From parts to purpose – embracing circularity by redefining furniture composition

Problem

In contemporary furniture markets there is a problem of the environmental impact caused by inefficient design, excessive waste generation, and unsustainable consumption.

Results are overproduction, resource depletion, and high carbon emissions during production processes. Additionally, limited design solutions don’t fully meet user needs, resulting in overbuying and potential waste.

The average 20-40 year-old moves 12x before purchasing a home.

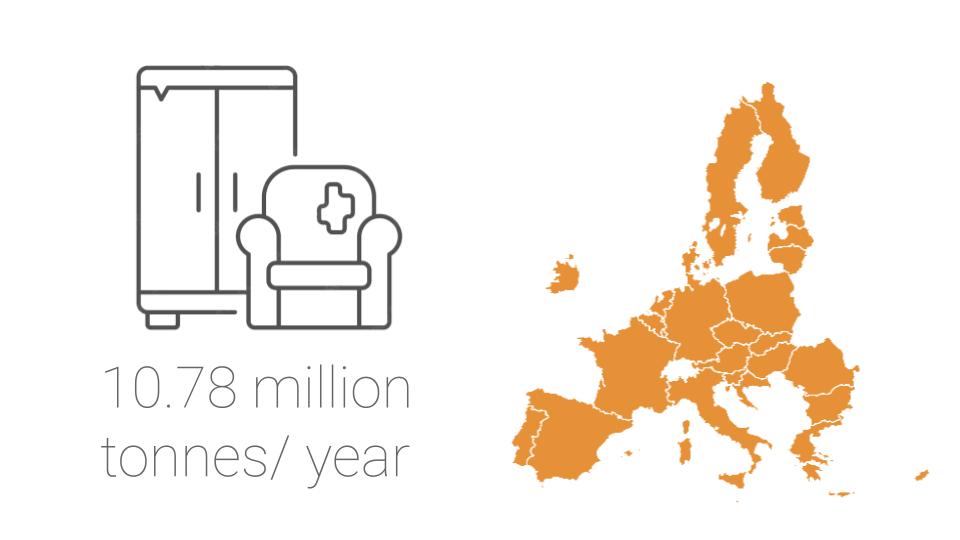

In the European Union only, it contributes to creating 10.78 million tonns of furniture waste annually.

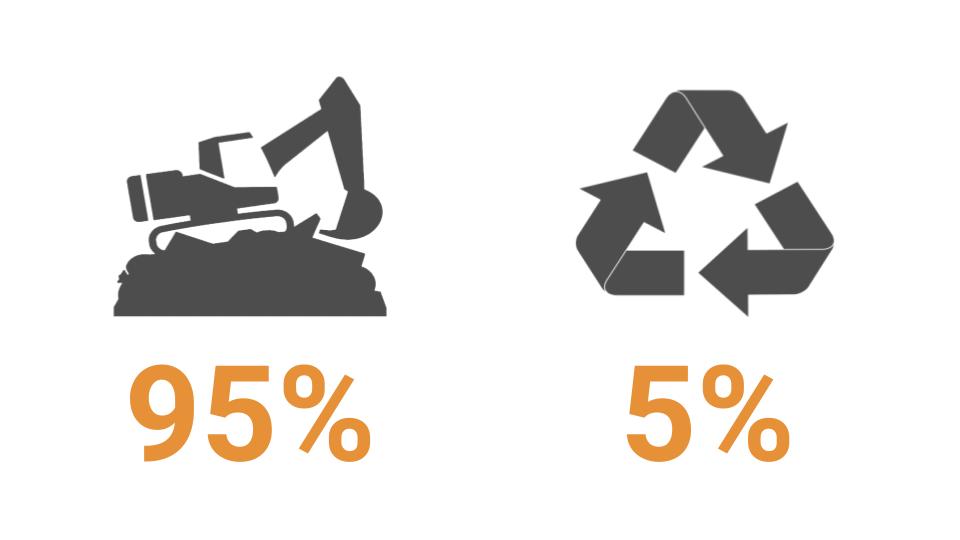

With around 95% of it incinerated or sent to landfill and only 5% recycled.

This low recycling rate highlights significant challenges in handling furniture waste, such as the complexity of materials used in furniture and complexity of separating them after the assembly.

But what is actually happening on the market?

To have a deeper understanding of everything, I will try to get into the problem of the biggest furniture producer in EU – IKEA.

One of IKEA’s most distinctive features is its flat-pack furniture. This allows furniture to be shipped and stored more efficiently, reducing costs and environmental impact. – Thumbs up for IKEA.

But at the same time while the company is committed to sustainability, and considered one of the most sustainable furniture businesses in EU, setting ambitious goals, such as using only renewable or recycled materials by 2030 and becoming climate positive, more than 70% of its products end up in landfills in less than 10 years of its usage.

Is this the right definition of sustainable?

There are two major problems causing this:

- Design principles – furniture composition

- Materiality

Furniture composition

Even though the furniture is designed to be disassembled and reassembled multiple times, the complexity of joinery and connections often makes that job impossible for a common user – they manage to disassemble it, but reassembling afterwards is a bit of a different story.

Materiality

IKEA is using recycled materials in its production, most of it are particle boards made from wood chips, sawdust, and resin.

Even though particle boards are technically recyclable, the process and sustainability can be challenging and energy demanding – mostly because of the adhesives used in the production.

The sustainable goal of furniture production is for it to be reused, refurbished and eventually recycled – in which IKEA is failing.

On the other hand, even though the idea of disassembling and reassembling furniture is there, its materiality makes it difficult as after even one disassembly, the joinery becomes lousy and material chipped.

SO FURNITURE INDUSTRY NEEDS A CHANGE

But is there anything that can make all the companies try harder and actually bring the change?

Apparently, there is.

You have all probably heard about EU Green Deal. The EU Green Deal aims to transform the EU into a resource-efficient and competitive economy with no net emissions of greenhouse gasses by 2050.

Key goals related to furniture production include:

1. Circular economy: products are designed to be reused, repaired, and recycled in order to minimize waste.

2. Sustainable products initiative: making products more durable, reusable, repairable, recyclable, and energy-efficient.

3. Reducing carbon footprint by promoting the use of sustainable materials and production processes.

Of course, the question is HOW?

How can furniture design principles answer to all the demands such as:

- supply chain disruptions

- raw material shortages

- increased energy costs

- environmental regulations and bureaucracy

- consumer trends and preferences

While contributing to circularity by promoting product longevity and resource efficiency, addressing broader environmental challenges within the furniture industry?

How to minimize a demand for different furniture pieces?

Maybe the furniture pieces themselves are the problem.

The more there are – the more we’ll need.

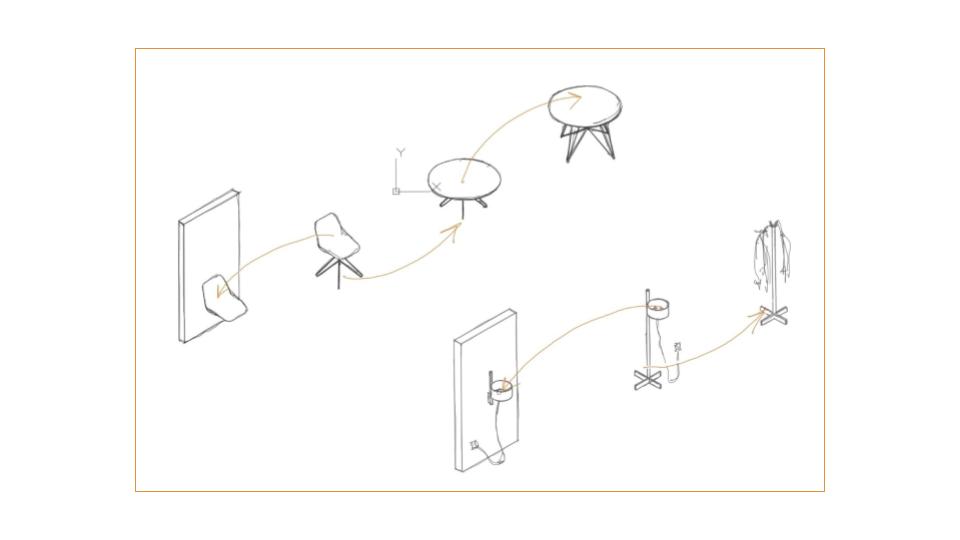

What if we look deeper and try to disassemble furniture pieces into the smaller pieces they are made of?

What if we consider furniture as sets of elements and shapes arranged and connected in different ways?

By deconstructing furniture into simple elements that can be differently rearranged, users can adapt and evolve their furniture over time to meet changing needs.

What do we get with that?

Less:

- resource depletion

- waste production

- energy consumption

- overproduction

- CO2 emissions (production and transport)

More:

- design possibilities

- circularity

- adaptability

- recycling and reusing

- refurbishment and repair

Materiality

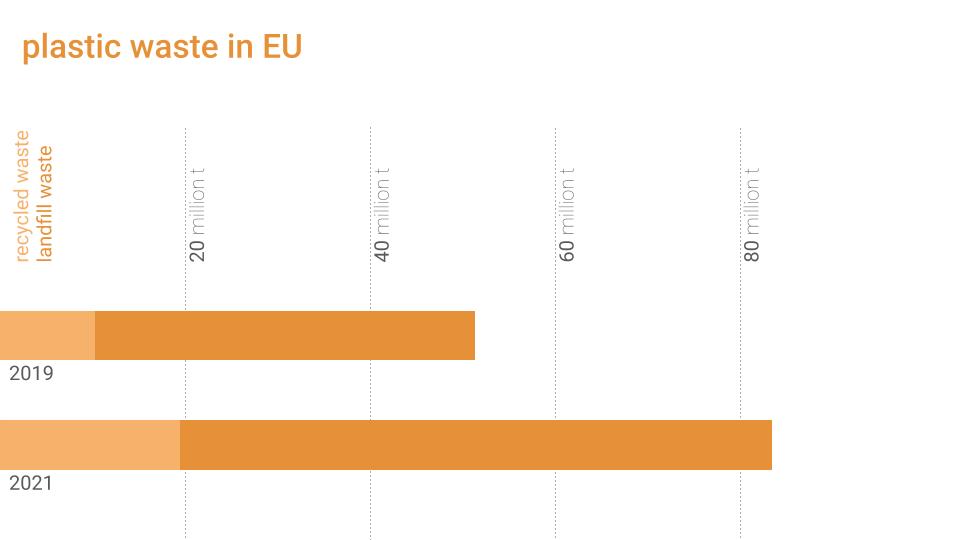

We are aware of the global plastic pollution crisis that is happening nowadays. In 2021, the EU-27 produced approximately 83 million tonnes of plastic waste. and only 1/4th was recycled. Comparing it to 2019 – where 53 million tonnes of plastic waste was generated – it is significantly more. But we can also notice that the recycling rate was 7.5% higer. The EU aims to recycle 55% of plastic waste by 2030 as a part of its circular economy strategy.

Let’s try to help each other.

By enhancing recycling plastics, the EU can mitigate these problems, conserve resources, and contribute to a more sustainable future.

There are many types of plastics – some have better recycling properties, some worse. So let’s see what is the best solution for us?

If we compare the properties, melting temperature, toxicity etc. – it is HDPE (High-Density Polyethylene): which is used for milk jugs and detergent bottles, shampoos, piping etc.

Recycling HDPE

– reduces the need for new plastic production, conserving fossil fuels and reducing carbon emissions

– reduces landfill waste and marine pollution, contributing to environmental sustainability

– it can save up to 88% of the energy needed to produce virgin HDPE, between 8-12 MJ/kg

Process:

- Collection: from recycling programs, industrial waste

- Sorting: by type and color to ensure uniformity

- Cleaning: to remove contaminants

- Shredding: into small flakes or pellets

- Melting: the plastic flakes or pellets on 130°C to 135°C

- Molding or extrusion: the mass is extruded or pressed into new shapes or boards

- Final processing

Proposal

How can we shape recycled HDPE into something useful?

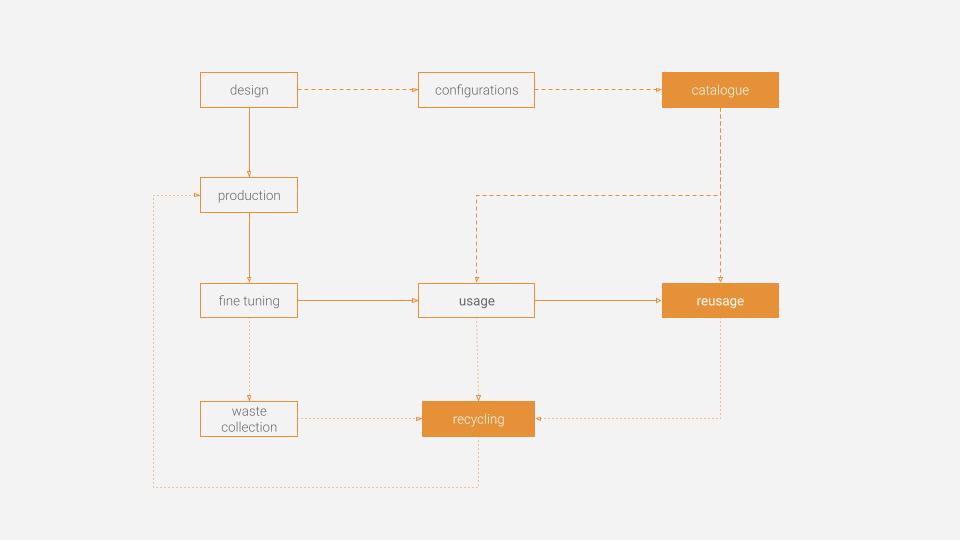

First, of course we need to design different elements that can be configured into furniture pieces and catalogue all the possible options.

Afterwards, of course to produce them, process them collect the waste and in the end put them into use.

After some time, they can be reused or recycled, but the final step is always remaking new elements from the waste.

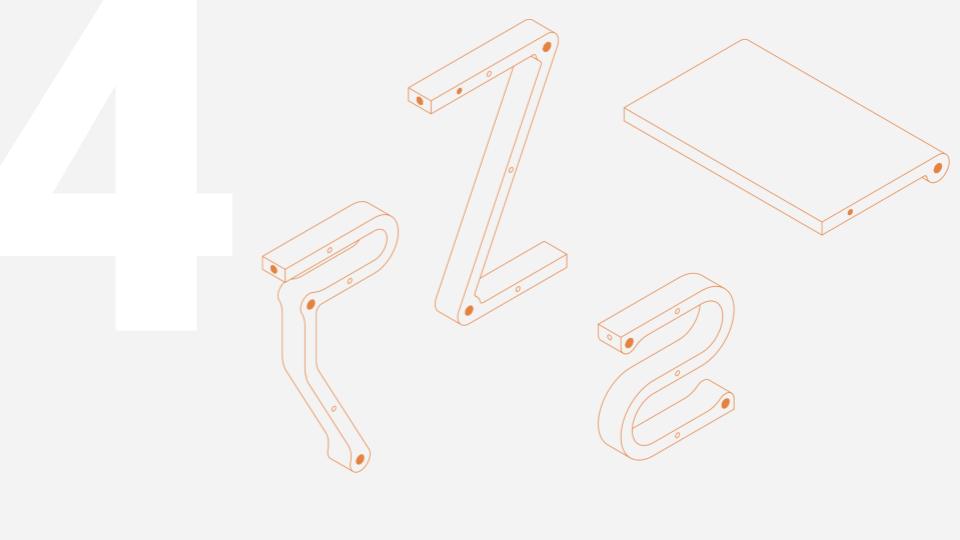

My proposal is a set that consists of 4 elements.

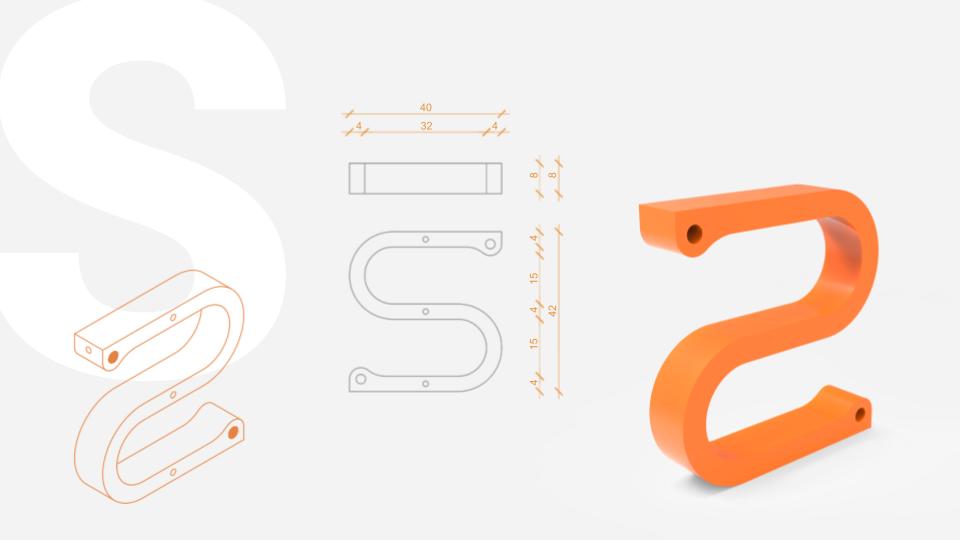

S shaped

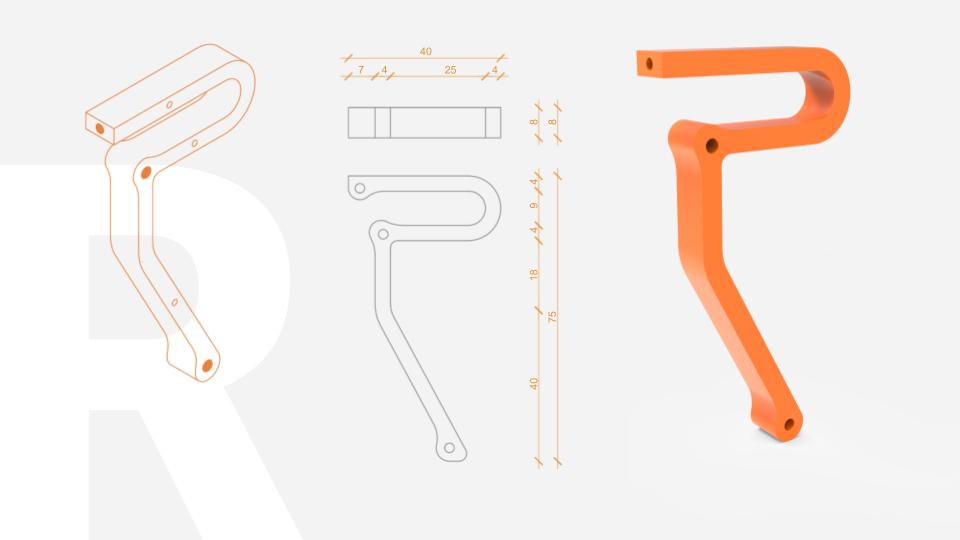

R shaped

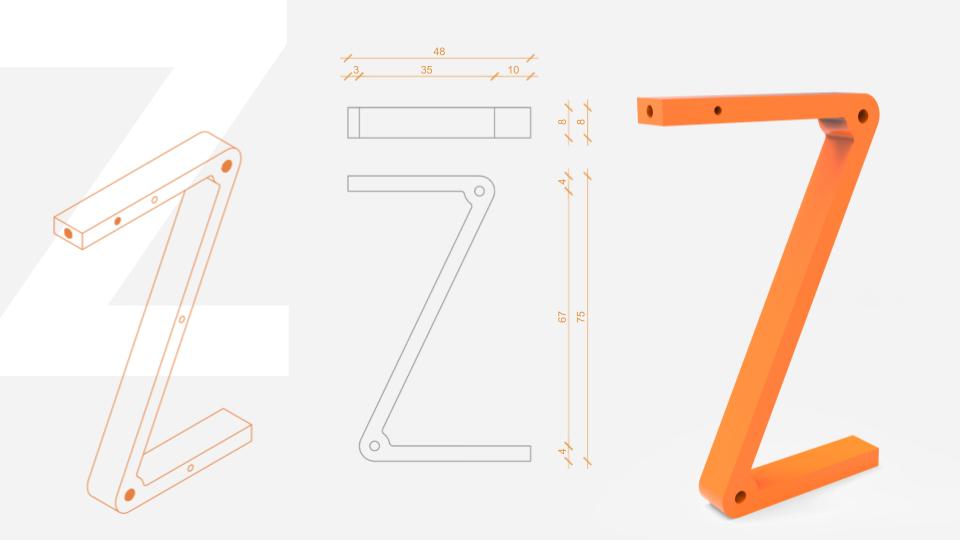

Z shaped

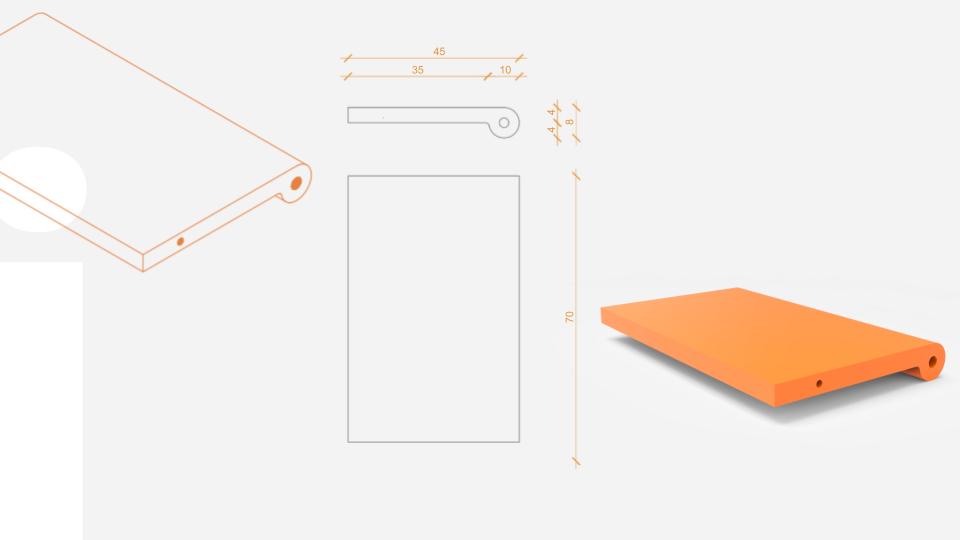

I shaped

But first – let’s start with how they can be connected?

The most important thing in the design process was to avoid complicated joinery, bolts, and 20-page instructions.

I aimed to make assembly easy and intuitive.

Having simple drawings, no tools needed, logic connections and quick disassembly.

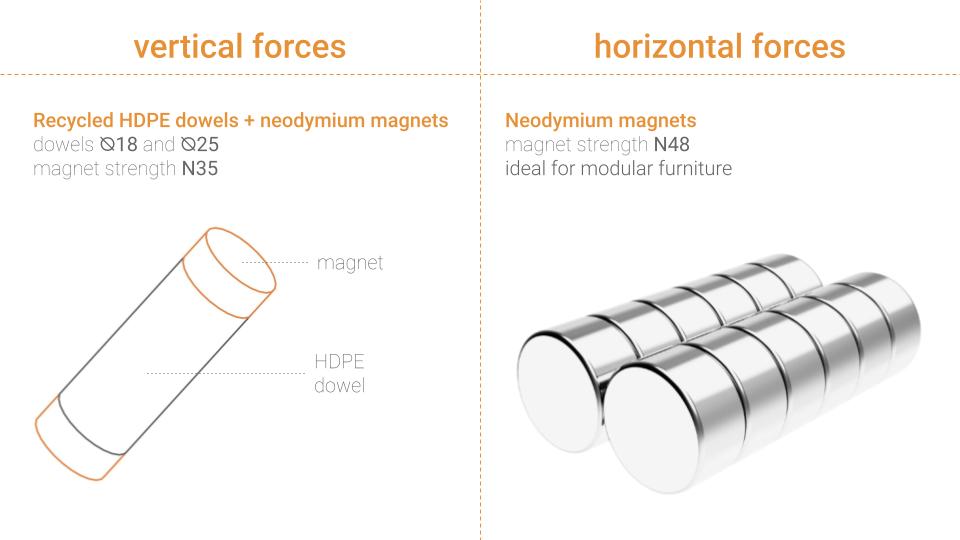

I decided to go with two basic type of connecting them

first one for VERTICAL forces and the second one for HORIZONTAL forces.

For the vertical ones I use recycled HDPE dowels with neodymium magnets on the ends in order to avoid any snap fit joints.

And for horizontal ones, just simple neodymium magnets with a grade 48.

Catalogue

How will everything look like?

Here we have a simple catalogue of some furniture pieces that can be assembled using these 4 elements.

Configurations

So we remember the guy from the beginning that moves a lot.

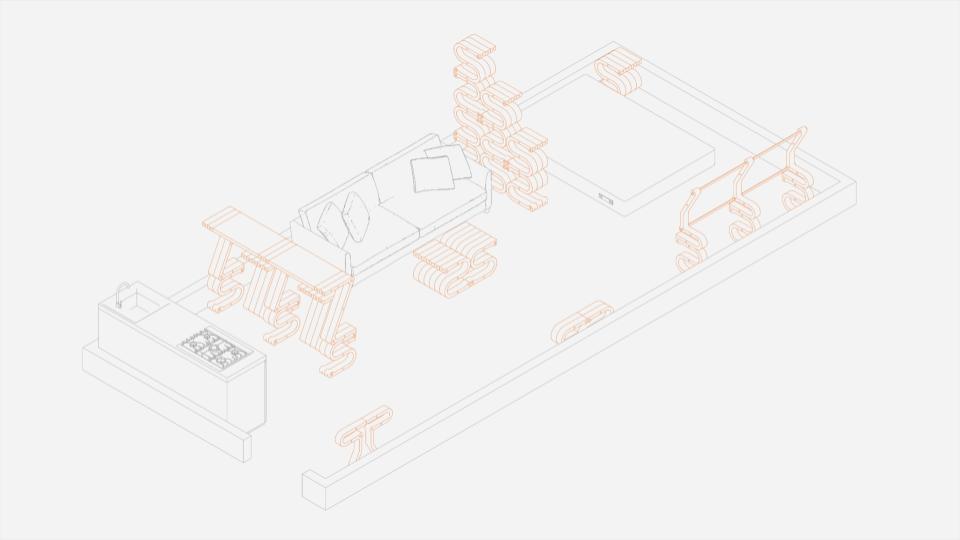

Let’s see the dull example of how he can use the same shapes in different apartments.

Let’s say he started studies in Barcelona and found a super small 16 sqm studio in the city center.

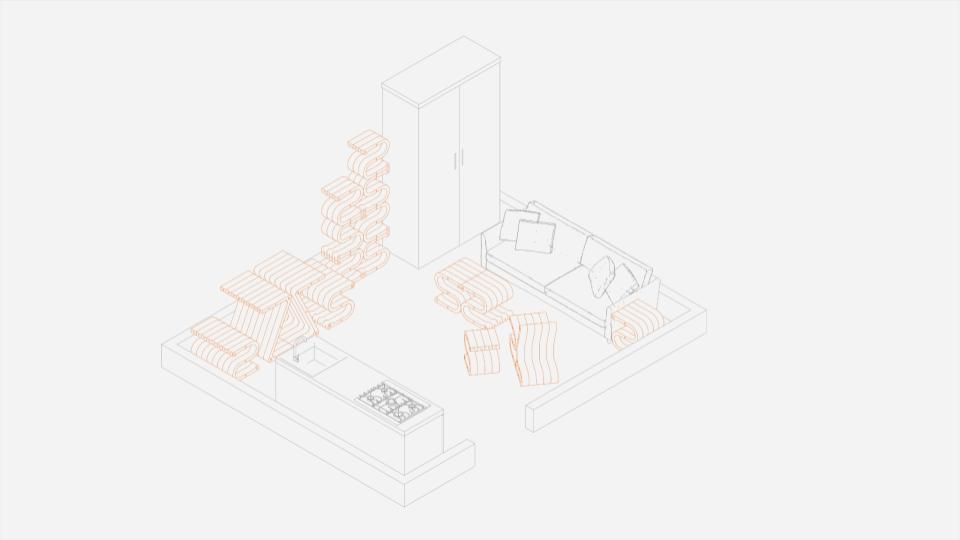

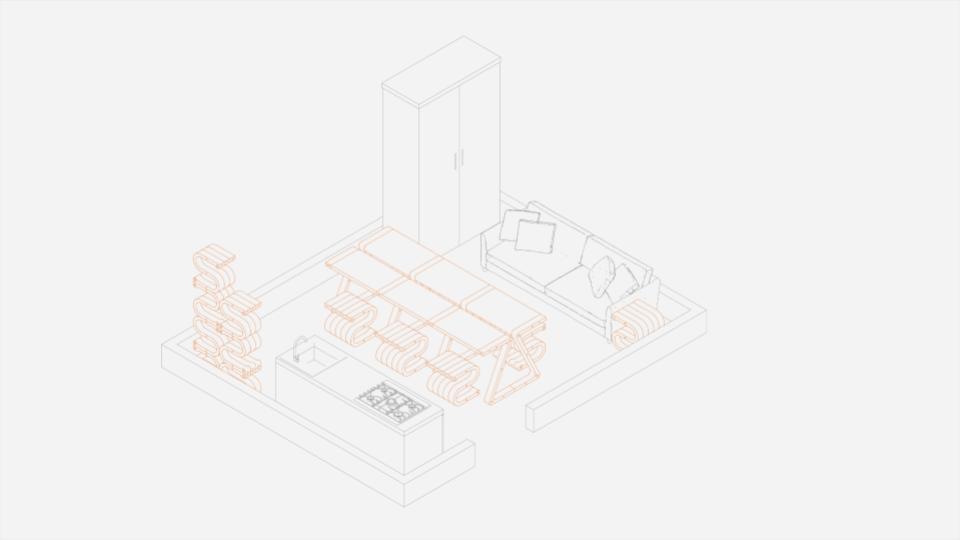

He ordered 61S shaped, 16Z shaped, and 5R shaped elements, and bought a couch and a wardrobe.

From all the elements he managed to achieve this situation.

From this set he assembled a table with two benches, a shelf, coffee table, two night stands and one big chair.

He finished his studies and wanted to call his friends to a dinner – but how can he host 6 of them in this small apartment? Where can they be seated?

He went to the website and got himself 6i shaped elements and with other ones he assembled a full dining table set for 6 people.

It took him less than 20 minutes to reassemble the whole apartment.

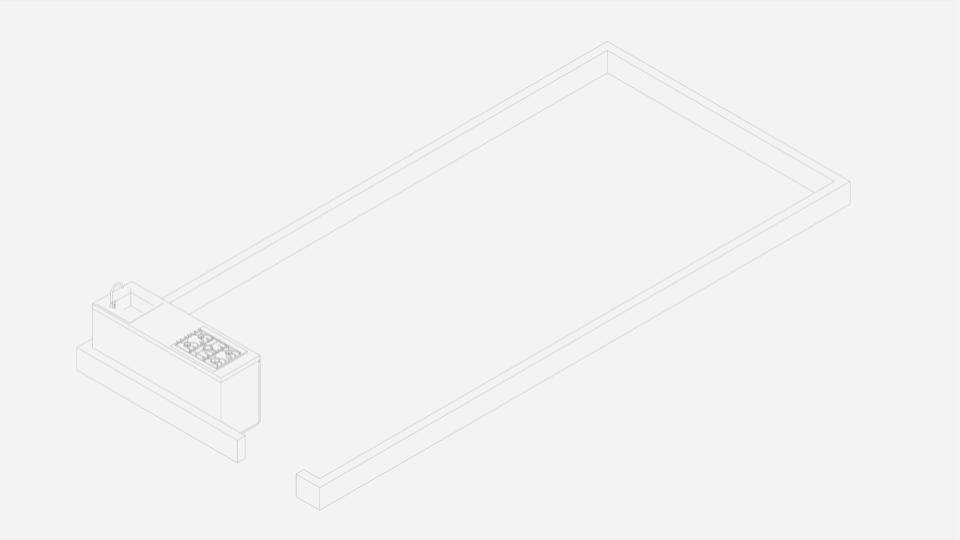

After a few months, his contract finished and he was looking for a new apartment.

He found a slightly bigger one. But oh that process of moving!

Anyways, with this system he managed to disassemble everything in a record time.

He put the couch and the wardrobe on Wallapop, because the moving van was asking him for 200e to move them uptown.

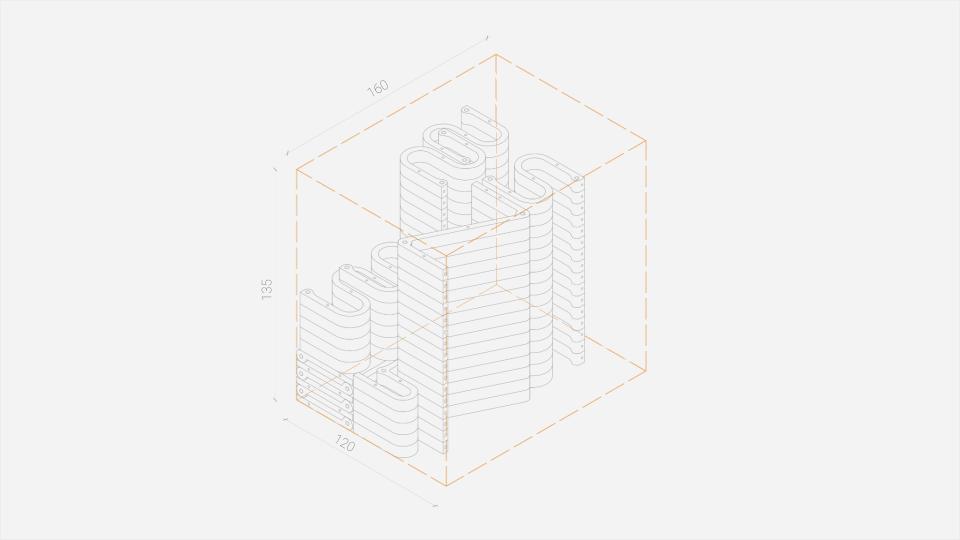

All the rest – he managed to fit in a medium taxi – the caddy with the trunk dimensions 120x160x135 with additional space left for his personal stuff.

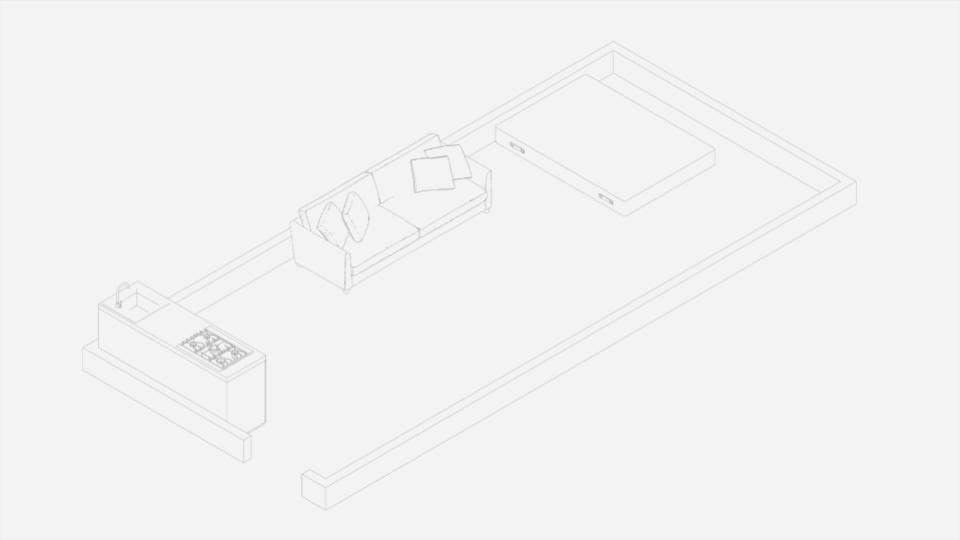

New apartment was longer, he could have a bed as well – so he got him a mattress and new couch. With the elements – he created all the furniture needed.

He can also easily redecorate if his feng shui changes.

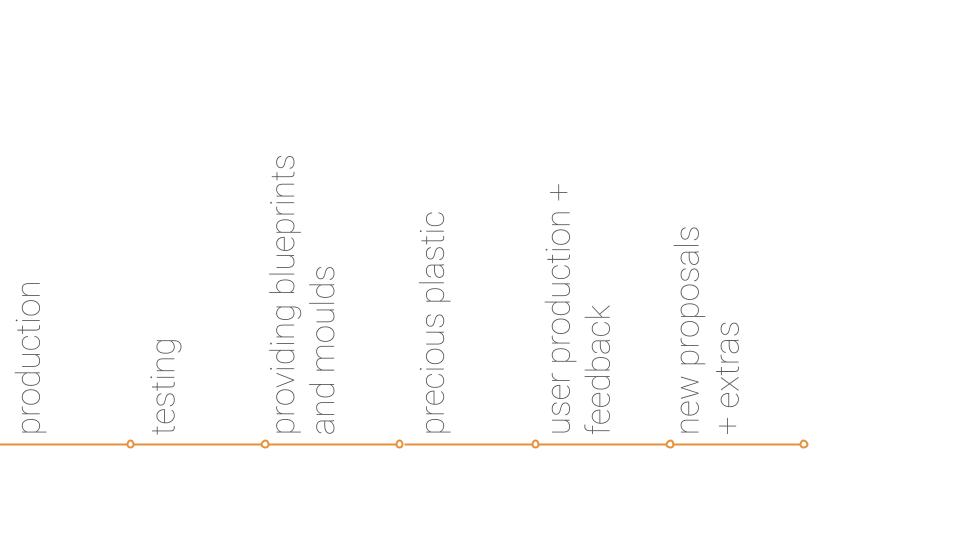

Future steps

What are the future steps?

Well, first of all production and testing.

Afterwards providing blueprints of molds and putting the catalog on precious plastics.

Precious Plastic

Precious Plastic is a global community-driven project that promotes local recycling of plastic.

There people can use provided blueprints to produce the elements and also give feedback/ alter the design/ and propose new ones. At the same time they can extend the creativity and suggest and produce extras like lampshades, different hangers, applications etc.