From Concept to Working Prototype

Content research

Before developing STARMI, research explored integrating electronic hardware into architectural design. The study examined responsive building systems, sensor technology, and kinetic principles, identifying origami-based folding facades as ideal for combining geometric adaptability with environmental responsiveness. This investigation into sensors, microcontrollers, and mechanical actuation established the foundation for an adaptive facade that improves interior comfort through real-time environmental monitoring.

INTRODUCTION

STARMI represents a new approach to adaptive architecture where buildings actively respond to their surroundings. This kinetic facade system merges origami folding principles with electronic sensing technology to create dynamic building envelopes. Unlike traditional static facades, STARMI uses motion, sound, and temperature sensors connected to an ESP32 microcontroller that drives a mechanical folding mechanism. When environmental conditions change—increased noise levels or movement detected—the six-armed radial module opens or closes accordingly.

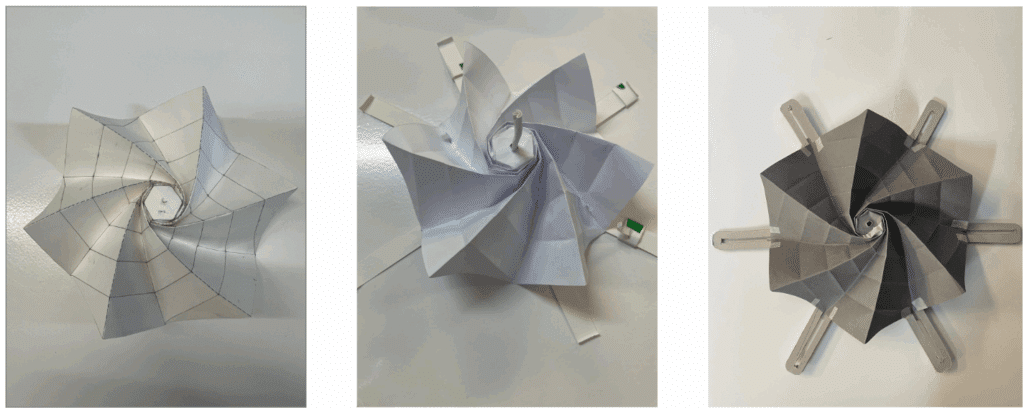

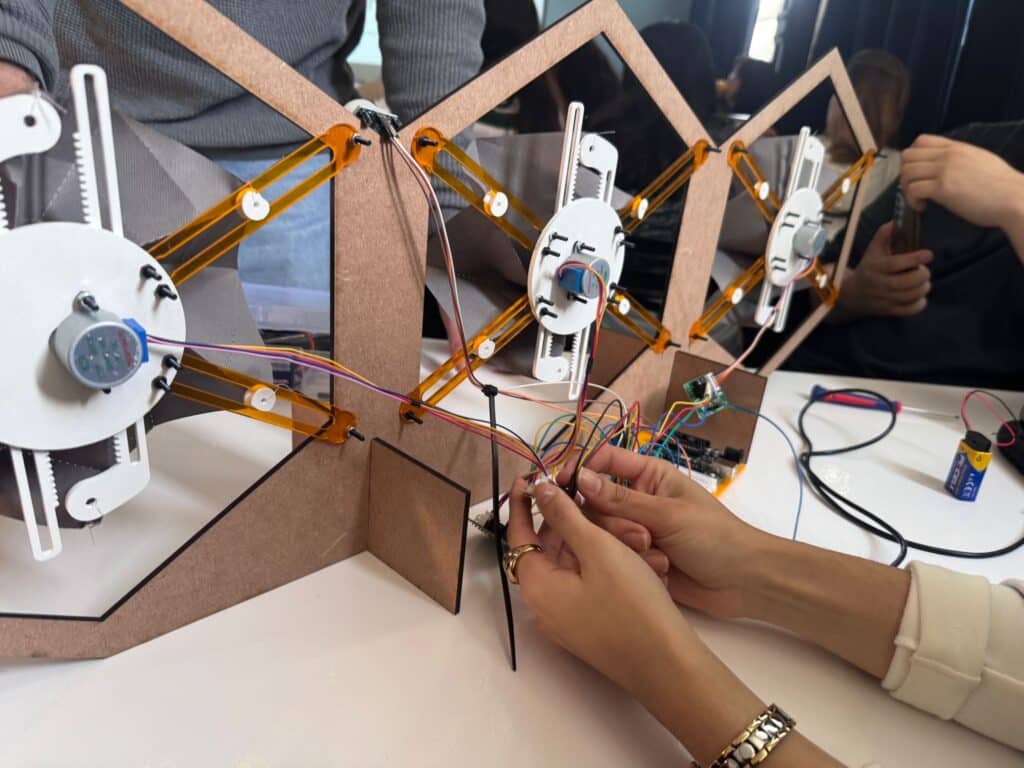

The result is a self-regulating system that reduces glare, minimizes noise pollution, and creates calmer interior spaces without manual intervention. Through iterative prototyping, the design evolved from single-point to dual-vertex actuation, achieving greater stability and synchronized movement that demonstrates the practical potential of sensor-driven architecture.

PROJECT DEVELOPMENT

.

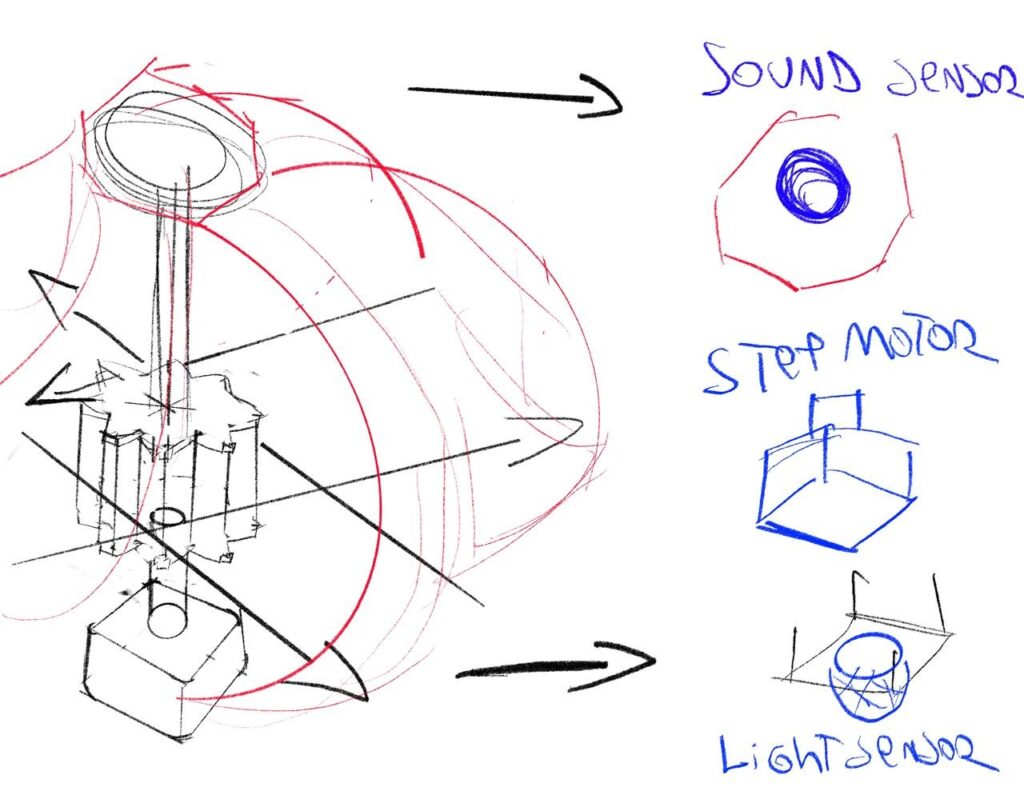

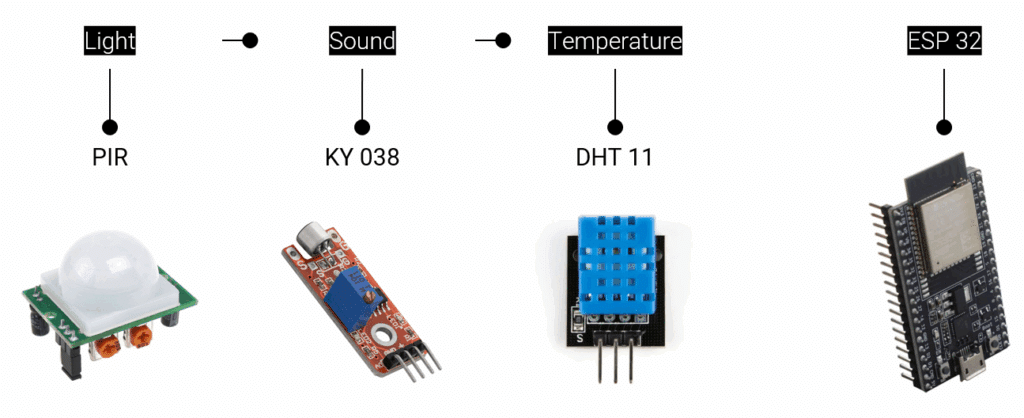

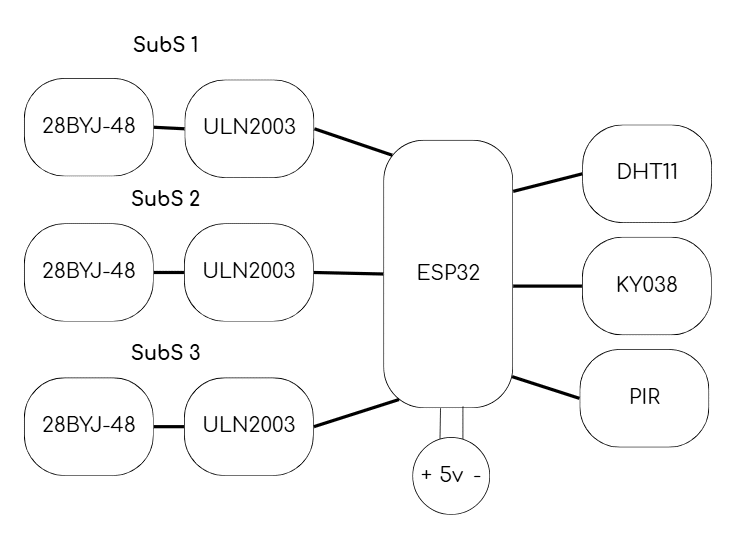

The STARMI system integrates a multi-layered architecture combining sensing, processing, and actuation subsystems. The sensing layer employs a PIR (Passive Infrared) sensor for motion detection, a KY-038 sound module for acoustic level monitoring, and a DHT11 sensor for ambient temperature and humidity tracking. These analog and digital inputs feed into an ESP32 microcontroller, which processes environmental data through programmed algorithms that determine actuation thresholds and response patterns.

The actuation mechanism utilizes a 28BYJ-48 stepper motor coupled with a ULN2003 driver board, providing precise angular control and torque management. A crank-and-rod linkage system translates rotational motor output into linear displacement across six radial arms. The geometric configuration features a central toothed shaft mounted on bearing assemblies, ensuring minimal friction and smooth kinematic motion.

.

.

.

Following the initial iterations using recycled materials, we modeled the parts in CAD software. The parts were then laser-cut from 3mm acrylic for small components and 4mm acrylic for the main structure. Once prepared, we assembled the electronic circuit with the components selected for this system.

The system comprises three main subsystems:

1. Sensing: The sensing subsystem includes a PIR (Passive Infrared) motion sensor for detecting presence, a KY-038 sound sensor module for audio detection, and a DHT-11 temperature and humidity sensor for environmental monitoring.

2. Control: An ESP32 microcontroller serves as the central processing unit, managing all sensor inputs and coordinating system responses.

3. Actuation and Mechanics: The actuation subsystem features a ULN2003 stepper driver controlling a 28BYJ-48 stepper motor. The mechanical system consists of a DHT-11 sensor integrated with the structure, a crank and rod mechanism, six radial arms for movement distribution, bearings supporting a central shaft for smooth rotation, and sliding slots designed for calibration adjustments.

.

.

The ESP32 microcontroller interfaces with three sensors through dedicated GPIO pins. The PIR sensor connects to a digital input pin, delivering HIGH/LOW signals upon motion detection. The KY-038 sound module uses an analog pin (ADC) for continuous sound intensity readings and a digital pin for threshold triggering. The DHT11 employs single-wire digital communication through a GPIO pin with pull-up resistor for temperature and humidity data. All sensors share common 3.3V power and ground connections. The ESP32 processes sensor data and outputs control signals to the ULN2003 driver, which actuates the stepper motor based on programmed environmental thresholds.

.

.

CONCLUSIONS

- The STARMI prototype successfully demonstrates a functional kinetic facade system where sensors capture environmental data and motors execute programmed responses effectively. The ESP32 microcontroller integrates PIR, sound, and temperature sensors to drive real-time adaptive movement, validating the core concept of hardware-driven responsive architecture.

- Key improvement opportunities include establishing ThingSpeak IoT connectivity for cloud-based data logging and visualization, enabling comprehensive performance analysis and algorithm optimization. Additionally, enhancing structural robustness and upgrading to industrial-grade sensors would improve accuracy and durability for real-world applications.

- Despite these development areas, the prototype proves that architectural elements can autonomously respond to environmental stimuli through electronic integration. This foundation establishes a viable pathway toward intelligent building envelopes that passively regulate interior comfort and adapt to occupant needs without manual intervention.

REFERENCES

Mahmoud, A. H., & Elghazi, Y. (2016). Origami explorations: A generative parametric technique for kinetic cellular façade to optimize daylight performance. eCAADe 34 – SHAPE, FORM AND GEOMETRY, 2, 401-408. https://www.researchgate.net/publication/308555888

Karanouh, A., & Kerber, E. (2015). Innovations in dynamic architecture. Journal of Facade Design and Engineering, 3(2), 185-221. https://doi.org/10.3233/FDE-150040

Paio, A., Osório, F., Oliveira, S., Valenti, G. M., & Guimarães, N. (2017). Architecture in-play: Future challenges. Nexus Network Journal, 20(1), 1-11. https://doi.org/10.1007/s00004-017-0364-6

Attia, S., Favoino, F., Loonen, R., Petrovski, A., & Monge-Barrio, A. (2015). Adaptive façades system assessment: An initial review. Advanced Building Skins, 1226-1233.