Introduction

As part of the IAAC MAEBB academic course, we have participated in the Furnish Kids 2.0 program. The program aims to improve public space through design interventions of tactical architecture. This year’s edition, hosted in the creative hubs of Barcelona and Milan, and co-funded by the European Union, concentrated on the ever-changing area of Plaça de les Glòries Catalanes. Through a series of workshops with kids from schools surrounding the Gran Via area, it has become clear to us that the site would benefit from a space where a whole class could enjoy outdoor, educational activities.

Project Objectives

Through the dialog with the kids, teachers, and MAEBB project tutors we have created a set of project objectives, listed below:

- We will try to maximize the use of materials already available to us. Materials with the most potential are leftover pine logs, and offcuts generated during plank production piled in the scrapyard,

- We need to be able to fabricate the design using only the tools available in the Valldaura Fab Lab,

- The design needs to fit a class of 30 schoolchildren, therefore it needs to be safe and adjusted for their needs,

- The design needs to provide a sense of enclosure from the busy Gran Via Street

Development process

We have developed our design by experimenting both with the physical and digital models. The physical 1:1 models helped us to imagine the proper dimensions, as well as methods for larger-scale fabrication. Smaller 1:5 scale models were helpful in imagining the esthetic outcome of the project. During the design process, we created two human-scale bench elements and two scaled ones.

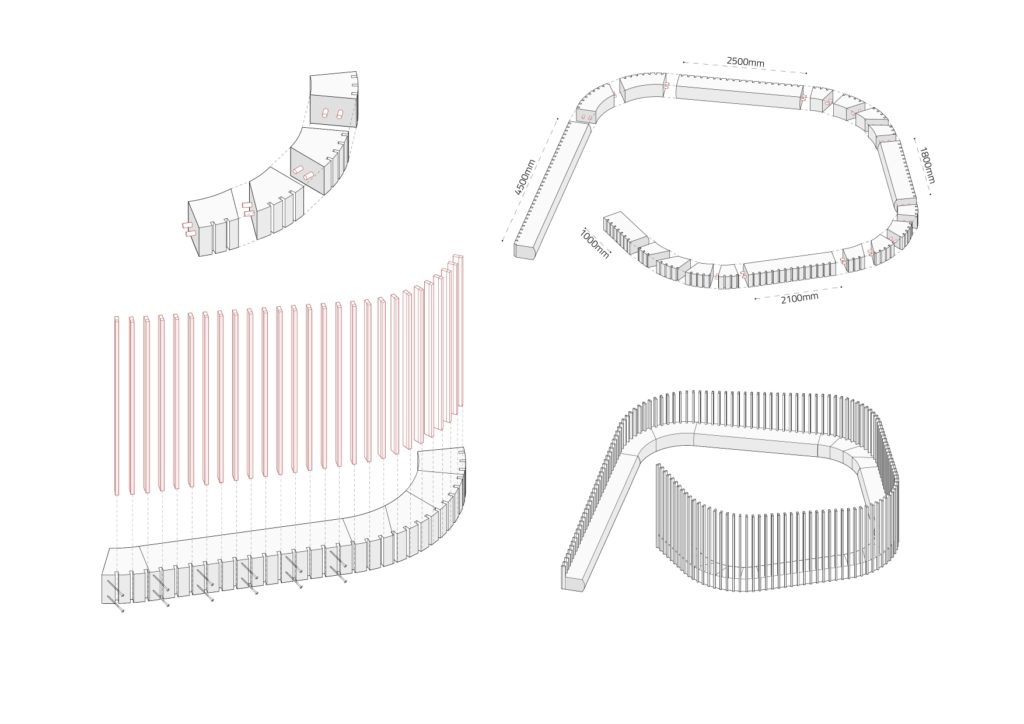

Digital tools were tremendously helpful in the project organization. We have used online catalogs to keep track of our building materials. The logs were measured, photographed, and scanned, while for the vertical elements, a special Rhino Grasshopper algorithm was created to test the optimal shape of the enclosure. When the design was finalized, we created specialized jigs that we later used to accelerate the fabrication. We have created three jigs: two were designed to cut precise, 3 cm holes in the surface of the logs, while the third was used to drill holes for screws in the vertical elements.

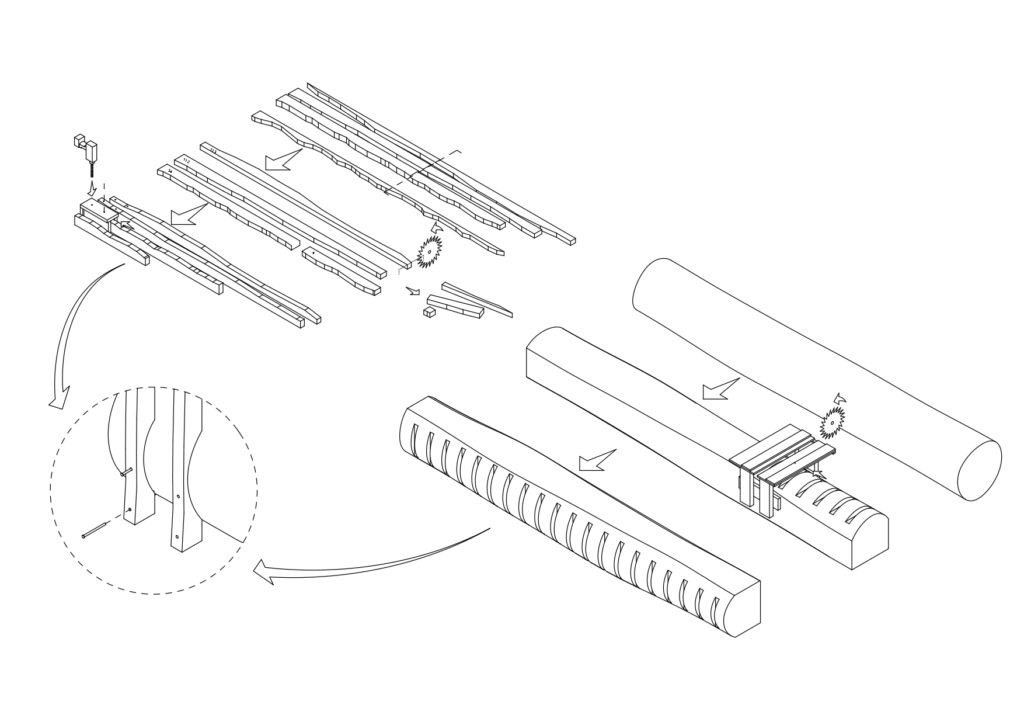

The logs were cut from three sides using the large outdoor sawmill, transported using the Bobcat, and smoothed and cleaned manually using mechanical tools such as sanding machines. Later, the jigs were used to cut the holes in which the vertical elements were later placed.

The vertical elements were first selected from the discard pile. Later, they were smoothed in the mechanical thickener and measured using a mechanical caliper. From the planks prepared this way, we have cut the final length of the elements using circular saws. We kept track of the elements with a list with numbers assigned to them.

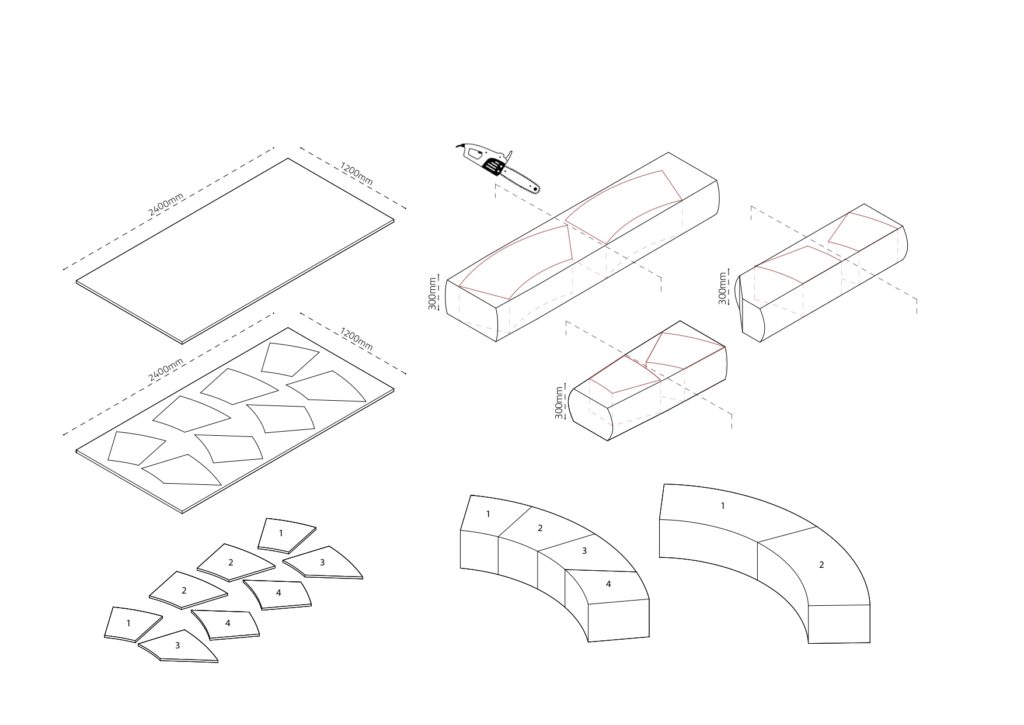

The curved log elements presented a particular challenge. We have tested various methods of creating them. Eventually, we decided to curve them from straight logs using CNC templates. The cutting process was only available to be performed using a chainsaw – with this task Bruno’s help was inestimable.

The elements were connected using large oak dowels. The system was chosen with little previous testing, therefore it presented a risk. During the assembling process, the dowel connection system turned out to be working fine, however, it needed some last-minute adjustments. Overall, during the production process, we have used a vast variety of mechanical tools:

Assembly process

All the elements of the finalized structure have been transported on-site and assembled with the use of a crane. Schoolchildren have been invited to participate in the assembling process. Children, inspired by the shape of the seatings nicknamed the project ‘El Cargol’ (The Snail). The structure is open to the public, and as a temporal intervention, is foreseen to be eventually dismantled and disposed of with no harm to the natural environment.

El Cargol was completed as a design + build studio within the 2022/23 MAEBB curriculum. The course was led by Michael Salka, Co-Director of the MAEBB ; and Vicente Guallart, Co-Director of the MAEBB, Bruno Ganem Coutinho, Manager of the Green Fab Lab at Valldaura Labs, Esin Aydemir, Academic co-ordinator of MAEBB, and Laia Pifarré, Operations Manager at Valldaura Labs, lent their support.