Research questions

What role does the geometry of 3D-printed patterns play in reducing water erosion in earth walls?

How do concave, convex, and flat patterns in 3D-printed walls differ in their ability to manage rainwater flow?

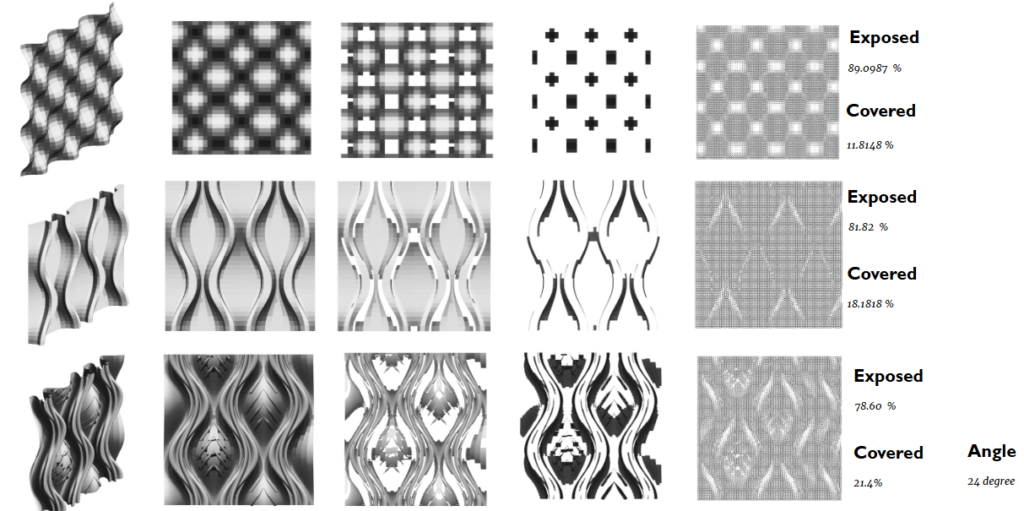

Can we reduce the surface area we coat on 3d printed walls and how does this vary across different surface textures?

Hypothesis

By combining Geometries with concave patterns , and offset surface textures in 3D-printed wall can we get a better performing wall in terms of rainwater management and wall protecting coatings.

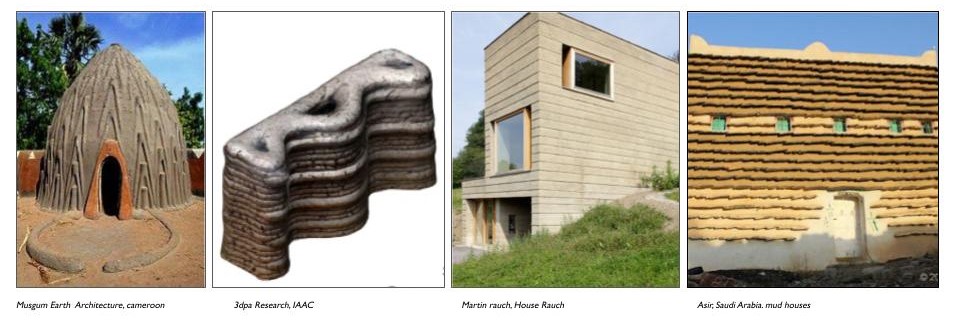

Vernacular and contemporary studies

Hypothesis

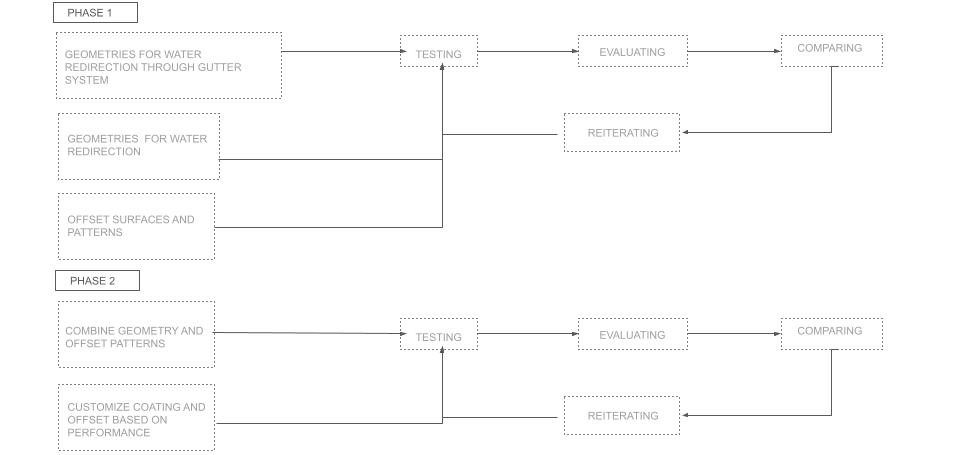

Methodology

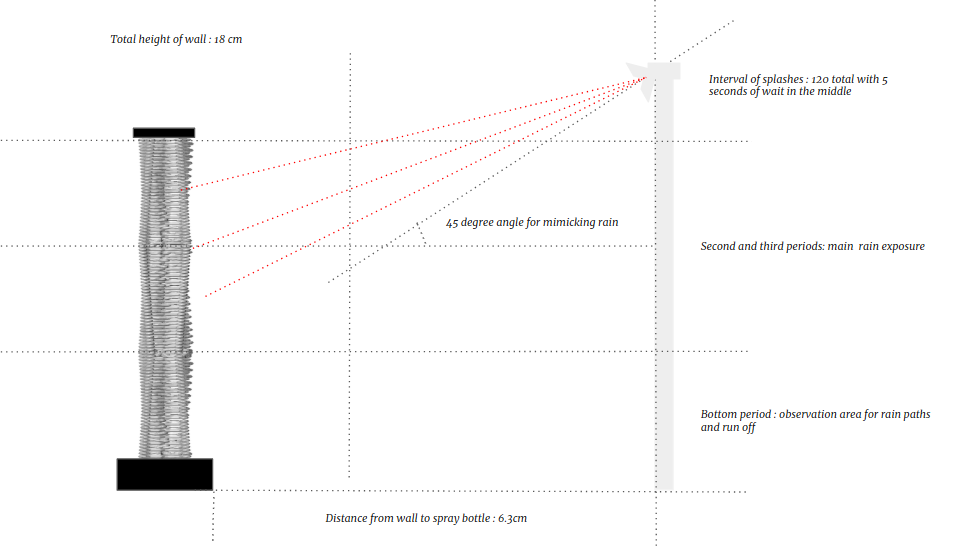

Testing set up

Testing Methodology

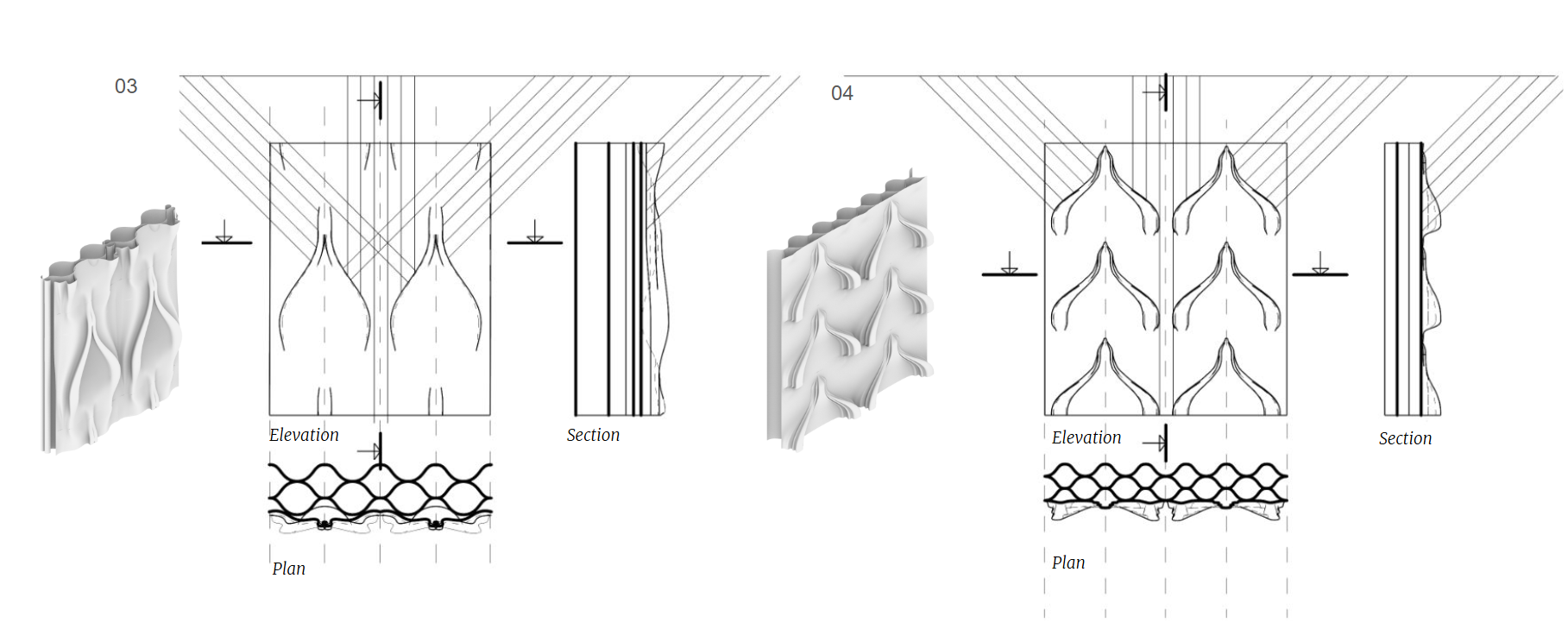

Geometries for Avoiding

Water Vector Drawing study

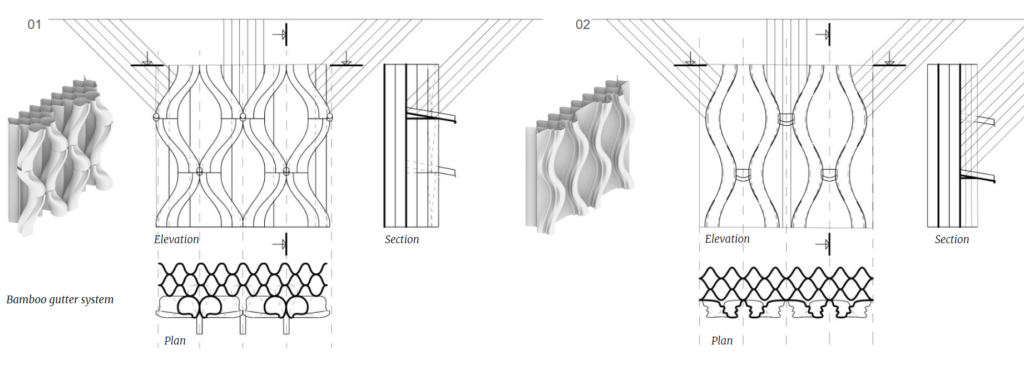

Geometries for water redirection through gutter system

Geometries for water redirection

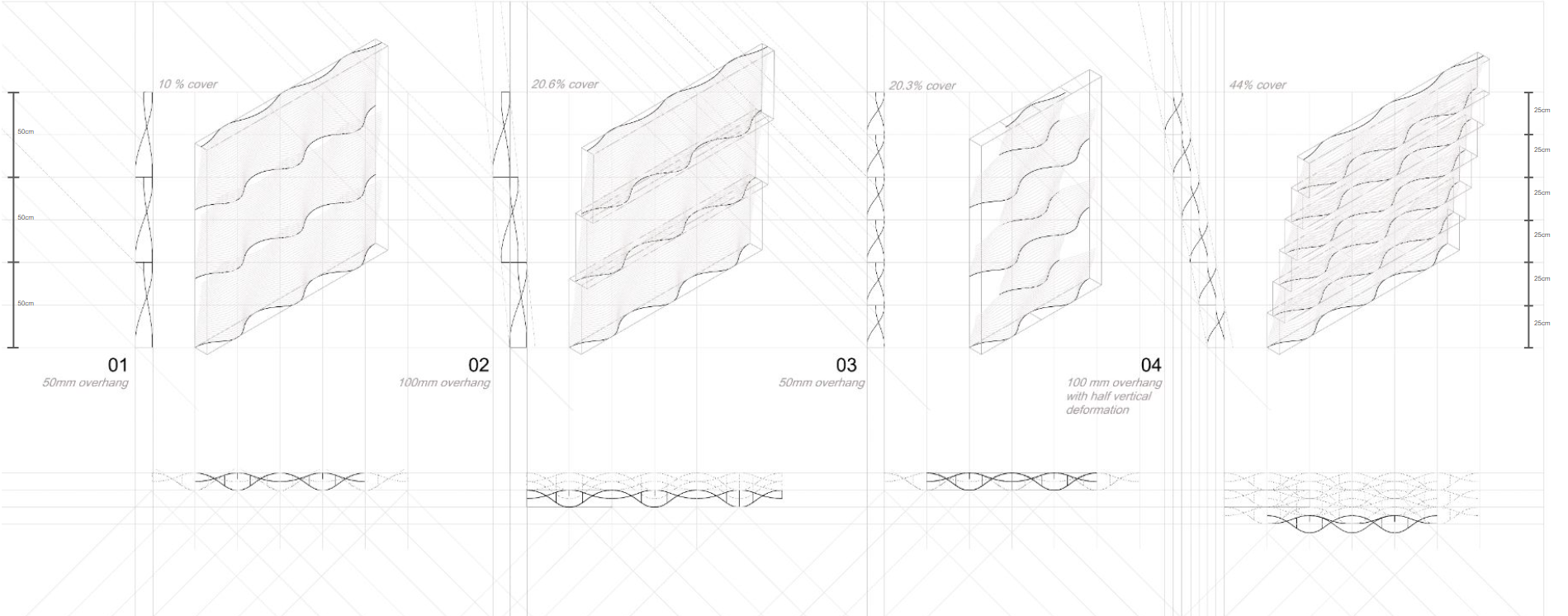

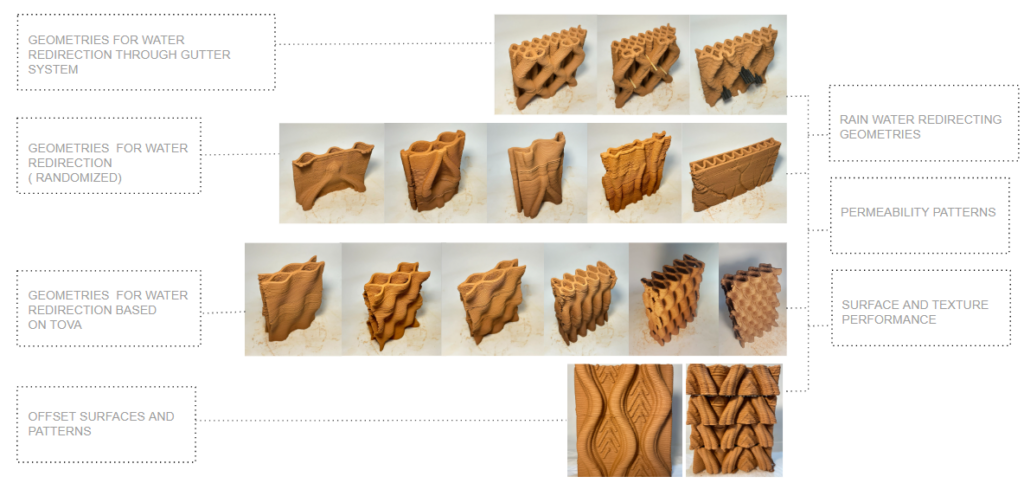

Clustering of geometries and surfaces for testing

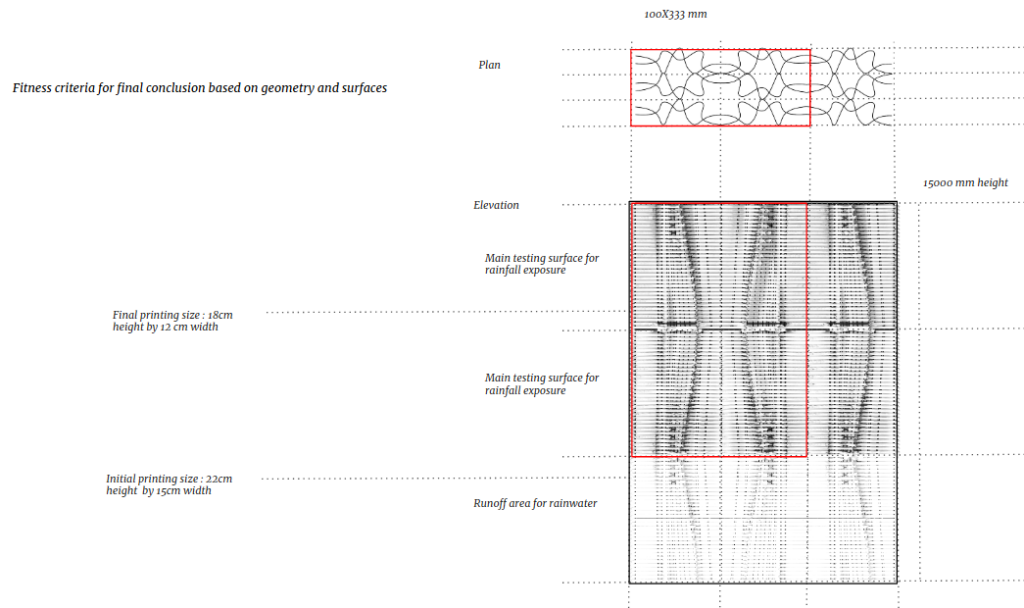

Testing sample

Test Findings

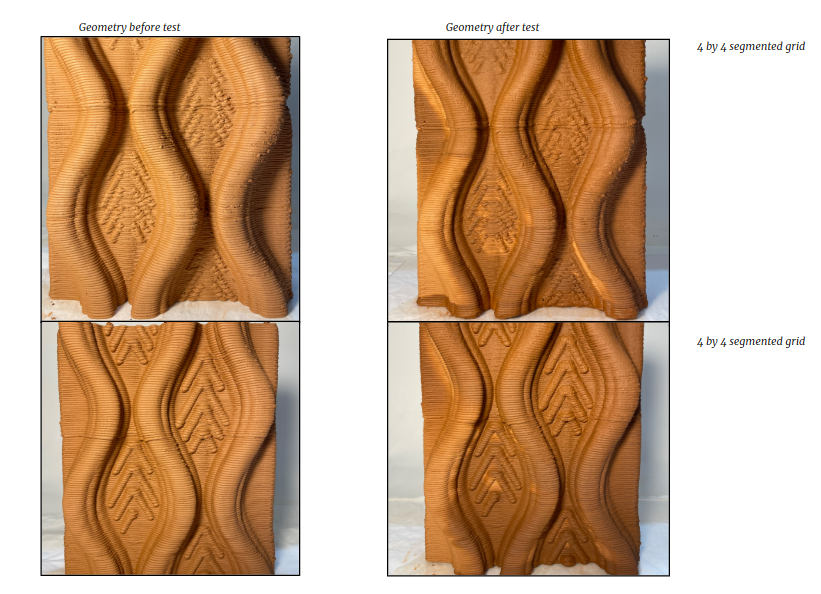

Water redirecting geometry 02 Splash interval : 120 with 5 sec pause in the middle After test : 4/16 with dry segments Percentage in wall grid : 20 %.

Final Geometry

Printed models from the earth at a scale of 1-to-3

The presentation compares two specific geometries, one with a 24-degree angle and another with a 10-degree angle, illustrating the impact of shape and slope on water redirection efficiency. These models were used for the big scale printing .

Surface Texture for water redirection through gutter system

1:1 Scale print tested.

1:1 Scale print tested.

A close-up detail of model 1-1 demonstrates the manual maintenance process applied after two days of drying to ensure water drip from the offset. We manually carved the drip in to the offset and coat it with a cover.

Surface percentage covered and saved from rain

Findings

- Successfully protected the covered layers

- Successfully created [ carved] a drip offset that works.

- Understand the maximum angle we can cover and actually print

Conclusive framework

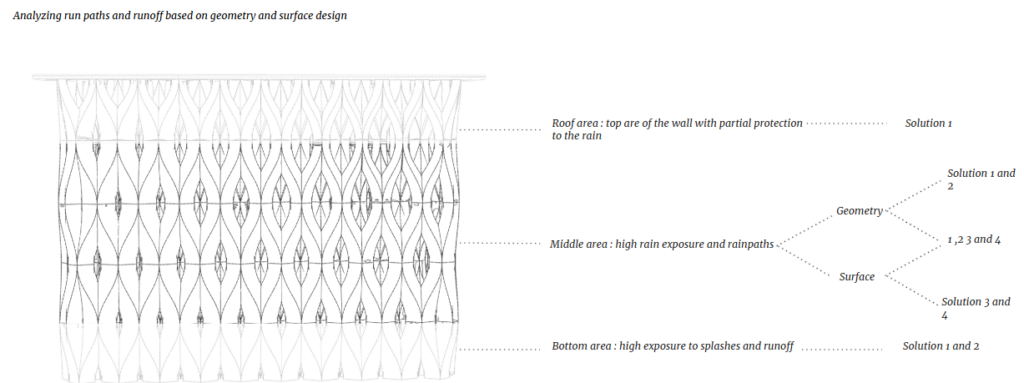

Analyzing run paths and runoff based on geometry and surface design

Conclusions

- We can achieve 44 % coverage. That means we can reduce the coating of surface. But this can only be achieved in a greater angle that can not be printed without danger currently, thus for now we can only reduce the coated surface by approximately 11 %.

- We have achieved perfect cover by enhancing the drip with carving after printing.

- We have achieved channeling water smoothly so we can either put sacrificial material in those place or use coating.

Further Steps

- We need to develop further strategies that can make the carving process easier and smoother.

- Develop new methodologies to actually measure the percentage of water exposure in real time.

- We need to Prepare a catalogue of geometries and textures for different types of water exposure.