Construction waste

In today’s world architects are facing a massive challenge. This challenge is called resource crisis. According to the European commission, construction industry is responsible for almost a third of worlds total waste and at least 40% of worlds CO2 emission. A big role plays a use of concrete, which main component, cement, is responsible for 8% of global CO2 emission. For a comparison global aviation traffic produces only 3% of all emission [1]. All of these factors are leading to the question, how can we reduce the use of resource and where can we extract materials, without reducing the harm to the planet?

Digitalisation

A key aspect for for every industry for reducing the CO2 footprint and becoming more efficient in the use of materials is digitalisation. Unfortunately architecture and construction are not leaders here. In 2015 McKinsey Global Institute created “industry digitization index”. This was a ranking of how digitalised certain industries are. According to this study architecture and construction is on the second place from behind. This means after a digital revolution architecture didn’t use the whole potential it could. Mario Carpo in his book “The second digital turn” writes the among all of the possibilities we had, the only output with BIM [2].

Case studies

Despite the topic is still not a mainstream among the architects, there are still many interesting cases and researches. An Austria based studio “Materialnomade” are dealing with a topic of material reuse and circular economy. The main principle of the office is — reuse. They deal with circular design in Vienna.

“Material nomads” try as much as possible to accompany the building during the demolition process. In the first step, they create a catalogue of components. This is a kind of database where the materials and dimensions of components are listed. They consider where and how the components can be used further. Logistics must also be considered when transporting the dismantled parts so that the CO2 footprint does not become too high.

As an example of such projects, we are shown a case of the facade conversion. The concrete posts of the curtain wall are further converted into park benches.

All components that cannot be used immediately are available in «Restore». Re-store is a digital catalog where anyone can buy the materials that the company has dismantled. IT find it extremely important to find the right metrics for the process of upcycling. A study[3] shows that the production of 1m3 of wood generates 310% more CO2 emissions than the dismantling of waste wood for reuse. But this is only one case of several.

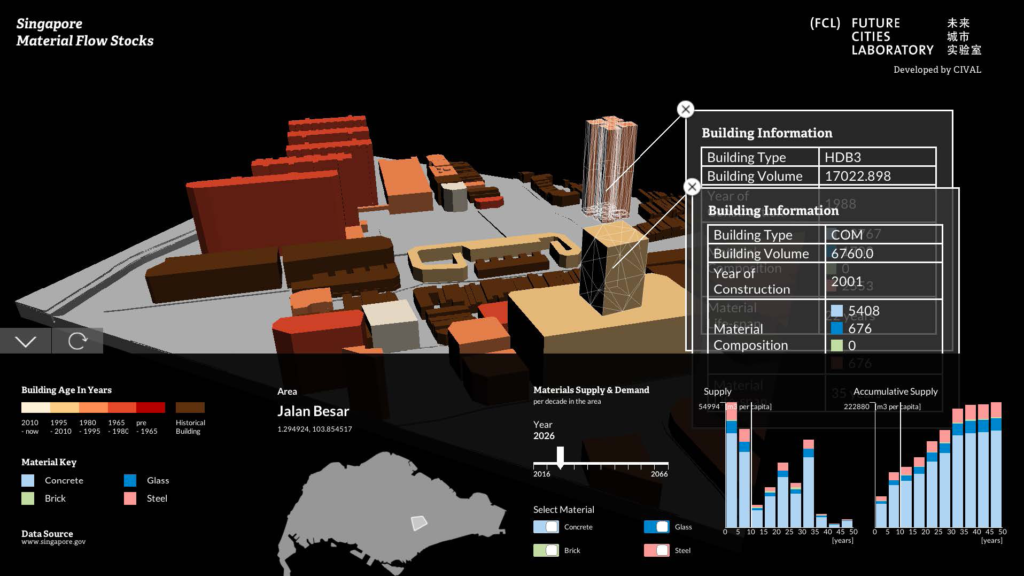

Another interesting research in this field was done at the ETH Zürich. Circular Future Cities is an interesting topic that deals with the concept of circular economy. The basic idea is the circular flow that starts with a raw material, wich is transformed to the product, and at the end, the product is reused to minimise the usage of new raw material for the following production. So the overall goal of the company is to study the possibilities of circular economy in the construction.The first step they call «system analysis and diagnosis». Here the idea is to look for potential materials in the city and map them. The mapping gives us the data, where and when we can collect and reuse materials. With the help of the software and machine learning we can scan the lira data of the city and analyze the context. Instead of the «urban mining» they introduce «urban harvesting». The difference is that as the miner you only react on the gems you might find. While during the harvesting thanks to your actions and analysis you know in advance when and where you can collect your reclaimed materials. So they aim to model the resources yields of building, with the help of software.Every part of the building has its own properties and longevity. All this information will be very useful, when you acquire materials after the building is demolished. So there is an idea to introduce material passport. This will be an item, that carries all the the documentation and maintenance of the material. This idea will be based on the blockchain technology. So that every item in the building will be unique, and will contain information about the item that we can not change. This offers a traceability and transparency to the construction market. There is an example of the SF Bridge 6,4 billion dollars. The anchor rods have been manufactured 5 years before the time they were installed. Most of them failed, and it was almost impossible to find out why it happened. You have to go through tones of paperwork and it might not help.The global idea with implementing blockchain to the construction offers a possibility to consider materials as Stocks. So the goal is to analyse and predict which parts or materials would have value in 5 years as the reuse materials. So that you can scan city to start acquiring them, and by the time the life span of the building has ended, you can either sell them or use as construction materials.

The idea of connecting blockchain tokens with physical object is really interesting. Especially important is the idea of material passport. When we come back to the work of «Materialnomaden», they face a constant problem when they try to reuse object. The problem is that you can’t know the history of the piece, so you have to make test to check if chemicals have been used, or make stress test to prove static stability. It takes a lot of time and energy, which makes the whole process not sustainable at all. That’s why the concept of material passport could solve this problem.Another important thing that the digital assets could change – is the use of resources. Today we are used to consider objects that we create in construction as the end products, without possibility of the further reuse. As a comparison think about how we treat a car compared to the floor in the house. We know that the more accurate we treat our car, the better will be the sell price. The buyer trust the car because he trusts the brand, he can check the documentation and he can also check the VIN number of the car. All of this makes a car unique object and provides information about the condition of the car. The same will happen to the object in construction. You will be much more careful when you construct something, because you will take into account the disassemble process and the possible sell price of you assets. That means that people who use better and more durable materials will have a profit in future.

References:

[1] Using Reclaimed Lumber and Wood Flooring in Construction: Measuring EnvironmentalImpact Using Life- Cycle Inventory Analysis.

[2] The Second Digital Turn, p.5, Mario Carpo, MIT Press, 2017

[3] The limits of simulation: Towards a new culture of architectural engineering, Jan Knippers, November 2017

Material reuse and upcycling is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the Master In Advanced Computation For Architecture & Design 2022/2023 by Student: Anton Klzshnia; Lead Faculty: Jane Burry