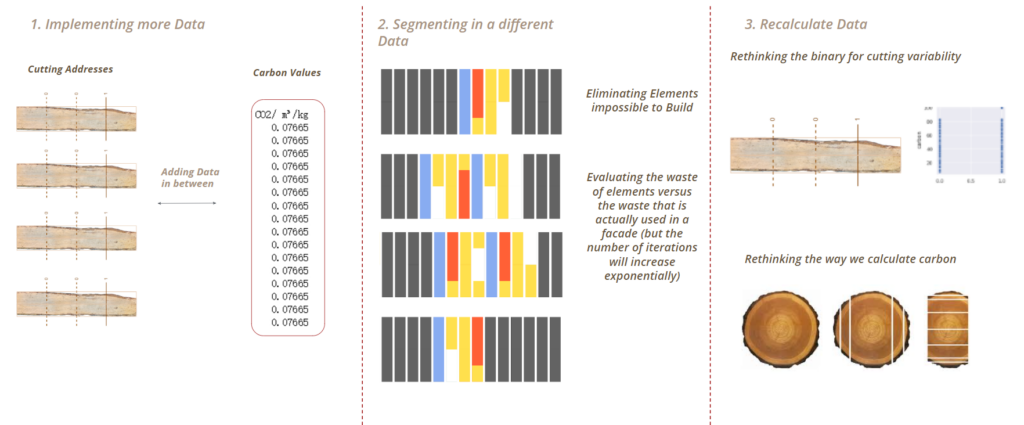

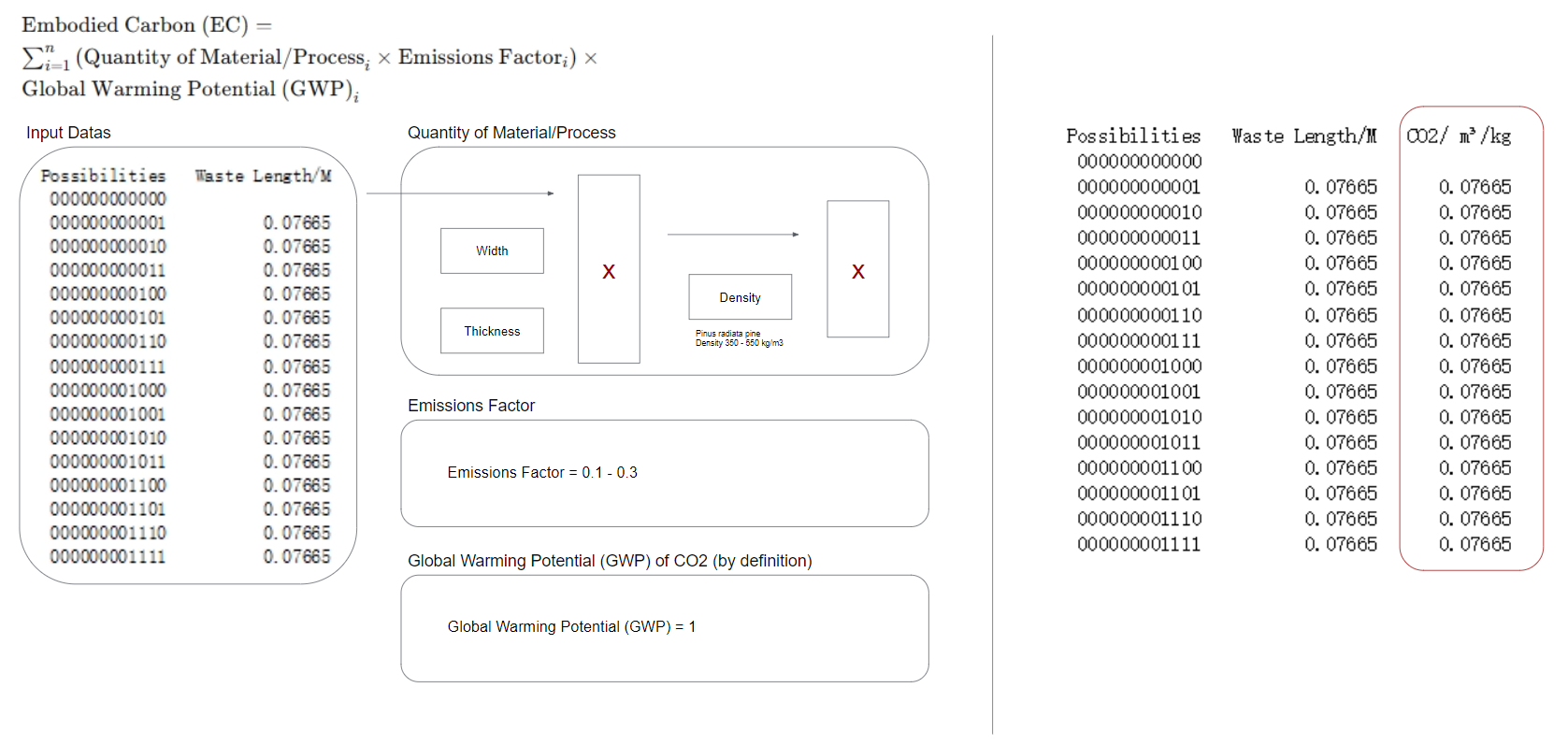

To create a embodied carbon calculator that utilizes design and raw sawn timber cuts as inputs to inform design and manufacture processes

Raw-Sawn-Timber and Wood Industry

Petras VESTARTAS

Design-to-Fabrication Workflow for Raw-Sawn-Timber using Joinery Solver

Wood waste is often disregarded in the wood industry and the construction industry. Majority of wood used in construction is sawn and processed wood that not only generates waste on its production but it is also associated with high CO2 emissions, because of the embodied energy being released during processes like: harvesting, transportation, edging and trimming.

Use of saw wood is being demanded nowadays due to the overstocking of forests, affordability and minimal processing regarding edging and trimming.

WORKFLOW

Pseudo Code – Embodied Calculator-Creating Data Set and Testing Models

Generating Data Sets

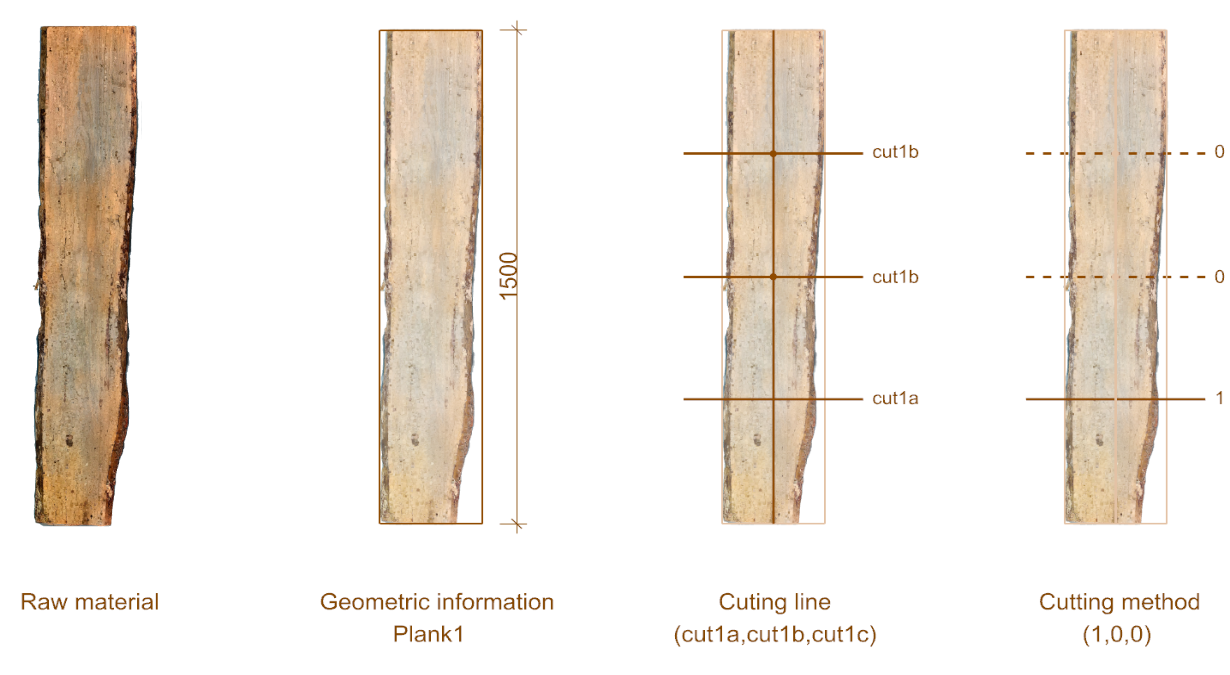

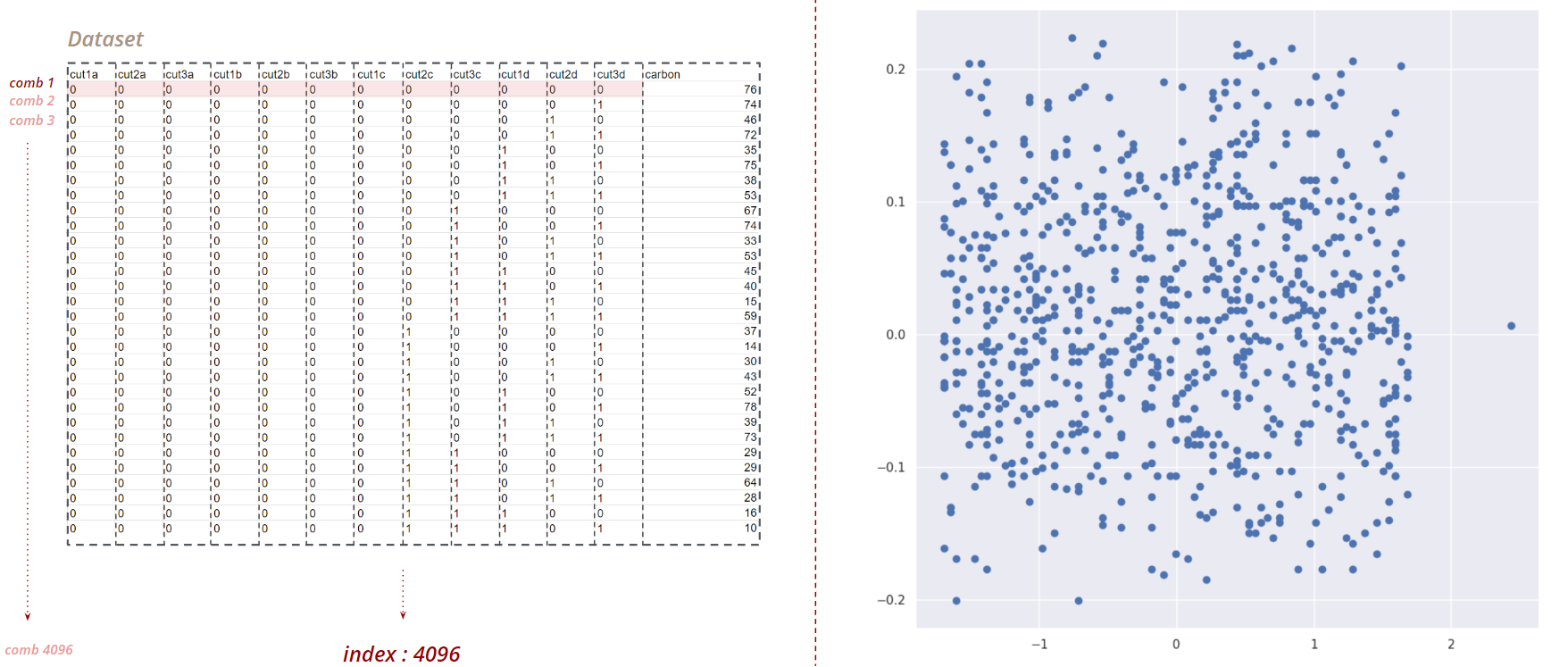

01 Cutting data sets

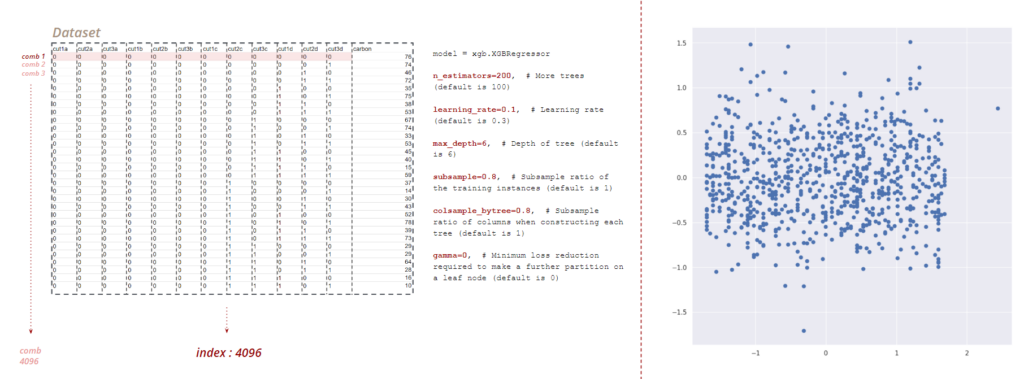

We abstract some physical information from raw materials. We attempt to cut the plank with three uniformly distributed cutting lines. These cutting lines are randomly present and represented by 0s and 1s. A value of 1 is recorded when a cut is needed, and 0 is recorded when no cut is required.

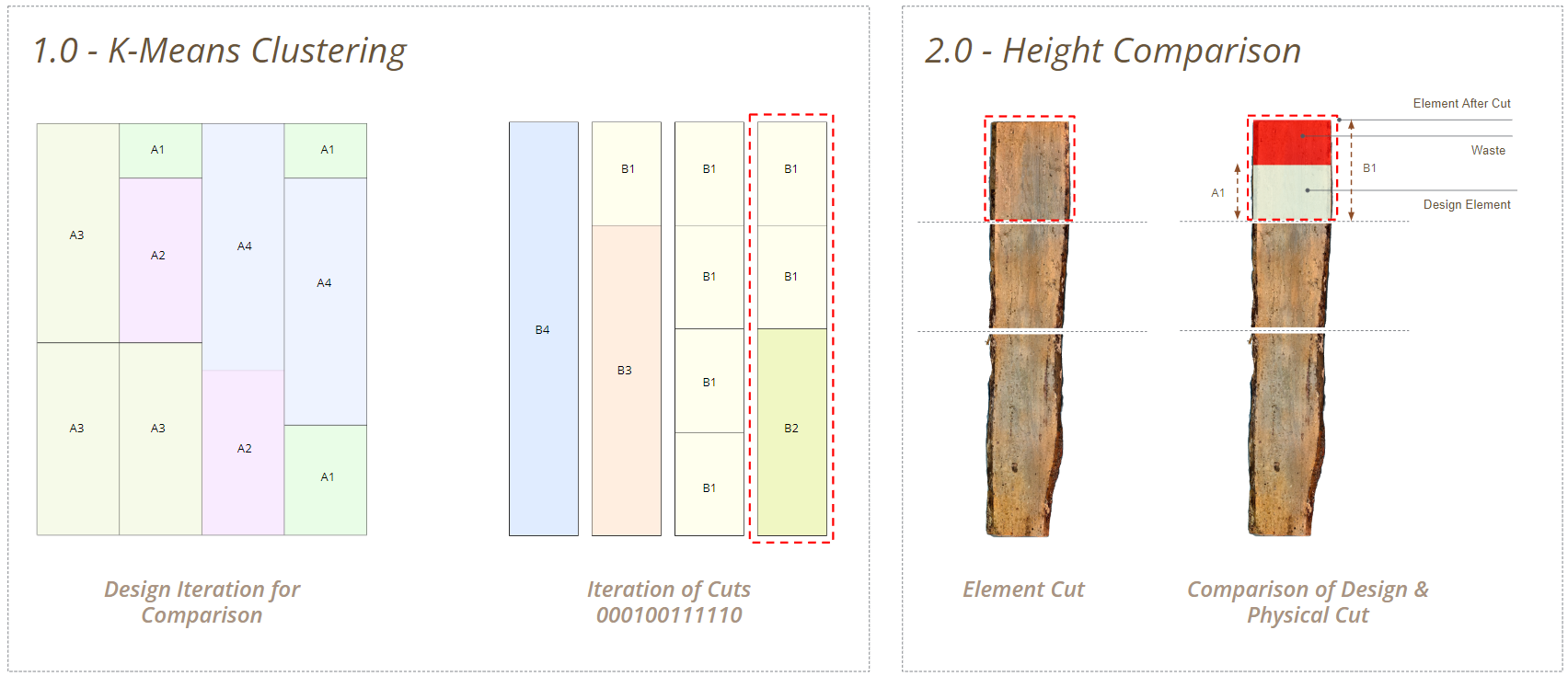

A single wooden board can generate 8 different cutting patterns. We represent this method in a dataset format. We apply this method to four wooden boards as training objects and deduce the possibilities of their combinations after different cuts. This is one of them. In the end, we will obtain 4096 different methods as the dataset

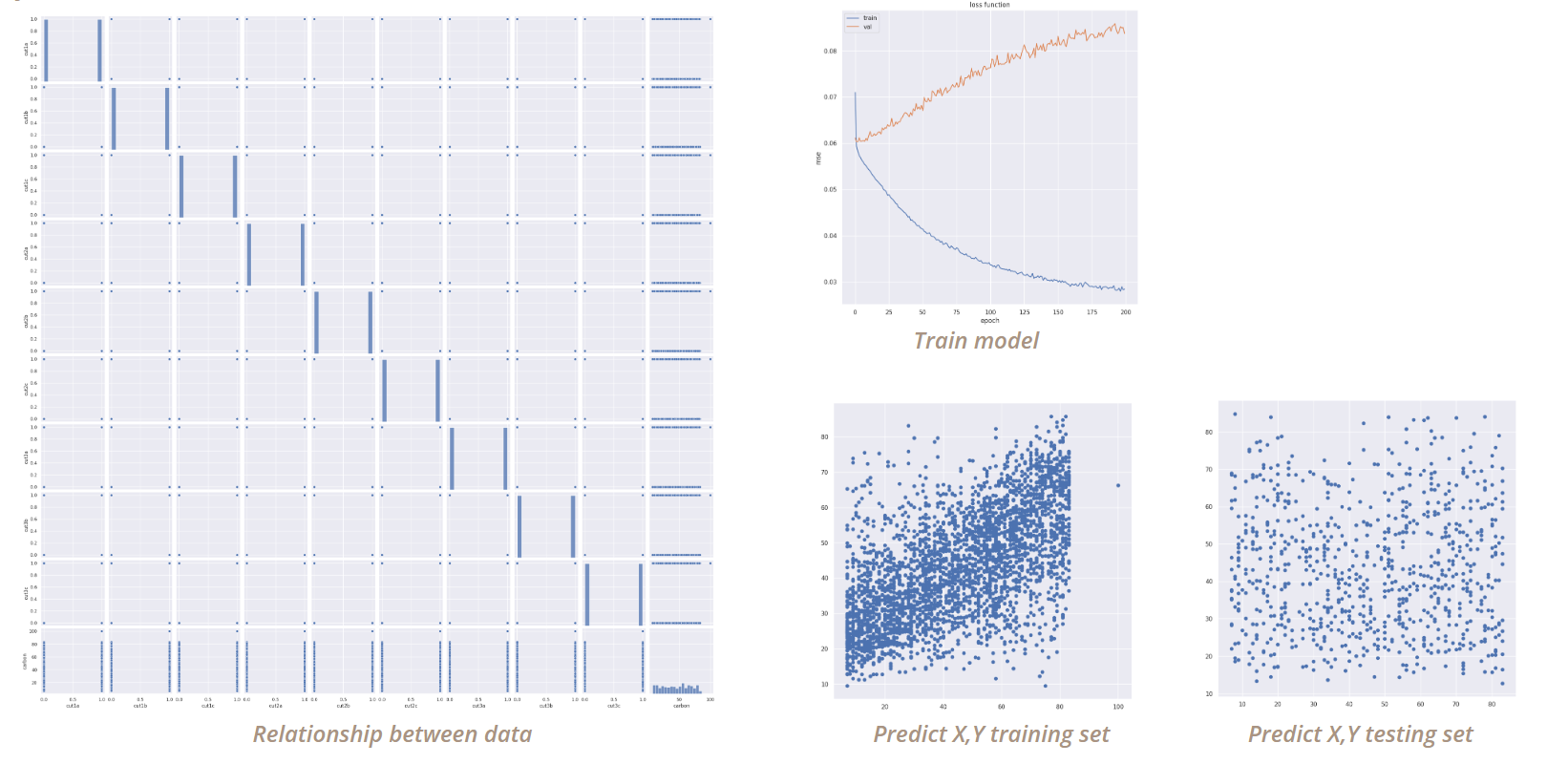

Comparisons

02 Cutting and design comparison

Comparison data sets

03 Cutting and design comparison

MACHINE LEARNING

Training Models

01 Linear Regression

02 Linear Regression (XGBoost)

03 Artificial Neural Network

Conclusions