Photo credit: Nestor Beguin

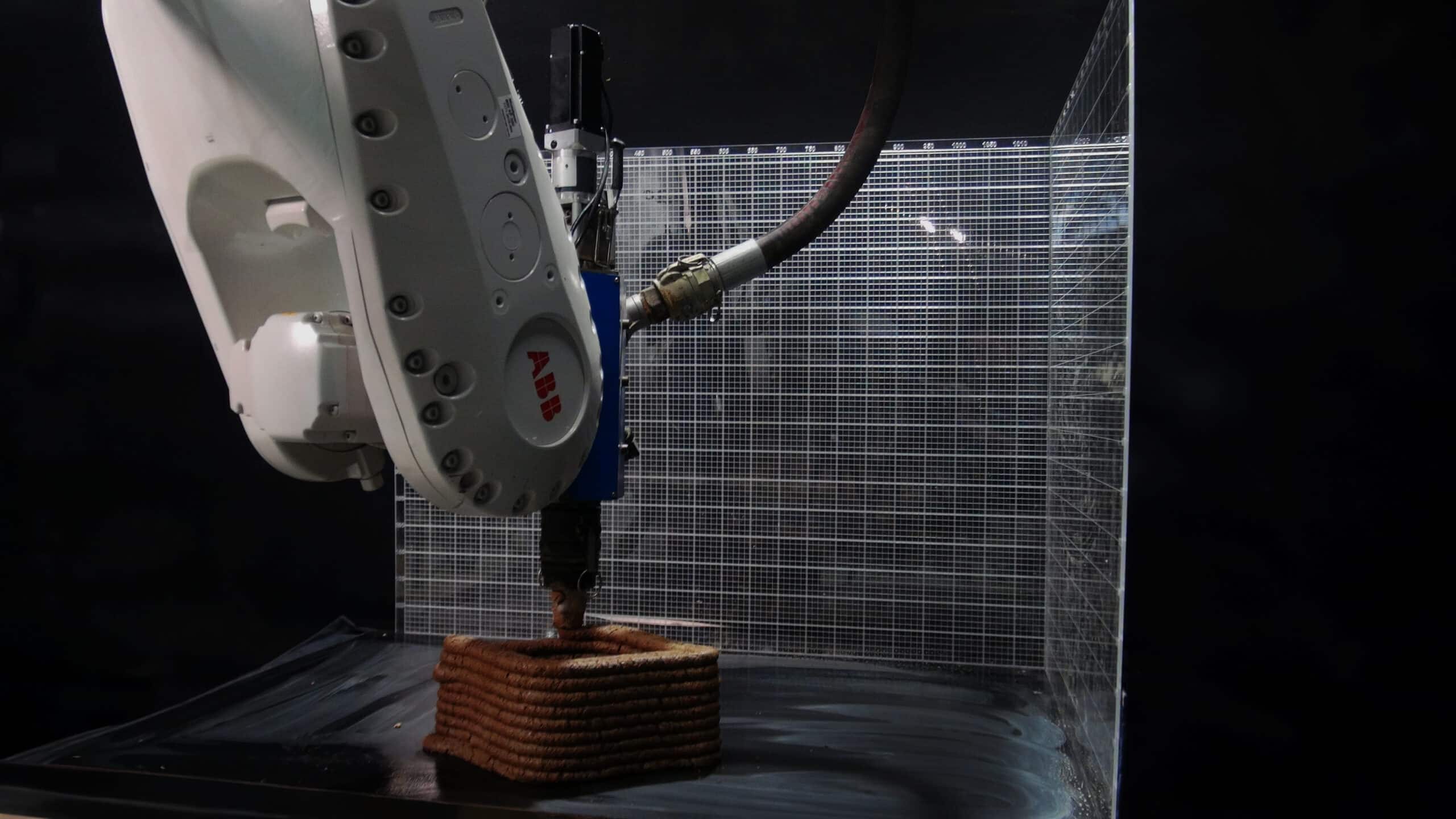

After the initial 4 weeks of Techne and an ultra fast learning curve into the material, the technology and the design for earth printing, it’s time to address a longer and more consistent phase of the work in which you are asked to develop technical and design solutions that will – hopefully!- be brought to the prototyping of the Forest Campus in January and February. After nine editions of 3dPA, the completion of an array of prototypes, and different research endeavours, our Forest Campus now hosts Tova and Teixit. FC is an architectural landscape of printed earth walls and tilted roof structures, a succession of fragmented spaces with an enclosed room, the library, and open-covered spaces dedicated to woodworking and 3D printing. This part of the Collserola Natural Park is a laboratory, a place for experimentation in the field of construction with local materials and robots, but also an architectural project where an ongoing collective building process invites reflection on how to live within a material and climatic context.

HELIA

Last year, the aim of the program was the design and partial construction of the largest indoor space of the Forest Campus, and the 24/25 have completed an impactful first part of the intervention by designing and printing “Helia”, 3dPA’s longest wall that combines together structure and various climatic performances such as self-shading, natural ventilation, thermal insulation and transmission. The legacy of the previous group, therefore, consists of a printed wall, a general spatial layout that indicates living and sleeping spaces. The 3dPA team has also developed a roof solution based on the Teixit structural and construction principles.

Our task this year is to complete this project to a level of detail comparable to that of our own dwellings. In other words, show ourselves and the world that 3d printing with earth is not only research but a tangible solution for housing today. Despite the 9 years of research completed by your predecessors at IAAC, there are plenty of aspects that can be developed to bring earth printing closer to the market: printing is still a slow process due to drying times, realistic solutions need to be engineered for large windows, wall textures can help both structure and coating, new wood to earth connections can still be invented…

3DPA 25/26 is about continuing the work of the previous year, yet bringing plenty of innovation into it. We inherit a project that contains existing solutions for:

- West wall

- Roof structure

- Passive climatic strategy

- Schematic distribution

From a wall to a space

Although Helia suggests an enclosed space, we will need to define its spatial distribution and its wall layout. This is a task that we will work through collectively through the early weeks of the Research phase and aim to have a tangible solution by mid-term.

For this exercise, we address questions of production and printing quantities, defining the maximum print length, which will help us in the design process. Other aspects that will be considered are: printing positions and radius, fragmentation of walls, positions of walls, doors and partitions.

The outcome of this process is a plan with the lengths and axes of the walls. Their thickness, textures, performances, and structure will be developed during the rest of the Charette Phase.

Research topics

During the years of development of the Forest Campus, the 3DPA team has identified a series of research topics that need development and inventive solutions. During the first Research session, the groups will be asked to select one of these topics without overlap, ensuring that all these aspects are covered. If a group wishes to propose a counterproposal, you will be able to do this during the first week, and this will be discussed with the faculty.

1. Wet State Wall Stability

3dPA has been printing with a maximum daily height of 20cm, which is an important limitation for construction standards. How can the wet-state wall stability be increased?

Objective: Investigation on how to increase printing productivity by stabilizing the walls during printing.

Proposed Methodology: Introduction of non-synthetic elements during printing to reinforce wet-state wall stability

Experimental campaign:

- Explore the influence of the introduction of a mesh on the wet-state wall stability.

- Explore the influence of wooden sticks manually inserted during the printing.

- Explore other methods that could stabilise wet walls.

- Without mixing the experiments of Matter and Research, relate their learnings

2. Ventilation for Wet State Drying

Printing cavities means that air doesn’t ventilate, and walls struggle to evacuate their humidity and increase their drying times (during TOVA, drying took up to 4 months). During the printing of Helia, the group noticed the radical difference in drying between the cavities with and without the natural ventilation conduits. This creates an important problem of uneven drying, but also represents an opportunity for increasing drying times.

Objective: Ventilate the cavity system to increase the wall’s drying times.

Proposed Methodology: Use 3d printing and other methods to evacuate air from printed cavities.

Experimental campaign:

- Compare different means of extracting moist air from cavities

- Compare the effects of mechanical and natural ventilation on drying

- Engineer a way to measure drying.

3. Introduction of Windows, Doors and Partitions

How to design the interface between a printed wall, windows, doors and partition walls. 3DPA uses a wall fragment strategy, meaning that, after printing, there will be a void in between them. How can this in between be used to install standardised glass or timber panels?

Objective: Design the most efficient earth/glass/timber connection details and control the structural effect of that connection. Consider thermal performance, thermal bridge and issues of tolerance and drying.

Proposed Methodology: Prototype earth/glass/timber connections at various scales, define and measure their efficiency.

Experimental campaign:

- Explore thermal bridge

- Explore assembly sequences

- Explore printing design patterns that lock a window detail

4. Performative Wall Textures

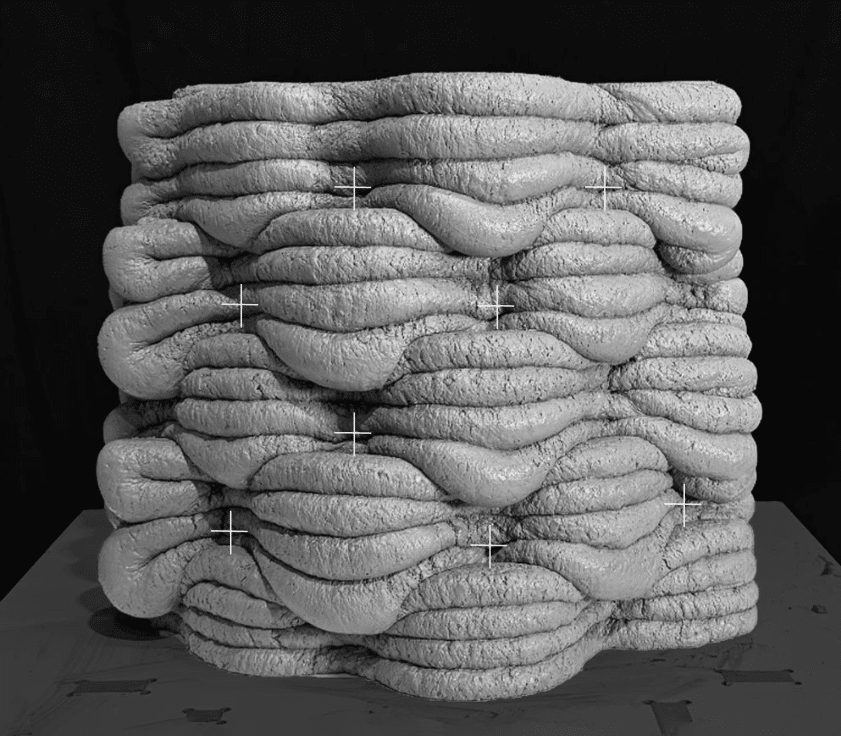

3D printing offers the possibility to customise wall textures. What are the benefits of this potential in internal and external wall surfaces, and can wall textures contribute to the structural behaviour of a wall?

Objective: Design wall textures and relate the solutions to performance in the domain of structure, wall finishings, and possibly water erosion.

Proposed Methodology: Work with geometry and printability knowledge to discover the different texture patterns possible and relate these to the selected performance.

Experimental campaign:

- Explore geometry and printability of wall textures

- Run compression tests on printed samples

- Run coating application tests on printed samples