Introduction

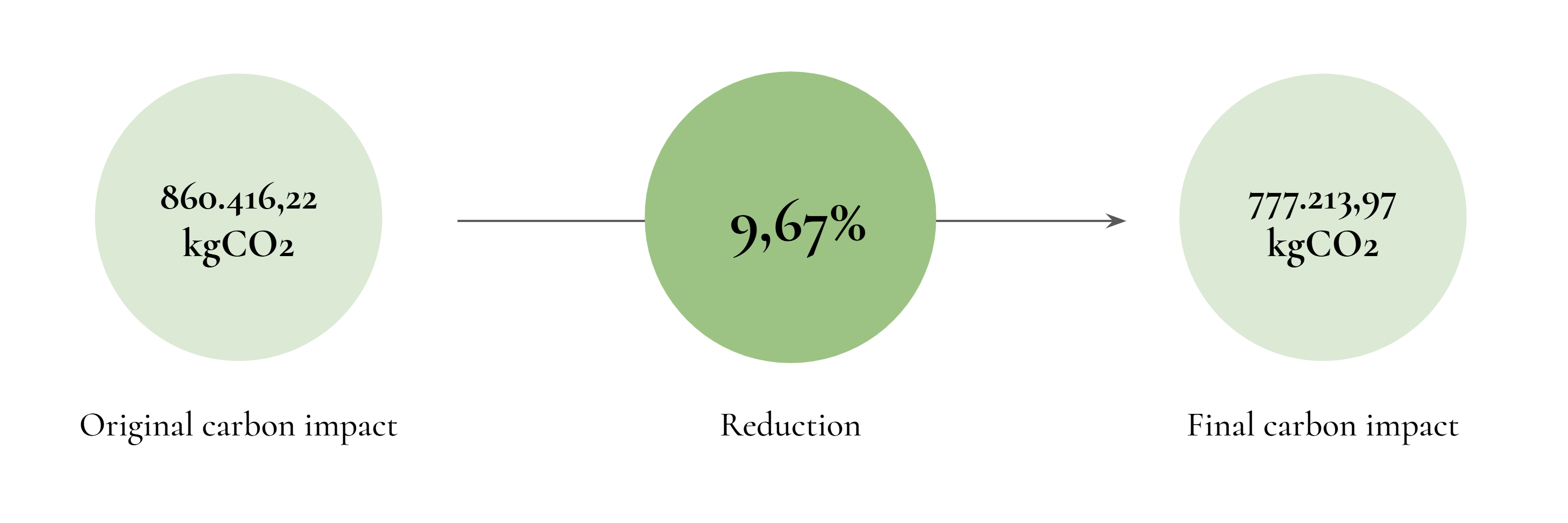

The course was an intensive, five-day workshop dedicated to calculating the carbon impact and exploring innovative solutions for the upcoming IAAC building. The goal was to present a proposal that could reduce the emissions in 40%.

Location

The design for the new IAAC building has already been approved and is now awaiting construction. Located 500 meters from the current facility, the project represents a retrofit, as the two existing sheds on the site will be preserved and modified to accommodate the new structure.

Initial analysis

Using the shared CAD files, the group of students was divided into three teams, each assigned to work on a different part of the building. Their goal was to calculate the mass and carbon impact of their respective sections. Once all the data was generated, it was consolidated to produce a comprehensive Material Flow Analysis (MFA).

Our team was tasked with calculating the material quantities for the façade and services. To achieve this, we developed a spreadsheet containing the following columns: element, material, generic material classification, units, thickness, area, volume, density, mass, GWP (Global Warming Potential), GWP unit, CO2 impact, and EPD (Environmental Product Declaration) source. The inclusion of multiple unit types—such as units, thickness, area, volume, density, and mass—was necessary to account for the varying measurement units used in different EPDs. Most of the EDPs were found here.

Once all the data was consolidated, the Material Flow Analysis (MFA) considered factors such as the building type (existing or proposed), the functional roles of materials (based on the six layers of brand—site, structure, skin, services, space plan, and stuff), and the generic material classification. While the graph compares the existing and proposed buildings for context, the existing building holds no relevance for carbon calculations since its emissions occurred years ago and are not part of the current impact assessment.

Given that the primary goal was to achieve a 40% reduction in emissions, a pie chart was created to provide a clear visualization of the carbon emissions distribution, so we could target properly. This chart, shown below, helps highlight the contributions of different elements to the overall carbon footprint.

Materials with higher CO2 impact:

Glass (52.8%)

Cement (19.8%)

Wood (12.2%)

Steel (5.5%)

Mineral Wool (2.0%)

Together, they correspond to 92% of the new building

860,416.22 kgCO2 is the amount of CO² released during the new construction phase

Modifications

Considering that the materials with the greatest impact on the building are glass, cement, wood, steel, and mineral wool, the team concentrated their efforts on these while also exploring less prominent materials.

Glass

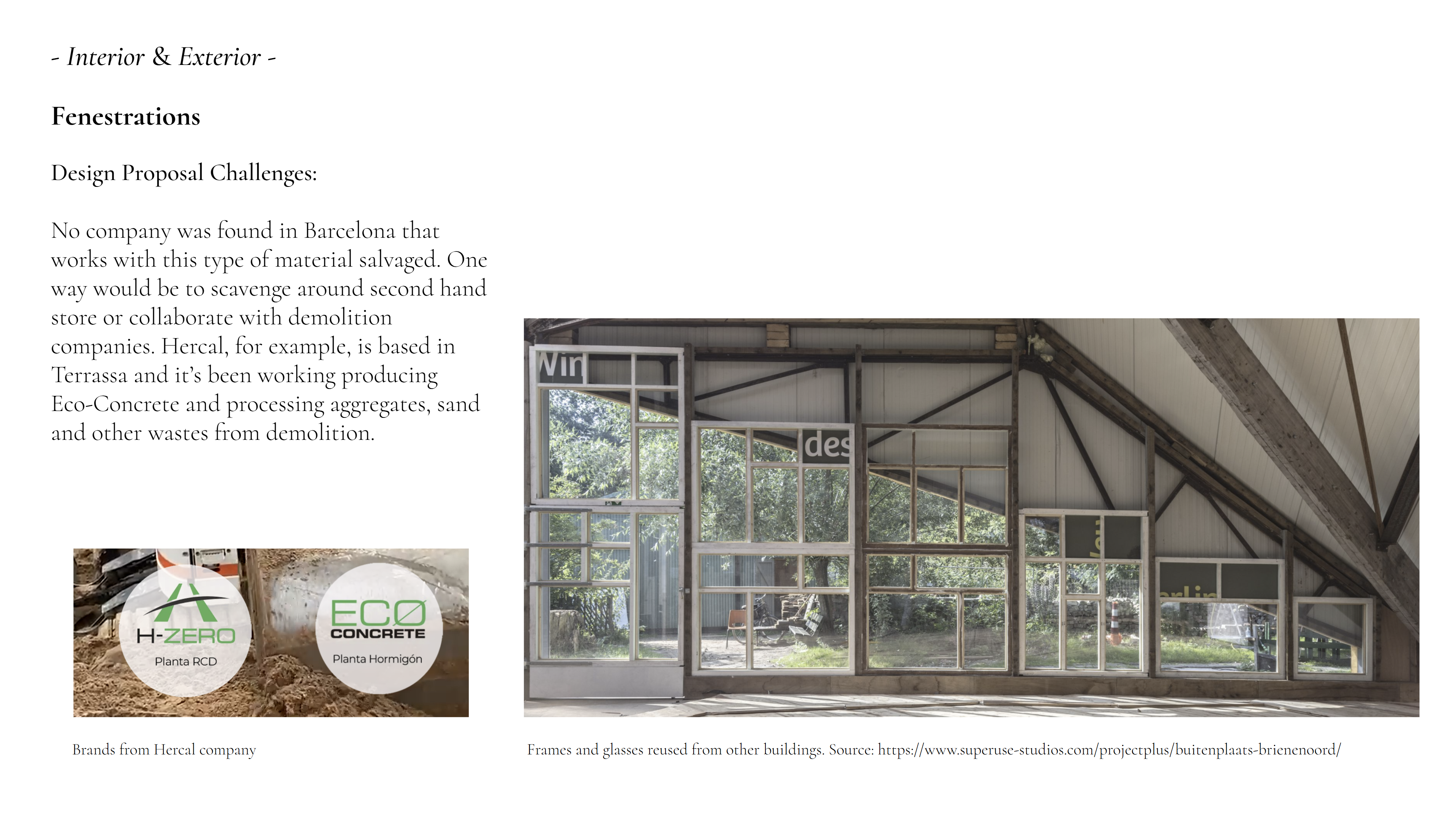

According to our calculations, glass accounts for more than half of the building’s carbon emissions. It is used both internally (fenestrations) and externally (front and side façades). Replacing glass is particularly challenging due to its unique properties, such as providing transparency, insulation, and recyclability. A significant reduction in emissions could be achieved by reusing glass and frames, but this poses challenges, as Barcelona currently lacks companies dedicated to collecting and repurposing these materials. The following images illustrate potential approaches to address this issue.

Design proposal for interior fenestrations

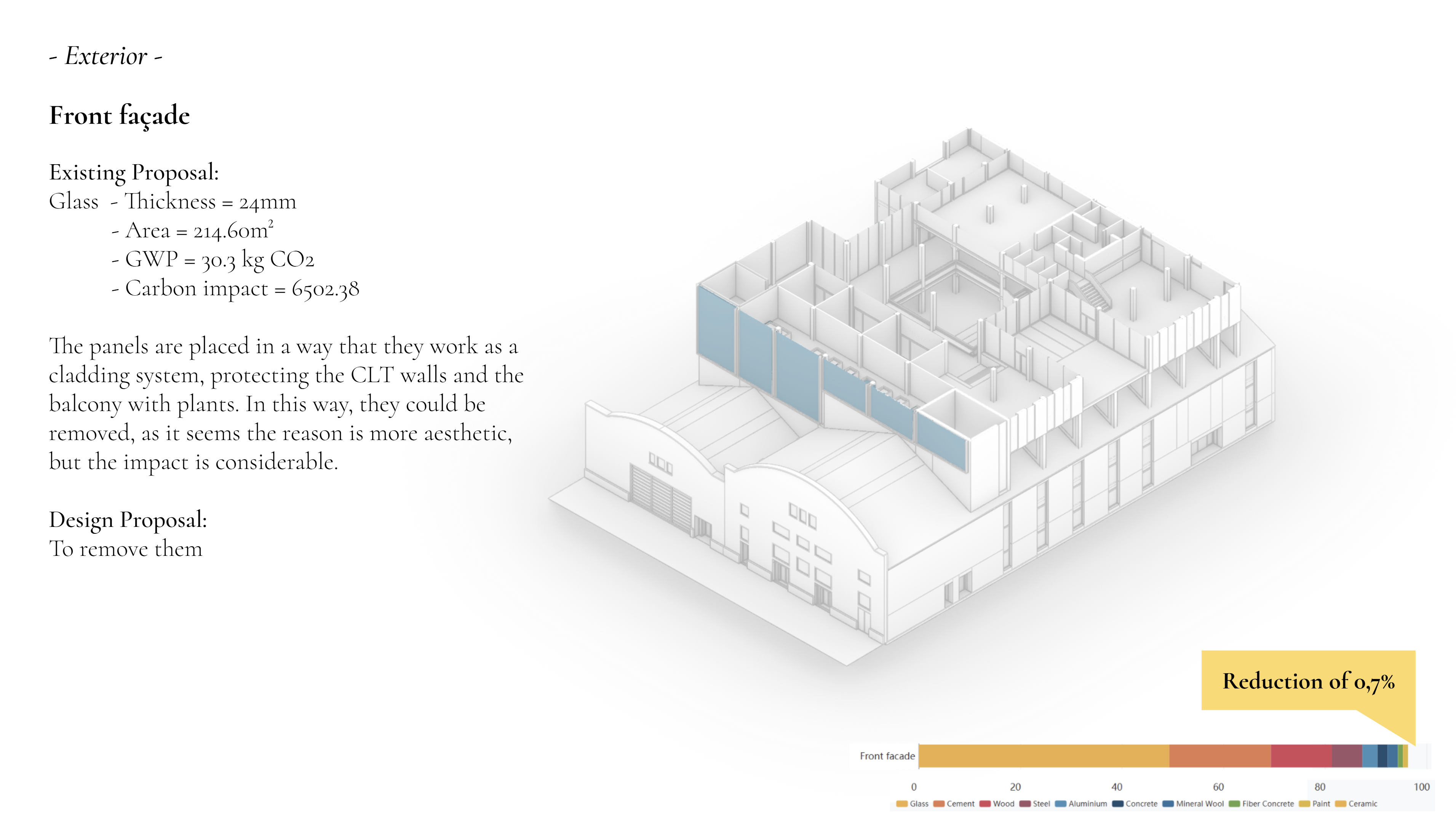

Design proposal for front facade

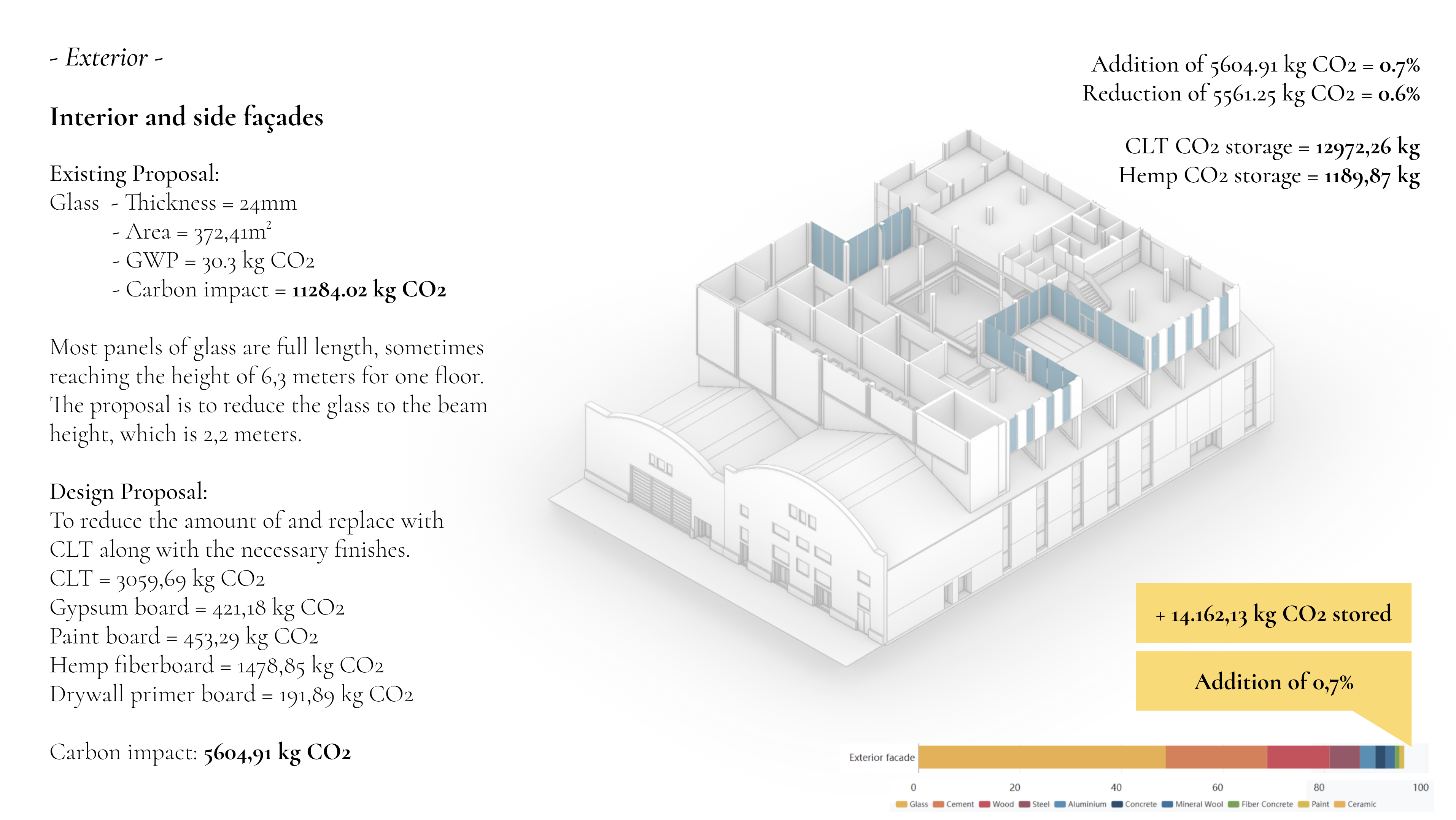

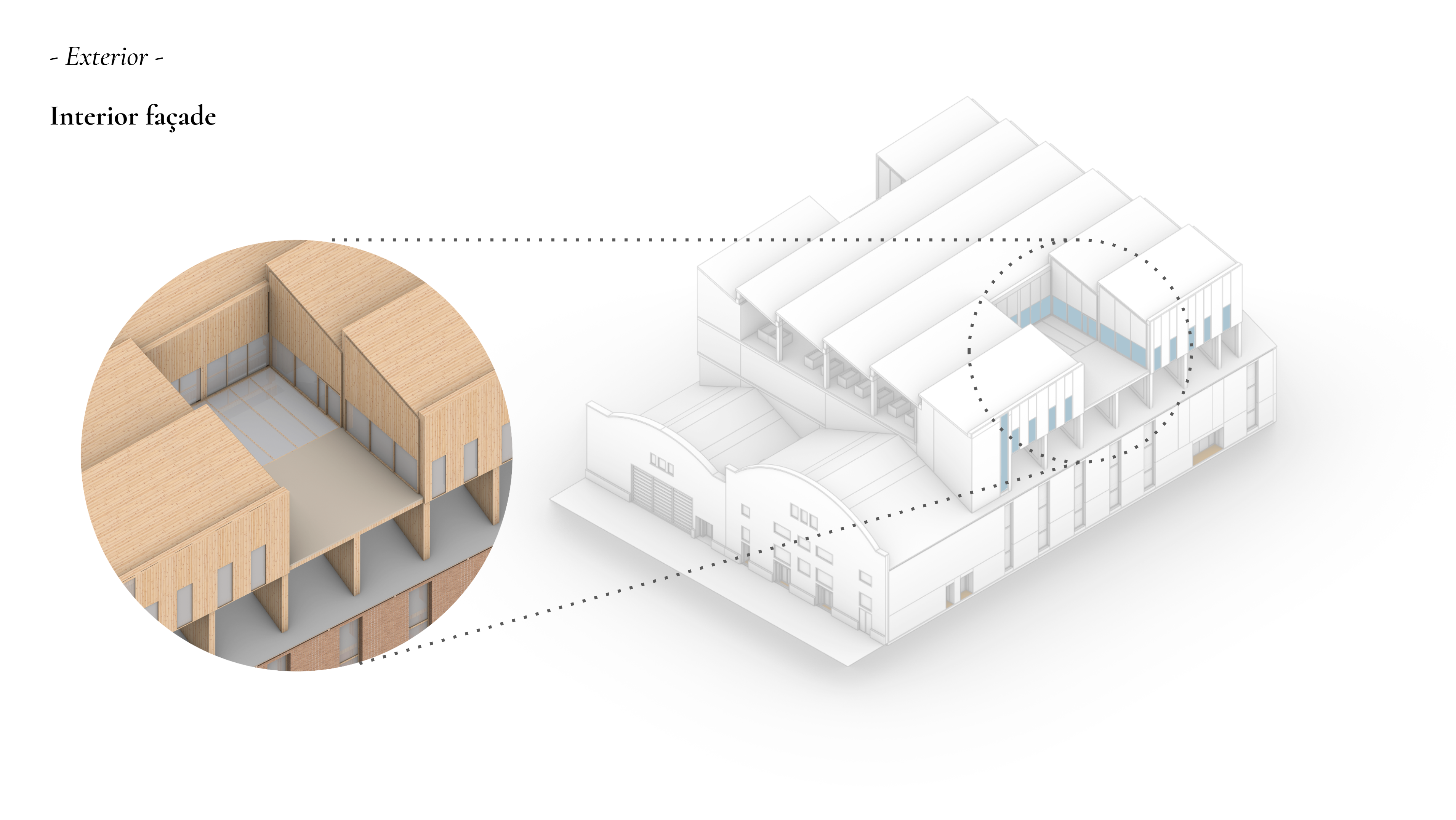

Design proposal for interior and side facades

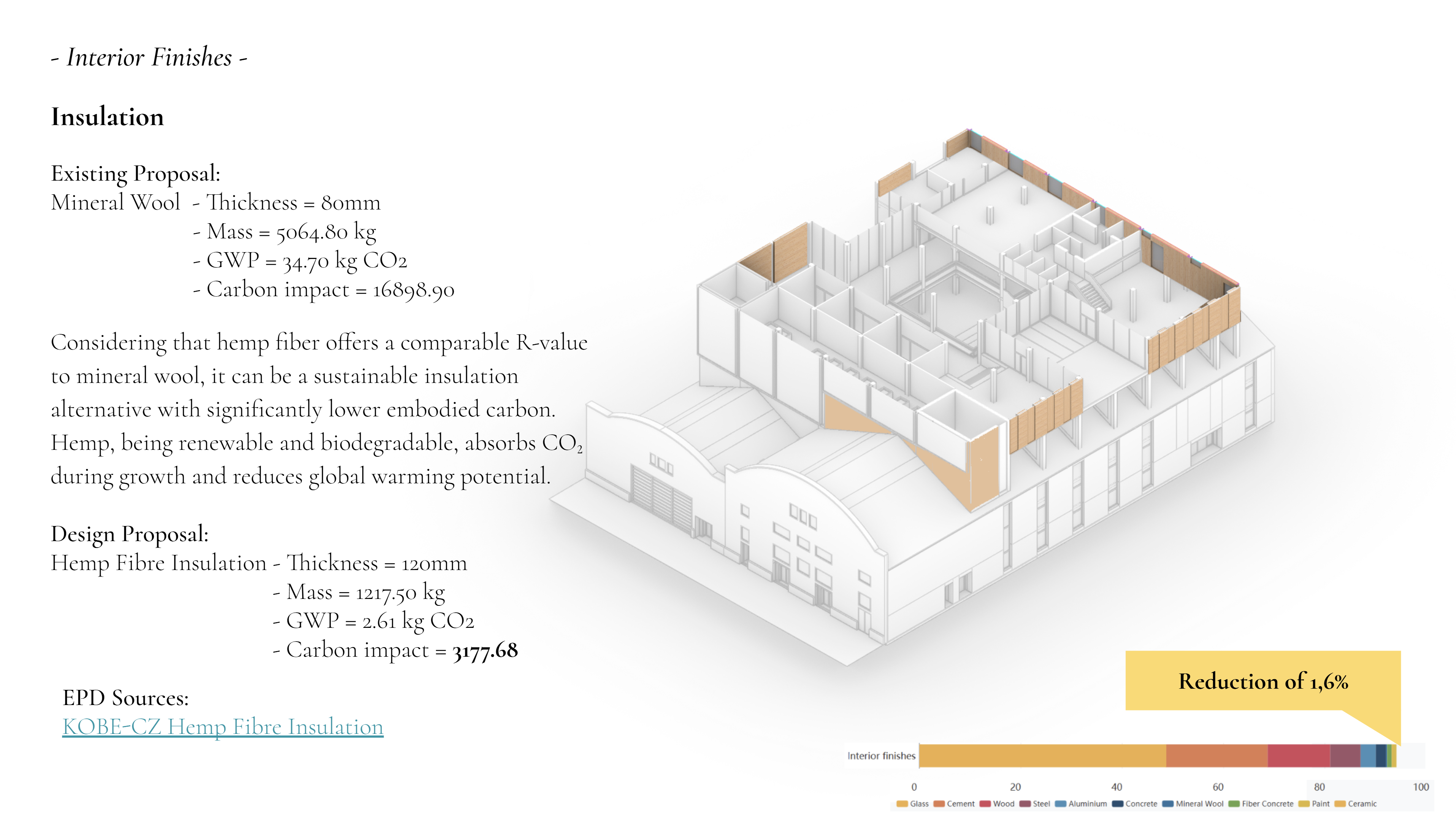

Mineral wool

Mineral wool acts well as an insulation material, however the amount of energy that goes into the manufacturing and installation is very high. Hemp fibre insulation which is a bio based alternative works well in tissue case as it not only has a lesser carbon impact but also stores carbon. Therefore in the long run hemp fibre works better in term s of carbon impact.

Design proposal for interior finishes – insulation

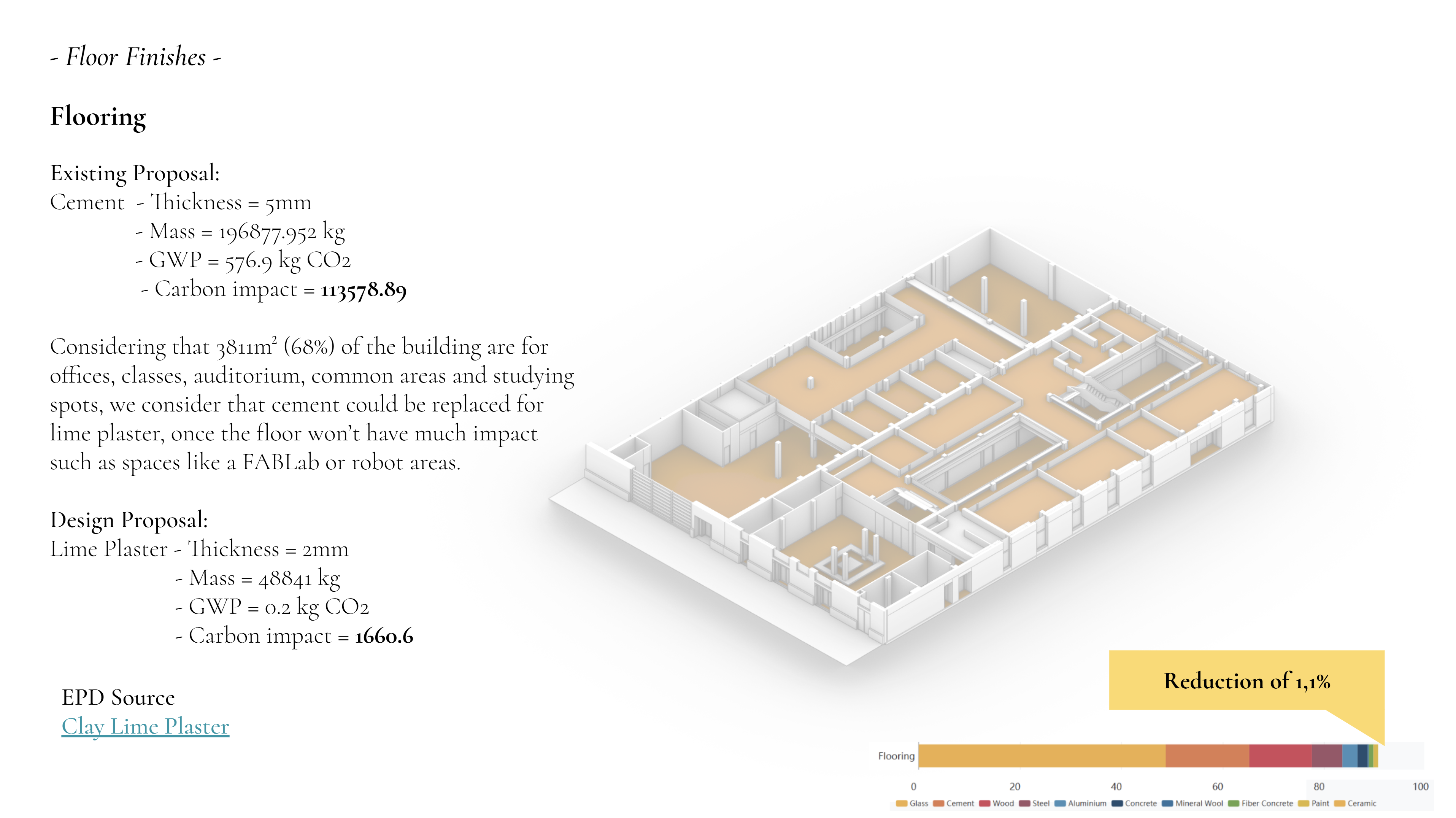

Cement

The draw back of utilising lime plaster is the durability and resilience, it cannot be utilised for all spaces and can be only used in spaces that do not have a rough or extreme working environment like a carpentry, robotics lab, etc.

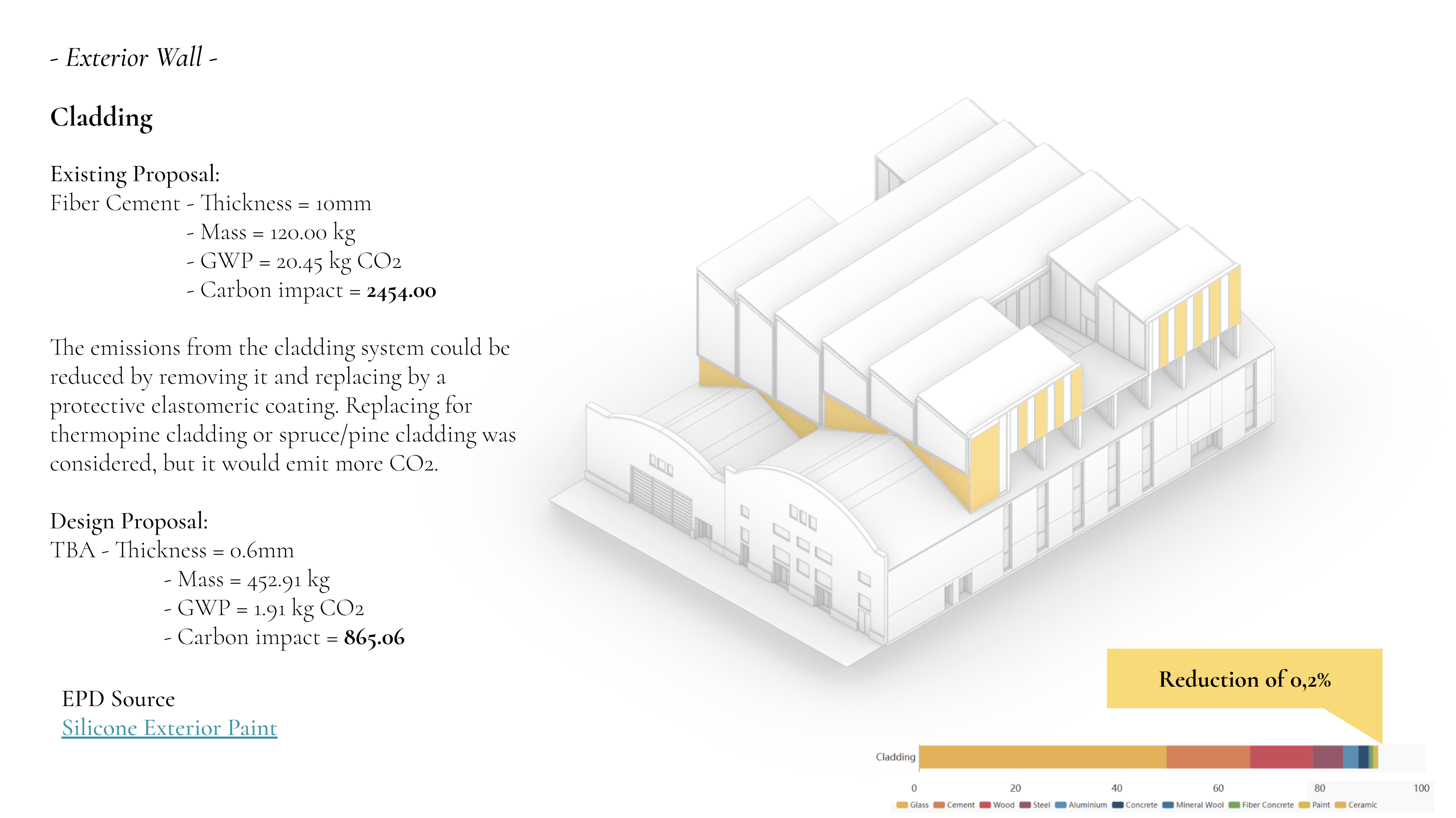

Fiber cement

An alternative to using fibre cement boards are using silicone based weatherproofing coats for the CLT surfaces. Although the coating would prove to be efficient the ideology of reusing the CLT panels in the future would be difficult as the silicone reacts with the wood. An alternative to this is using natural based exterior finishes such as Linseed oil which cab be reapplied when required and this would allow the CLT panels to be reused in the future.

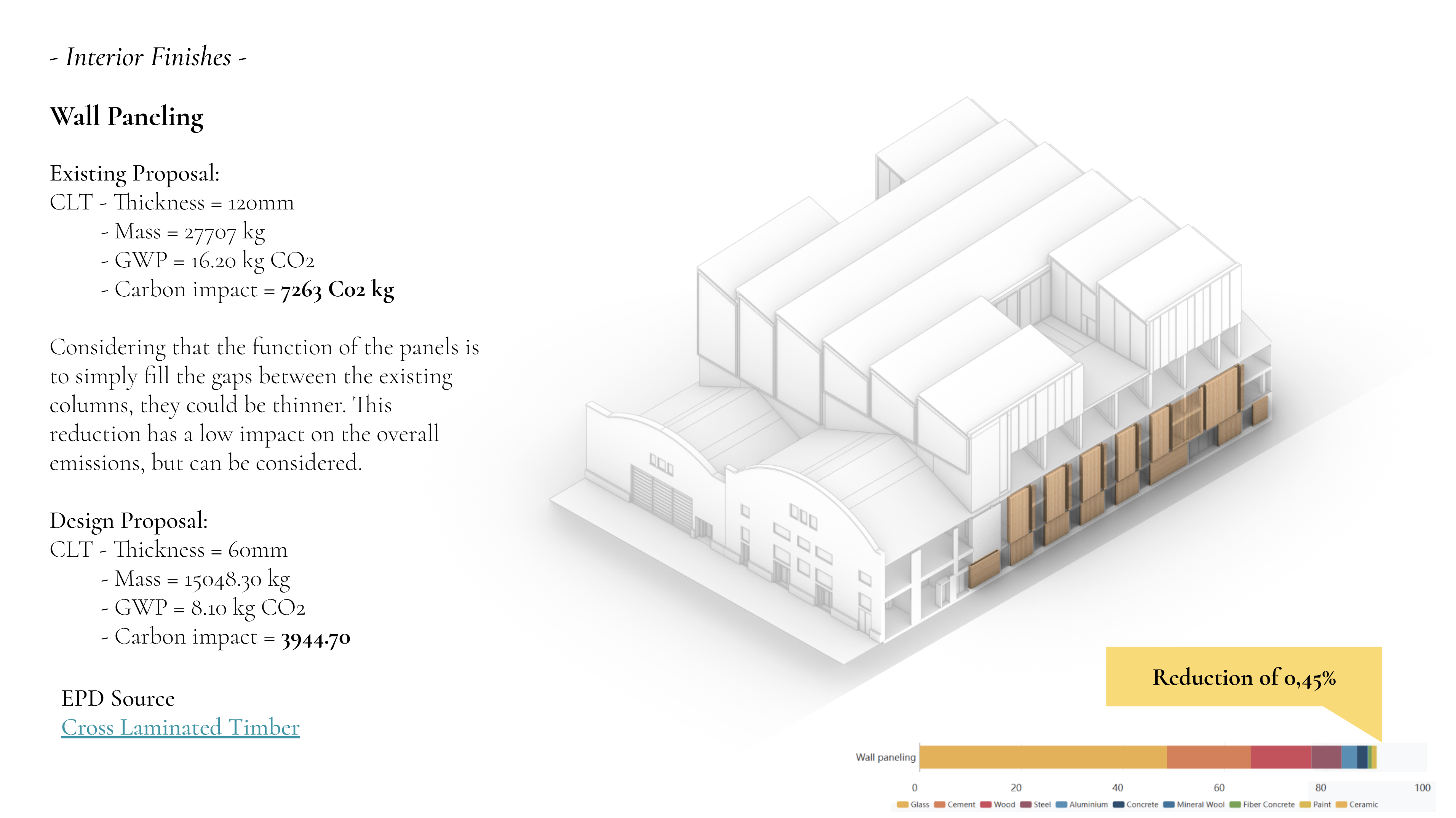

Wood

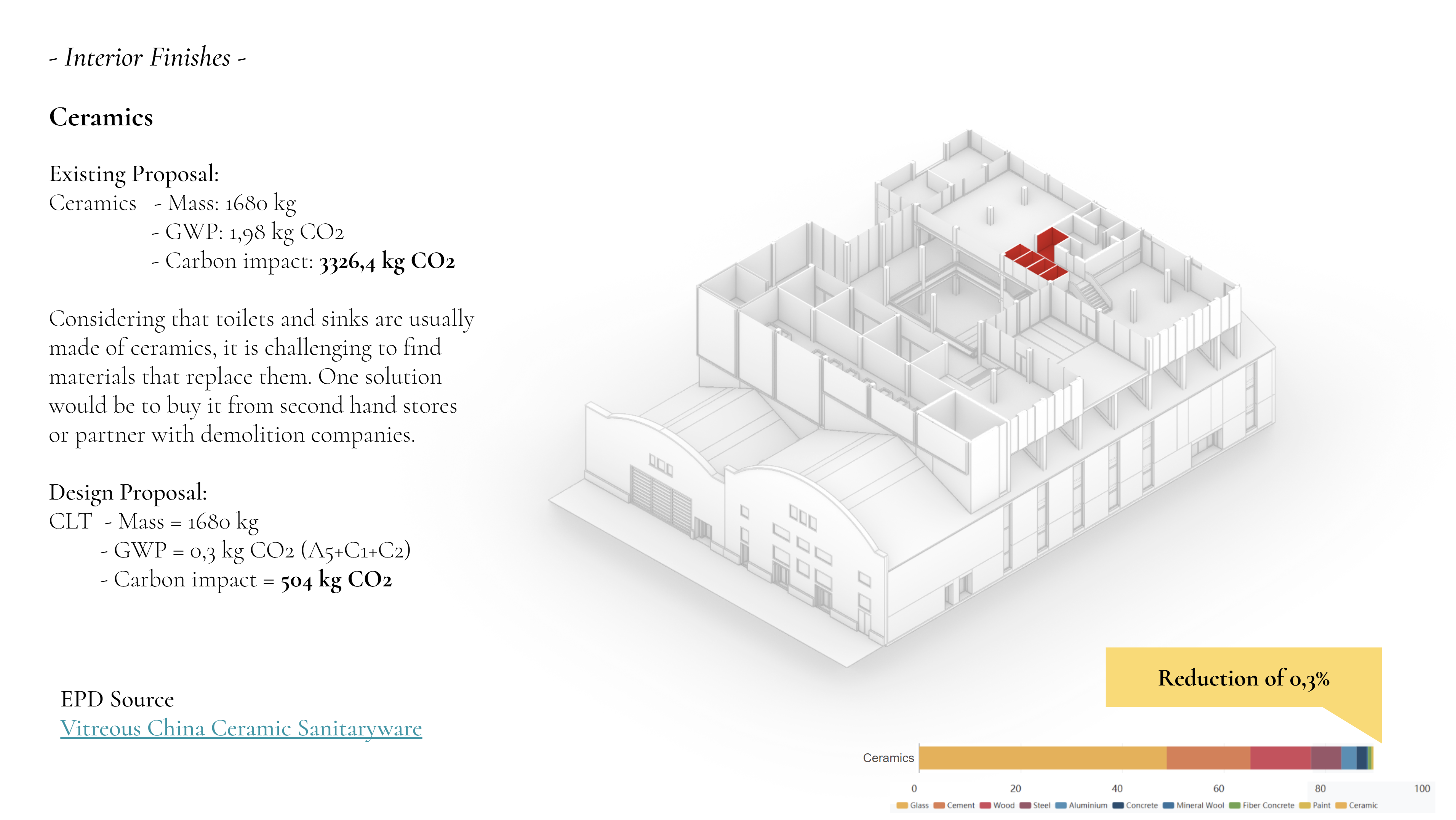

Ceramics

Ceramics consume a large amount of energy when it comes to their production. Rather than procuring new ceramics every time a building is constructed, we can source ceramics from different demolition sites. By doing so the carbon impact is significantly reduced as it only has to be taken into consideration based on transportation and installation.

Conslusion

Achieving a 40% reduction in carbon emissions is a difficult task considering the building has already been design keeping in mind such factors. In order to further reduce the carbon emissions the design has to be altered to maximise efficiency and minimise material wastage or consumption such that it is in an ideal position of carbon storage and emission. Apart from carbon emissions we must also consider the future utility of these material have as this too affects the carbon impact on an overall scheme.