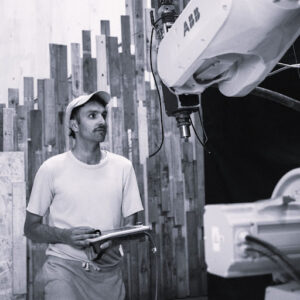

Credits: Demonstrator from the 2022-23 IAAC Summer Workshop, IaaC + The Circular Factory.

Description

In an era marked by demographic growth, resource scarcity, and the challenges of global warming, the construction sector faces an urgent need to transition towards faster, cleaner, more efficient, and customizable building systems. Concurrently, the advent of Industry 4.0 brings with it transformative technologies—robotics, sensing, computational design, artificial intelligence, and cyber-physical systems—that promise to revolutionise the way we design, build, and inhabit the structures of tomorrow.

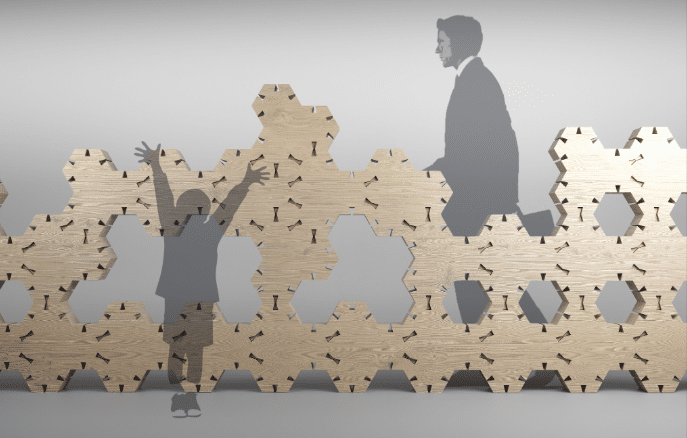

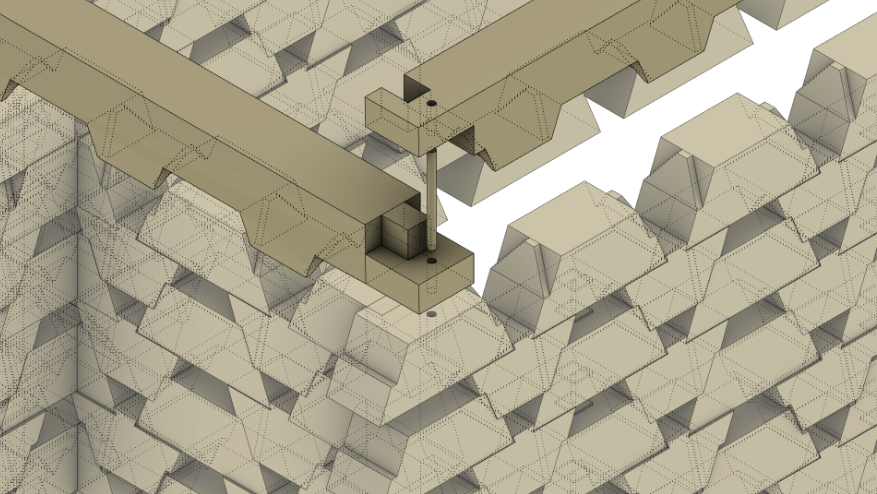

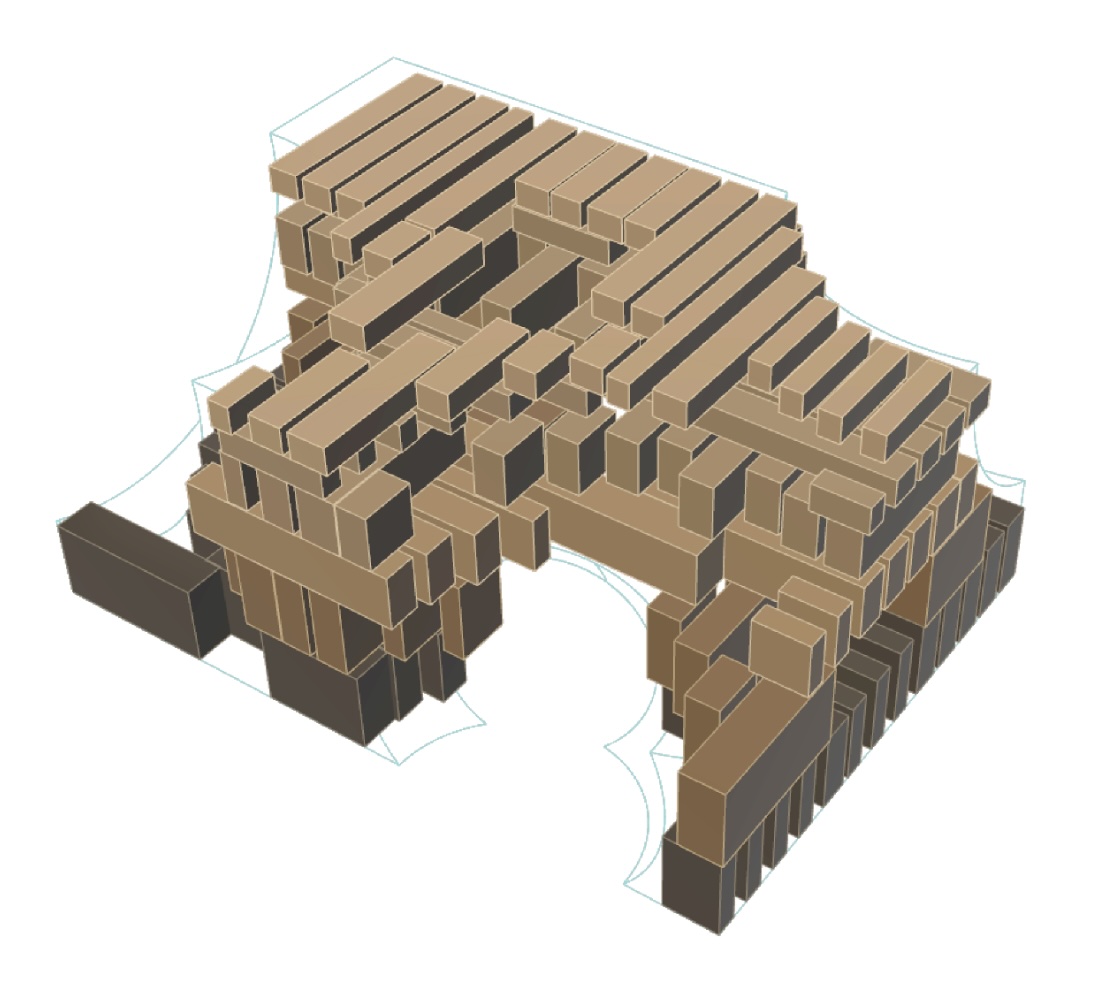

This seminar focuses on the wood industry, particularly on the potential to repurpose the vast quantities of leftover materials from manufacturing processes, which are often deemed waste. Traditionally, these materials are either burned for energy recovery or simply discarded in landfills. However, through the integration of 3D scanning methods and computer vision, this “waste” can be catalogued and incorporated into flexible digital production systems, such as robotic fabrication. By leveraging these technologies, we can develop automated design and manufacturing processes that adapt to varying material inputs, enabling the creation of unique products that are tailored to their specific functions—pioneering a new era of robotic craftsmanship.

Given the increasing demand for wood and the fragile nature of forest ecosystems, this course will also address how architecture can contribute to extending the lifespan of wood. By utilising discarded wood in new structural applications, we can design longer-lasting materials that reduce the need for virgin resources while also taking advantage of wood’s inherent properties.

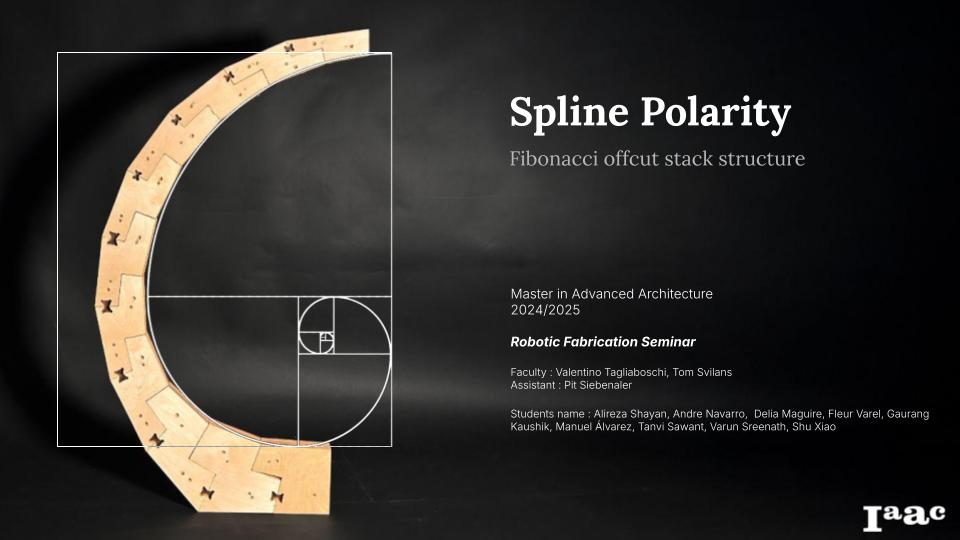

Phase 1: Design Exploration (First Term)

Students will work in small groups to explore various design-to-fabrication concepts for reclaimed timber elements. This phase includes skill-building tutorials covering topics such as computational design and digital fabrication workflows. Each group will develop a project proposal, complete with renders, technical specifications, budgets, and timelines. The phase culminates in a competitive review of the proposed projects.

Phase 2: Prototype Development (Second Term)

In the second term, students will collaborate as a collective to engineer and produce a large-scale prototype based on the most promising project proposal from Phase 1. This phase will emphasise teamwork, project management, and the integration of the learned technologies into a cohesive, functional product.

Learning Objectives

At course completion the student will learn to:

- Manage an architectural project from design to construction, incorporating digital data flows and automated processes.

- Apply Computational design principles to create mass-customised products based on material inputs.

- Integrate computer vision algorithms into specific fabrication applications.

- Implement robotic fabrication in architectural projects.

- Develop design and technology for a circular economy, focusing on extending material lifetimes and reducing waste.