GET TO KNOW MYCELIUM

Mycelium is an eco-friendly, self-growing, and versatile material with significant potential in construction, packaging, and sustainable design. Its lightweight strength, fire resistance, and biodegradability make it a key player in the transition to circular economy solutions and biodegradable materials. However, moisture sensitivity and scalability remain challenges that require ongoing innovation and optimization.

REISHI MUAHROOM | GANODERMA LUCIDUM

The shift from Oyster mushroom (Pleurotus ostreatus) to Reishi mushroom (Ganoderma lucidum) mycelium in production is driven by the need for greater durability, fire resistance, and superior acoustic properties in large-scale applications. While Oyster mycelium offers rapid growth and scalability, its lower density, moisture sensitivity, and structural limitations pose challenges for long-term use. Reishi mycelium, despite its slower growth, provides a stronger, more resilient, and fire-retardant material ideal for acoustic panels, ensuring better performance, longevity, and sustainability in architectural and interior applications

CORK | MAIN SUBSTRATE

Cork’s exceptional acoustic properties, including sound absorption, vibration dampening, and insulation, make it a widely used material in architecture, recording studios, and transportation. As sustainability becomes a priority, recycled cork is emerging as a key solution in eco-friendly construction, promoting a circular economy while reducing carbon footprints. Its biodegradability, non-toxicity, and ability to be repurposed into insulation and acoustic panels position cork as a leading material in the shift toward sustainable architecture.

PROTOTYPES | BASE RECIPE

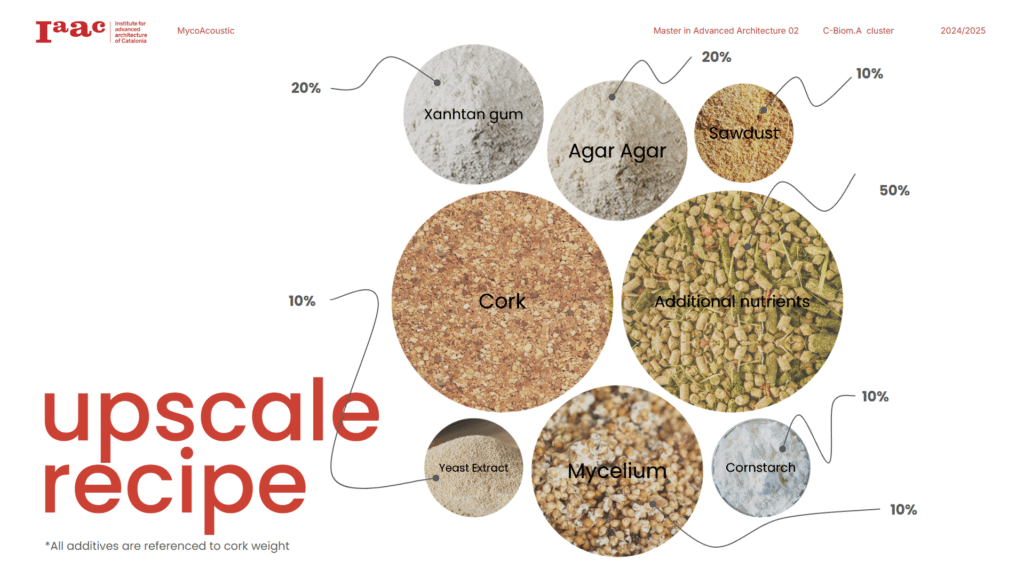

The base recipe, initially developed for a 10x10x10 prototype, was reassessed to evaluate its potential for upscaling. The primary objective was to observe any structural changes, particularly the formation of cracks, after the material had fully dried. The experiment followed a systematic approach, starting with the base substrate and incrementally incorporating binder components to analyze their impact on the drying process.

Once the optimal composition was identified—minimizing crack formation, reducing weight, and limiting shrinkage—the refined substrate was subjected to further testing. At this stage, mycelium was introduced to assess the substrate’s suitability for fungal growth. This final phase aimed to determine whether the adjusted formulation could support mycelium development under controlled conditions.

The results from this study contribute to understanding material behavior at larger scales, providing insights into structural integrity and biological compatibility.

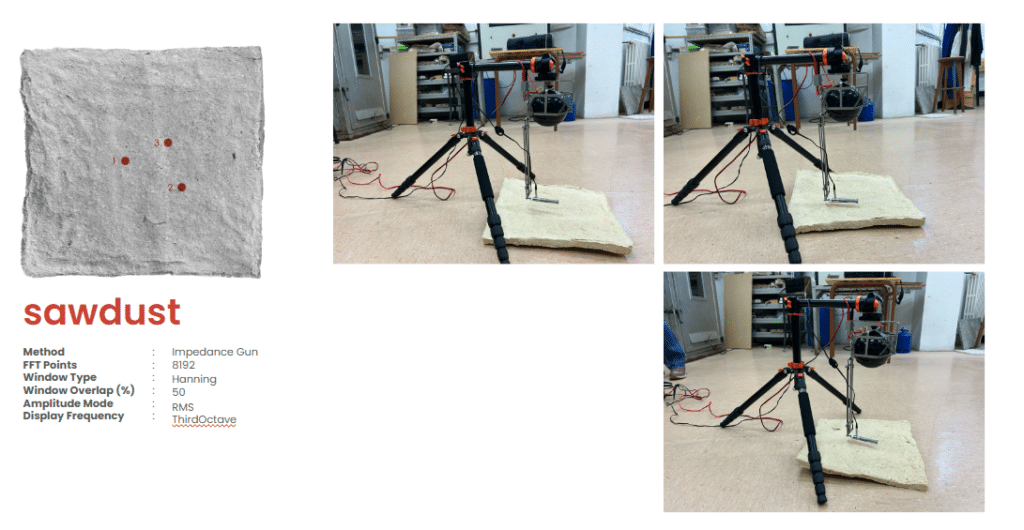

ACOUSTIC TEST

ACOUSTIC RESULT

DESIGN DRIVE | FABRICATION METHOD

Why 3D printing?

Pattern and amplitude influenced by mycelium growth pattern

Vertical printing

Influence of Coral-Like Differential Growth on Mycelium-Based Structures

Coral-inspired differential growth generates intricate geometries with embedded air pockets, increasing surface area and contact points for mycelium colonization. This design not only enhances biological integration but also introduces variations in material density.

Moreover, the negative spaces devoid of a substrate base, once fully colonized by mycelium roots, result in a contrasting texture of soft and hard regions. This structural variation is expected to influence acoustic properties. The softer regions are anticipated to enhance sound absorption, while the denser, harder areas contribute to sound scattering and distribution.

This interplay between material texture and acoustic response highlights the potential of mycelium-based structures in architectural and sound design applications.