Throughout the seminar, students will simultaneously develop their skills in both robotic systems and physical computing, equipping them with the essential tools to create systems that sense, respond to, and influence their environment. By working with robots and microcontrollers, students will learn to build interactive devices using sensors and actuators.

By integrating robot and physical computing into architectural design, students will open new possibilities for creating responsive, intelligent systems that enhance the built environment. These technologies enable architecture to become more than just static structures; they transform it into a dynamic, living entity that can adapt, interact, and evolve with its surroundings.

Learning Objectives

At course completion the students:

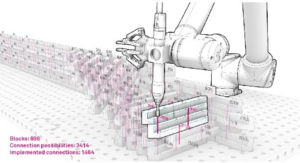

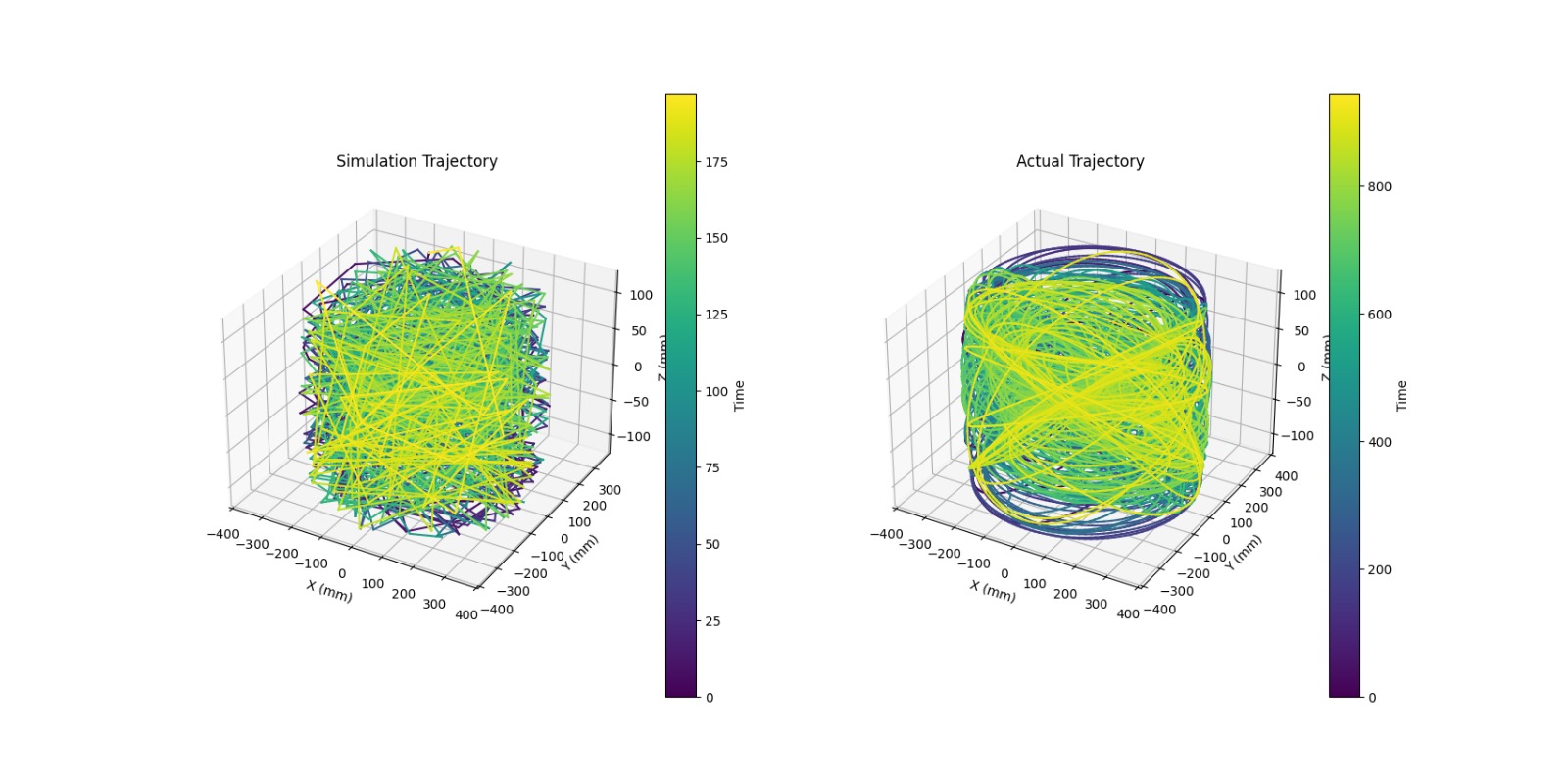

- Understand the basics of robotic kinematics, robotic simulation and robotic control.

- Communication between robotic arms and custom end effector.

- How to calibrate/adjust end-effector tools and possible modifications of them

- Be Can generate the robotic simulation and production files to produce a prototype.

- Data collection from robotic toolpath.

- Familiarise students with Arduino for prototyping.

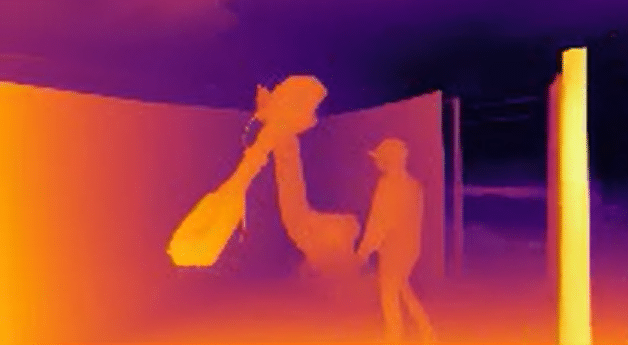

- Develop the skills to design systems that sense their environment.

- Build smart apparatus capable of reacting intelligently to external conditions, integrating technology into architectural projects to create responsive, interactive spaces.

- Understand how the collected data can be utilized in AI-driven architectural solutions.