How can we ensure high quality products using non-standardized wood in architecture?

Abstract

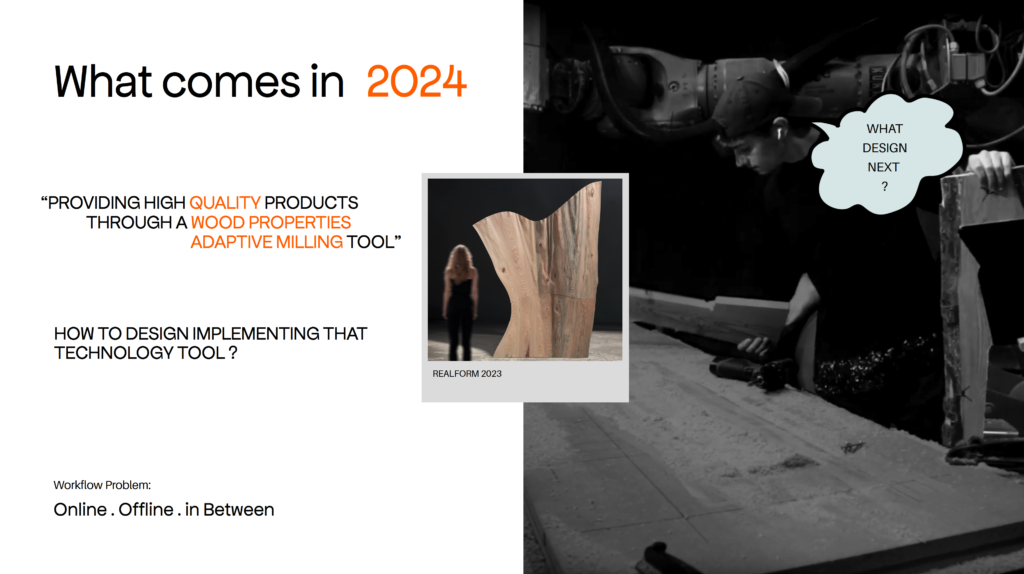

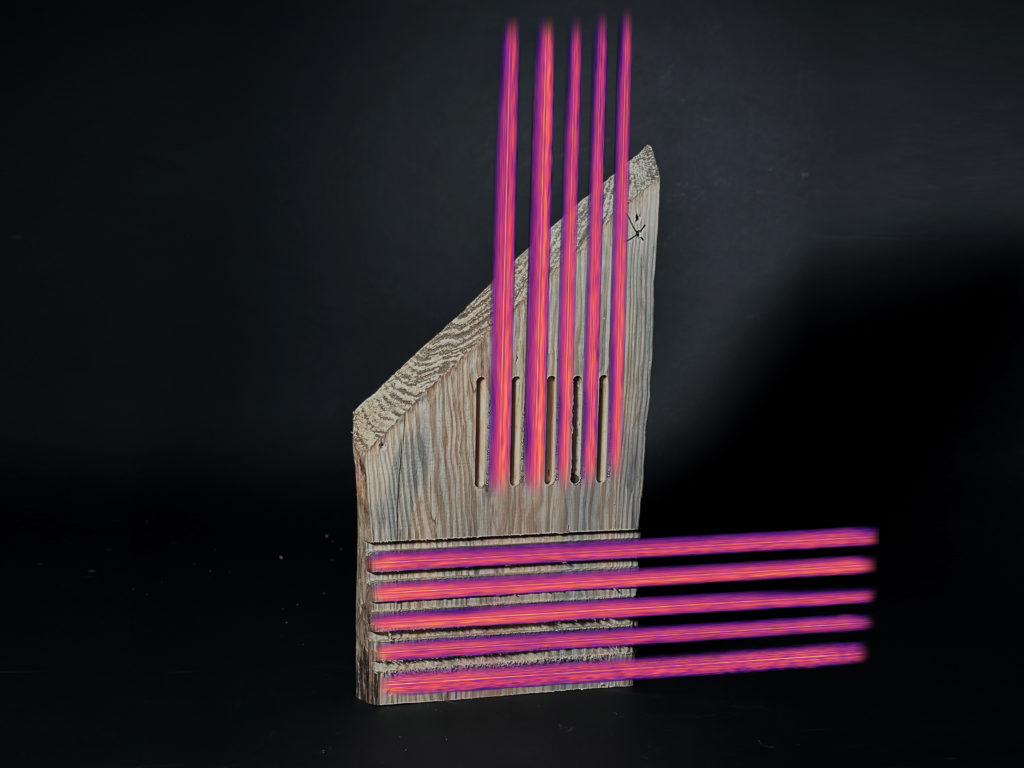

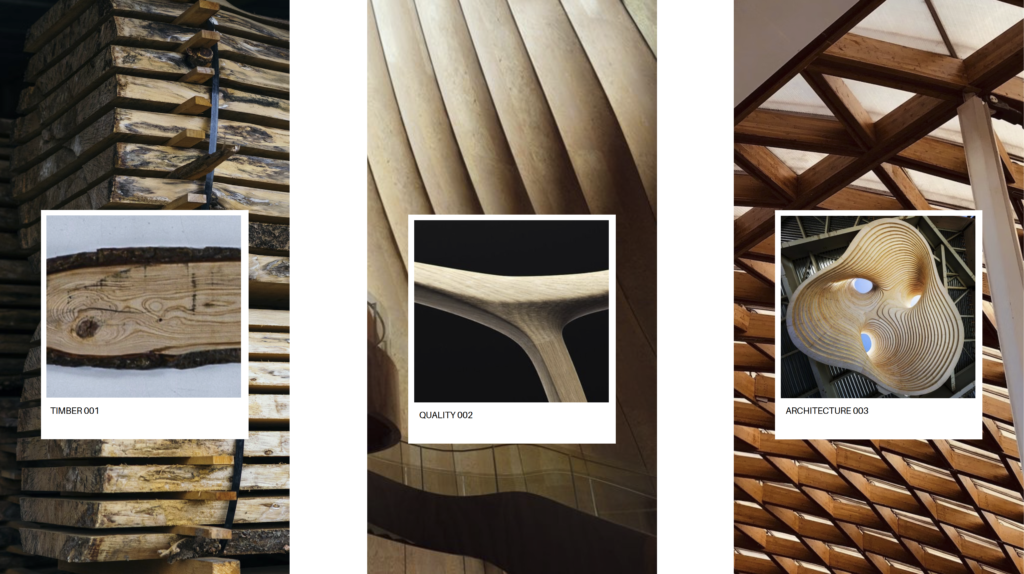

Inspired by the success of the “Realform” research project, which ingeniously reuses non-standardized wood scraps and uses the grain data to create a seamless, material-based design, this project aims to advance the topic of sustainability in architecture. Building on the foundation of ‘Realform’, the Research “Harmonic Grain Craft’s” aim is to create high-quality architectural products from leftover materials, adding significant value to these resources. The highly effective approach is realized through the implementation of an adaptive milling tool that analyses wood properties / grains and acoustic data during the milling process. This tool not only increases productivity, but also the quality of the end products. By incorporating the properties and grain of the wood into the design process, the project harmonizes craftsmanship and technology and sets a new standard for sustainable architecture. In this way, the project not only contributes to waste minimization, but also redefines how architecture can be seamlessly combined with the beauty of natural materials.

This research takes place in the masters program MRAC02 at “IAAC” and cooperates with “The Circular Factory” as an industrial partner.

The innovative “Realform” research project focuses on the reuse of non-standardized wood to create architectural surface elements with a dual commitment to sustainability and aesthetics. “Realform” is an example of the success of aesthetically pleasing results through thoughtful design and careful surfacing techniques. The project not only helped to reduce waste by utilizing leftover materials, but also laid the foundations for future progress. The use of material-informed design, in particular the integration of grain data, created the conditions for efficient, waste-minimizing and material-informed design. In addition to aesthetic success, “Realform” also faced challenges in terms of time efficiency and manufacturing precision that offered opportunities for improvement. In light of these hurdles, subsequent research aims to build on the valuable findings and improve both the efficiency and quality of architectural products made from non-standardized wood.

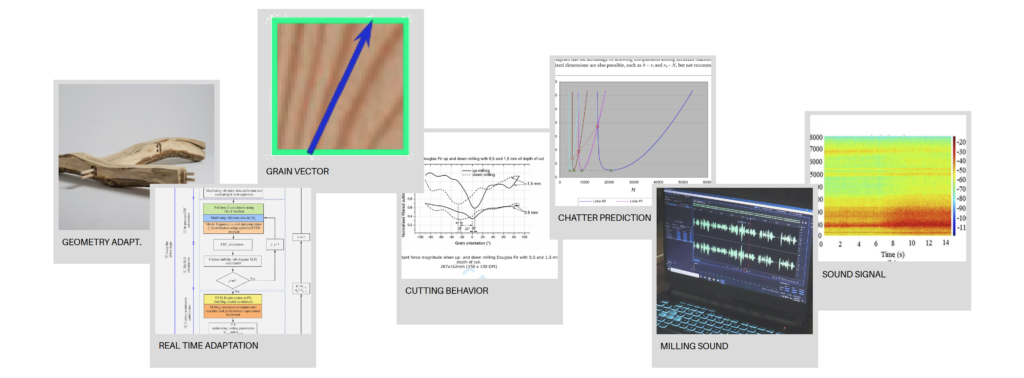

Those seven references listed below from left to right and many more, taught and guided the research about how non-standardized wood has been used to inform design and fabrication, about how grain information of the wood has been extracted, about different workflows to adapt fabrication machine settings in advance or in real-time, about the relation of wood grain directionality and most importantly how sound data can be analyzed to understand the cutting behavior.

In the current milling workflows the fabrication is planed and programmed from a combination of the desired geometry and the required milling data. Once the fabrication is done the output material will be analyzed and either as good enough labeled or it needs to be repeated. The research aims among others to have the material properties information at first place and inform the fabrication planing together with design geometry and milling data. For that it has been analyzed which properties of the wood could change and which the research will focus on. As well the milling parameters have been analyzed on what can change and which settings the research wants to adapt.

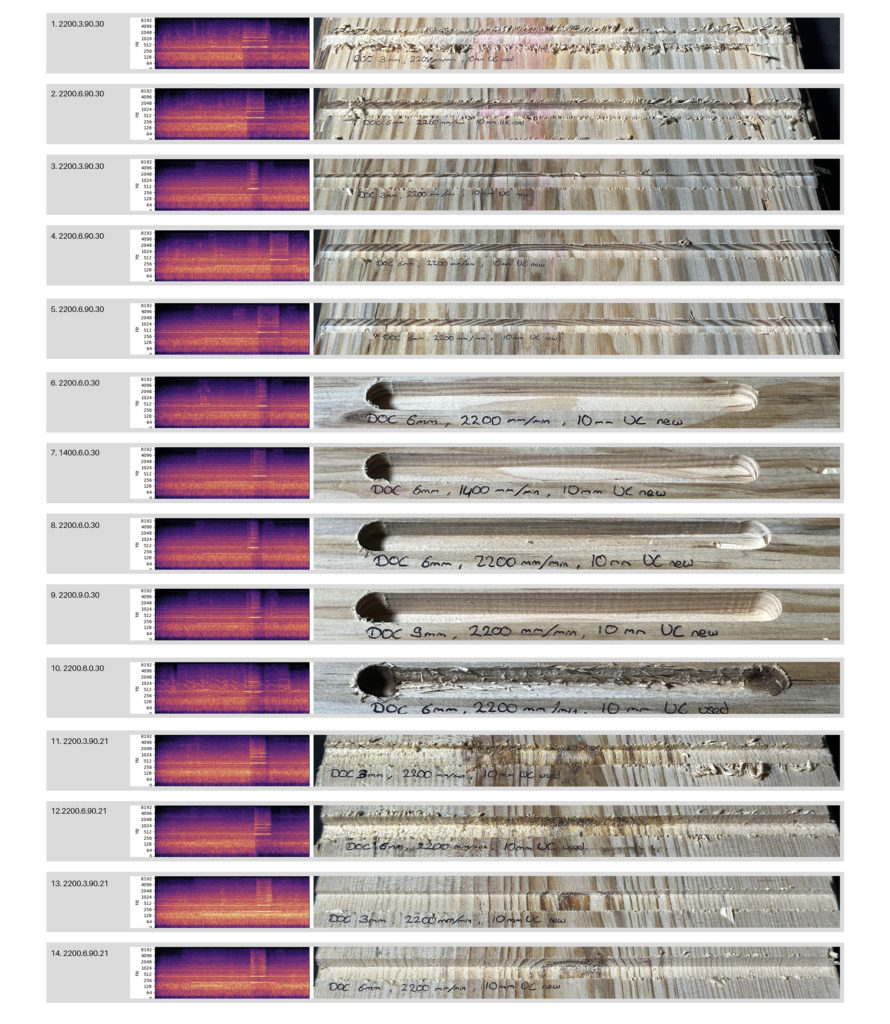

Once the changing wood properties and machine parameters have been selected, there is a need to evaluate the setup and understand first relations between the changed parameters, before final testing data will be created. Also understanding the options of how sound data can be analyzed is crucial to understand which information needs to get extracted in order to compare different milling out comes. What can be told so far is that only the sound information during the milling process is interesting. In this window we want to know all the frequencies that overpass a certain magnitude of each frame during the milling process. In the reference (Dr. Smith, Scott; The science of milling sounds.) it is well explained that normal sound in milling is related to the rpm and and tool-teeth number for example the tooth impact frequency or harmonics. They exist therefore linear. Chatter would be clustered as bad sound and exists exponential since it is not a forced vibration, but a self-excited vibration. From the read sound-data can now be evaluated if chatter existed and frequencies outside harmonics exist. The final test and data collection will investigate the relation between all parameters.

In the setup validation test it has been verified if we can detect in the sound data following changes:

- DOC (depth of cut)

- repeatability

- grain direction

- feed rate

- path location

- board thickness

- tool age

Future Steps