Techne 4 focuses on designing the print path for 3D Printing Architecture (3dPA). With a 45 mm print width, walls can include cavities, which save material, speed up drying, improve structure, and support climate control. These print paths are key features, not just “infill,” in large-scale earth 3D printing.

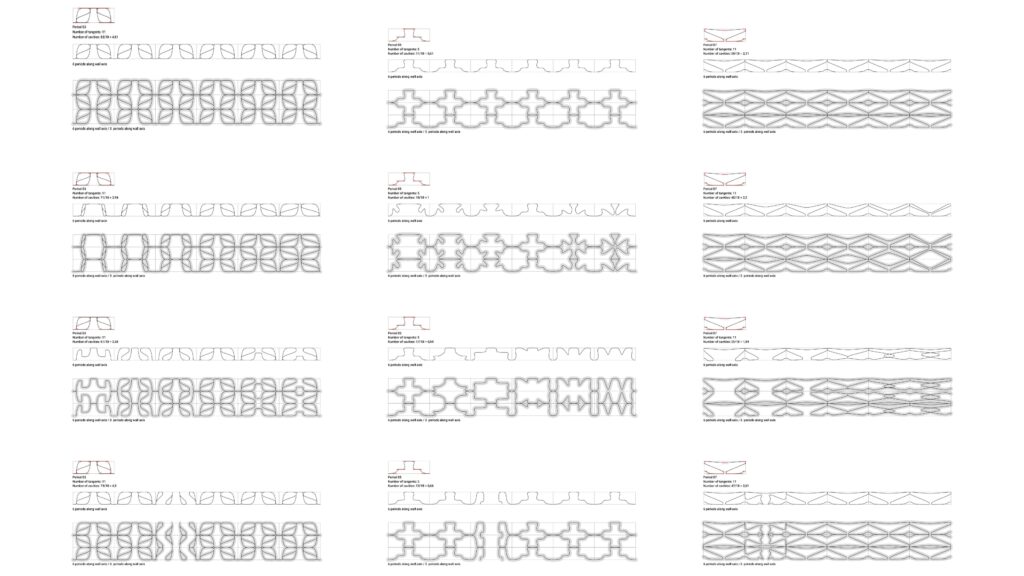

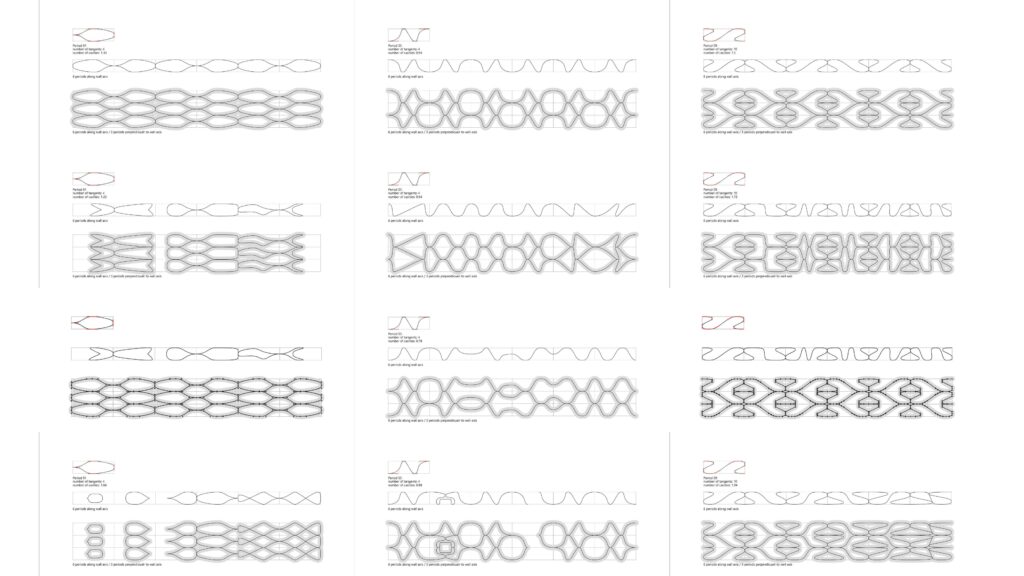

Over time, three effective printing patterns have emerged, used in projects like Living Prototype, Tova, and Teixit. The workshop aims to explore existing patterns and create new ones, combining physical and digital modeling techniques. Furthermore, once producing a massive amount of iterations we began to apply meaning/functions that could potentially work with the form. This meaning came from the potential exemplified by openings, structural potential, and simplicity in print paths.

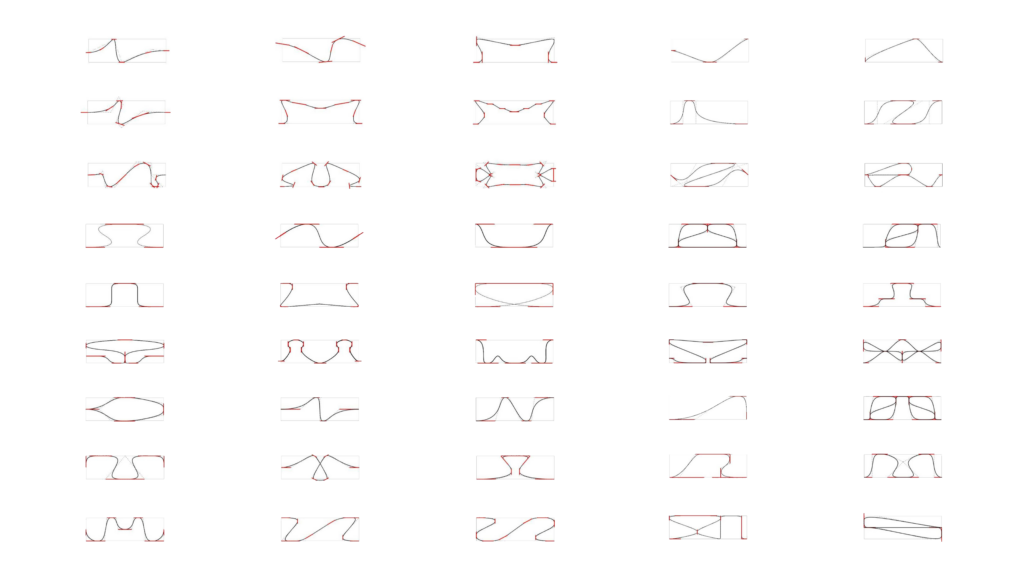

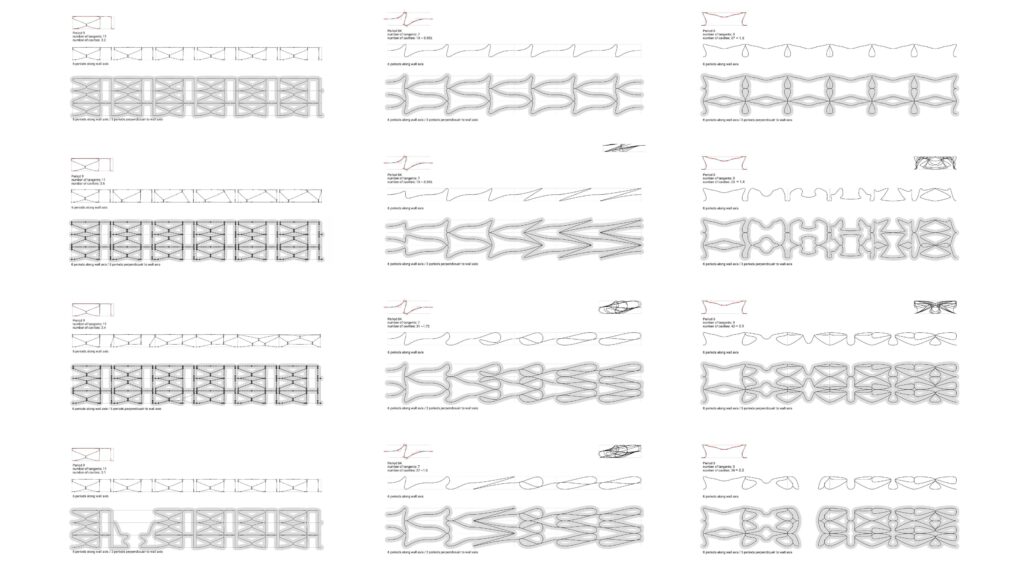

To better understand the potential for 3D printing and architectural applications, each period was explored in four directions:

- No deformations – an undeformed period mirrored and copied

- Geometric deformations – changing the form of a period without creating cavities

- Topological – using geometric deformations to change the amount of cavities within a period or multiple periods

- Exceptions – including breaks in the pattern and altered forms to create conditions that may include architectural details like windows, doors, or ventilation

After producing an extensive catalogue of different periods, the team realized that despite the massive diversity in their appearance, most of them fell into previously existing period families. This demonstrated to us the extent of malleability within certain periods and highlighted the importance of other ‘real world’ factors, such as the length of the period and its relation to material conservation and efficiency. By conducting this exercise, the group further validated the effectiveness of existing period strategies and demonstrated the flexibility of periods with minimal deviations.

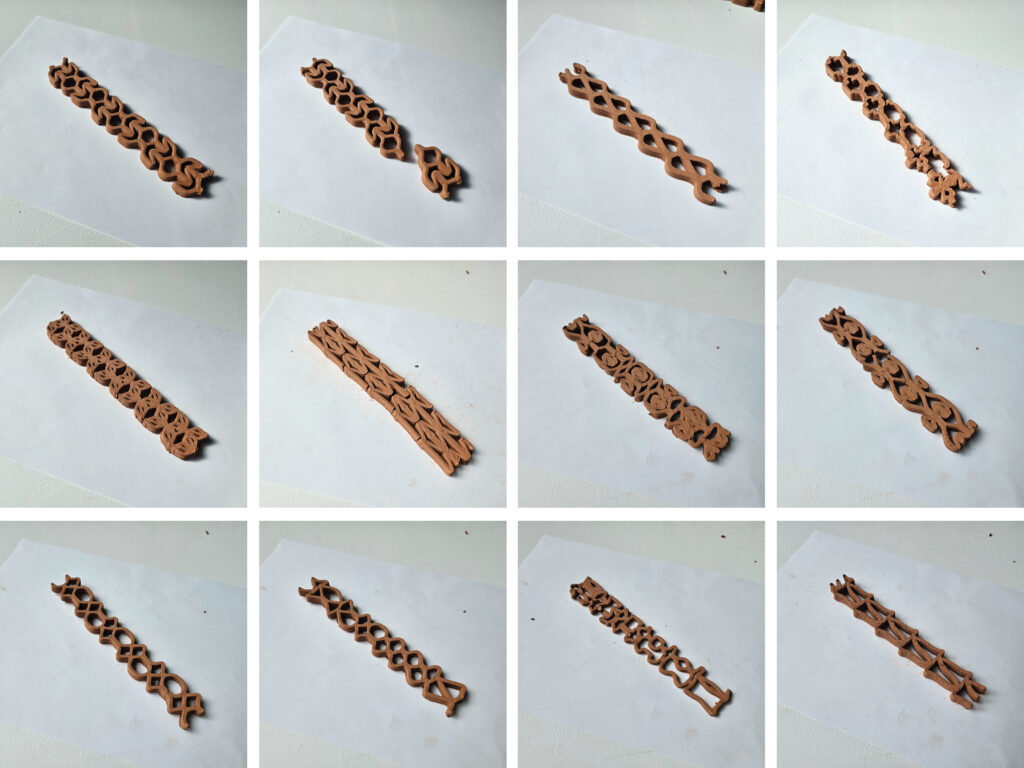

The last step in the process involved printing 1 centimeter of each pattern. Insights gained from this step of the process are essential to understanding the viability of each periods application. In particular, it was a great way to understand the consistency of drying and areas more susceptible to cracking. Furthermore, it highlights the areas needing adjustment in regards to the toolpath and material distribution/overlap.