INTRODUCTION

As part of the Structural Design Essentials Workshop, our team explored alternative beam designs for Alejandro Aravena’s Quinta Monroy project. Using reclaimed timber, we designed and analyzed a castellated beam to support vertical growth. Both digital simulations with Karamba3D and physical tests were conducted to evaluate its structural performance and sustainability.

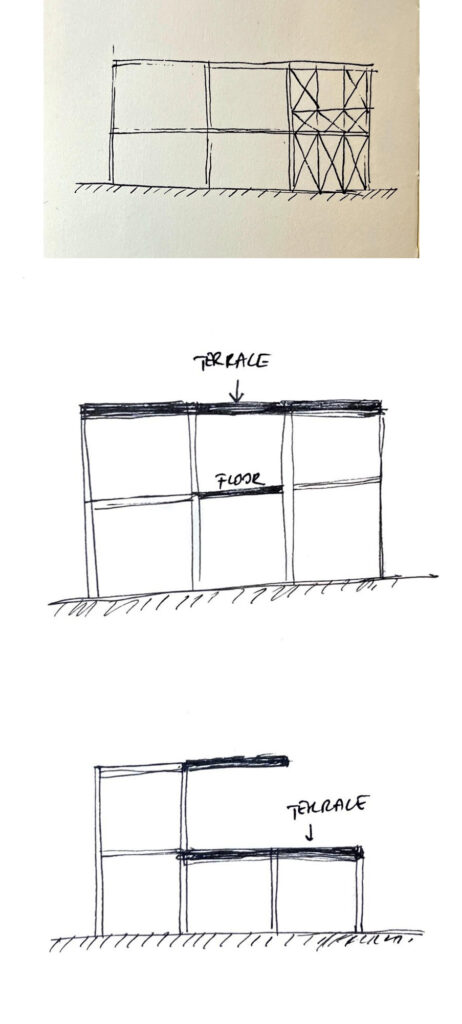

SKETCHES

Quinta Monroy

Maximizing the life and usage of living spaces.

Variation 1 : Accessible Roof

Exploring ways to extend the usage of empty spaces with waste wood.

Variation 2 : Extended Common Areas

Diminishing existing walls and using the waste material as structure

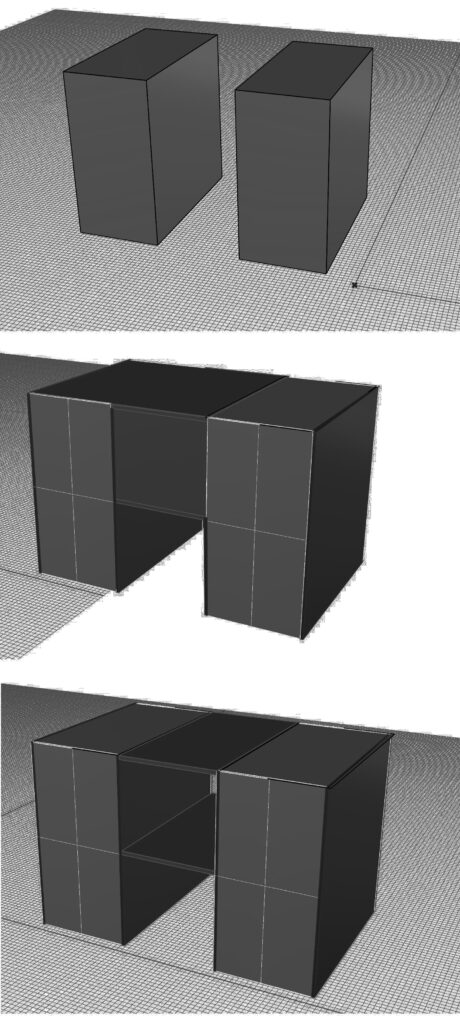

Quinta Monroy

Maximizing the life and usage of living spaces.

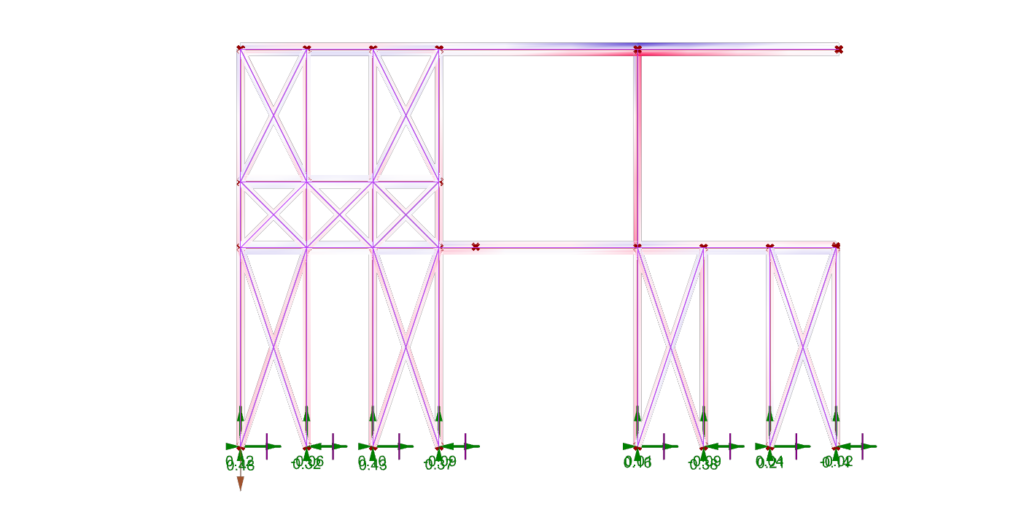

Deformation : 0

Deformation : 100

Displacements:

LCO: 0.130225

LC1: 1.775493

LC2: 0.028764

LC3: 0.120911

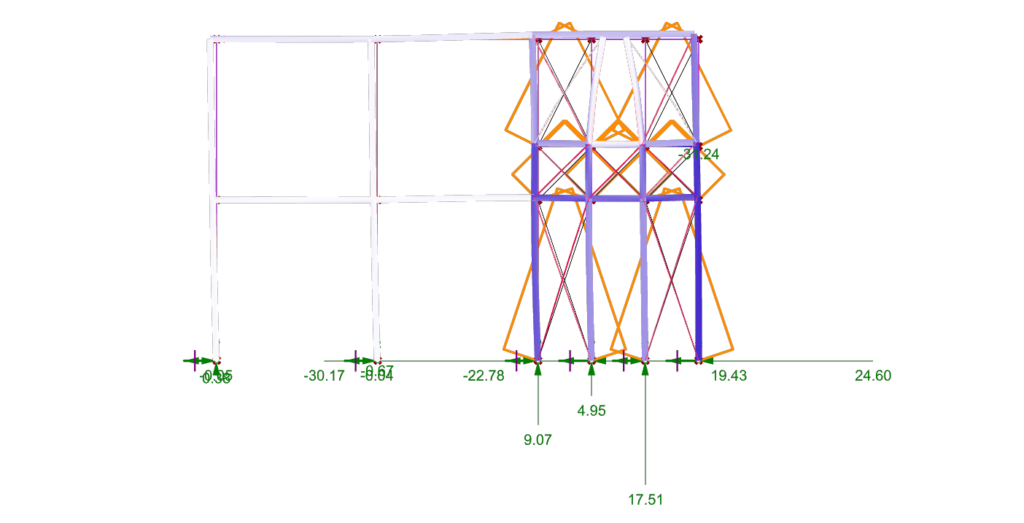

Deformation : 0

Deformation : 100

Displacements:

LCO: 0.229886

LC1: 0.780657

LC2: 0.116473

LC3: 0.084721

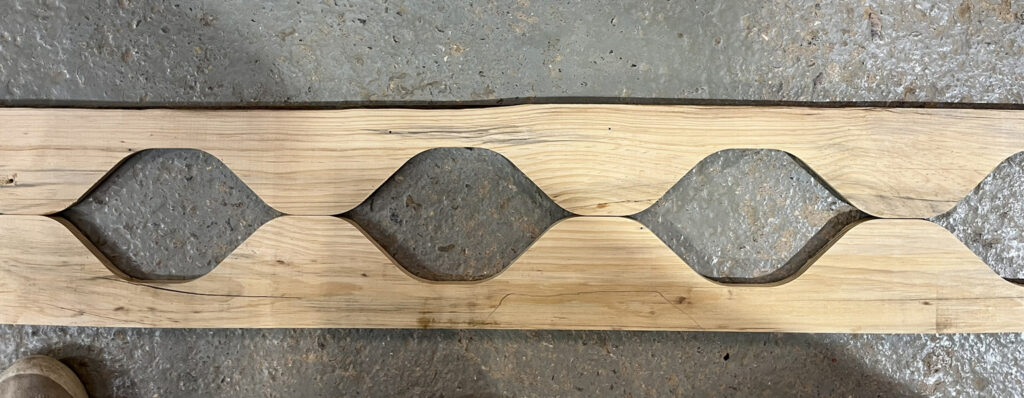

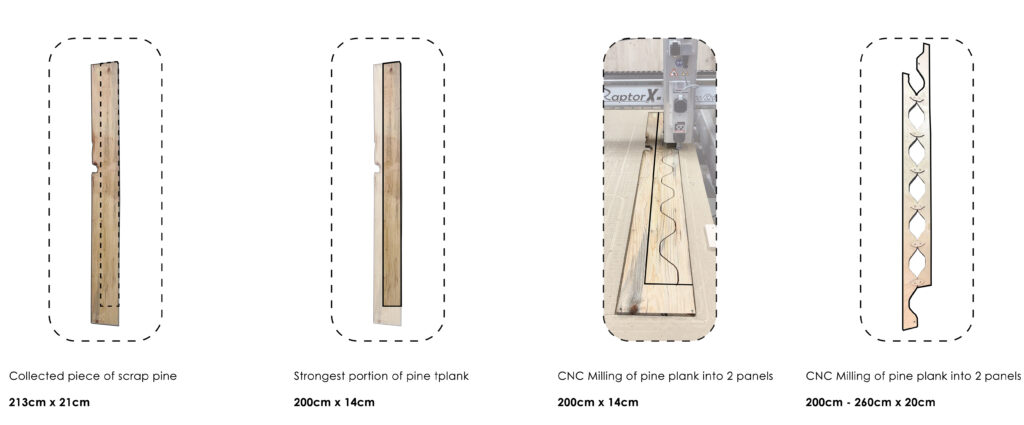

Dimensions: 213,5 x 22 cm

Material: Offcut Pine Plank

Variation 1 : Accessible Roof

Cross-section: O-Section

Domestic dwelling floor finish : 0.5 kN/m2

Variation 2 : Extended Common Areas

Cross-section: O-section

Domestic dwelling floor finish : 0.5 kN/m2

Roof finish load : 0.3 kN/m2

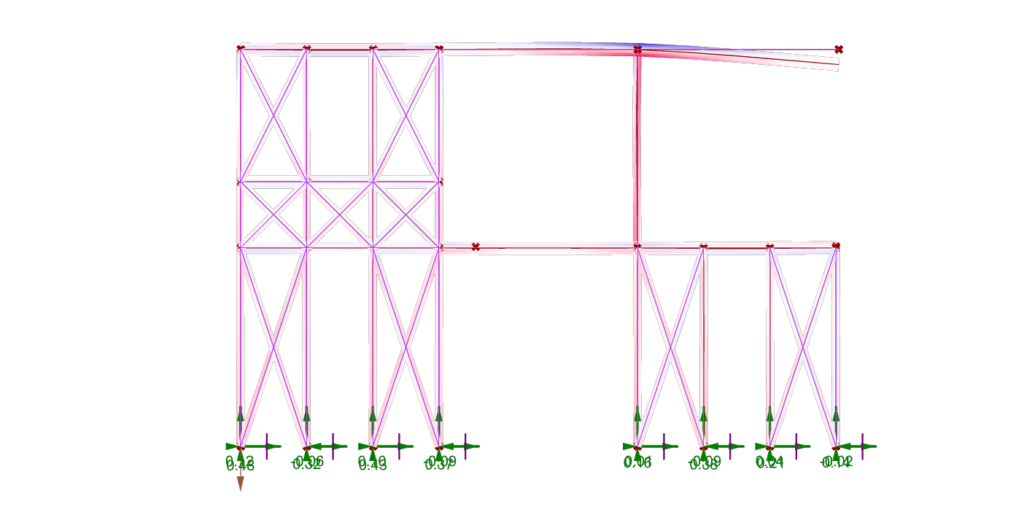

DESIGN STRATEGY

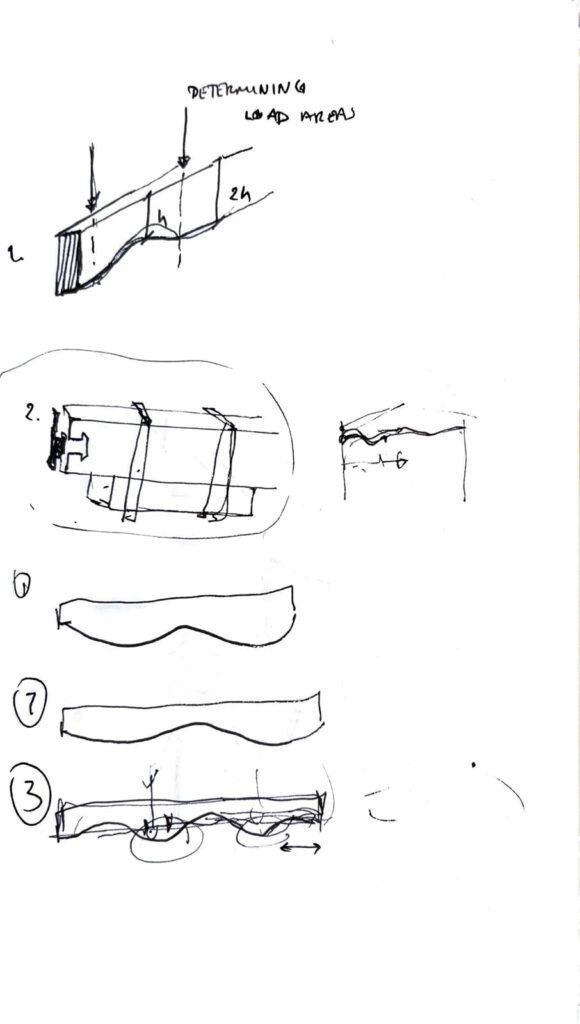

Taking a regular rectangular shape and using a castellated pattern to amplify its depth and strength. Being as lightweight as possible and without waste

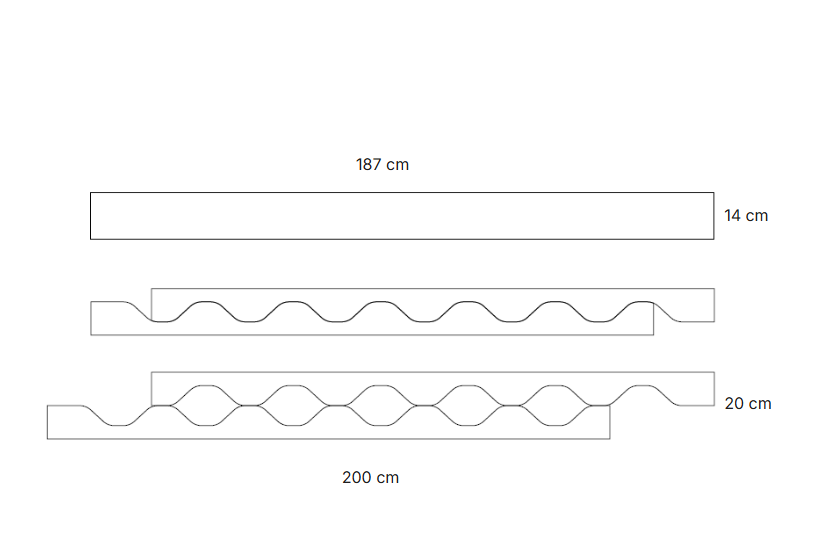

DESIGN ITERATIONS

The main design principle was re-using a waste material on high efficiency. The design gives a chance to double the height to strengthen the beam.

Different type of connections are tried. Within in a limited time best option was using dowels (12 dowels) and a small connection piece.

The struggle was designing a without dowel option but the main aim was having it without dowels.

BEAM DIAGRAM

The chosen material was expected to be cracked, at first it cracked and at the end it buckled.

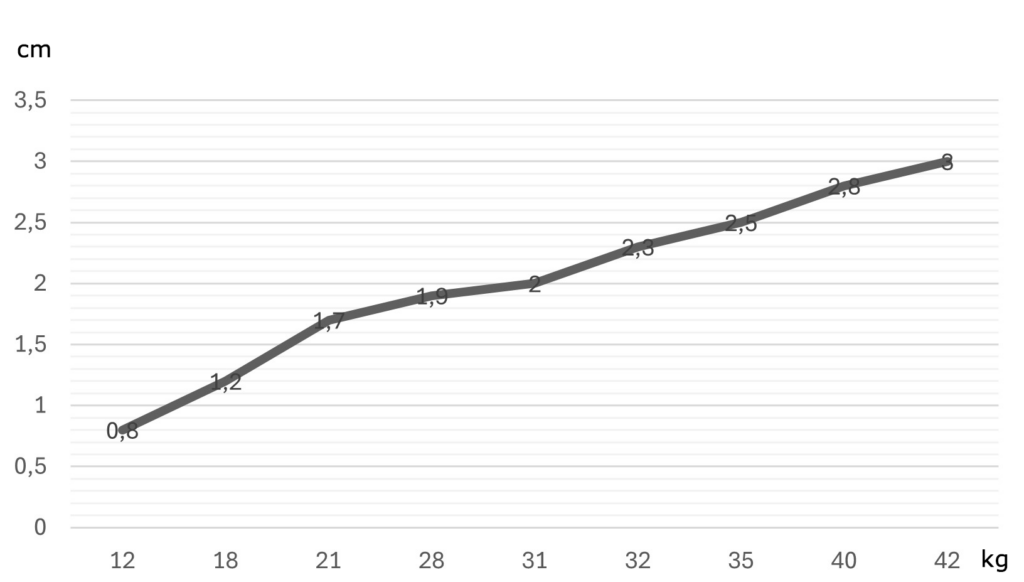

Deformation Graph

BEAM TEST

Max Deformation in Beam Test = 3cm

Max Load = 42kg

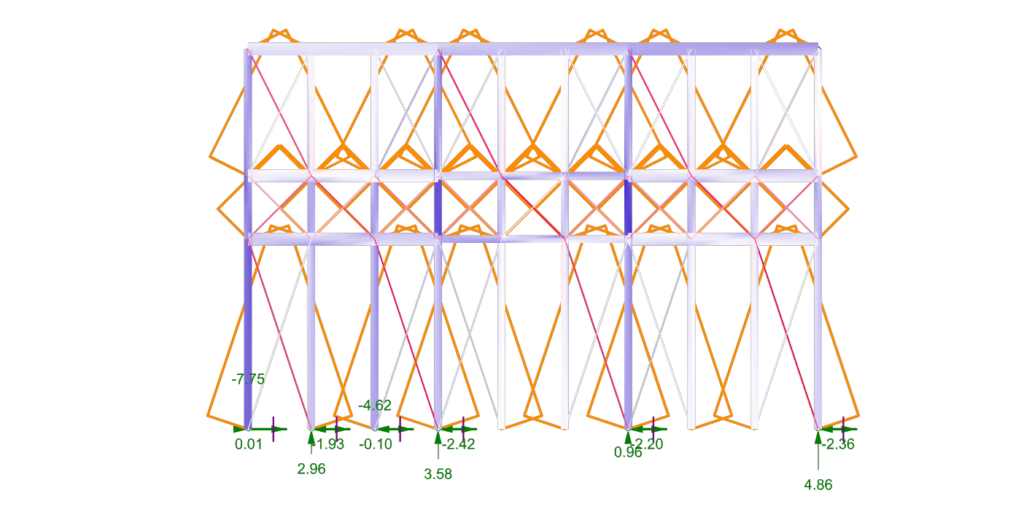

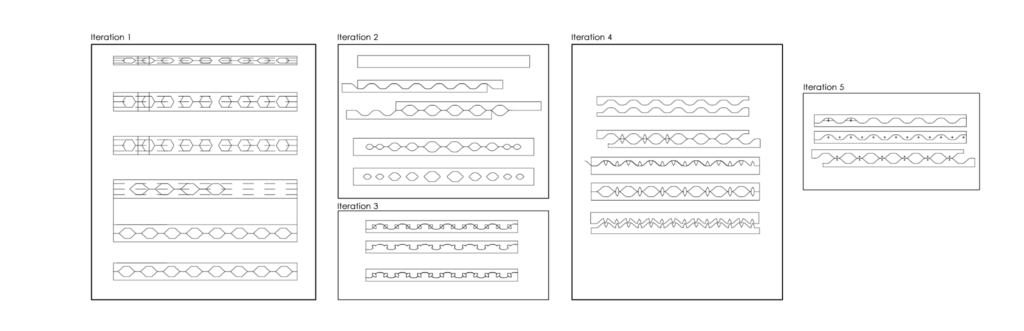

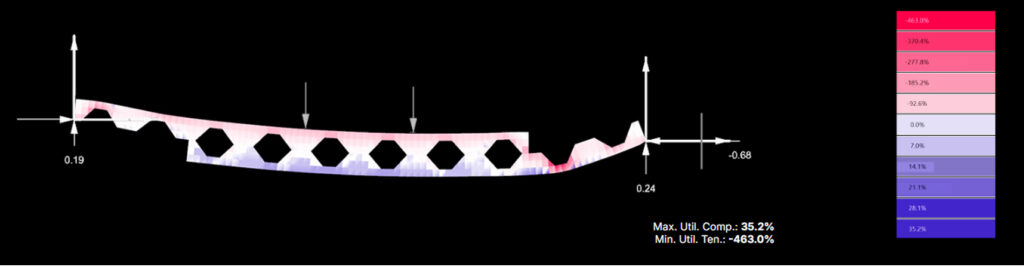

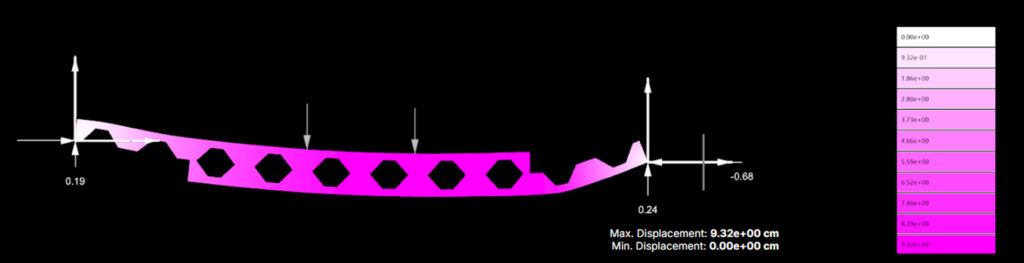

KARAMBA ANALYSIS

Max Deformation in Karamba = 72cm

Karamba analysis showed too much deformation and shear. Causing buckling and cracking at the ends.

Improvements:

Using a stronger wood

Less voids towards the ends of the beam

Fixing the joints of two pieces

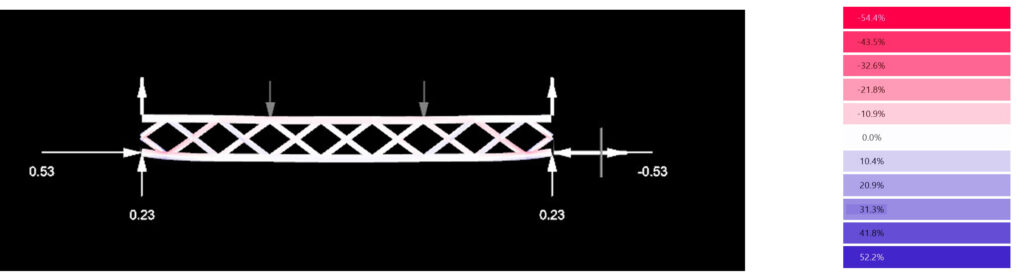

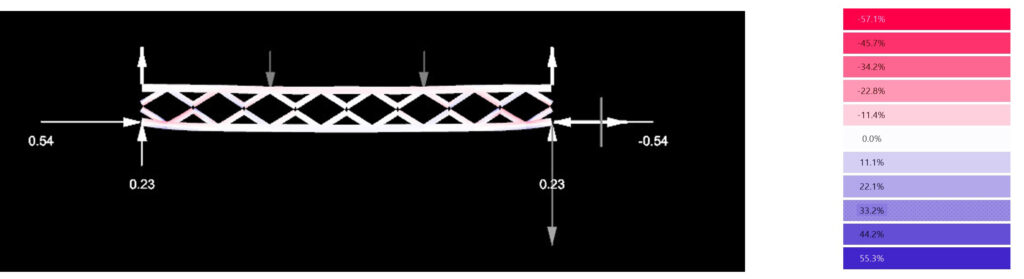

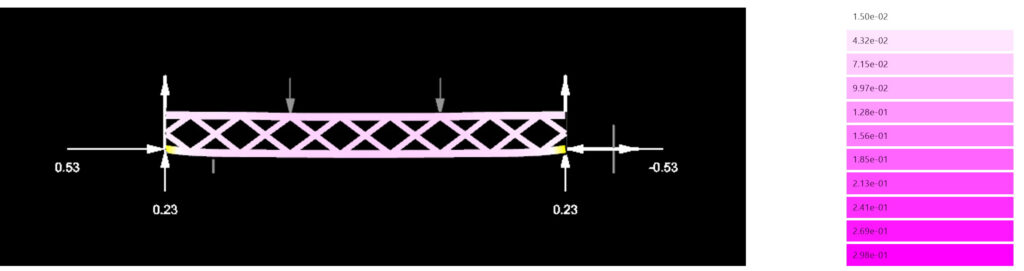

2D utilisation comparison

Max. Util. Comp.: 52.2%

Min. Util. Ten.: -54.4%

Max. Displacement: 2.98e-01 cm

Min. Displacement: 1.50e-02 cm

Max. Displacement: 6.76e-02 cm

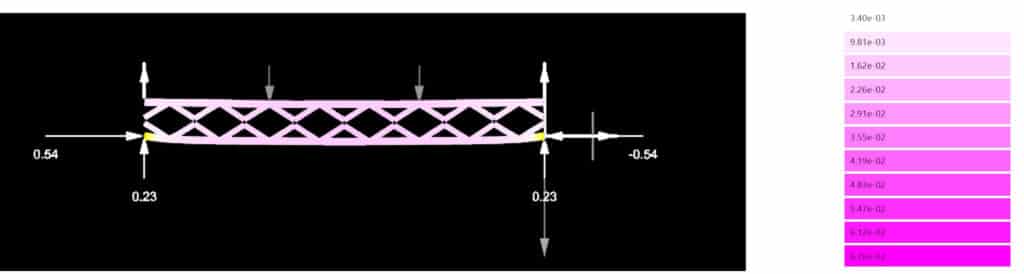

Min. Displacement: 3.40e-03 cm

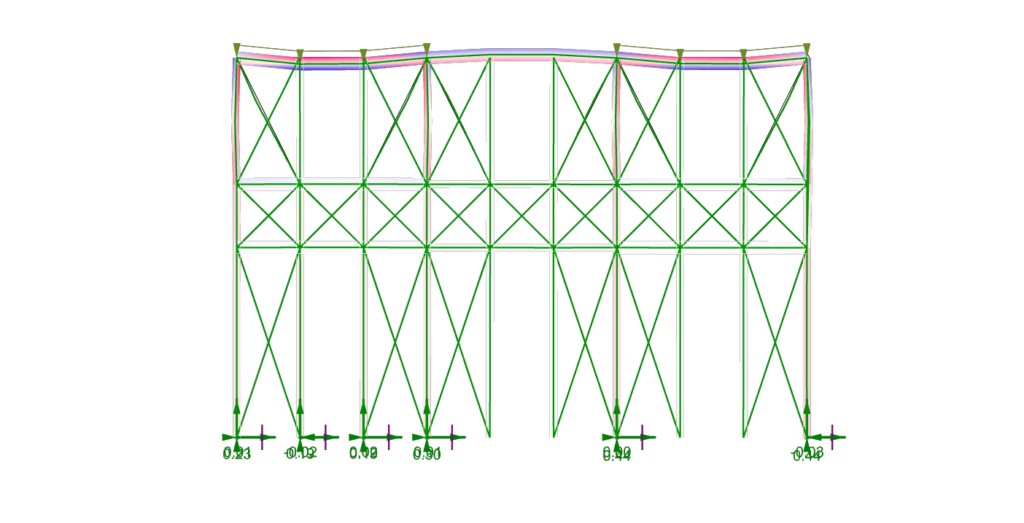

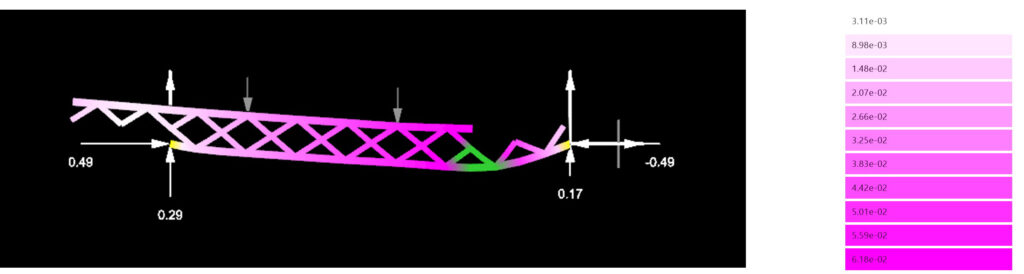

2D displacement comparison

Max. Displacement: 6.18e-02 cm

Min. Displacement: 3.11e-03 cm

Max. Displacement: 2.98e-01 cm

Min. Displacement: 1.50e-02 cm

Max. Displacement: 6.76e-02 cm

Min. Displacement: 3.40e-03 cm

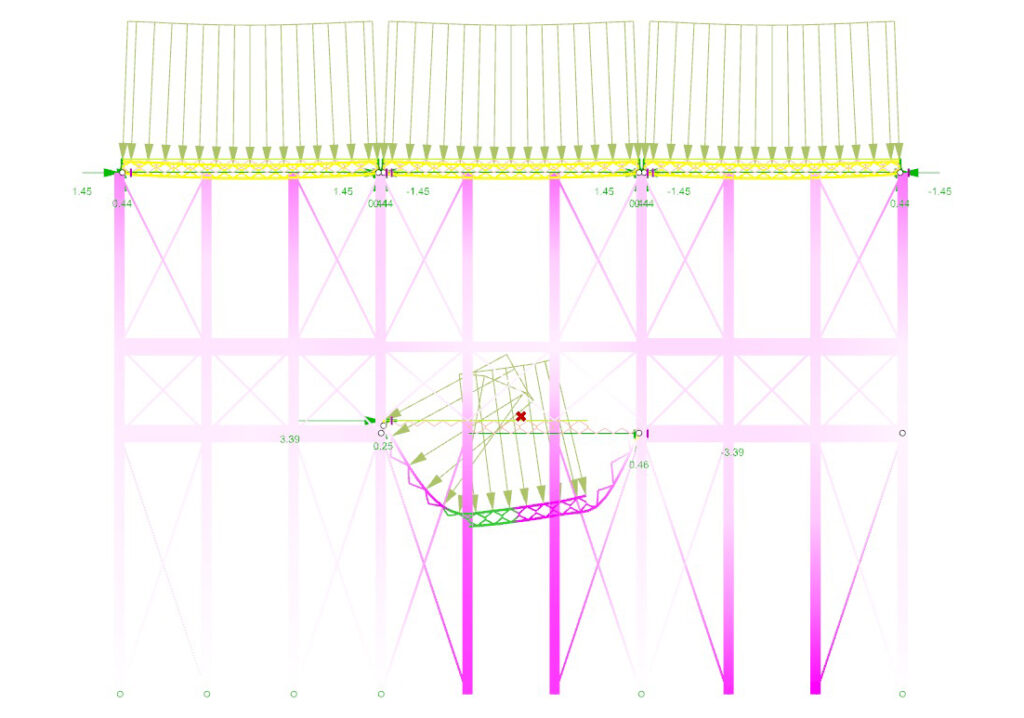

Implemented Beams into Existing Structure

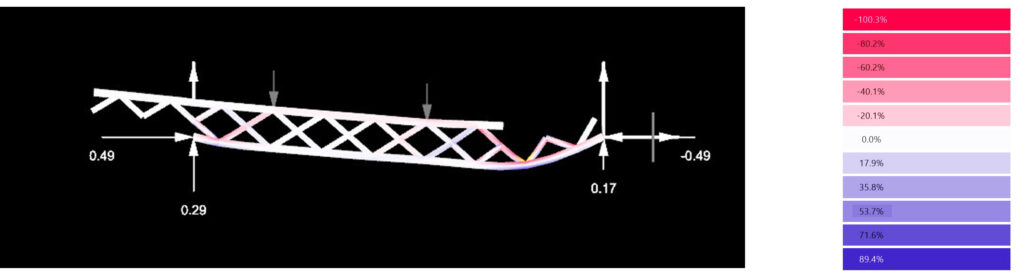

2D utilization analysis

2D displacement analysis

Snow load: 0.3 kN/m2

Span: 3m

h: span/20

Snow load: 0.3 kN/m2

Span: 3m

h: span/20

Max. Util. Comp.: 540.7%

Min. Util. Ten.: –599.2%

Max. Displacement: 4.68e+00 cm

Min. Displacement: 3.87e-01 cm

Solid timber beam

170x75mm deep C24 12.3kg for 2m

480 kg/m3 CO₂ Emission

Castellated RE-USE beam

200x9mm deep plywood 2kg for 2m

21.1744 kg/m3 CO₂ Emission

CNC MILLING