Group 20

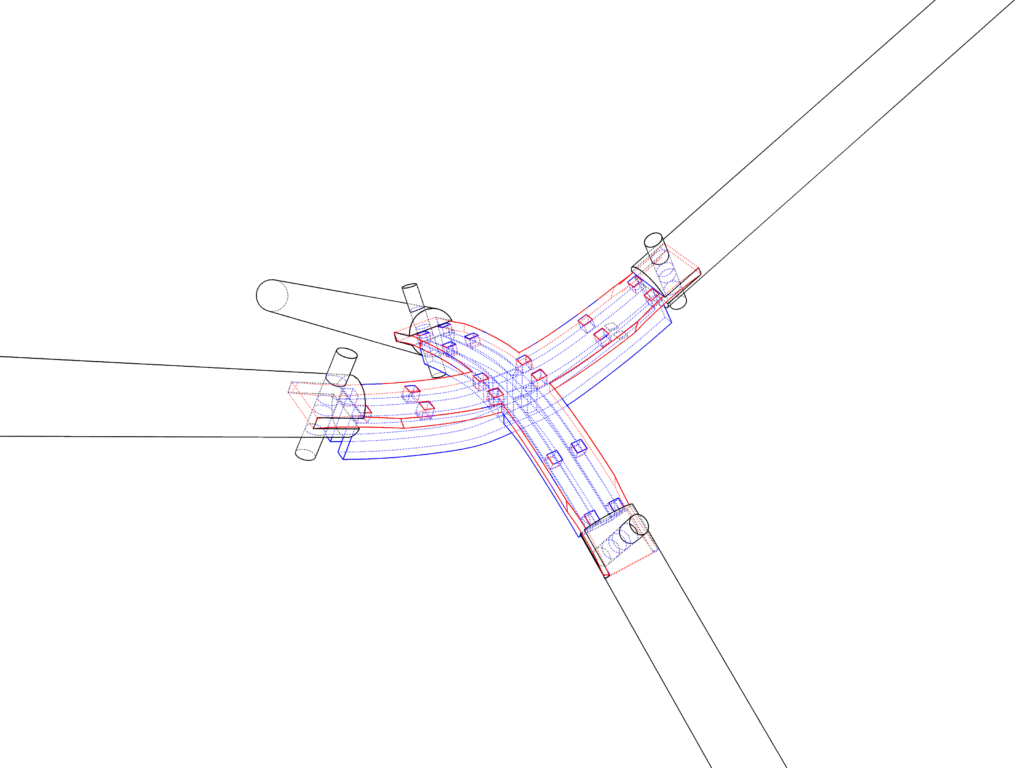

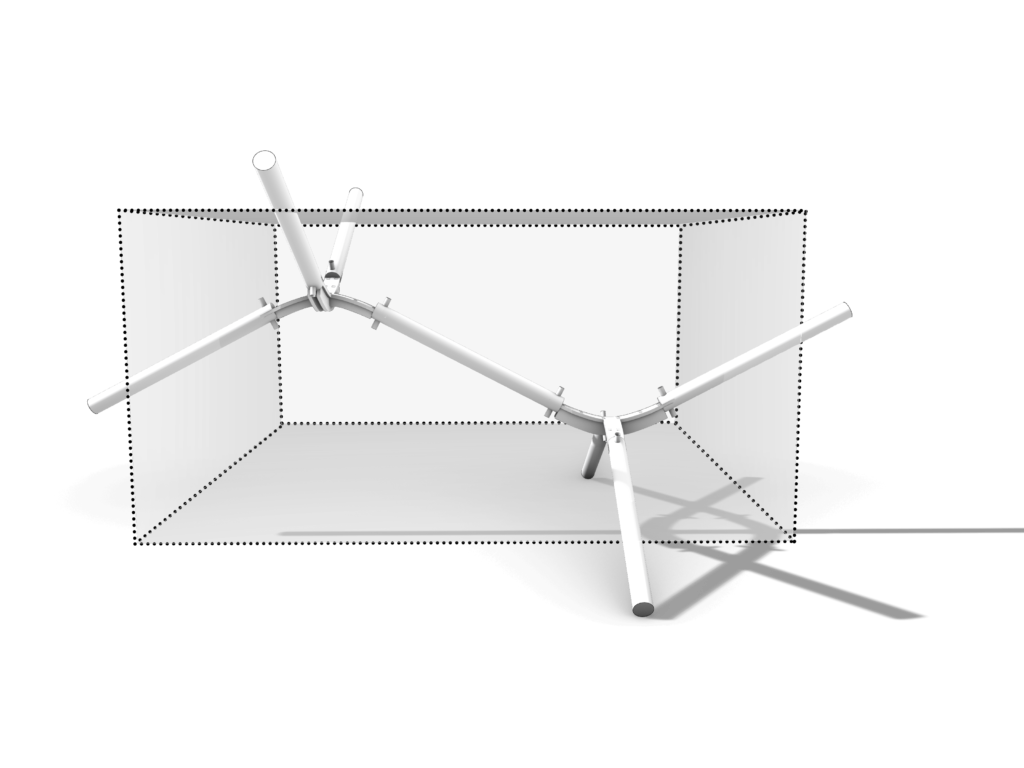

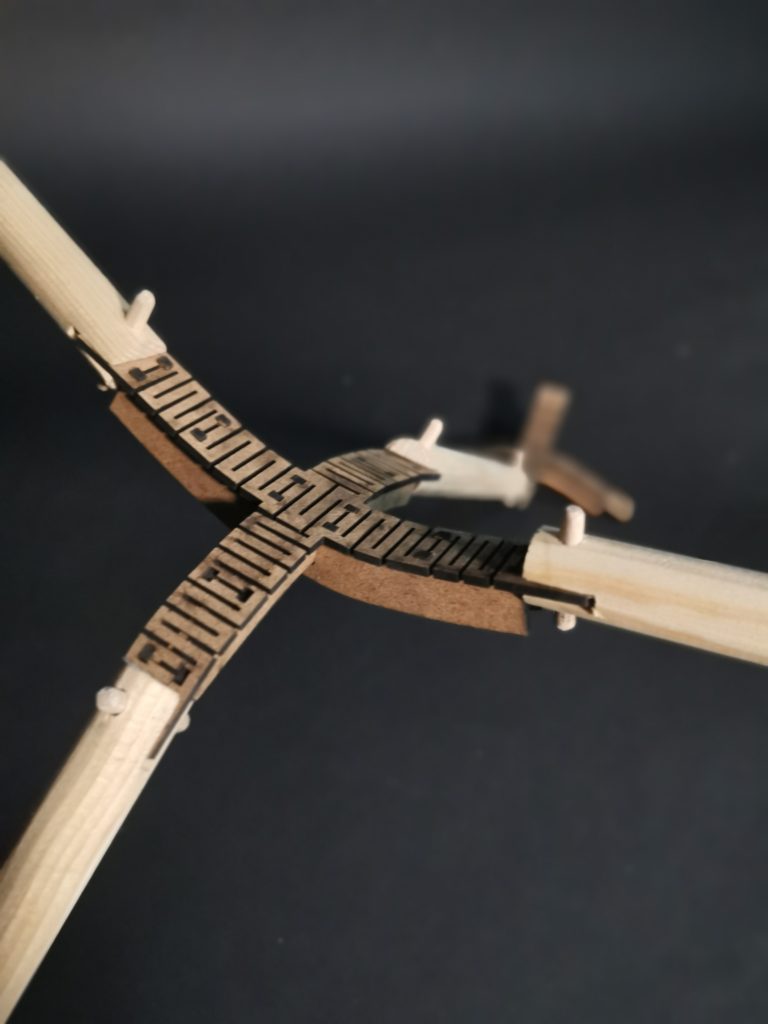

Timber Spatial Joint

Concept

The aim of this timber spatial joint was to explore the bending technique applied to plywood or MDF using kerfing but also apply it in 2 directions instead of 1. The bent joint is then inserted into the circular wooden sticks and fixed in place using a wooden dowel.

Production Process

First Trial: Bending Acrylic with Heat

Challenges Faced:

- Difficult to bend the acrylic in Opposite directions as the center is affected by one of the directions.

- Difficult to align the grooves in the joint with the fingers on the bottom supports.

- Time-consuming

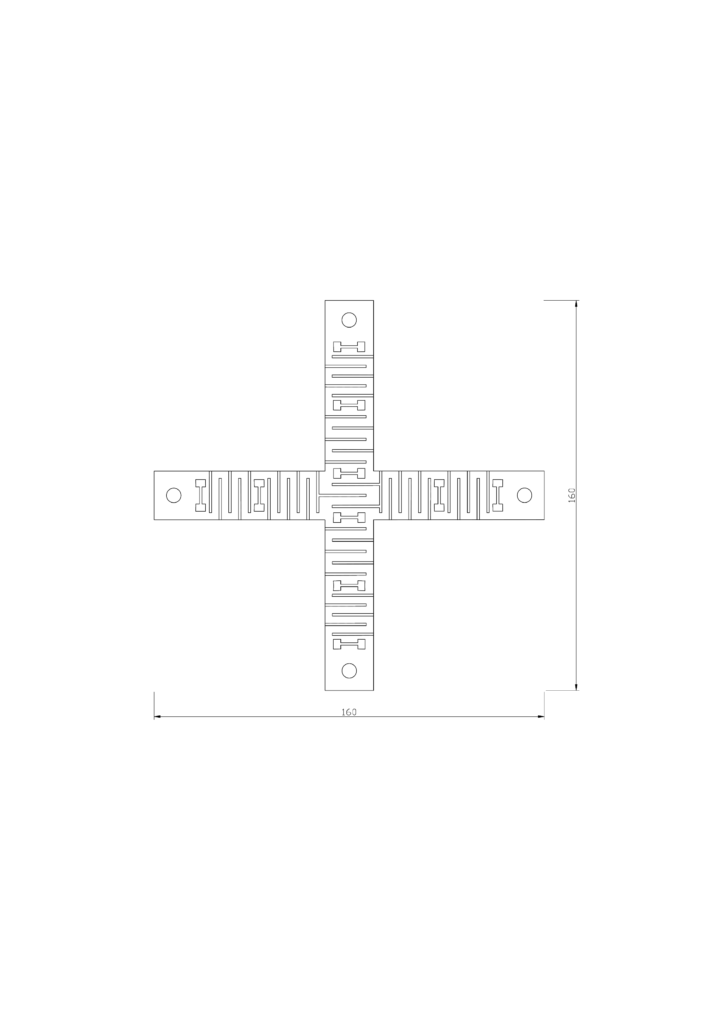

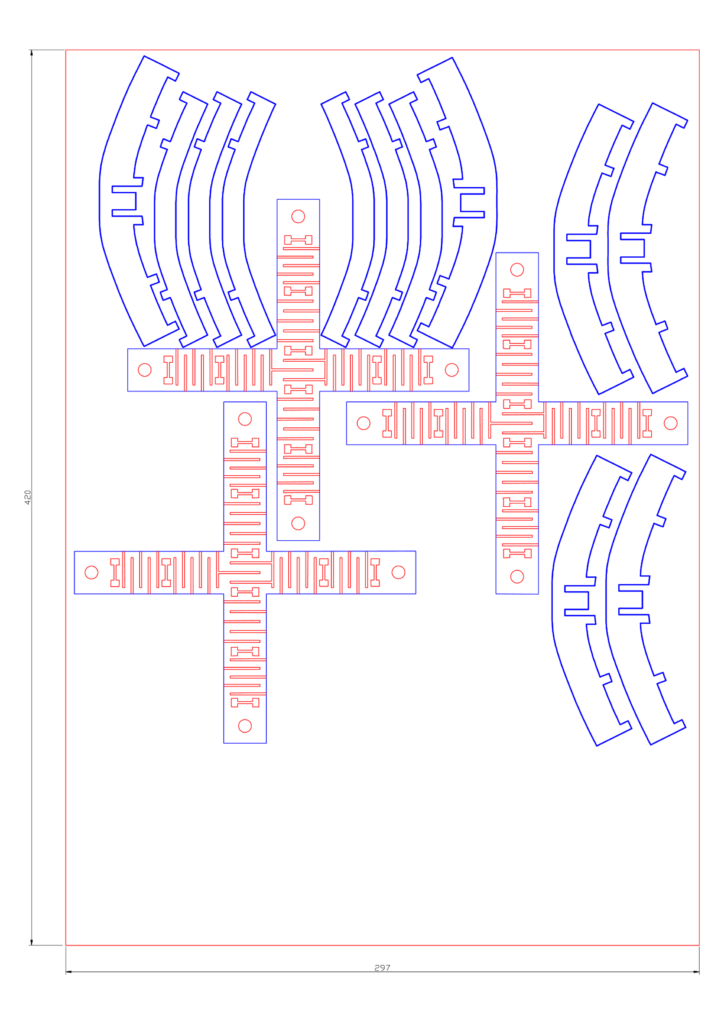

Second Trial: Bending MDF using Kerfing Technique

Challenges Mitigated:

- Easier to bend in both directions

- Grooves easily align with fingers

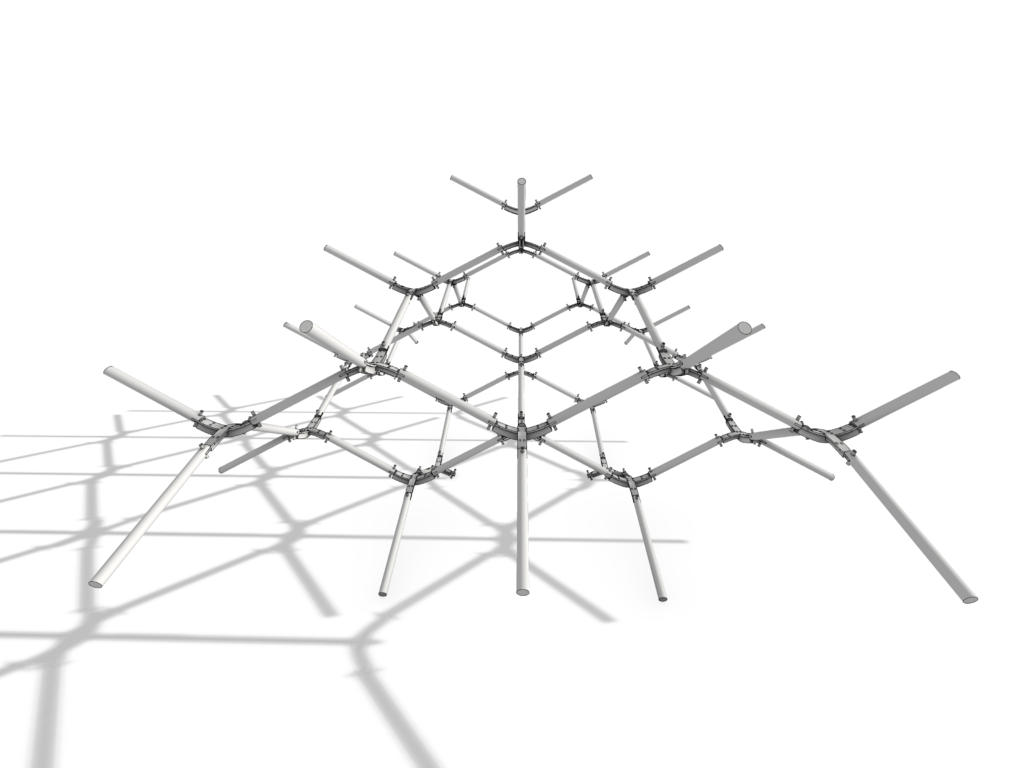

Spatial Network

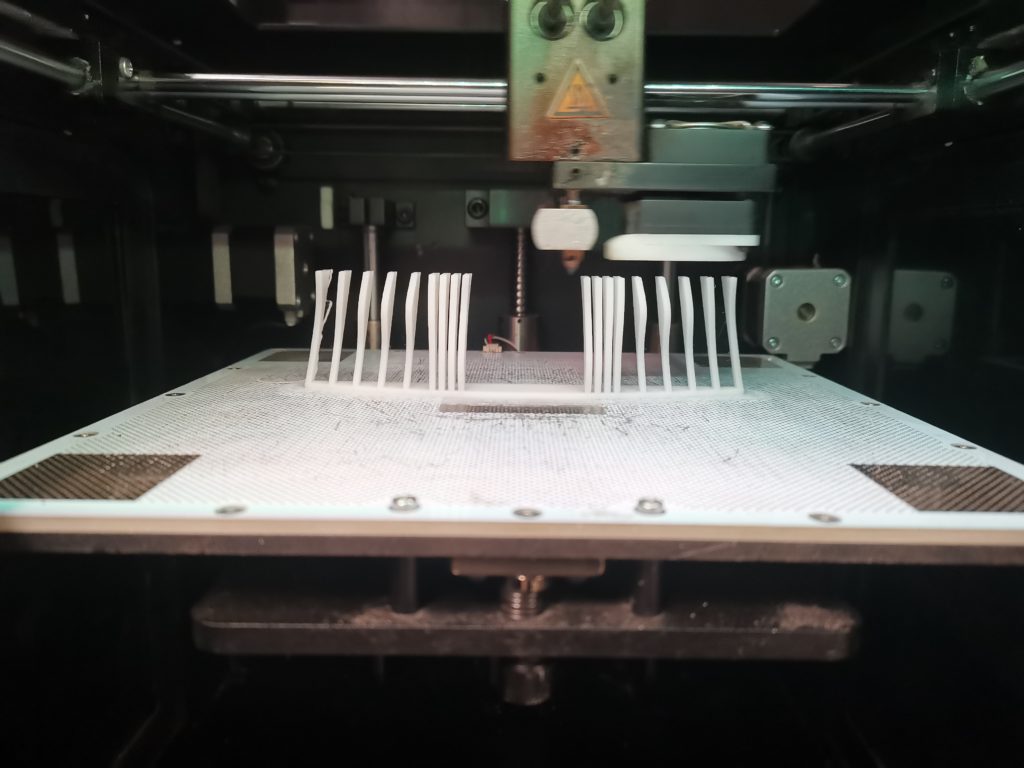

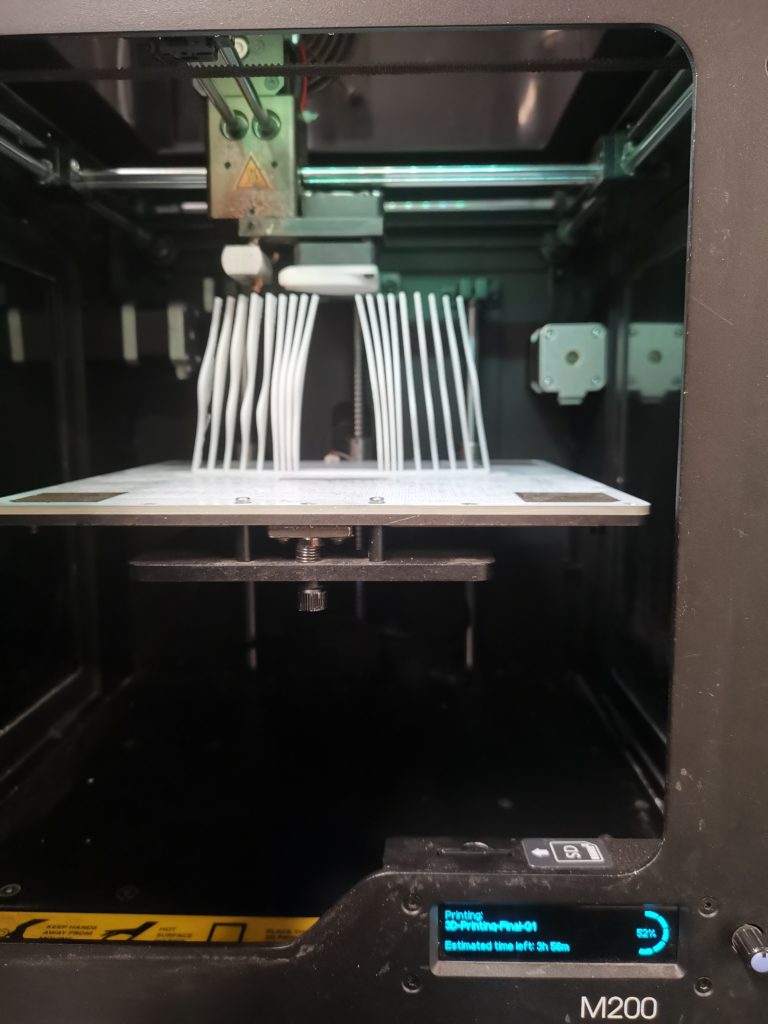

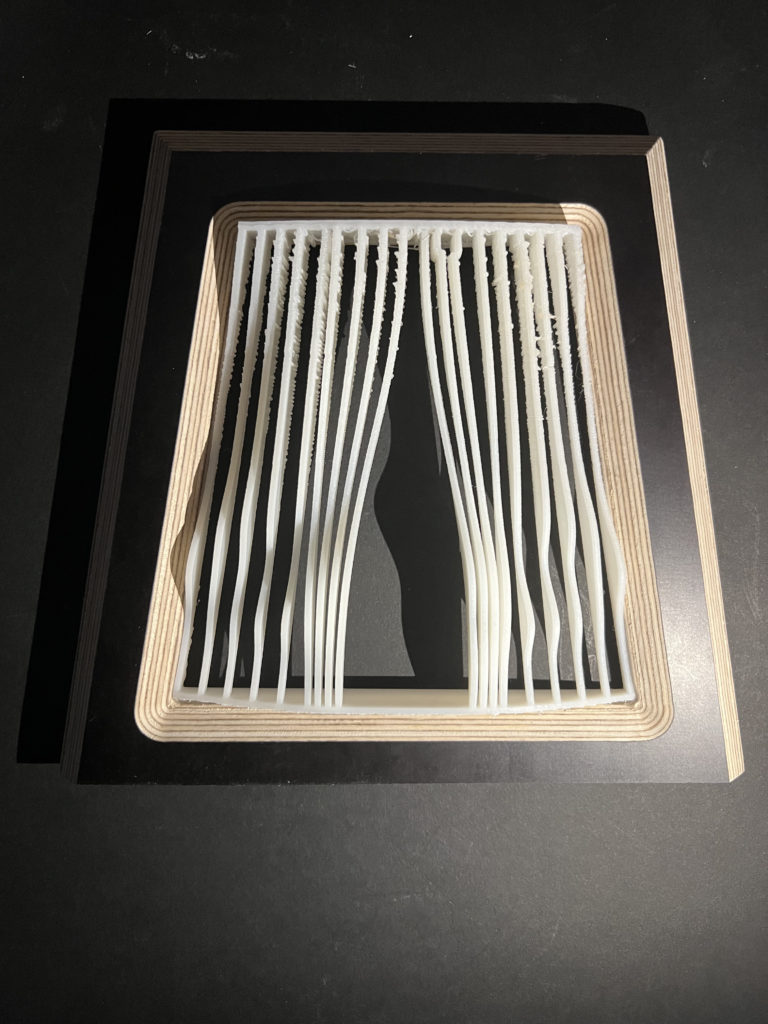

3D Printed Rigid Curtain

Printer: M200

Estimated Print Time: 8h 11 min

Material: Z-ABS 2

Nozzle Diameter: 0.4 mm

Layer Thickness: 0.29 mm

Infill Density: 20%

Surface Layers Top: 4

Surface Layers Bottom: 4

Raft Enabled: Yes

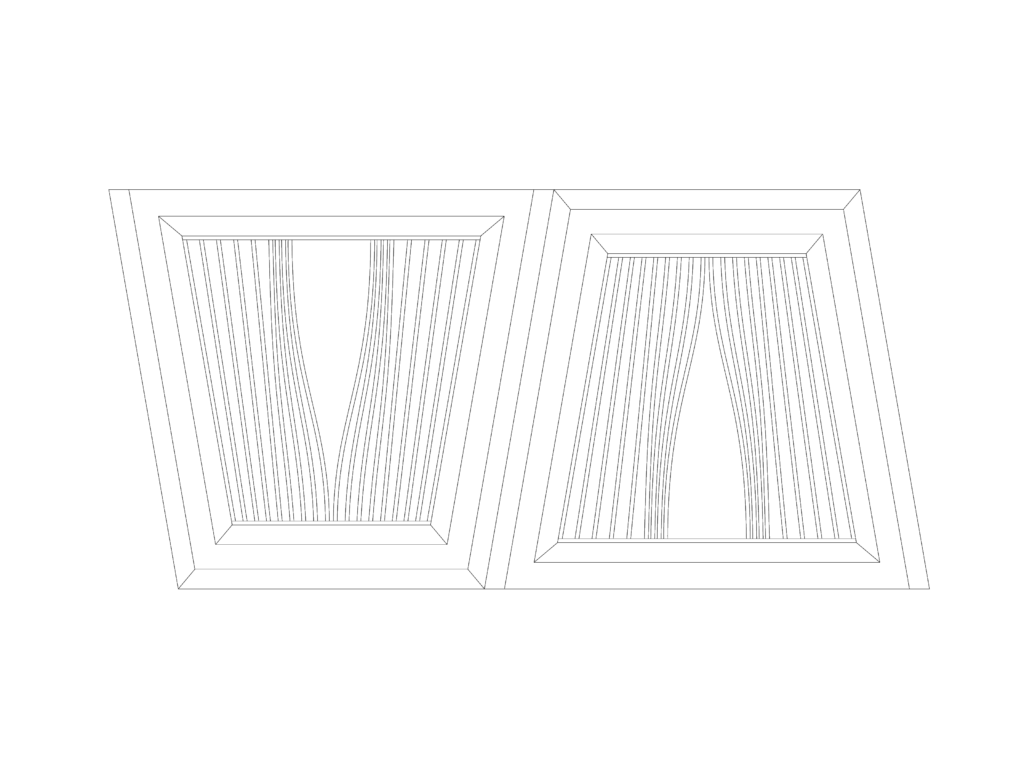

CNC MILLING

The CNC Milling machine produces high accuracy parts from Rhino or CAD with a high level of automation.

As a subtractive manufacturing technology, the CNC cuts away pieces from a block. This can create complex 3D forms in relatively quick timeframes.

For this exploration we are provided a hexagonal module of 360x180mm.

We developed a circular pattern structure that could have different heights, depths, and areas all through a grasshopper script. We imagined the script being tailored depending on weather and lighting needs for a facade.

Pocketing

Flat Mill

Flute: 2

Diameter: 6

Spindle Speed: 12000

Cut Direction: UpCut

Stepdown Control (dZ): -3mm

Stepover Control:-

Total mill time: 20 min.

Material: 30mm Plywood

Machine: Shopbot

Post Processor: .sbp

Workpiece volume – 360x180x30mm