It seems we can’t find what you’re looking for. Perhaps searching can help.

Syllabus

The widespread use of Additive Manufacturing technologies has brought a significant revolution in the field of design and fabrication, both in domestic and industrial settings. Designers today are much closer to the actual process of manufacturing and production, as was promised when these technologies arise. Despite the numerous challenges that come with the idea of 3D printing buildings, this technology is progressively finding its way into the architecture, engineering and construction (AEC) sector.

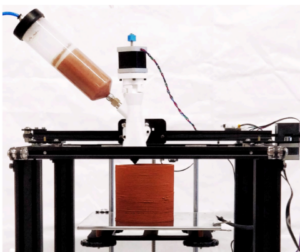

The TECHNE W2 MACHINE aims to provide students with a comprehensive understanding of paste-based additive manufacturing and the technologies and methodologies we use in 3DPA. We will examine the technology, techniques and materials required for clay-based 3D printing. Students will develop a solid foundation of the principles, gaining knowledge and skills necessary to work independently with the Ender platform, as it will be the tool of choice during the rest of the course stages.

Students will have access to previous works, enabling them to progress faster and deeper in their understanding of the machine protocols and operation parameters. Test prints will still need to be conducted to validate and refine previous findings.

Scale

Throughout the development of the 3DPA course, we will utilize different scale models and prototypes to validate findings, ideas and intuitions. The choice of scales will be closely linked to the available machines that we will be using and what we would like to explore. By working in different scales, we can gain a comprehensive understanding of concepts such as layer mechanics, material consistency, shrinkage and the influence of gcode planning in the print, among others.

| 1:1 | 1:3

1:5 |

1:10

1:20 |

||

| WASP CRANE XXL | KUKA KR150 | ABB 140 | Ender 5 Plus | Ender 5 |

This workshop has a specific focus on understanding machine protocols in two different scales. On a smaller scale, we will check what is the influence of the materiality in the fabrication process and explore the various adjustable variables that exist. On the other hand, on a larger scale, we will understand the behaviour of earth, as the material weight increases cubically and layer mechanics are different as a result of different rheology.

We will use the opportunity of being in Valldaura to gain extensive knowledge with the Wasp Crane, as it will become the production tool for the 1:1 prototyping phase that will follow techne.

The different scales will also inform the designs we can achieve, as the resolution and detail need to change, affecting layer bonding. In our regular workflow, we will test concepts mainly in desktop printers, as the time of production can be reduced. Larger prints will require longer timings due to logistics and calibration challenges. Larger prints also are more difficult to time-estimate, as more parameters can deviate for theoretical planning.

Material

During this workshop, we will also address material preparation for both small and large additive manufacturing processes. For the small-scale printer, we will utilize premixed red clay. For the large-scale printer, we will work with Valldaura’s soil.

Clay is particularly suitable for the small scale due to its fine-grained nature and excellent plasticity. The characteristics of the material are a perfect match for the small-diameter nozzles. We will also learn how to prepare the mix and refill the cartridges for smooth, air-free, printing.

Taking advantage of previous knowledge from the Matter workshop, we will prepare a -Valldaura- soil-based material mix that is suitable for large-scale printing. The coarser properties of the soil and the size of the aggregates will have an impact on the quality of the deposited layer, the goal of this first 1:1 print is to understand the rheology required for the material. One of the goals is to investigate the behaviour of the earth mixes used previously and test their feasibility with an additive manufacturing process.

A Tool

A 3D printer, like a pencil or a computer, is just a tool. Sometimes we need to remind ourselves that we, as designers, have the responsibility for what is being produced and ultimately, our goal is to design with and for this technology. Despite being a pivotal topic of the postgraduate, it is essential to keep in mind that a machine is another tool in the 3DPA toolkit.

During the year, we will be using the Ender 5 platform as a production machine for small-scale prototyping, thus it is crucial to understand the cartesian mechatronics of the machine itself and how to properly maintain the machine. Students will be responsible for taking care of the printers and doing proper maintenance of the extrusion system. We will be using an Ender that has been modified by the staff with the FabLab BCN paste extruder.

Methodology

Students will participate in theoretical sessions during the mornings, focusing on the fundamental principles and concepts for creating a workflow for paste-based additive manufacturing, both abstract and hands-on. These sessions will cover various topics, including grasshopper tutorials for gcode generation, toolpath manipulations, machine protocols and control systems, printing techniques, and material properties.

Half of the workshop time will be learning-by-doing activities, with specific exercises to apply their theoretical knowledge. Students will work in small groups and each of them will have a printer assigned. Practical sessions will cover essential skills for fabrication such as machine calibration, mixing and loading of clay cartridges, and adjusting printing parameters.

Throughout the workshop, students will receive support from workshop assistants, who will provide assistance in both computation and fabrication. They will be available to answer questions and provide guidance.

Learning Objectives

The workshop has a clear hands-on and learning-by-doing directive, intended to force students to solve problems as they occur. At the completion of it, students will:

- Understand the principles and workflow for clay 3D printing:

- Define a Design-to-Production scenario.

- Be able to generate Gcodes for the printer and run them.

- Control the variables and parameters of operation.

- Gain knowledge of the mechatronics of the Ender platform:

- Mounting and calibration of paste extruding systems.

- Assembly and general maintenance of the printer.

- Understand the cartesian movement mechanics and its controller interface.

- Understand the principles and workflow of 1:1 earth-based 3D printing:

- Assembly of the WASP crane. General idea of a Construction Site 4.0

- Getting familiar with the design to production workflow in 1:1.

- Understand the production requirements for large-scale printing.

- Get familiar with the WASP Crane Gcode generator.

- Understand the polar movement mechanics and the controller interface of the WASP crane.