we aim to enhance this phase by electrifying all machinery (ensuring our energy is clean) and implementing precision excavation techniques to maximize energy efficiency.

Hypothetical Case: Electrical Foundation Company (EFC)

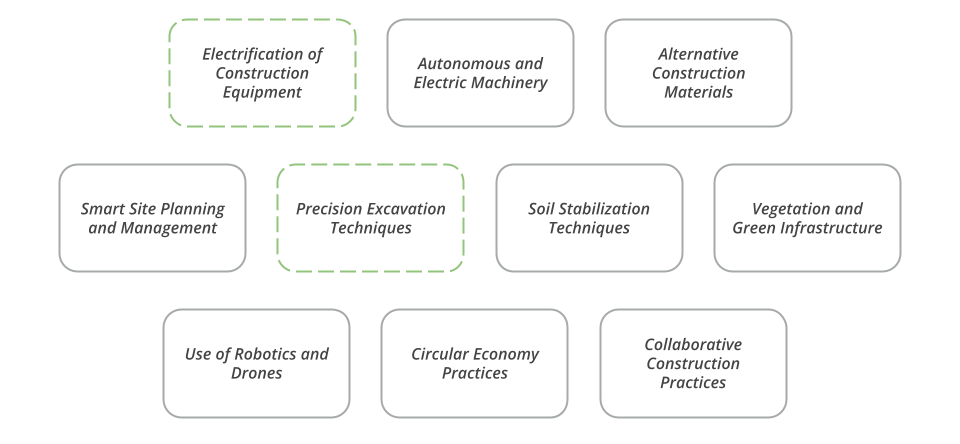

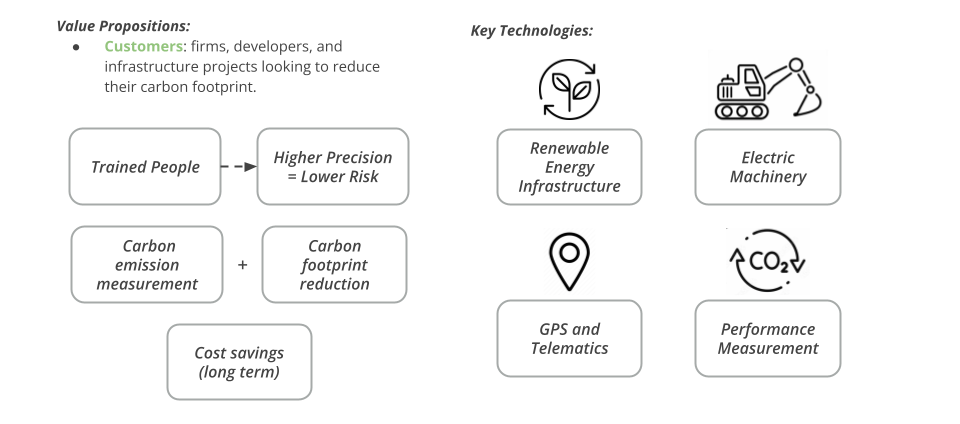

To enhance the realism of our case, we opted to establish our own company. Initially, we outlined our value propositions and identified the key technologies essential for achieving our goals.

- Mitigation of risks associated with training individuals in high-precision excavation techniques and fostering human-machine collaboration to enhance efficiency.

- Long-term cost savings through reduced operating expenses and potential tax incentives for utilizing renewable energy sources, such as Plan Moves III in Spain. This approach enables us to maintain competitiveness within the market.

- Substantial reduction in carbon footprint compared to traditional foundation construction methods, with operational emissions expected to decrease to nearly zero.

For further insight, you can explore a cost and emissions savings calculator provided by Volvo at the following link: Volvo CO2 Savings Calculator

In order to achive this, we have developed a list of key technologies that will allow us to guarantee this objectives.

Renewable Energy Infrastructure (off-site and on-site):

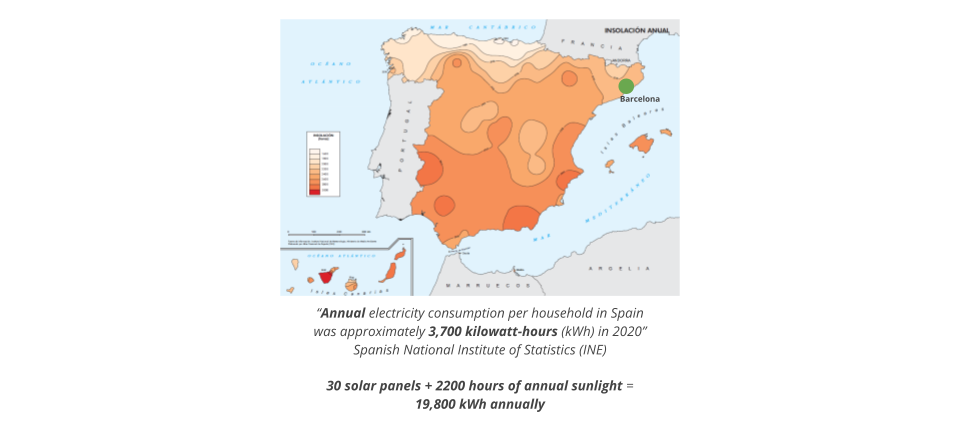

Barcelona (Spain) benefits from ample sunshine, boasting an average of 2,200 hours of annual sunlight. With 30 solar panels, this translates to approximately 19,800 kWh of energy generated per year. To put this into perspective, data from the Spanish National Institute of Statistics (INE) shows that the average annual electricity consumption per household in Spain was around 3,700 kilowatt-hours (kWh) in 2020.

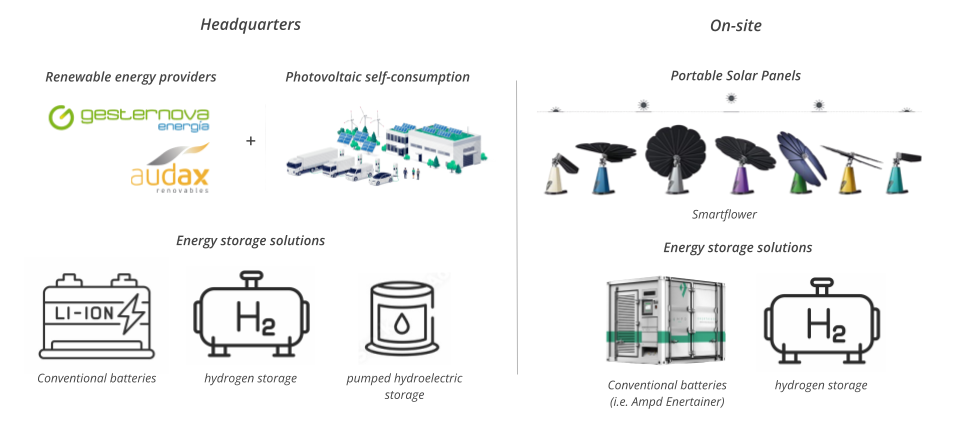

Given this abundant solar potential, collaborating with renewable energy providers such as Gesternova or Audax Renovables and investing in solar panels (both fixed and portable) and energy storage solutions offers a sustainable path for powering electrified equipment with renewable energy. These solutions encompass a range of options, from conventional batteries to advanced technologies like hydrogen storage and pumped hydroelectric storage, facilitating a transition to cleaner energy sources.

Electric Machinery and Devices:

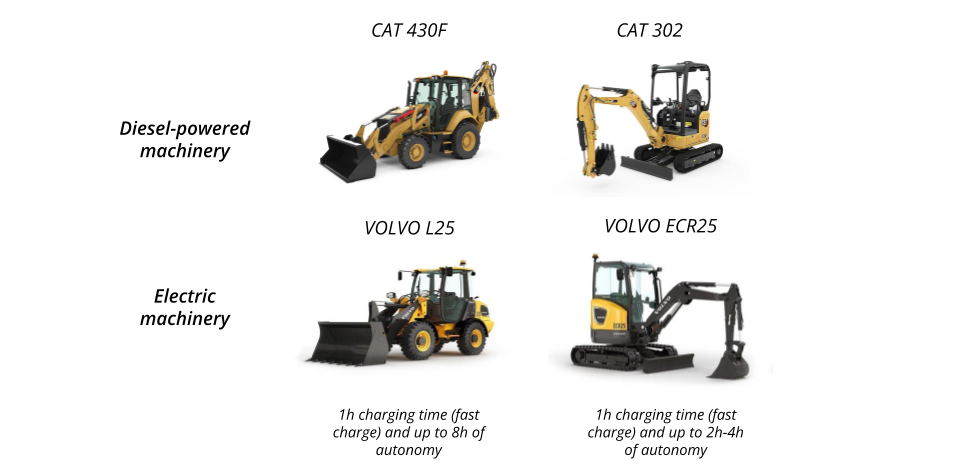

By harnessing our 100% renewable energy, we can employ electrically powered excavators, compactors, and other equipment to replace diesel-powered machinery. Additionally, integrating GPS and telematics systems enables precision excavation and provides real-time data on equipment performance and location. This approach not only reduces fuel related costs but also significantly lowers emissions.

Performance Measurement:

The equation below illustrates how the performance of equipment, whether fueled by electricity or conventional fuel, is affected by various factors. These factors include the specific requirements of the client project, such as the type of soil being worked on, the overall area of the construction site, and the volume of material being handled. Additionally, the equation accounts for the inherent characteristics of the equipment itself, including the type of tool being used, the equipment’s capacity, and the proficiency of the operator handling it. By considering all these variables, we can understand how they collectively impact the efficiency and effectiveness of the equipment in completing the task at hand.

Furthermore, by implementing sensors and data analytics to monitor and capture carbon emissions generated during construction activities, we ensure our commitment to achieving zero operational emissions.

Future Steps:

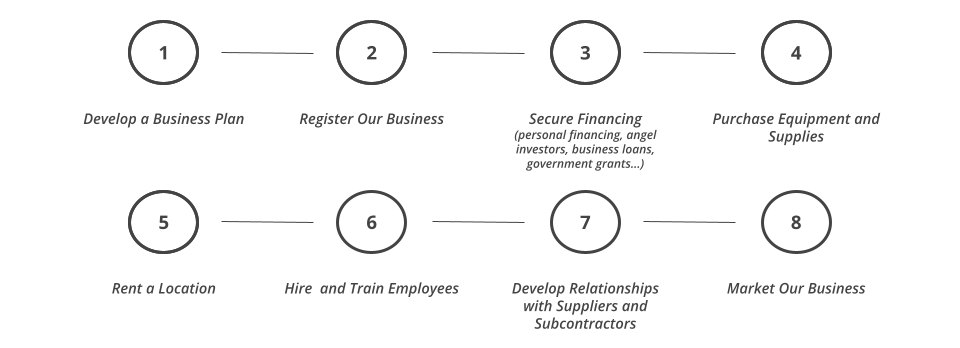

While our business value propositions and key technologies are clear, transforming the idea into reality requires following numerous steps:

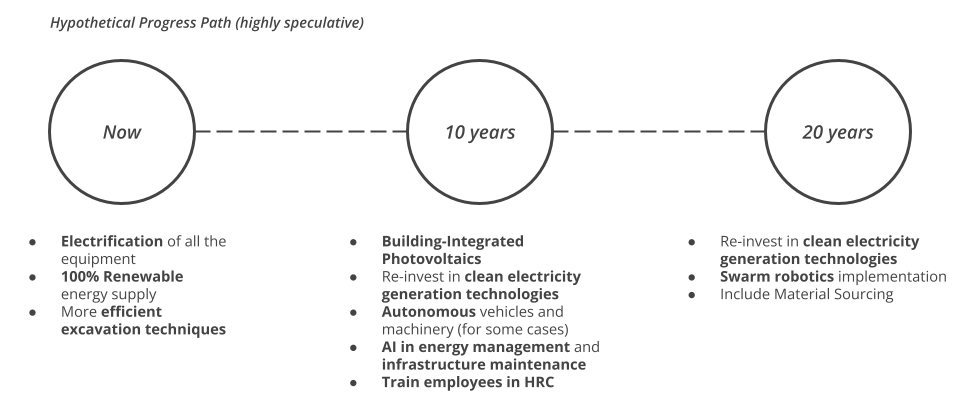

As an extra, if we aim to progress and evolve our business in the coming decades, these are the improvements we would implement across various aspects of the business to enhance and sustain relevance in the market: