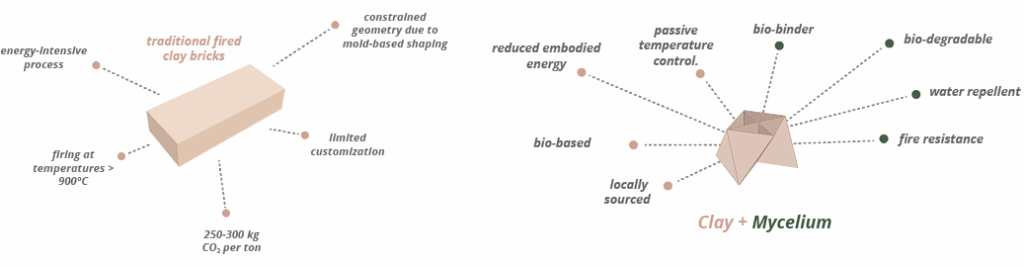

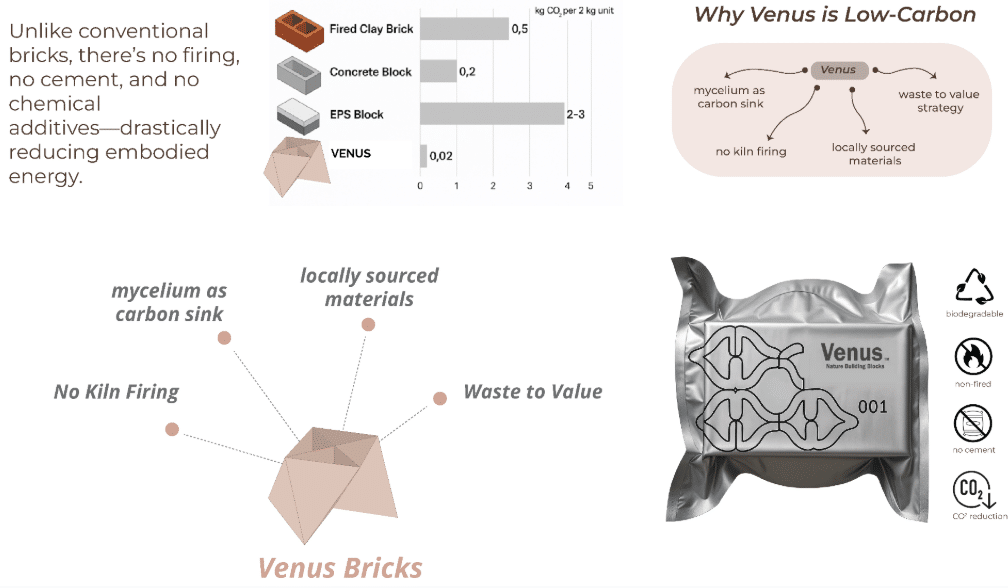

VENUS is a 3D printable bio-composite made from clay and mycelium. It merges natural building materials with bio-based growth to create modular, biodegradable, and regenerative architectural components.

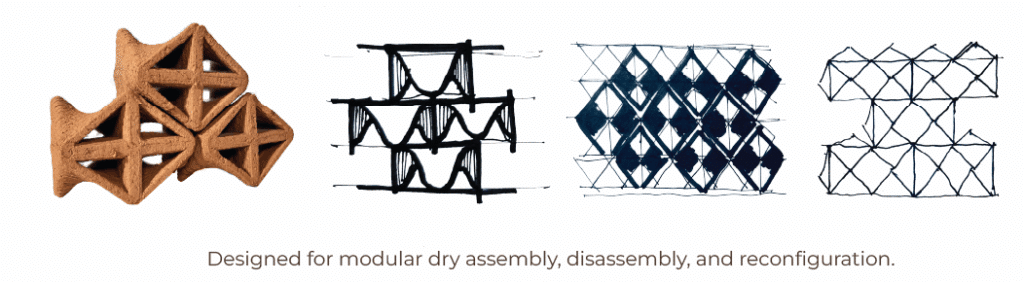

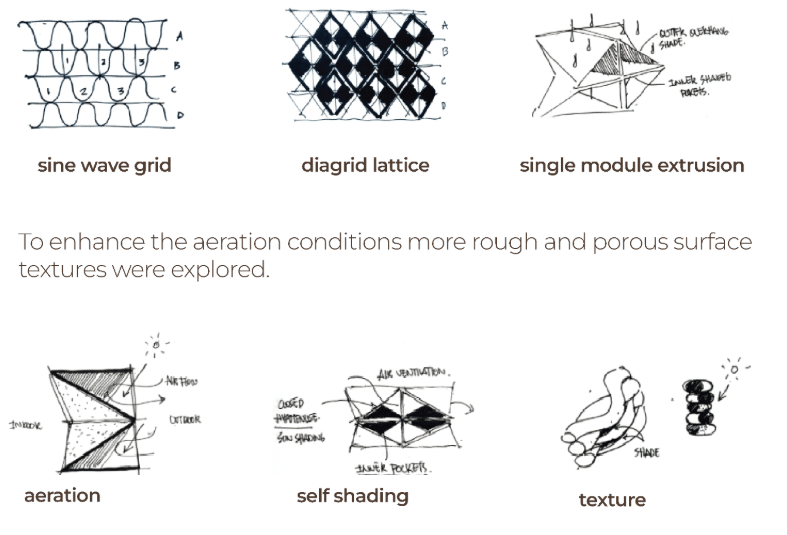

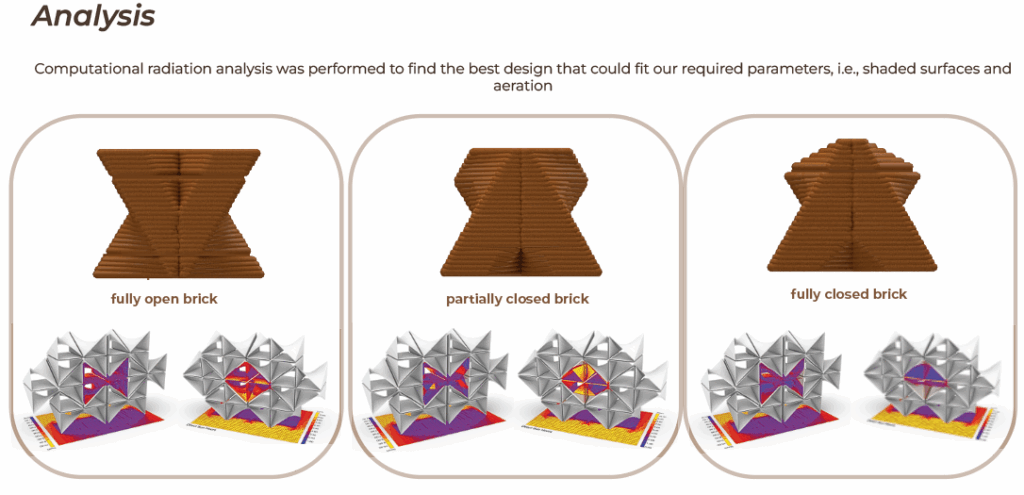

Design

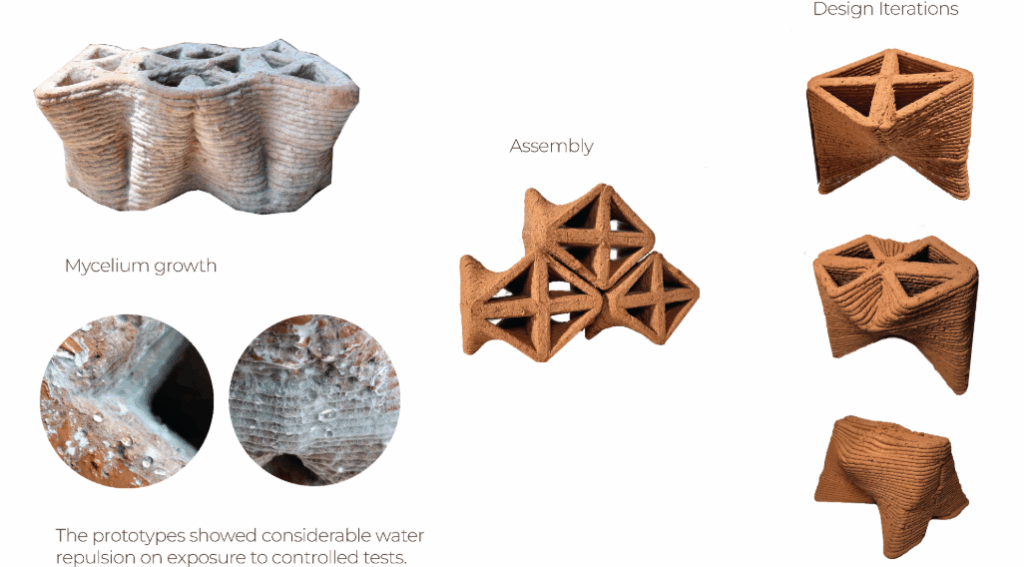

The voids in the geometry enhance ventilation, critical for mycelium growth. Simultaneously, the organic content in the bricks regulates mycelium-colonized surfaces, particularly in shaded and moist environments.

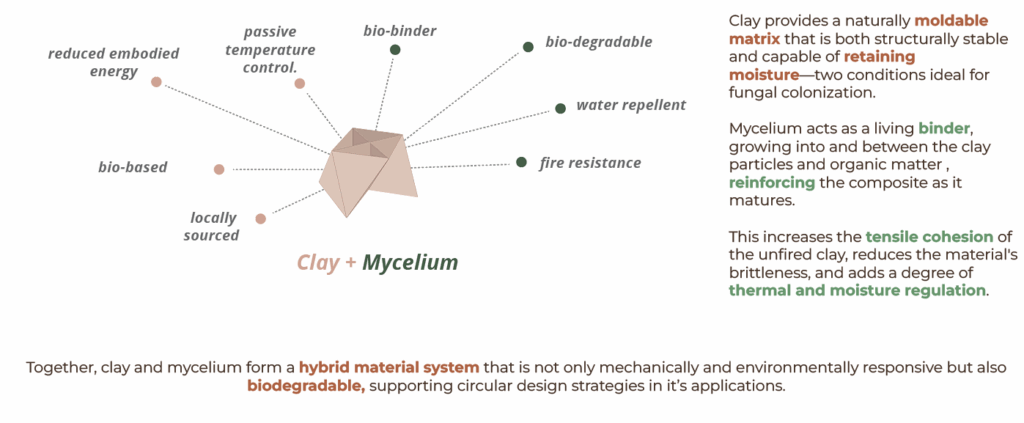

How Does the Bio-Composite Work?

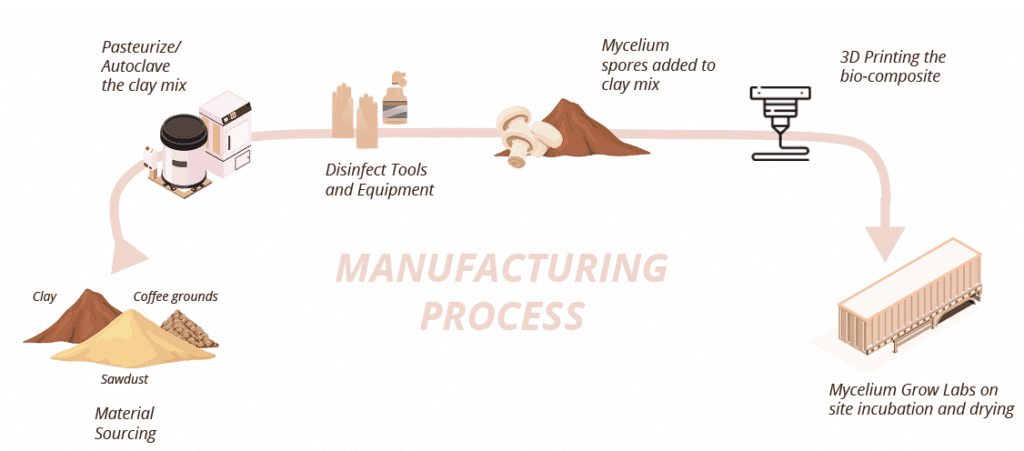

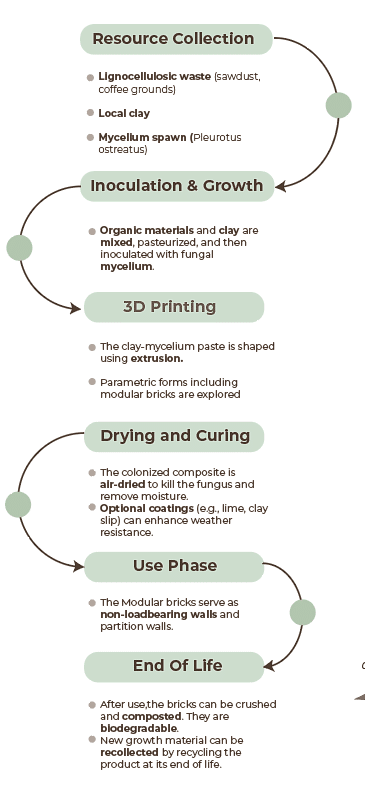

Production Process

Clay is mixed with sawdust and spent coffee grounds to create a nutrient-rich substrate and inoculated with mycelium spores.

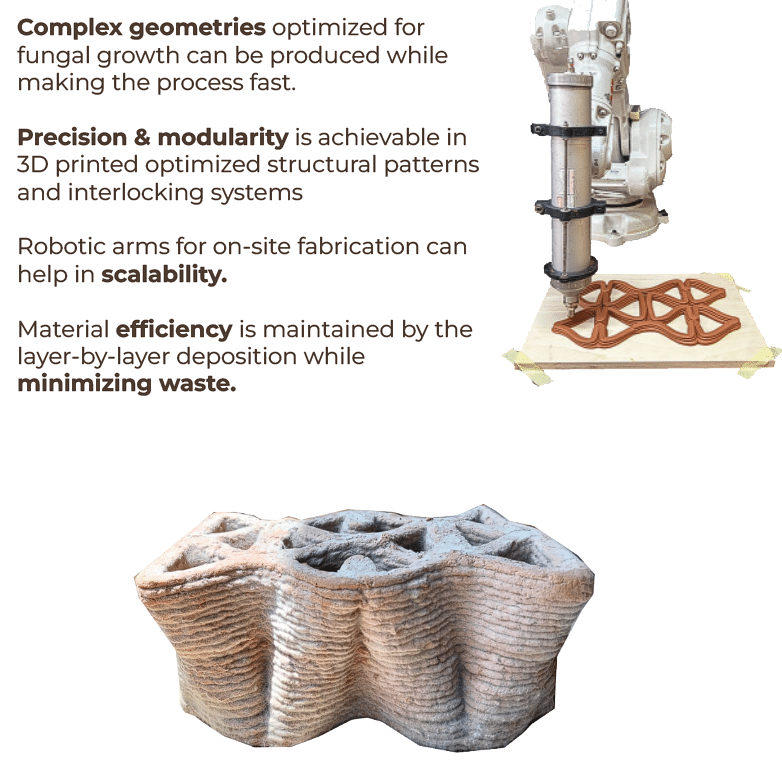

The biocomposite paste is loaded into a robotic 3D printing system and extruded layer by layer into modular brick forms.

This is left to incubate under controlled humidity and temperature.

Once colonized, the material gains internal cohesion from the mycelium’s fibrous growth.

The bricks are dried naturally, avoiding the energy-intensive firing process.

Why 3-D Printing?

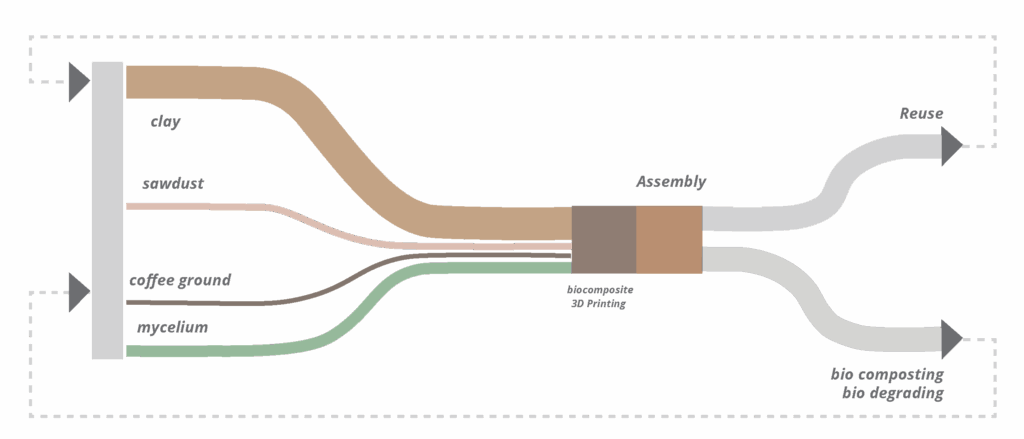

Circular economy Impact

Prototypes

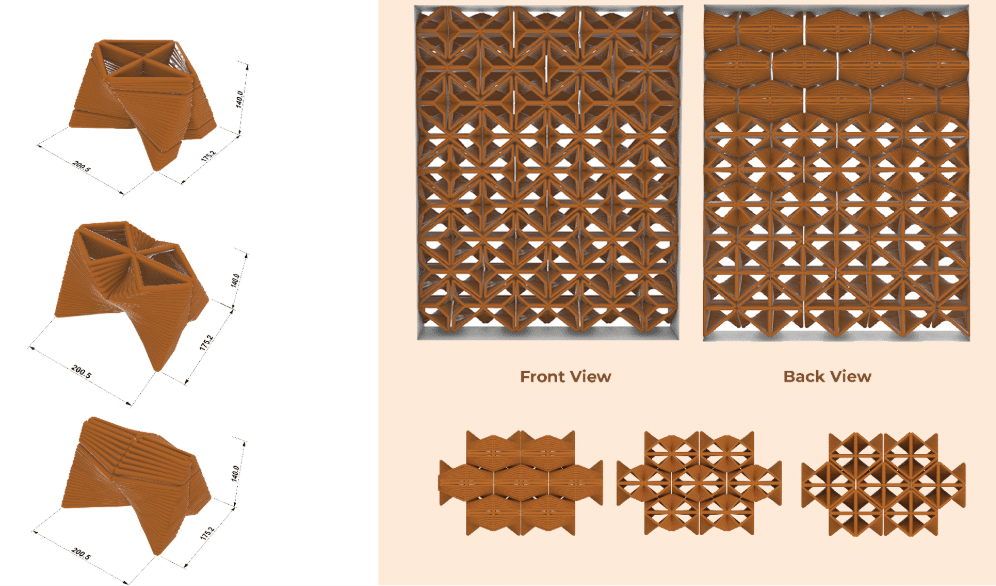

Design Application

Interior Partitions and Temporary Walls :

They are ideal for creating non-load-bearing partitions in interior spaces. Their modular, interlocking design allows for flexible layouts that can be easily assembled and reconfigured without adhesives

Future Potential :

Eco-pavilions and temporary structures and curved walls andmodular domes