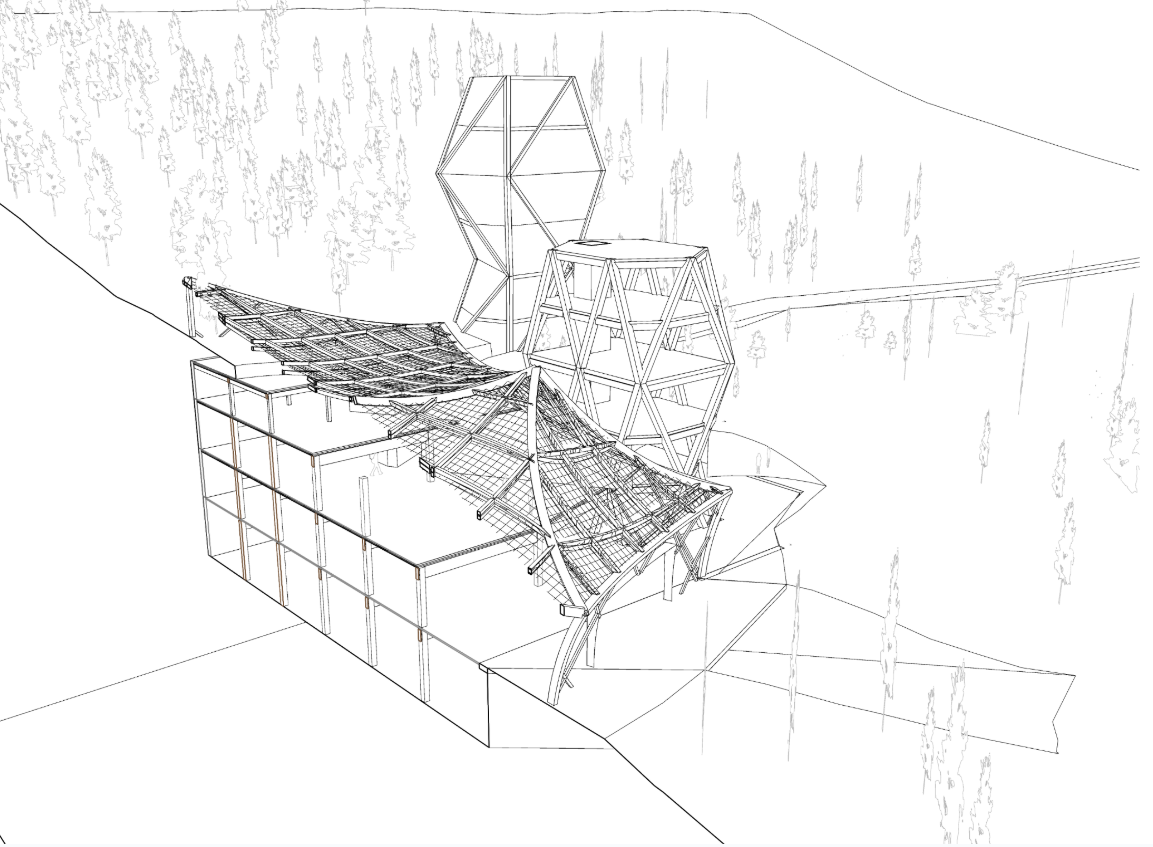

BIOBASE(D) is a forest management and research center in the Pyrenees, dedicated to preventing forest fires through sustainable forestry and education. The building’s design responds to the local climate, highlights the potential of timber as a construction material, and offers visitors and staff a unique experience in this remarkable forest basecamp. Committed to sustainability and self-sufficiency, it integrates resource-efficient systems, including a carefully designed energy strategy.

The energy design for the Forest Management Center is centered around creating a self-sufficient, sustainable building that serves as a model for ecological architecture. The building, which houses offices, residential spaces, and a visitor center, utilizes a blend of natural and renewable energy systems to reduce its reliance on external resources. Photovoltaic (PV) panels are strategically integrated into the design, capturing solar energy to power the building’s electrical needs throughout the year. Complementing this, a compost heating system harnesses organic waste generated on-site to provide efficient, renewable heating, ensuring a minimal environmental impact.

The goal of these systems is not only to minimize energy consumption and carbon emissions but to create a building that can sustain itself in harmony with the surrounding forest ecosystem. By embracing these innovative energy solutions, Biobase(d) aims to demonstrate the potential of green architecture to meet the growing need for eco-conscious, self-sufficient structures in sensitive natural environments.

HEATING STRATEGY

The base of the building is embedded into the mountain and enclosed by a dome, optimizing solar gain and heat retention. Additionally, this part of the building houses functions with lower heating requirements, while the more temperature-sensitive spaces, such as residences and offices, are located in the towers. Given these factors, we believe that active heating is not necessary for the base of the building.

The building is home to sheep, and their manure, along with human waste and food scraps, is composted to ensure that no nutrients go to waste. As organic matter breaks down, the compost pile generates significant heat. This heat is captured and used to warm the two towers through a Compost Heat Recovery System.

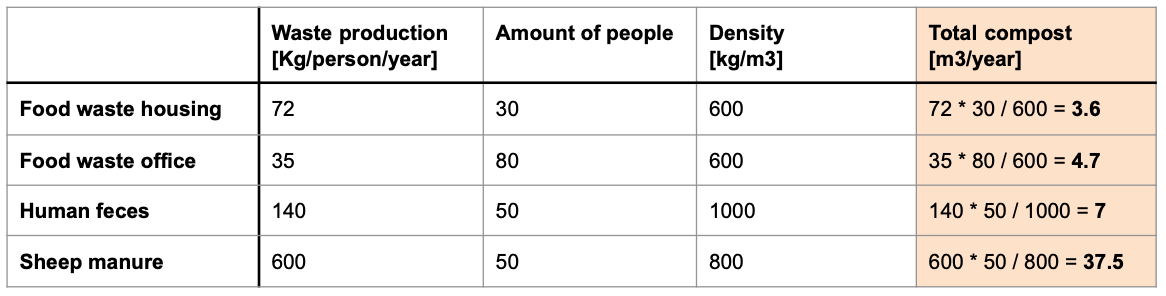

To assess the feasibility of using compost heat recovery, we first calculated the total annual waste production for food waste, human feces, and sheep manure. As shown in the table below, the total volume of fresh compost amounts to 52.8 m³ per year. Since an equal volume of brown organic matter—such as wood chips—is required for proper composting, the total composting volume doubles to 105.6 m³ per year. Given that our forest management center produces an abundance of wood chips, this approach aligns well with our resource availability while maximizing the efficiency of our compost heat recovery system.

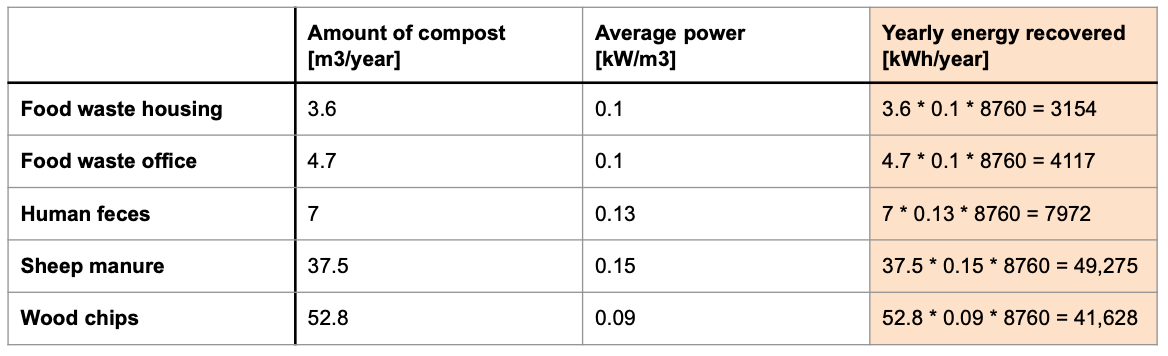

Next, we consulted a literature review that provided data on the average power output generated by different types of waste during composting. By multiplying this average power with the total volume of compost, we calculated a total annual energy recovery of 106,146 kWh/year.

The total energy recovered from the compost is 106,146 kWh/year, which is sufficient to meet the heating needs of both towers.

- Office tower (517 m²):

Energy consumption for heating is 40 kWh/m².

Heating consumption for the office tower = 517 * 40 = 20,680 kWh/year. - Residential tower (535 m²):

Energy consumption for heating is 60 kWh/m².

Heating consumption for the residential tower = 535 * 60 = 32,100 kWh/year.

Total heating consumption for both towers = 20,680 + 32,100 = 52,780 kWh/year.

Since the total energy production from the compost heat recovery system is 106,146 kWh/year, this system can fully cover the heating demands of both towers.

CO2 Savings

Using natural gas for heating, the consumption is 0.21 m³/kWh.

For the total heating consumption of 52,780 kWh/year, this results in:

0.21 * 52,780 = 11,084 m³ of natural gas.

Each cubic meter of natural gas emits 1.91 kg of CO2.

Thus, the CO2 savings from using compost heat recovery instead of natural gas is:

1.91 * 11,084 = 21,170 kg of CO2 saved per year.

This demonstrates a significant environmental benefit from utilizing compost heat recovery for heating the towers.

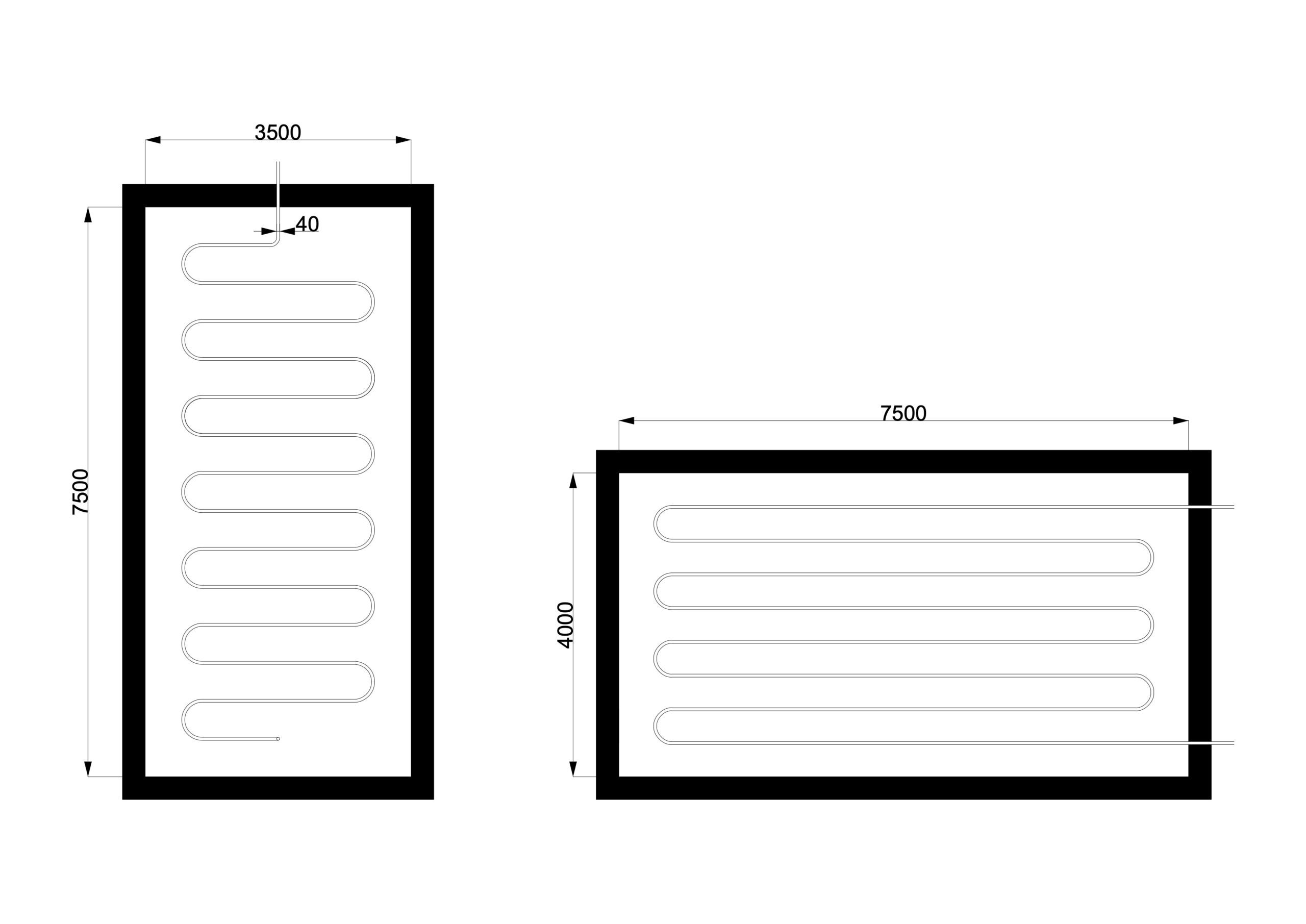

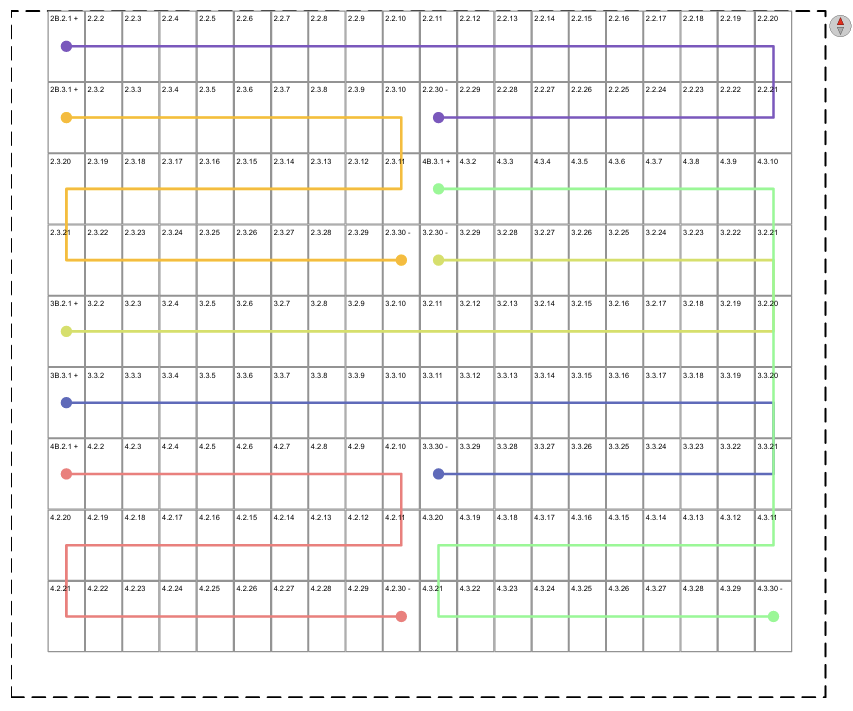

The image below illustrates the plan (left) and section (right) views of the compost heat recovery system. As previously calculated, the total volume of the compost tank is 105 m³. Cold water enters the system at the bottom of the compost pile, where it flows through the organic material, moving from one side to the other and gradually rising through the pile. As the water passes through, it slowly heats up by absorbing the heat generated by the composting process. The now-warmed water is then distributed through pipes for radiant floor heating, which efficiently warms the two towers.

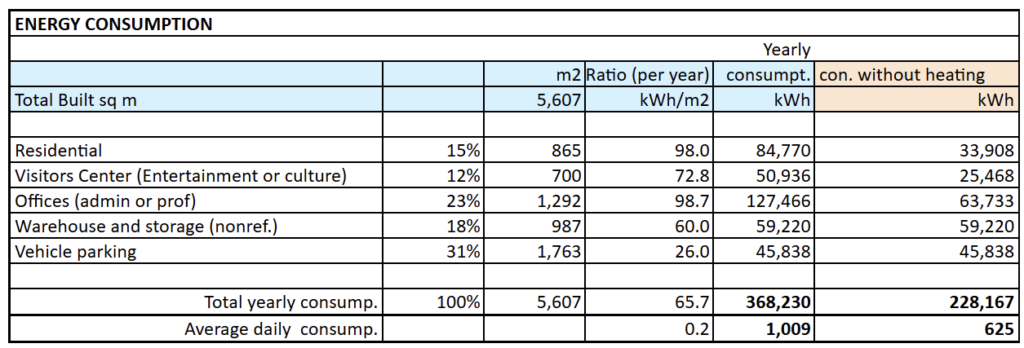

ENERGY CONSUMPTION

The tables below display the total energy and power consumption of the building. To calculate the total energy consumption, we first determined the energy consumption of each building function and then summed these values. Since the heating for the building will be provided by the compost heat recovery system, we have subtracted the heating demand from the overall energy consumption.

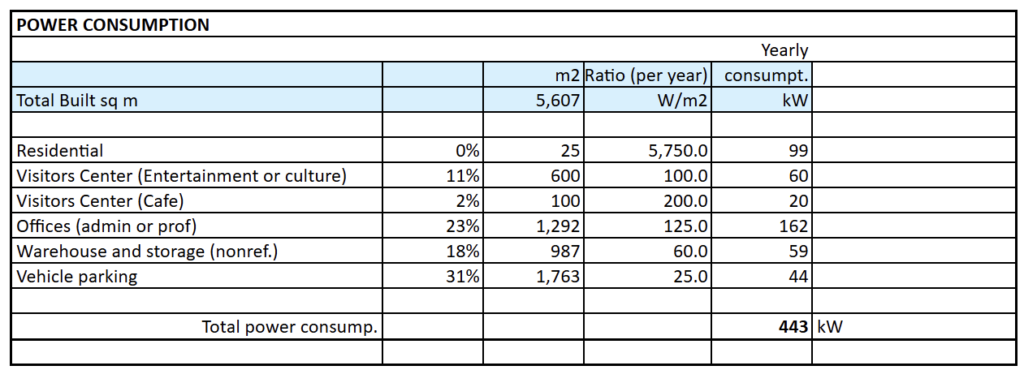

PV DESIGN

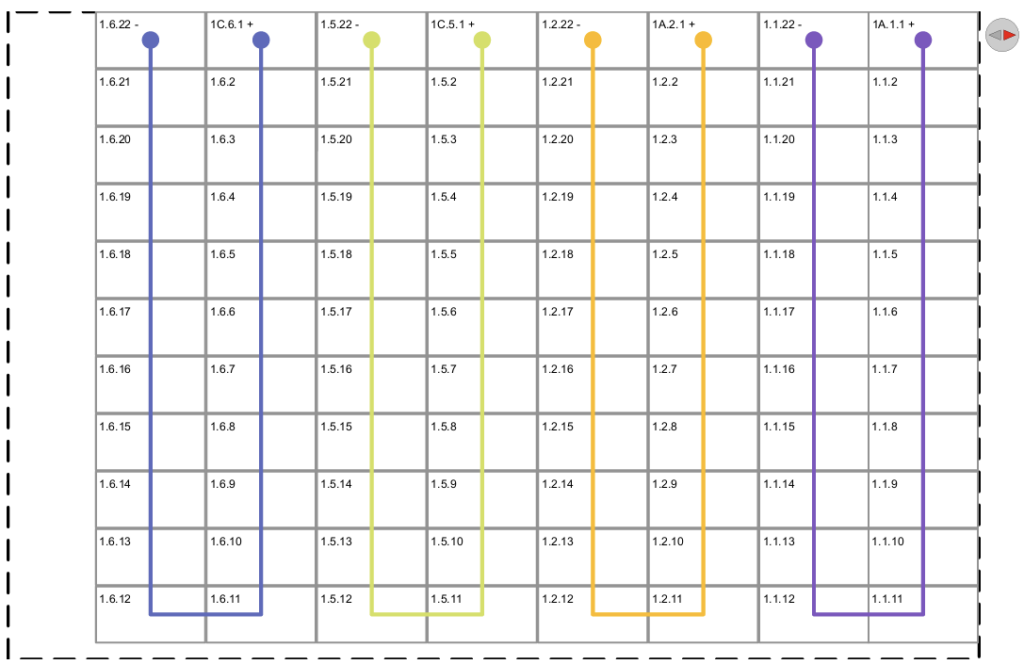

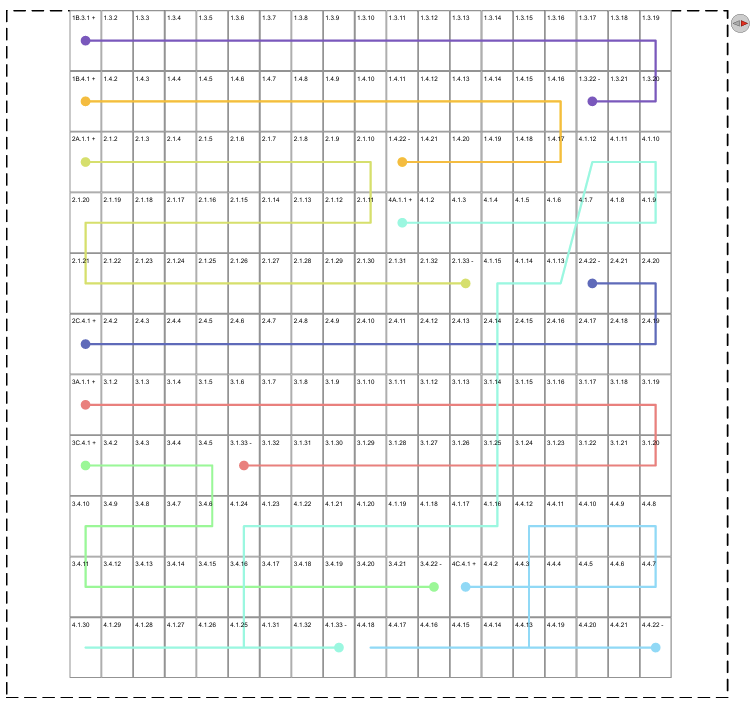

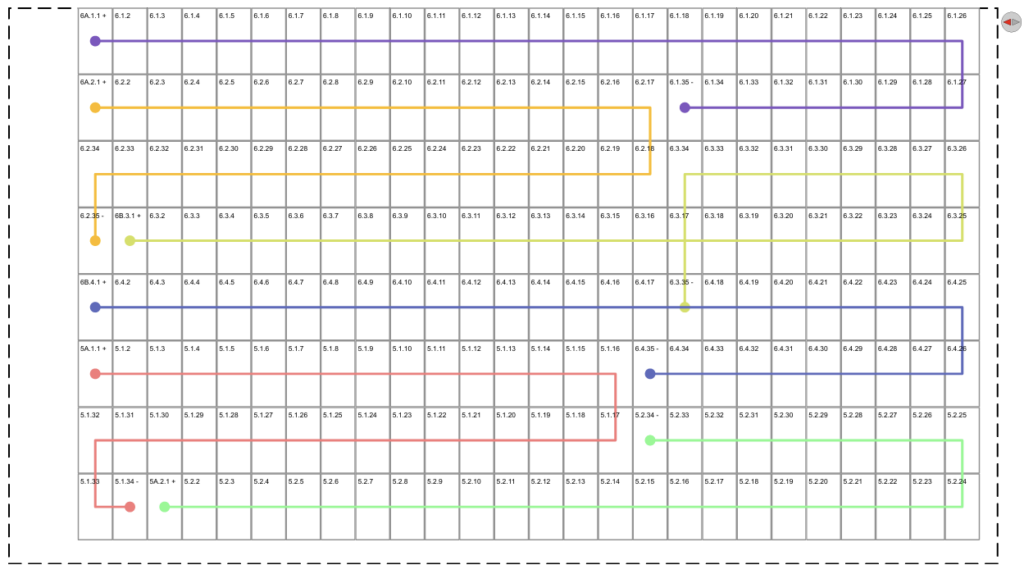

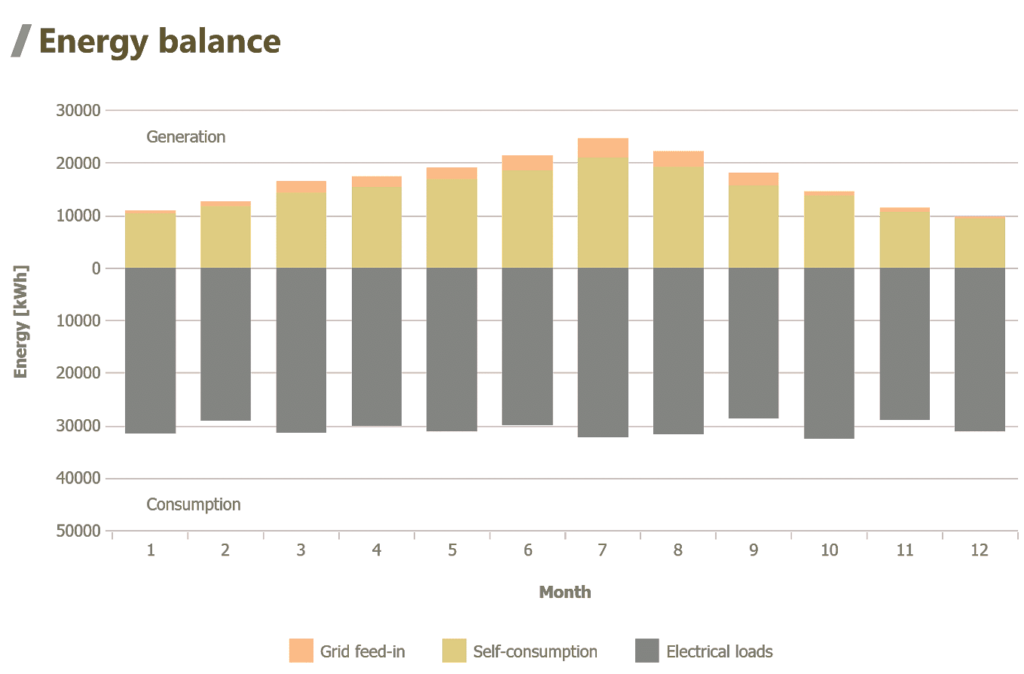

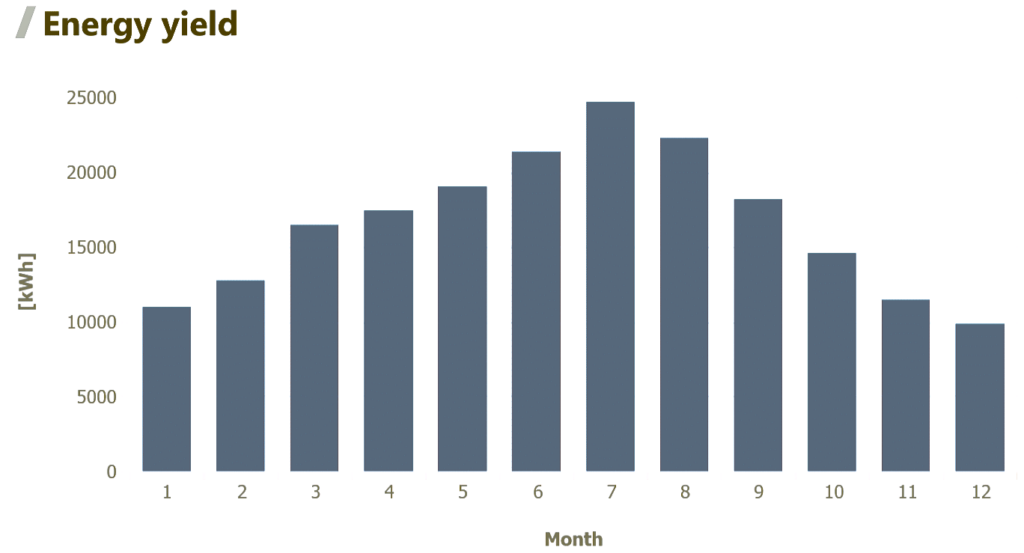

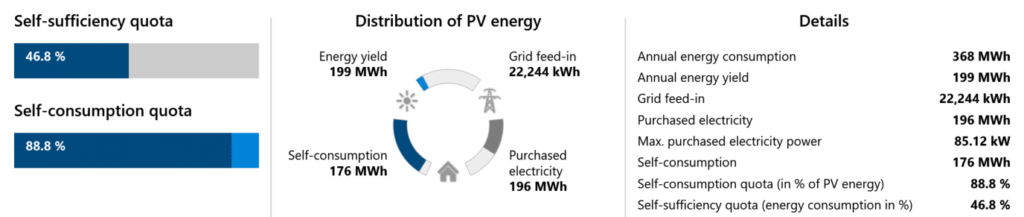

For the PV design a combination of Onyx clear panels on the dome and SMA PV panels on the rooftops of the residential and office towers are used. The Onyx clear panels allow natural light to penetrate the building while generating energy, making them perfect for the dome. For the rooftops, standard PV panels, are strategically placed to maximize solar exposure. To ensure optimal performance, the Sunny Design platform helped simulate energy output based on the building’s location and roof orientation, ensuring the building meets its energy needs sustainably.

- Panels on Dome = 685

- Panels on Tower roofs = 72

- Total no. of PV panels = 757

The total no. of PV inverters used to connected the PV panels = 7

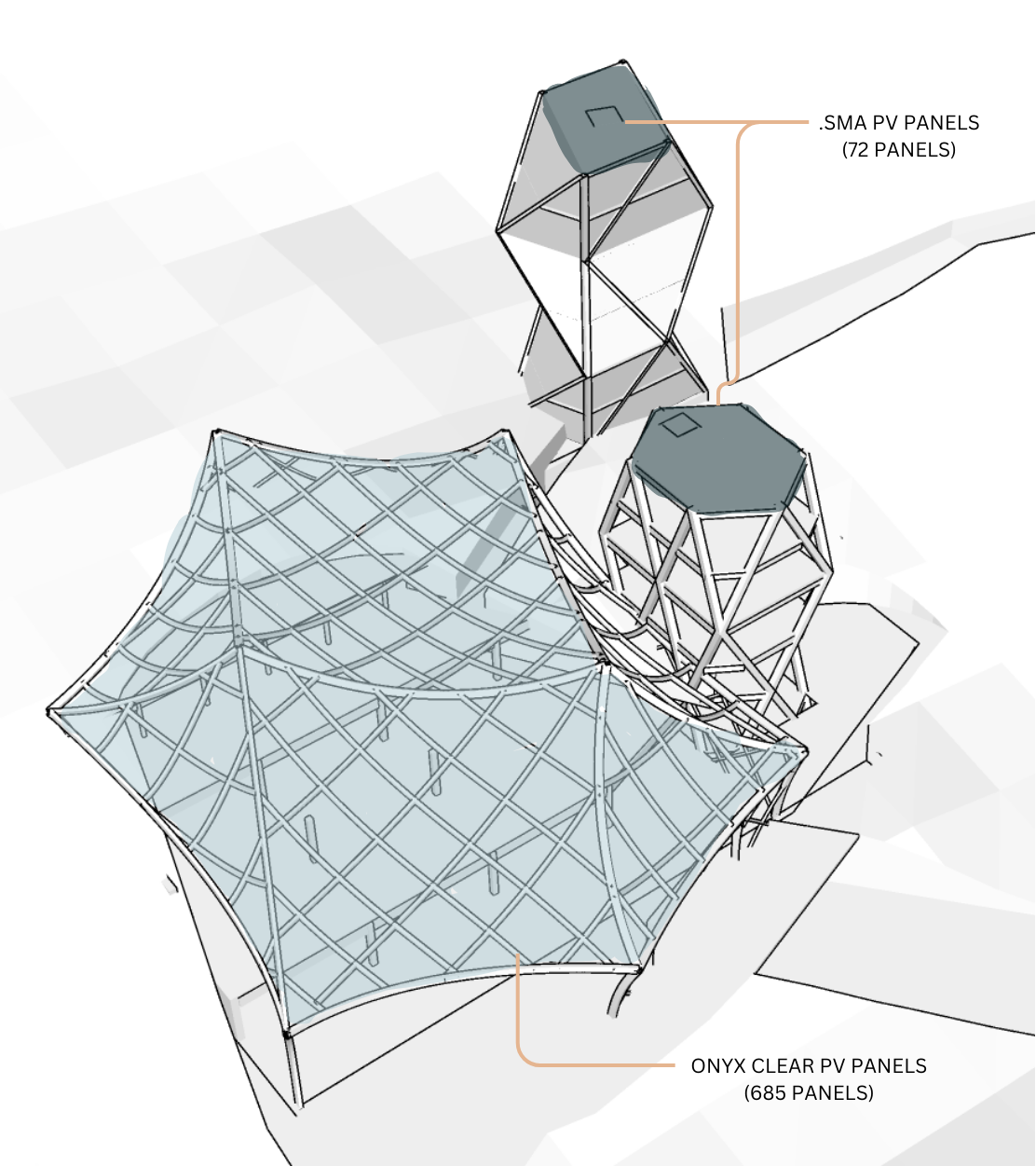

Energy – consumption and Investment costs :

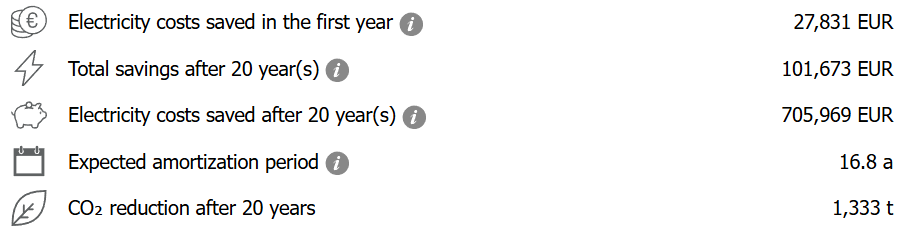

Total investment costs = 430,699.50 EUR

Through Sunny design, we have achieved increased self-consumption to 88.8 % and self-sufficiency of 46.8% and using battery storage system to store the excess amount of energy produced , making it more self-sufficient.