The seminar explores a series of methodologies, that incorporate advanced design thinking, generative algorithms and mass customized fabrication in existing industrial processes. This development is accompanied with novel interfaces for robotic programming and large-scale automated construction.

Syllabus

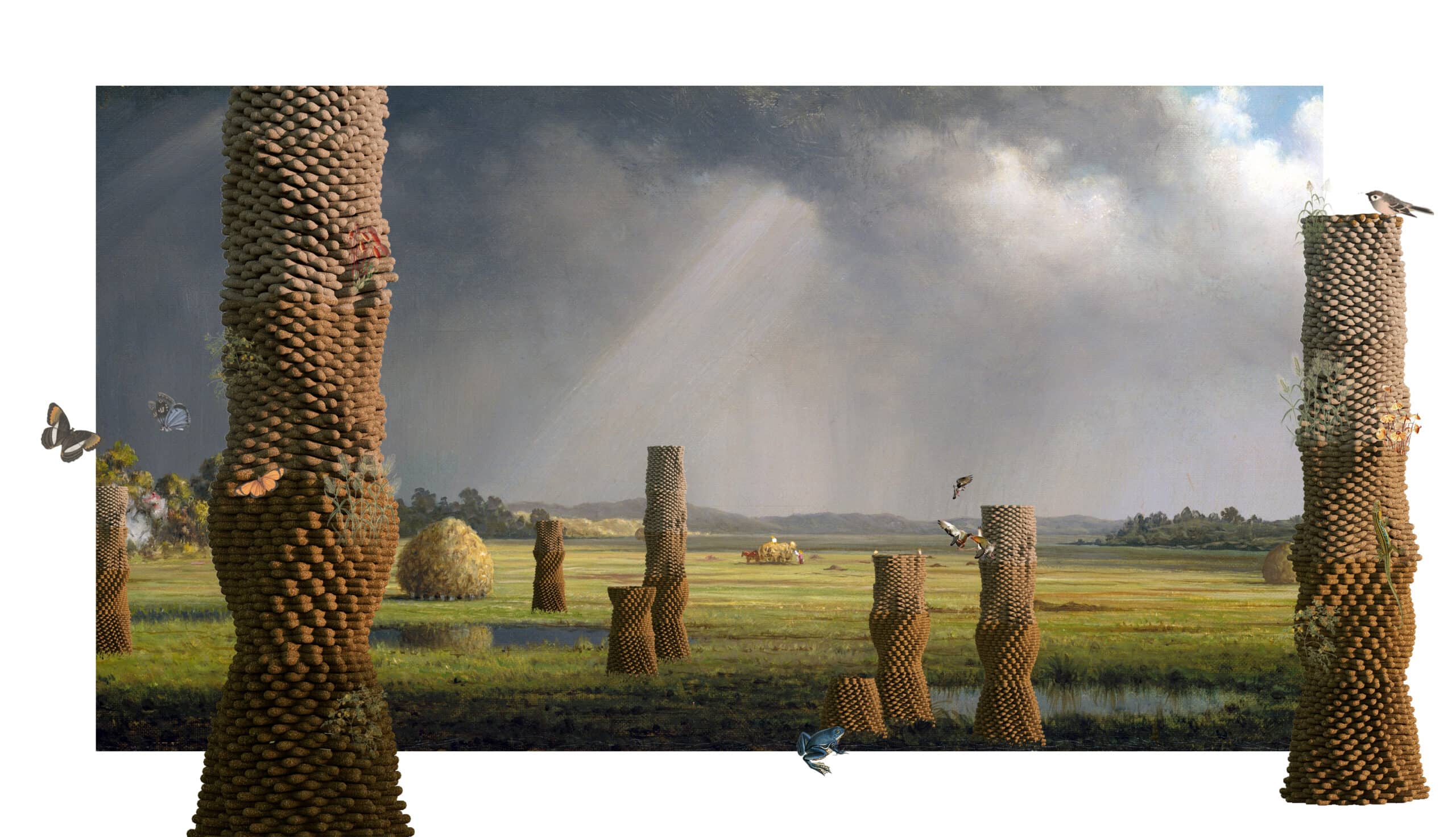

Credits: Canned sugar based PLA bioplastics and wood, Mamou-Mani Ltd

Robotics has opened up new avenues of designing, making, assembling and indeed the whole spectrum of architectural production. Although robots, particularly industrial robots, have been around since the 1960s, have not yet been directly linked to the design process.

The construction sector has not yet taken full advantage of the digital revolution that is happening in other manufacturing sectors, such as in the automobile and aerospatial engineering industries. While studies predict that Automation, Robotics, and AI will possibly increase productivity by 60% in the construction sector, they also open new opportunities for design and for increased building performance.

In this context, today we find ourselves looking at the midst of a significant transformation regarding the way we produce products thanks to the digitization of manufacturing. This brings us to the emergence of a community of research and education centres including IAAC exploring new fabrication methods that can be more efficient, sustainable, and customisable thanks to the use of robotic fabrication within its educational programs, consolidating an emerging paradigm within the current production system.

To quote Richard Sennett, “Making is thinking”, this seminar will focus on a manufacturing driven design approach towards conceiving spaces. Students are offered the opportunity to learn and explore robotic fabrication within IAAC’s particularly open environment for direct manipulation and testing. In parallel, students are encouraged to develop a design protocol suitable for robotic fabrication that could serve to envision an application at architectural scale.

In this connection, with Robotic fabrication, tackling architecture details becomes an exciting new field of exploration for designers. The seminar invites students to explore joints and additive manufacturing through robotic systems in architecture facade design. Therefore, the seminar will conclude with a robotically fabricated prototype fabrication, together with a video of the design process, the prototype fabrication and the envisioned architecture.

Learning Objectives

At course completion the student will:

- Have an overview of the possible robotic fabrication processes available for architects and designers;

- Understand the basics of robotic kinematics, robotic simulation and robotic control;

- Be capable of generating the robotic simulation and production files to produce a prototype;

- Be capable of integrating the limitations and opportunities of a specific robotics process into a final architecture design.

Faculty

Faculty Assistants

Projects from this course

Sinuous Cork façade

INTRODUCTION TO ROBOTIC FABRICATION A façade which transforms according to the 360 degrees of rotation from one module to the next stacked on it, where the trifurcating arms give varying degrees of porosity and light filtration based on the module stacking References The modular constructivism style is based on carefully structured modules which allow for intricate … Read more