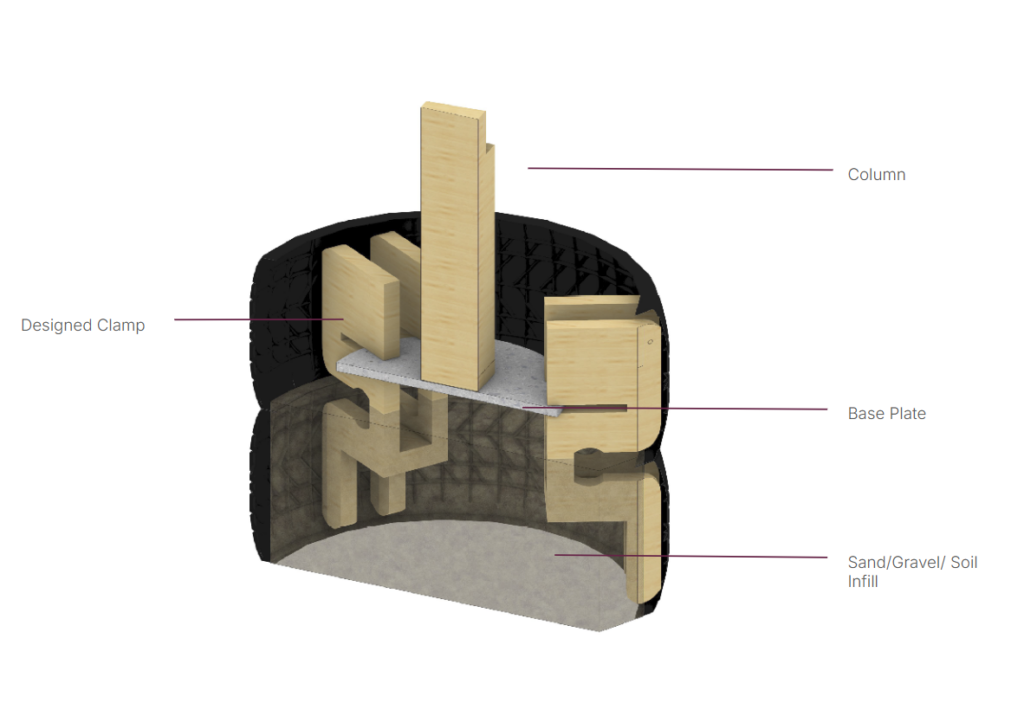

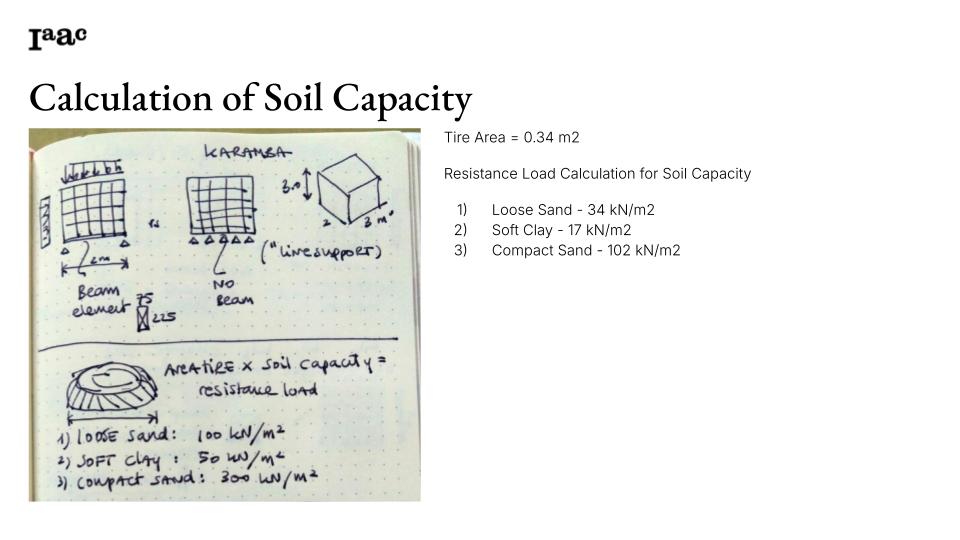

Our project explores the reuse of discarded tires and construction pallet waste in a low-cost, modular foundation and flooring system. The project integrates a stacked tire foundation, where the lower tire distributes load while the upper resists lateral forces and uplift. A custom clamp secures both tires, anchoring a base plate with tolerance for vernacular construction errors. Reclaimed wooden pallets form a suspended floor, maximizing material efficiency. By repurposing waste into structural elements,we aim to promote circular construction, reducing landfill impact while developing an adaptable, resource-conscious building method.

Why Tyre Foundations?

Car tires are used in foundations for their strength, durability, and load distribution, absorbing shocks in unstable soil. Recycling/Reusing them creates a cost-effective, eco-friendly, and resilient foundation while reducing waste.

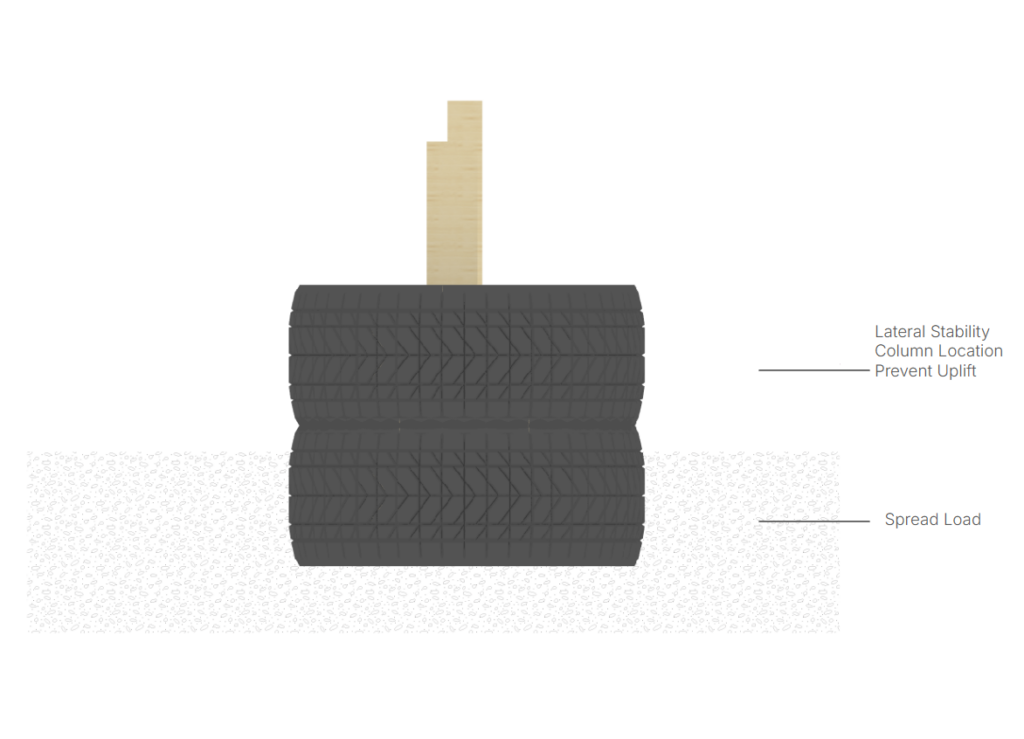

Using two tires instead of one in a tire foundation improves stability and load distribution. The larger surface area reduces pressure on the ground, preventing excessive settling or sinking. Additionally, two tires provide better structural integrity, enhancing the foundation’s strength and durability.

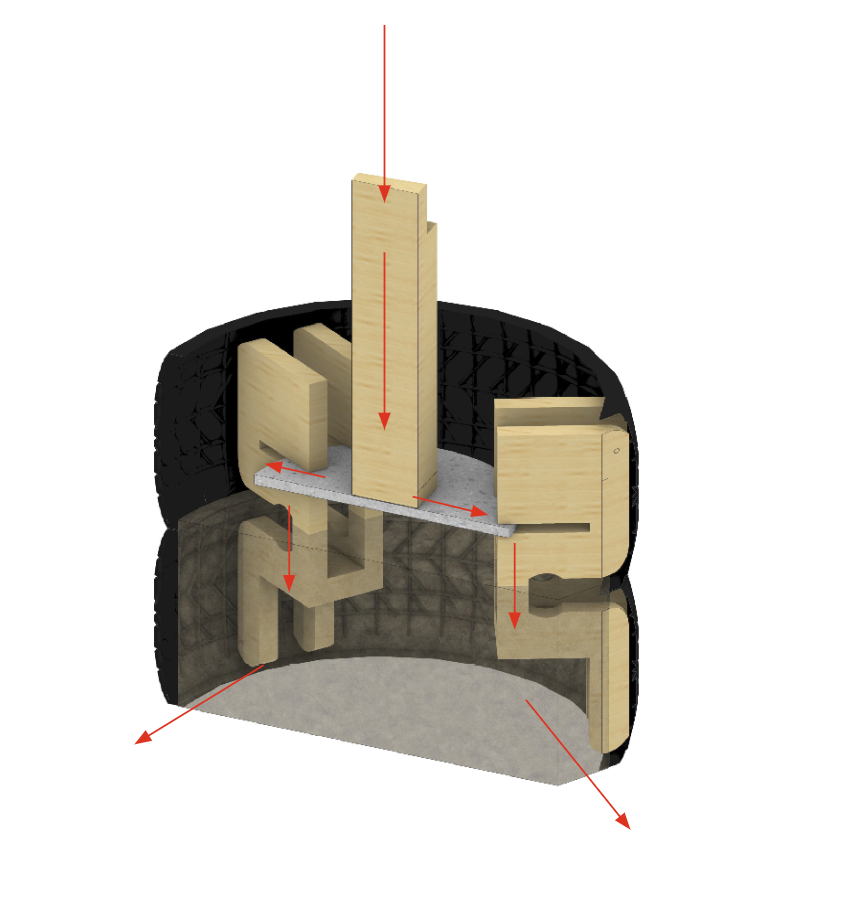

Two tires are stacked, with only the bottom tire buried in the soil. The bottom tire distributes load, while the top tire provides stability, resists lateral wind loads, prevents uplift, and secures the base plate in place. The vertical section of the clamp reinforces the tire structure, maintaining its shape and preventing any deformation under load.

The vertical load is first transferred from the column to the base plate, which serves as the primary connection point. From there, the load is distributed to the clamp, ensuring a secure transfer of forces. Finally, the clamp directs the load into the ground, providing stability and structural support to the foundation.

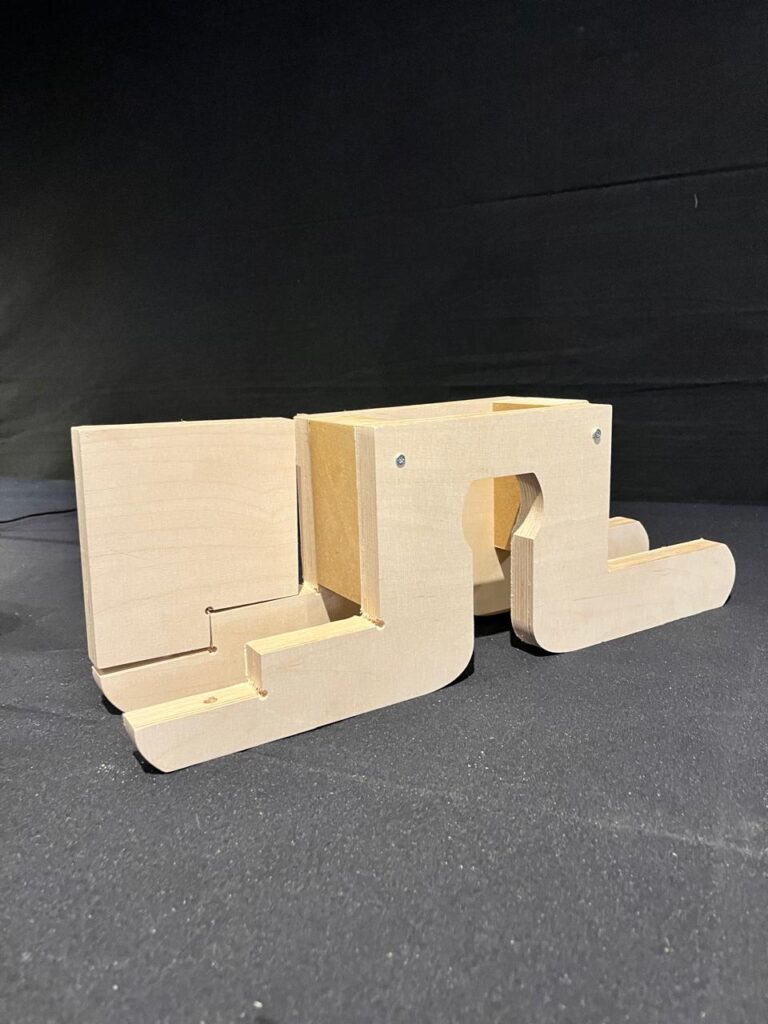

Clamp Design

The clamp has three main functions:

1 Holding both tires together and resisting shear forces as they try to slide apart—one fixed in soil, the other resisting lateral wind loads.

2 Resisting uplift with a detachable upper hinge that locks in after the base plate is placed.

3 Providing anchorage for the column base plate with a 10 cm positioning tolerance, to allow for typical errors in low-cost vernacular construction.

Clamp Shear Testing

Based on our calculations of the loads, the clamp is required to resist 4kN. It’s failure at 30 kN proves that the design is successful in resisting the required load. Additionally, it is important to note that three clamps are installed per tyre.

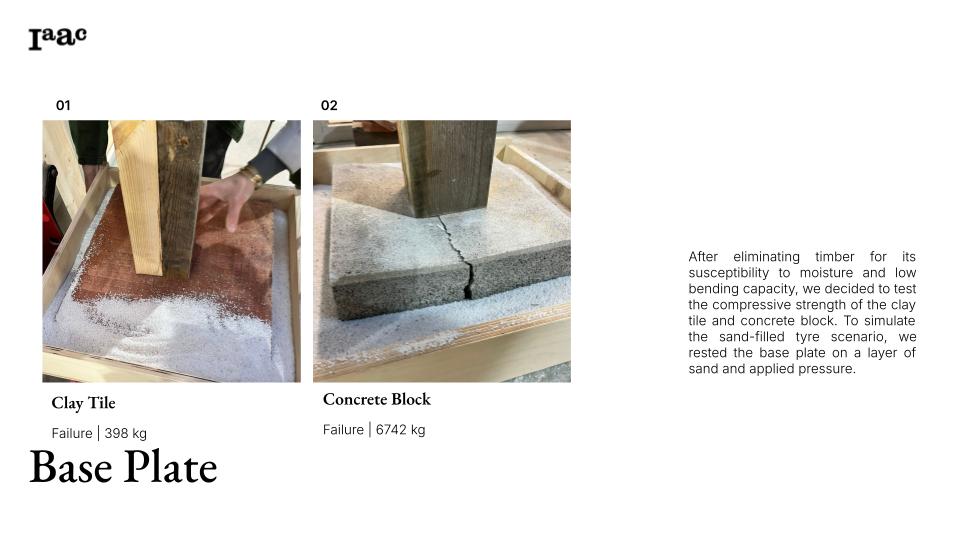

Timber Plate

Failure | 730 kg

Clay Tile

Failure | 46 kg

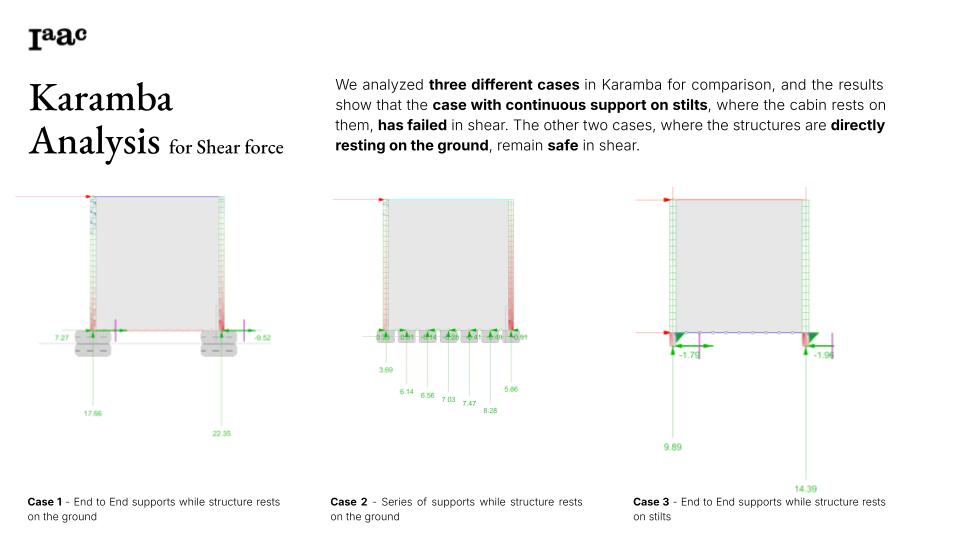

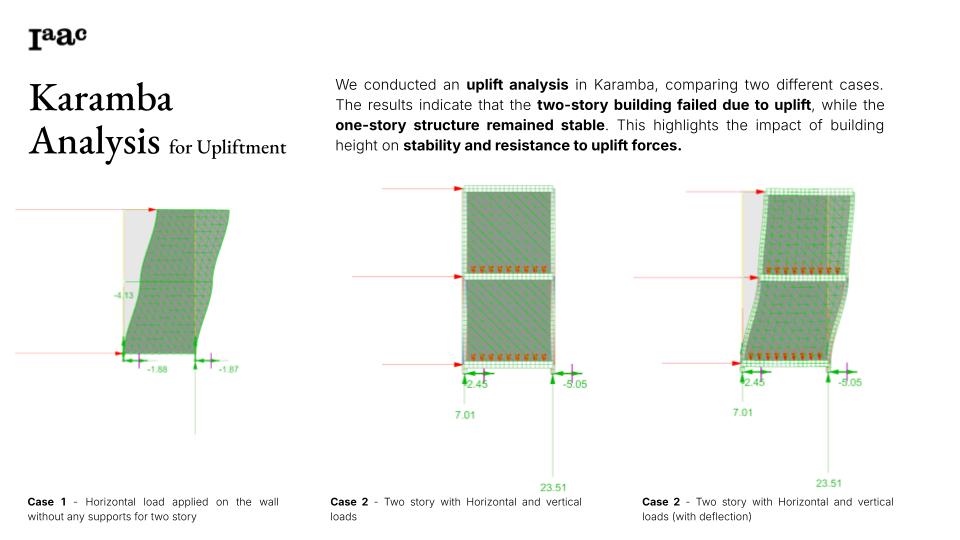

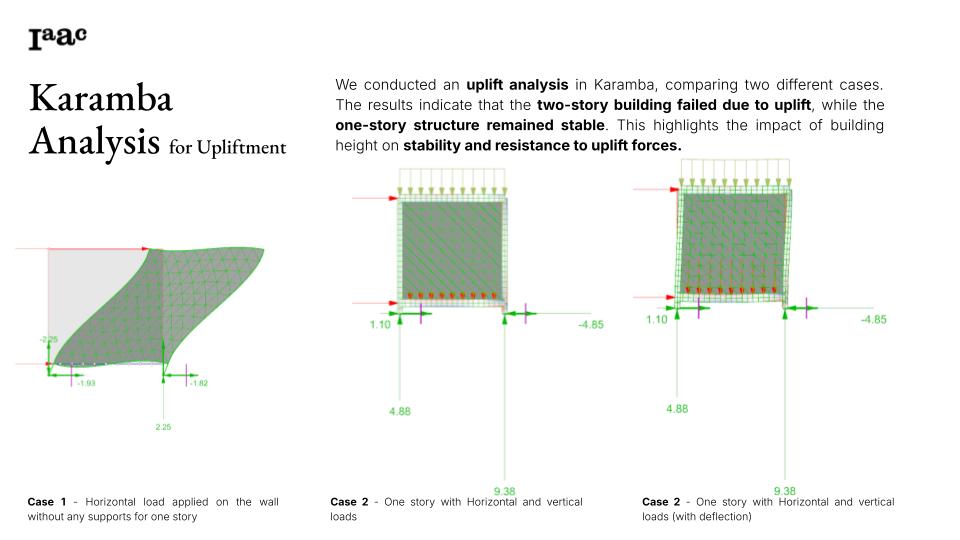

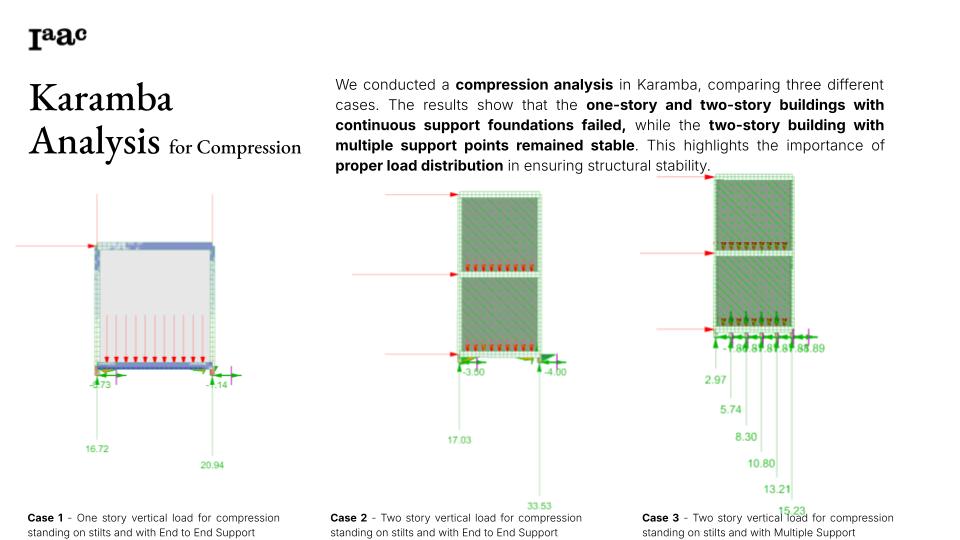

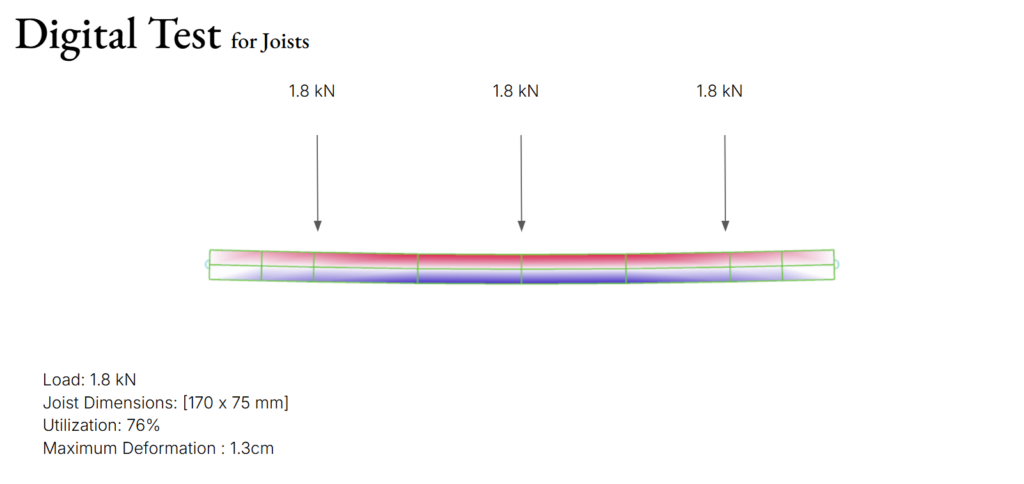

Karamba Analysis

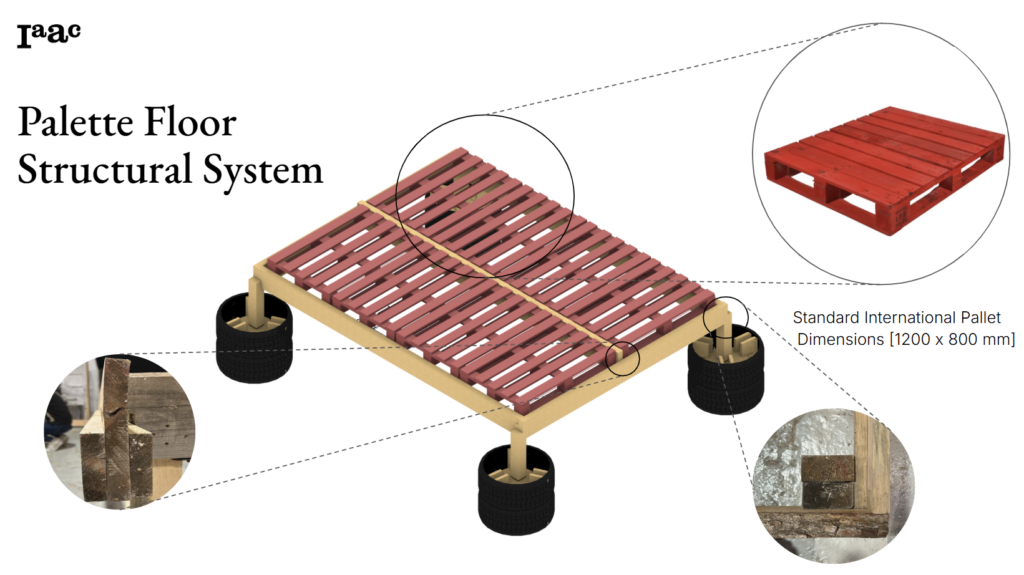

Palette Floor System

Why Palettes?

Over 90% of wooden pallets are discarded after a single use. Reusing them in structural applications reduces landfill waste and supports circular building practices. Instead of discarding or downcycling, we propose repurposing pallets as a structural floor system, utilizing their modular strength to achieve larger beam spans and optimize material efficiency

Gallery