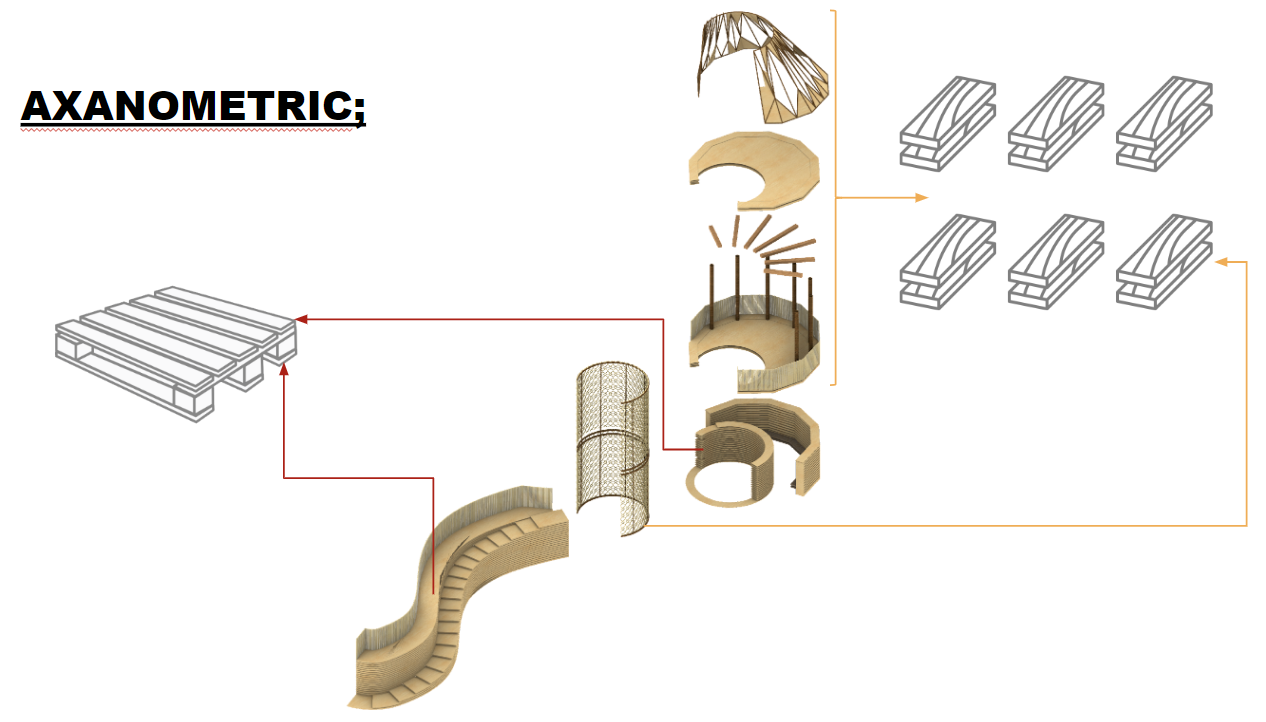

Credits: Marina Spa Prototype / Helen & Hard, Tom Svilans, Design-to-Production GmbH, Winther A/S

How have digital tools changed age-old practices of wood craft and timber construction?

This seemingly simple question has been asked and answered in many different ways since the introduction of numerical control and automation in timber manufacturing, and has led to the design and construction of entirely novel timber morphologies and dramatic new architectures.

The capacity of digital modelling tools to represent forms is enormous; however, the affordances of timber and timber manufacturing are more tempered. By engaging with the processes of fabrication directly, and experiencing the consequences of our design decisions, we can better understand how to navigate these affordances with our design ambitions intact. The tools and contexts of craftsmanship have changed, however the central principles remain the same: a deep understanding of the capacities, constraints, and inclinations of both tool and material, guided by a learned knowledge of the specific consequences of specific decisions.

Credits: Marina Spa Prototype / Helen & Hard, Tom Svilans, Design-to-Production GmbH, Winther A/S

So what new tectonic languages can we impart to our constructions? How can we appropriate the mechanical movements of a CNC router and turn them into a choreography that traces out our design ambitions? In this seminar, we will explore the world of digitally designed and fabricated timber structures – how they are conceived, communicated, and materialised – and how to predict the impacts of design decisions on material behaviour. Through this effort, we will begin to form the beginnings of our own material practice – operating in the fertile space between digital drawing and physical making.

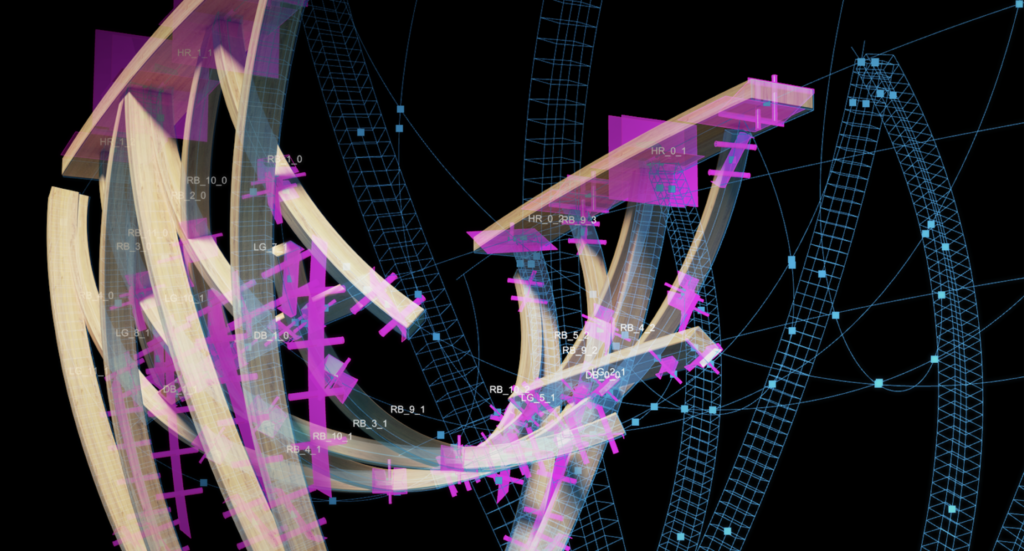

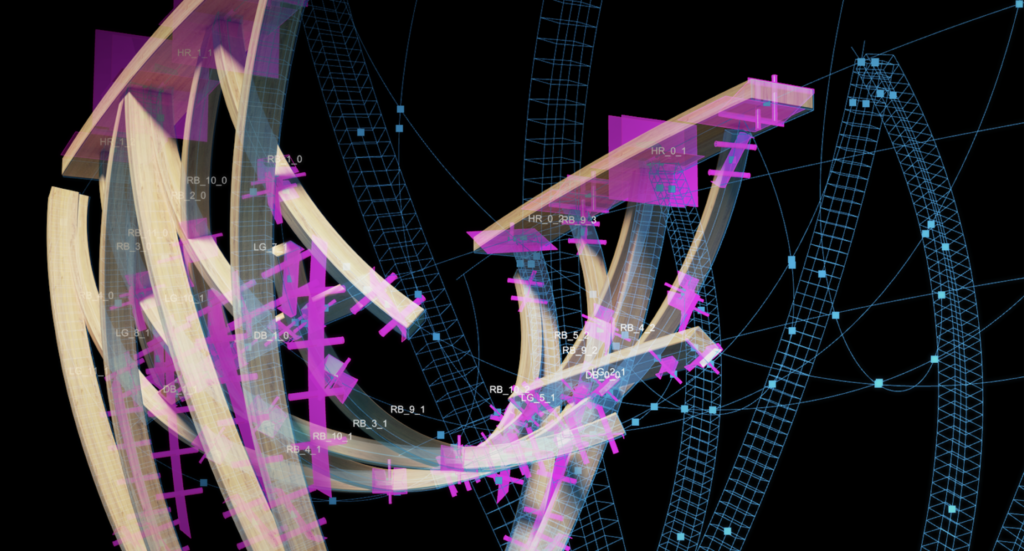

Credits: Fabrication-led design modelling / Tom Svilans

Learning Objectives

At course completion the student will:

- Understand the basics of material properties and behaviours in timber;

- Understand the basics of the production constraints of CNC-machined timber elements;

- Be capable of designing and making architectural assemblies that recognize these constraints and how to mitigate them;

- Be capable of moving from a schematic design proposal of a timber assembly to a fabrication-ready proposition.