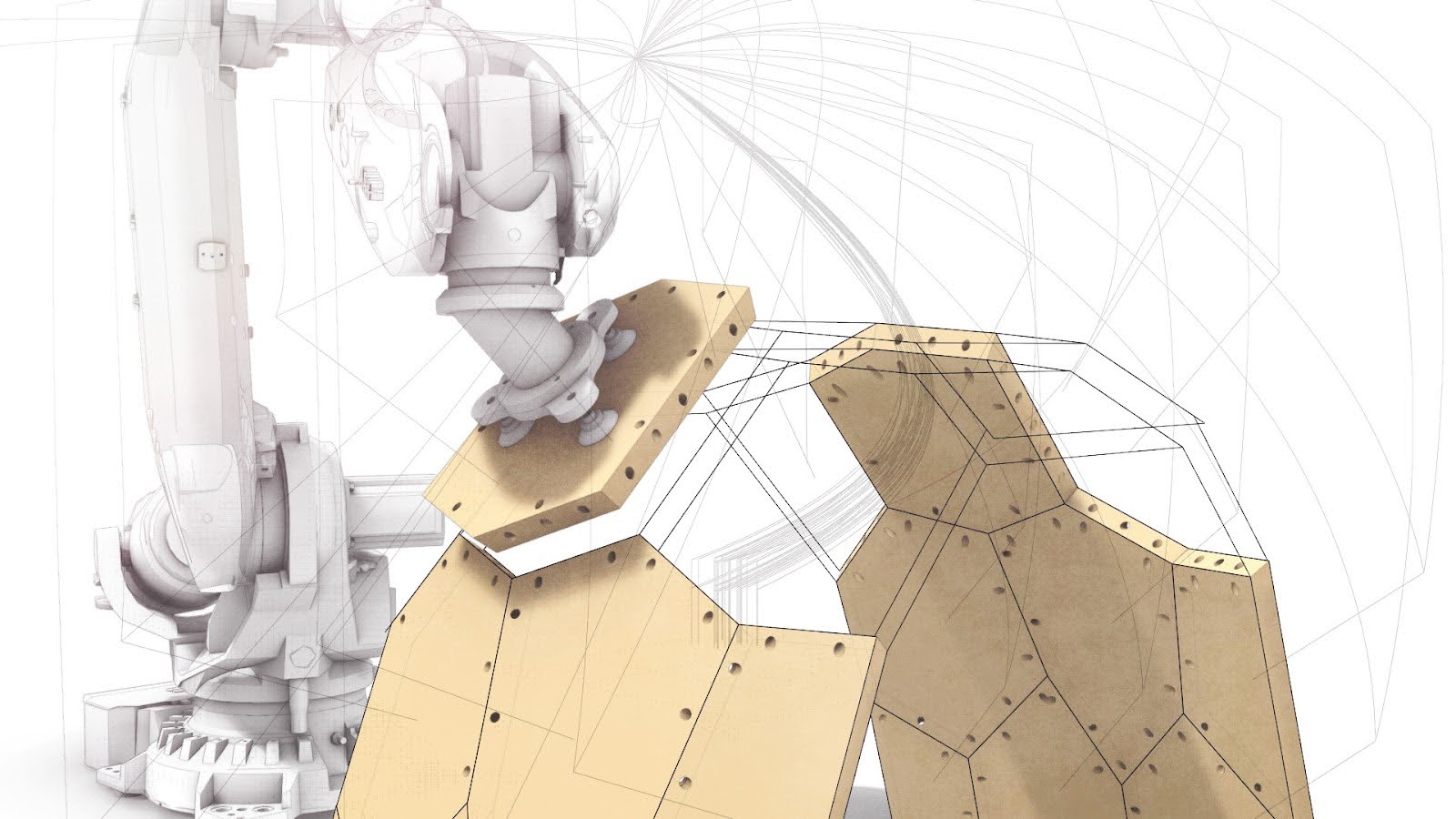

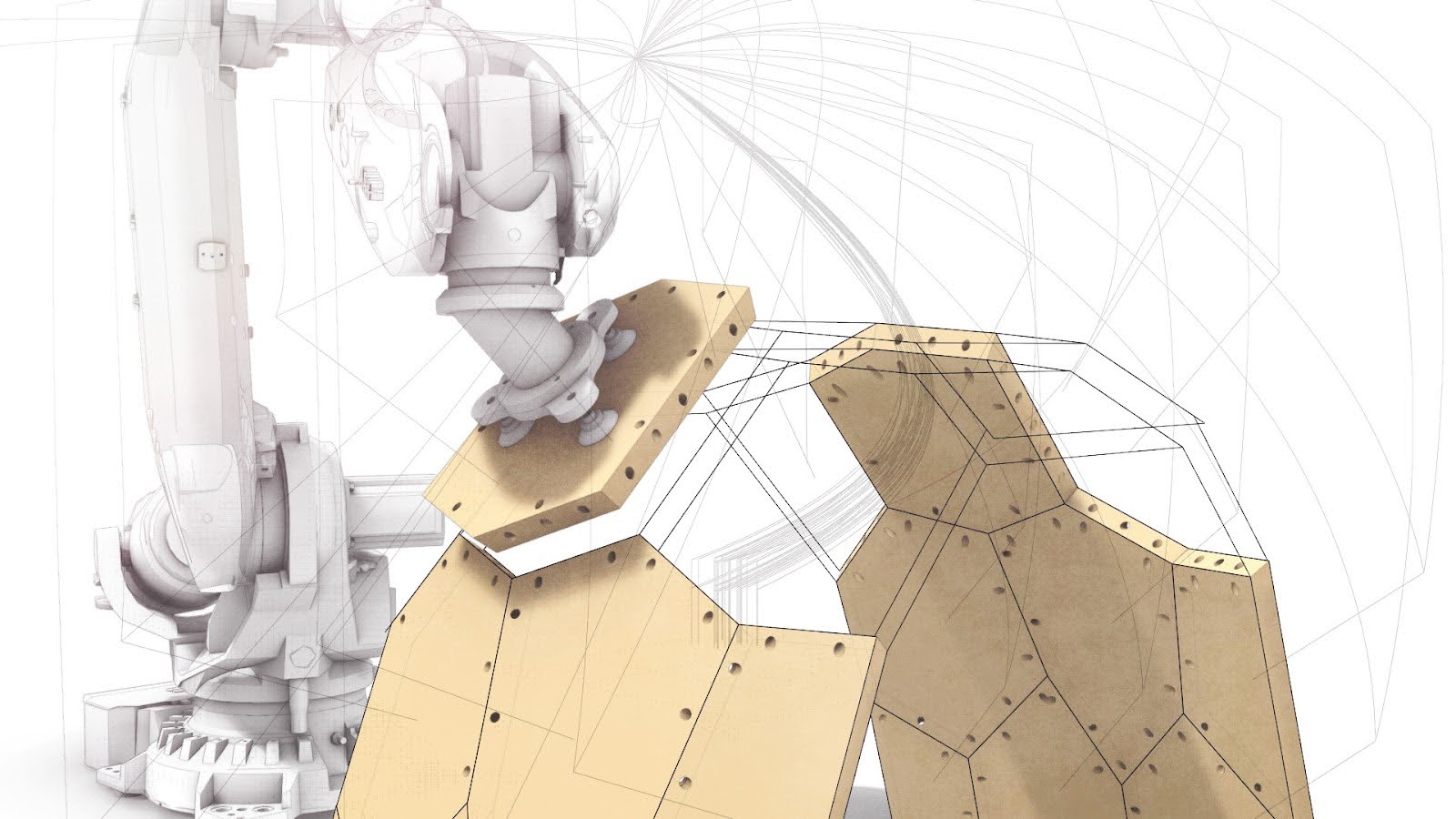

Credits: Visual of the robotic fabrication and assembly process, Valentino Tagliaboschi

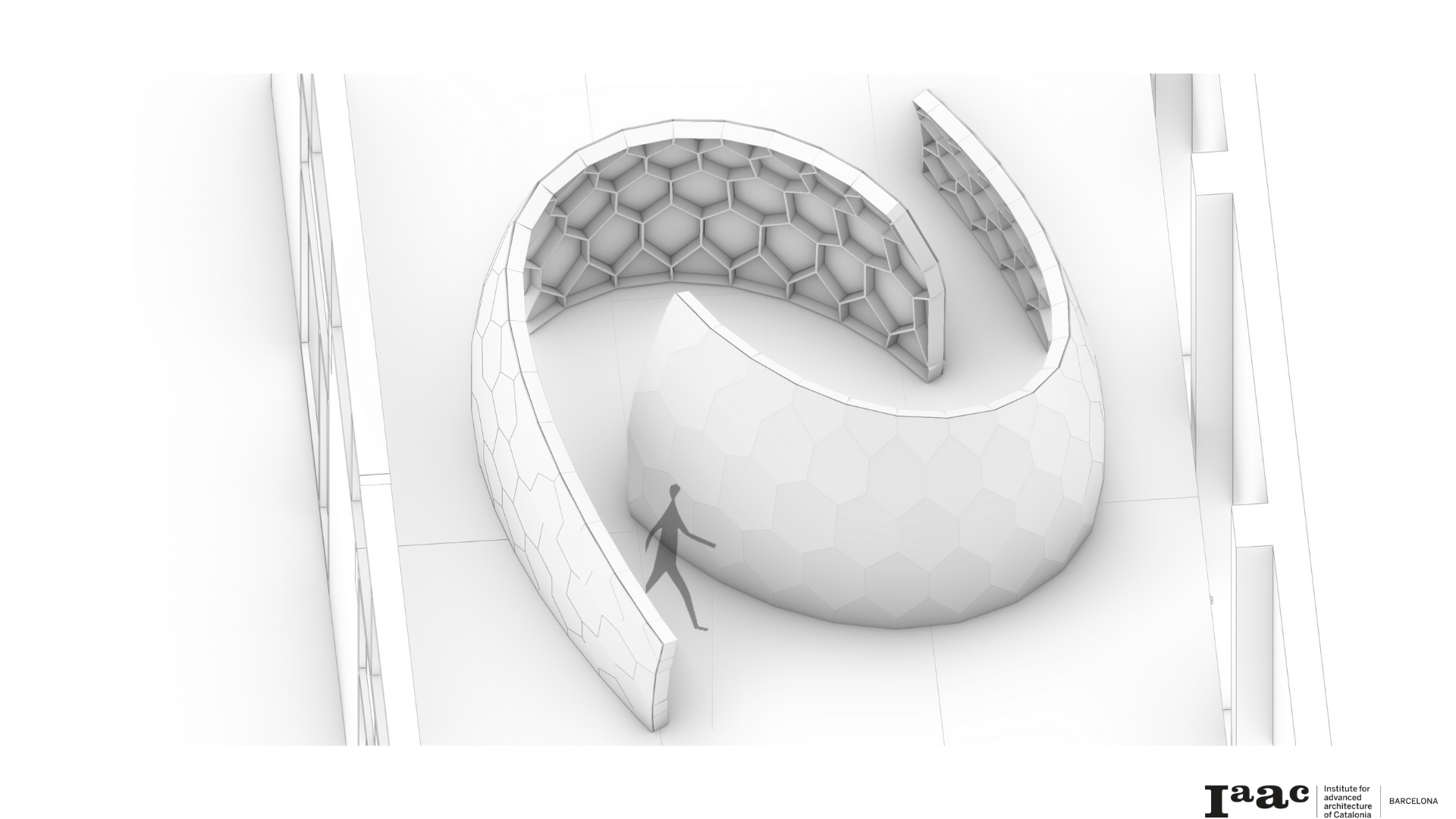

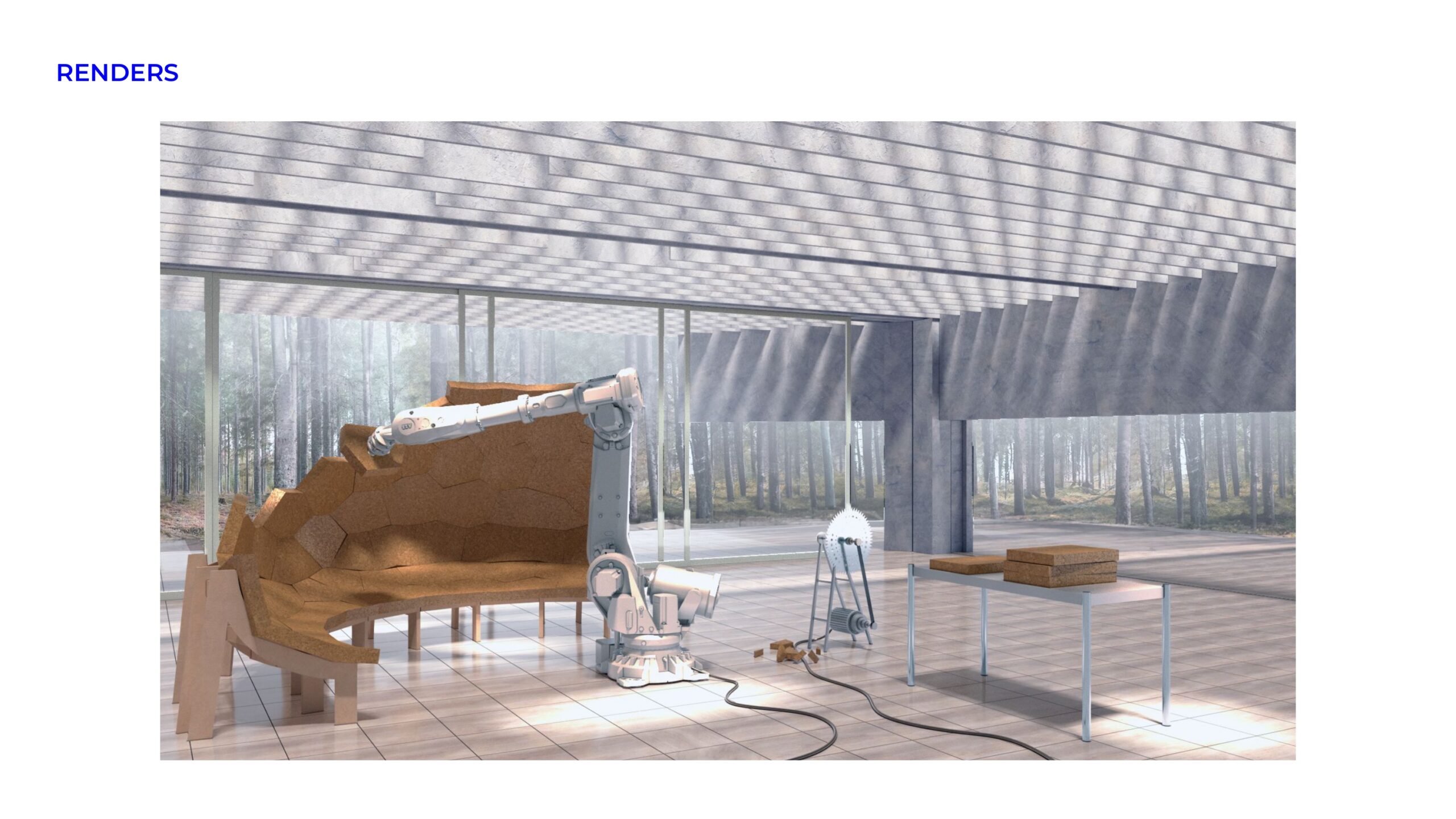

This one-week intensive seminar aims to introduce participants to robotic manipulation processes for the fabrication and assembly of segmented shell structures while investigating whether cork panels can be used to fulfil all the functions of the building envelope, providing thermal and acoustic insulation as well as satisfactory structural performances in a complex domed structure, easy to assemble and disassemble.

The proposed robotic fabrication workflow integrates pick-and-place with part-to-tool operations. We refer to part-to-tool processes when the robot holds the part and brings it to the tool, facilitating the integration of multiple operations with various tools.

Participants will collaborate in groups to develop a design-to-fabrication strategy for small architectural objects such as cabins, shelters, office pods, meeting rooms, phone booths, or pavilions. Simultaneously, students will engage in hands-on fabrication and assembly of a small demonstrator using the IaaC’s new robot ABB IRB 6700, gaining practical experience in robot motion planning and implementation.

Learning Objectives

At course completion the student will:

- Fundamentals of motion planning and toolpath design for robotic fabrication;

- Basics of robotic kinematics, simulation and control;

- Tool calibration and robot operation;

- Pick-and-place and part-to-tool robotic processes;

- Design strategies for segmented shell structures: planar and offsettable tiling of freeforms;

- Design for robotic fabrication and assembly.