Case Study

CYCLOPEAN HOUSE

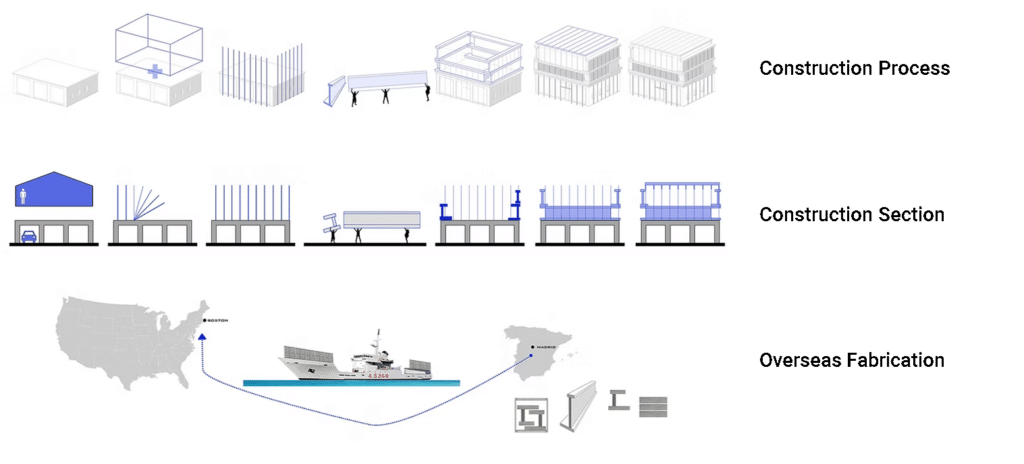

Constructed in 2015, this project was designed by Ensemble Studio and resides in Brookline, Massachusetts.

“Cyclopean House is built, using the vigor of the builder, and the ingenuity of the engineer, to start a journey from the place of its manufacture –Madrid- to the place where it can definitely lie -on top of an existing garage, the ugly duckling of the area.” Why foam? This lightweight construction was used to avoid digging new foundations, or overloading the existing garage.”

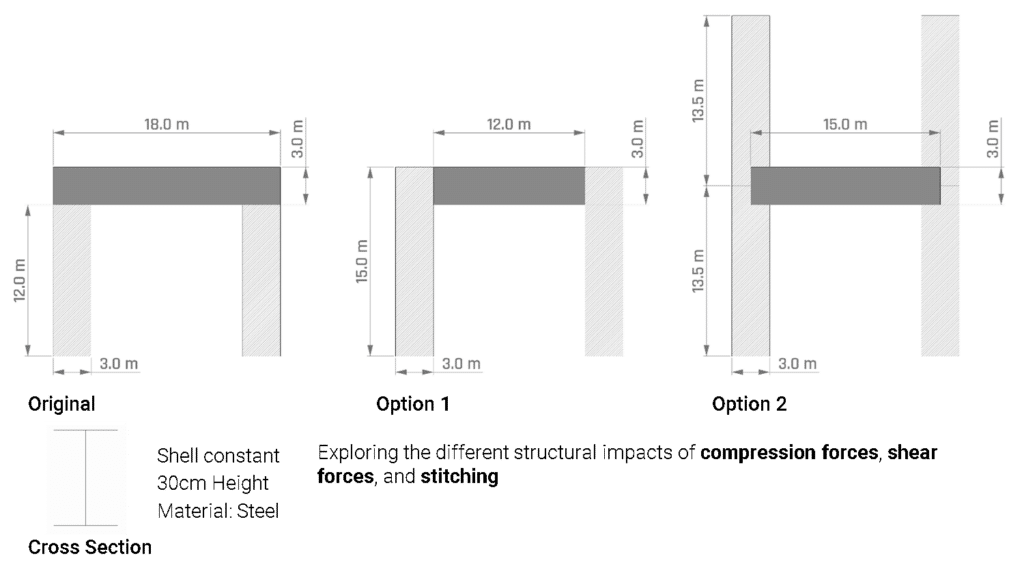

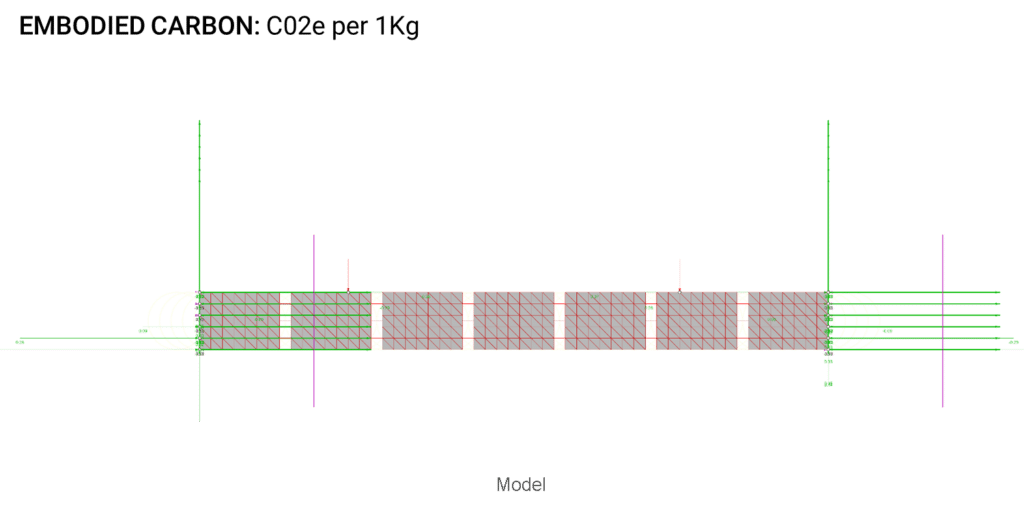

Ideation

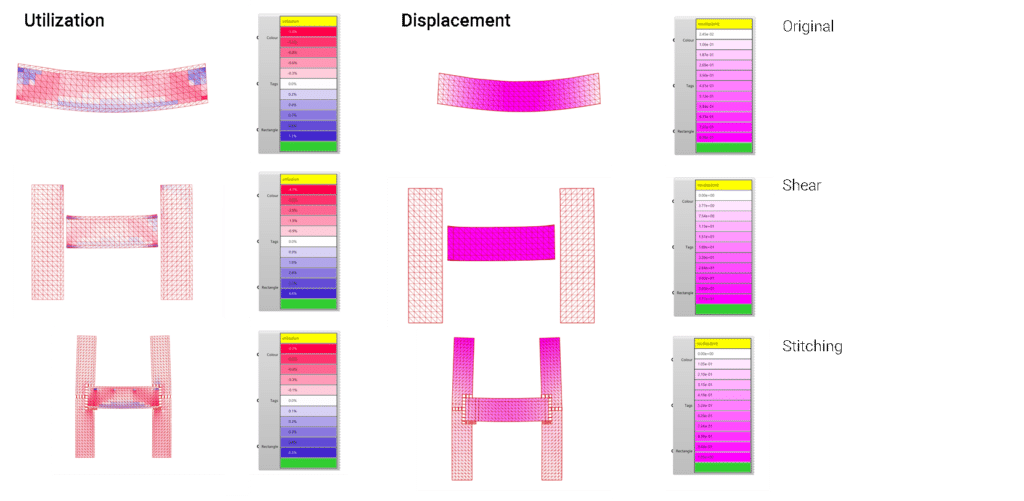

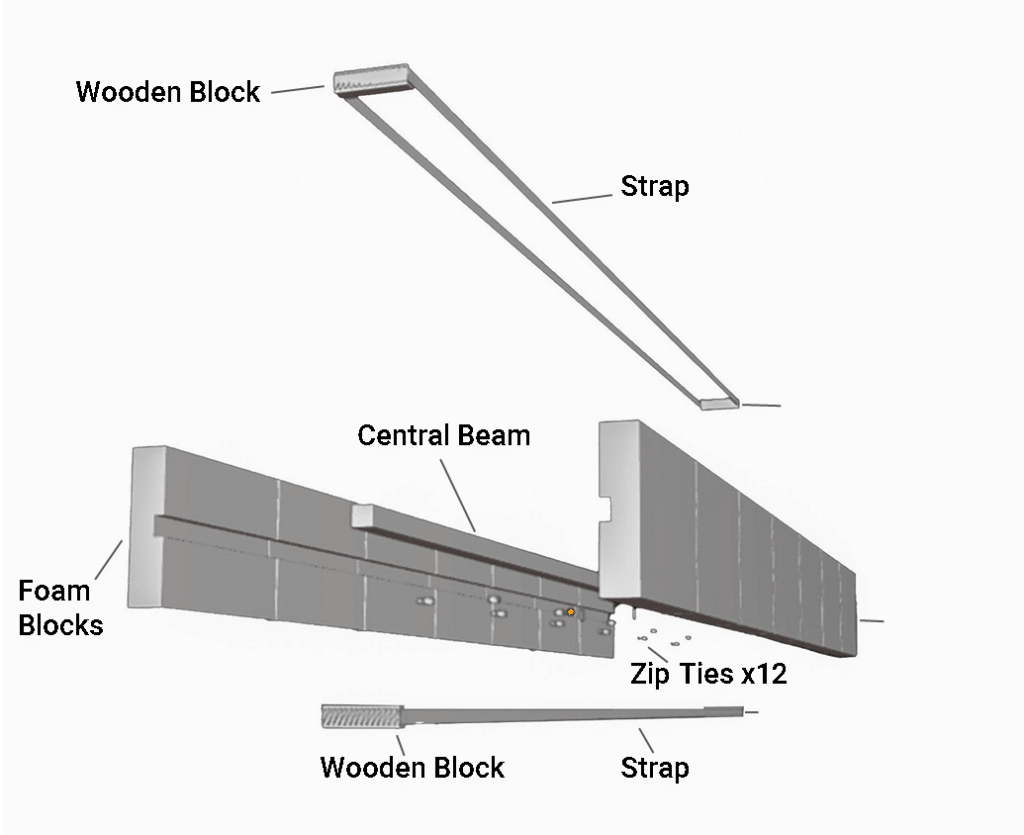

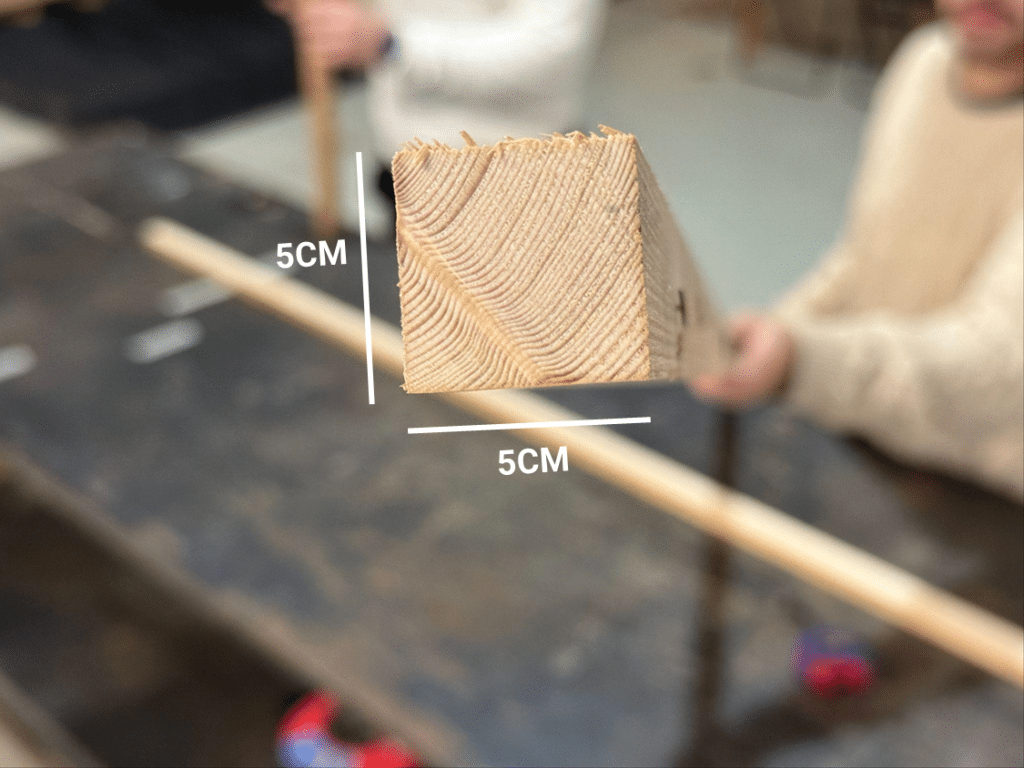

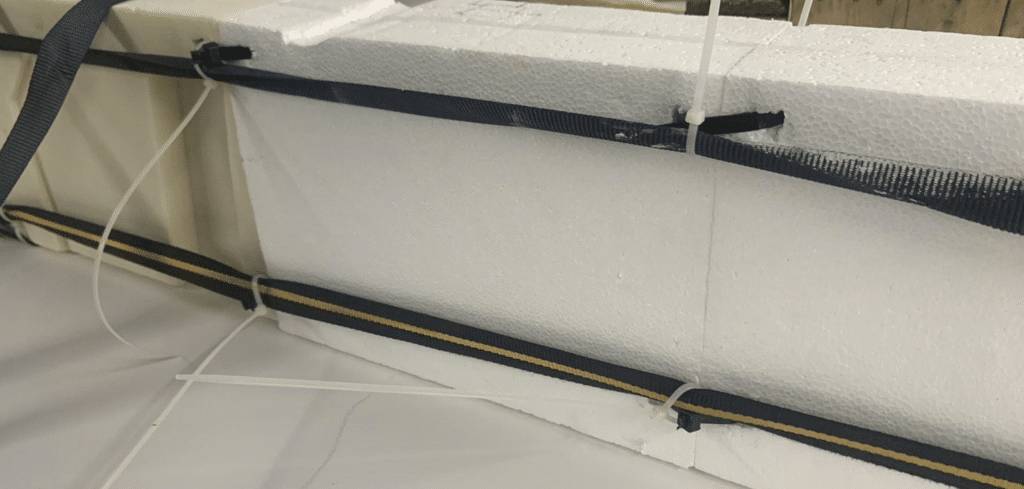

Beam Building + Test

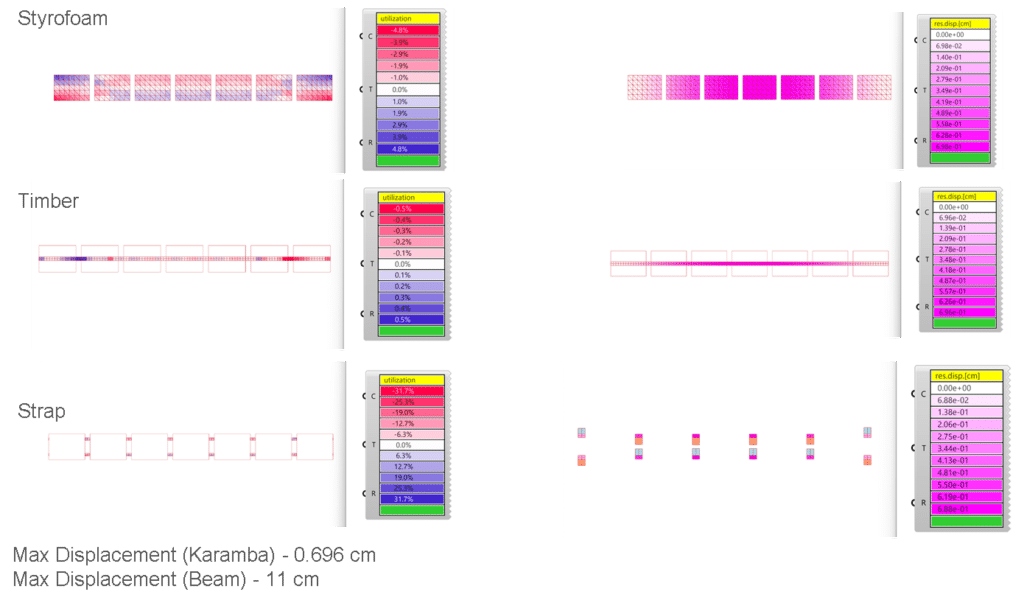

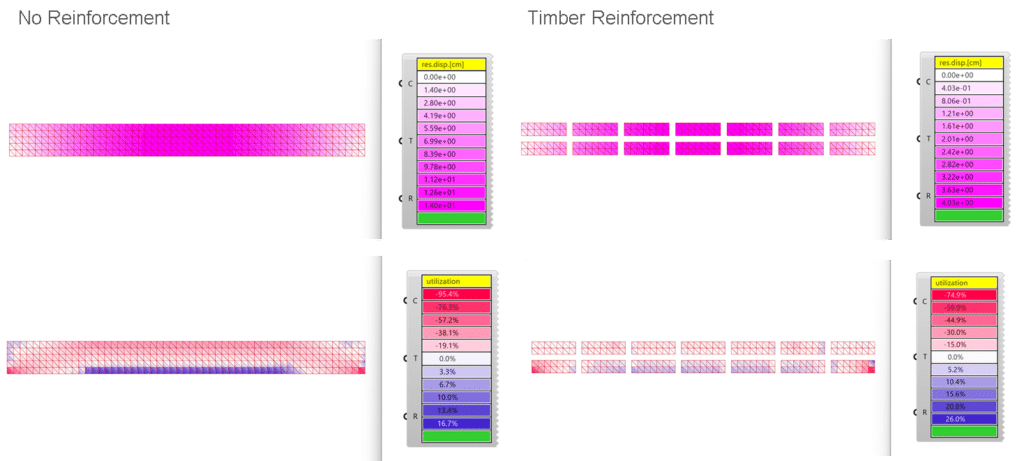

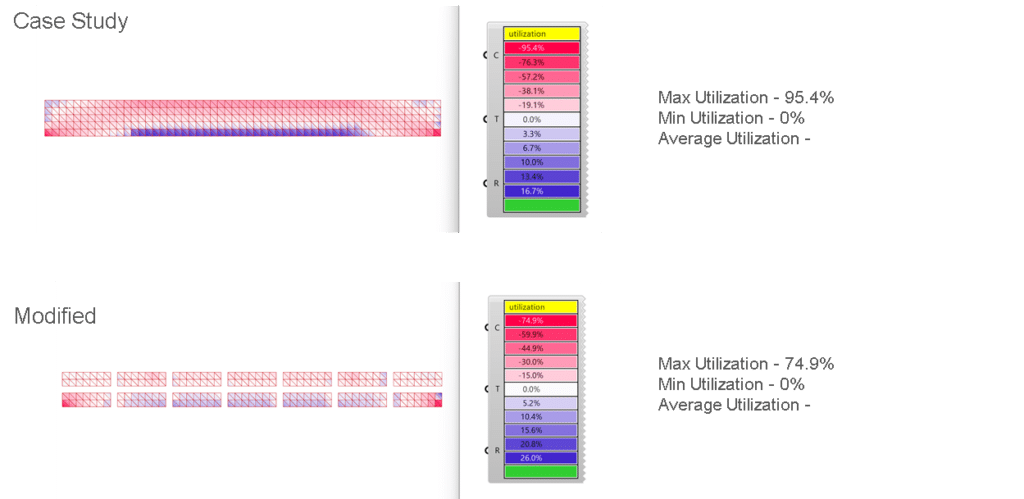

Analysis + Conclusion

We can use the same beam type for the structure!

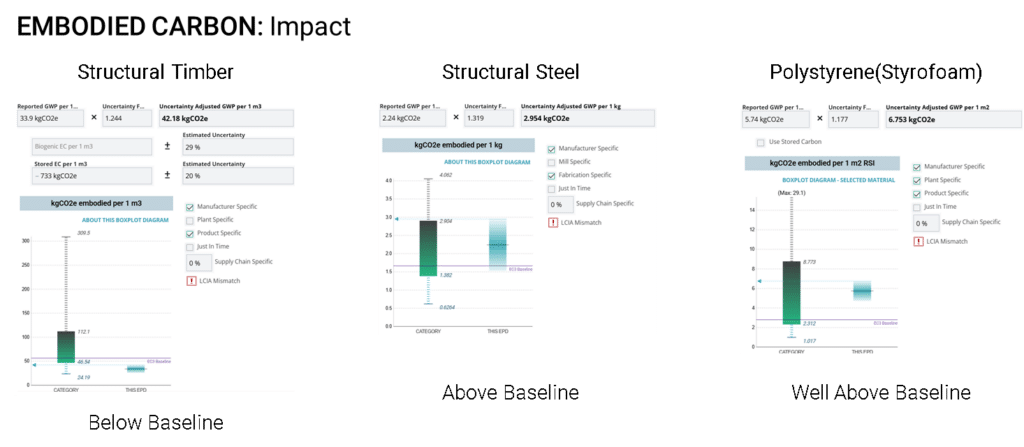

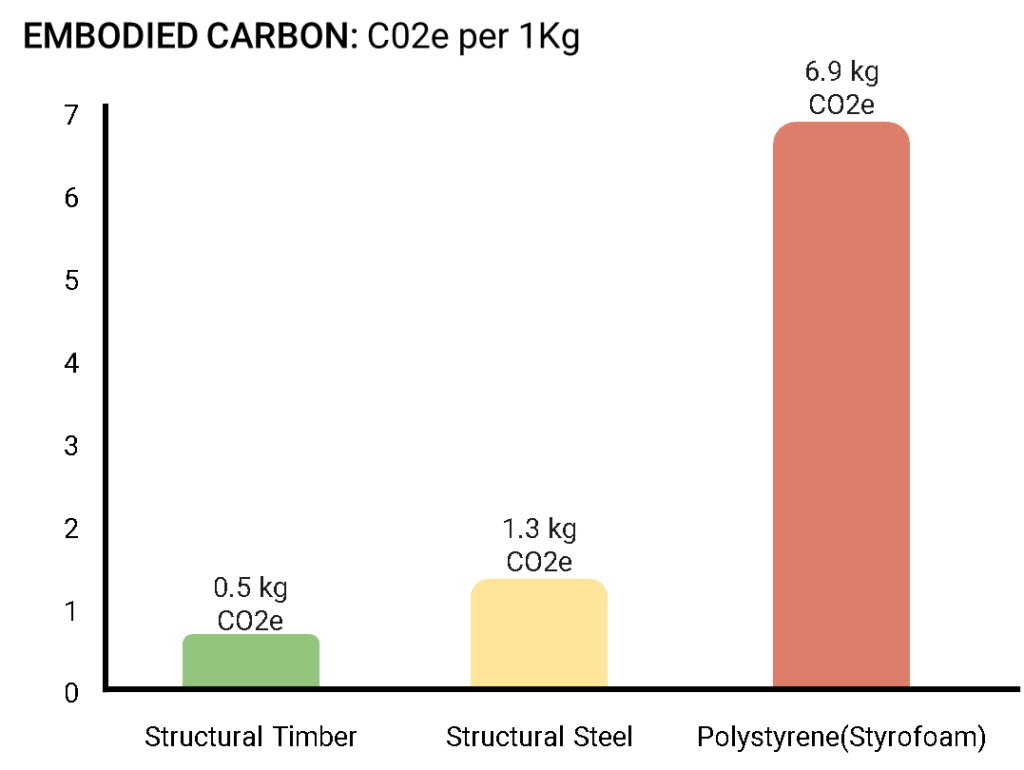

Although the Cyclopean House proves to be a very interesting in theory, if the same concept was applied in commercial use it would most likely NOT be with recycled Polystyrene, creating a much larger carbon footprint than wood or steel.