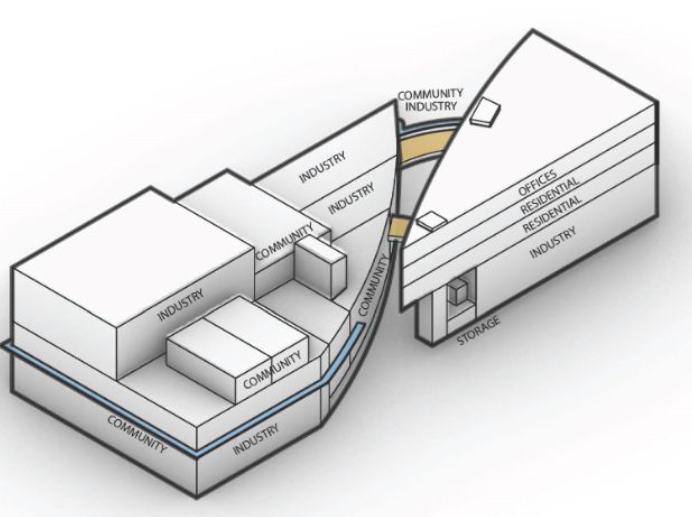

NAME: The Treeline – Sawmill Factory, with office, community and residential spaces

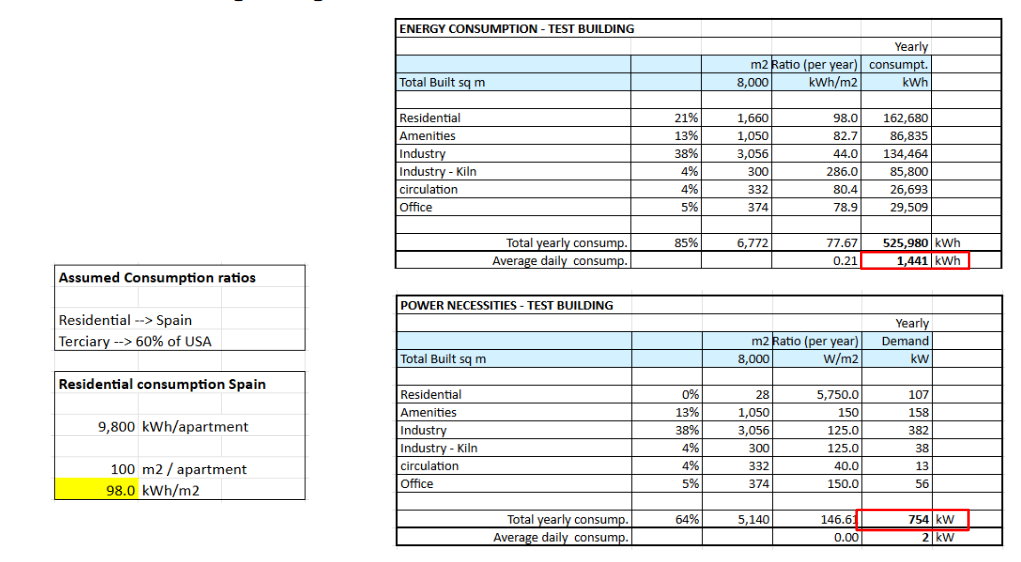

Energy Consumption and Power Necessities

Approach

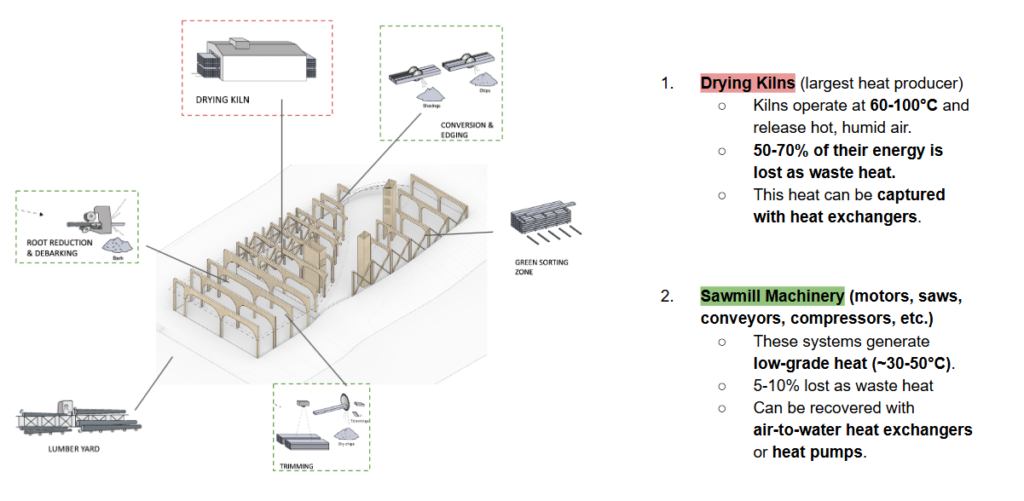

To align with the overarching sustainability values of our project, we approached the Energy Design module with the goal of reducing our carbon footprint while enhancing self-sufficiency. A key part of our strategy was to optimize energy performance by leveraging solar potential, utilizing biomass from our sawmill factory’s waste products (such as dust and offcuts) to generate thermal energy, and evaluating the implementation of a heat recovery system to harness excess heat from the sawmill

machinery.

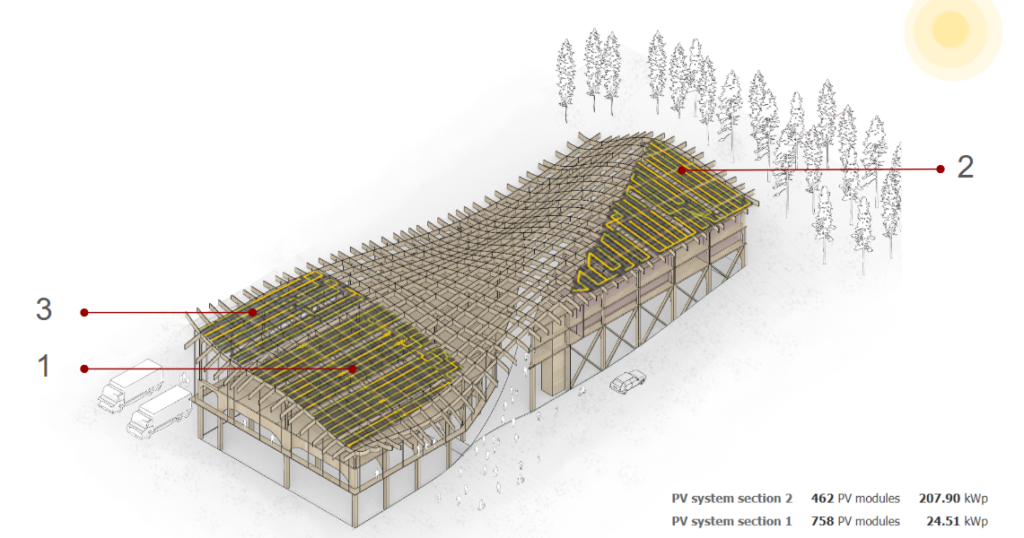

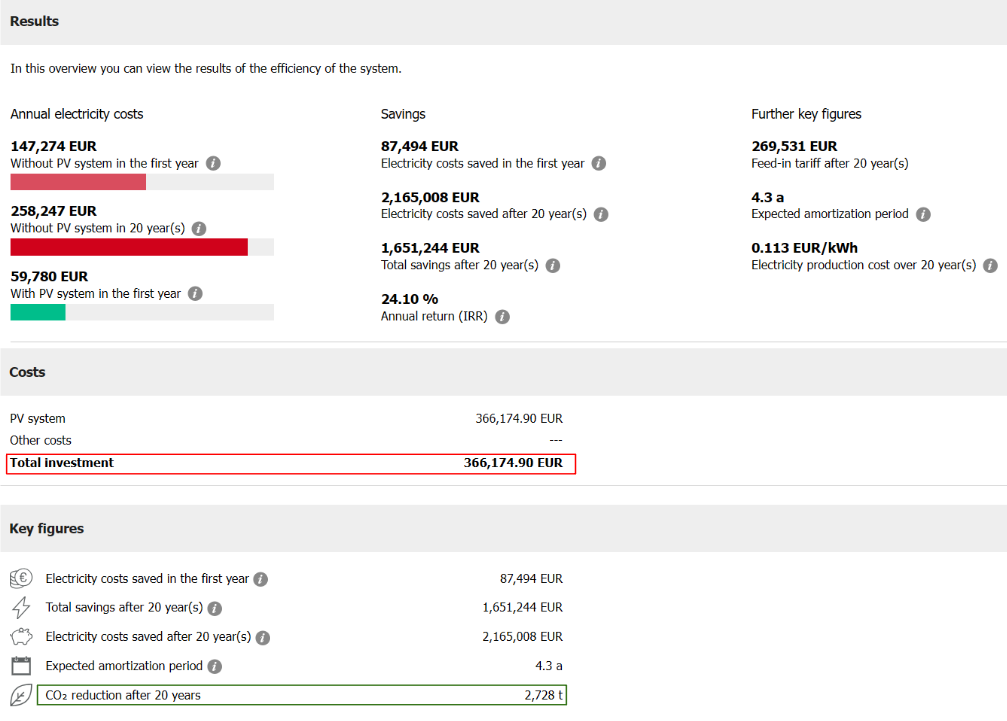

Photovoltaic Panels

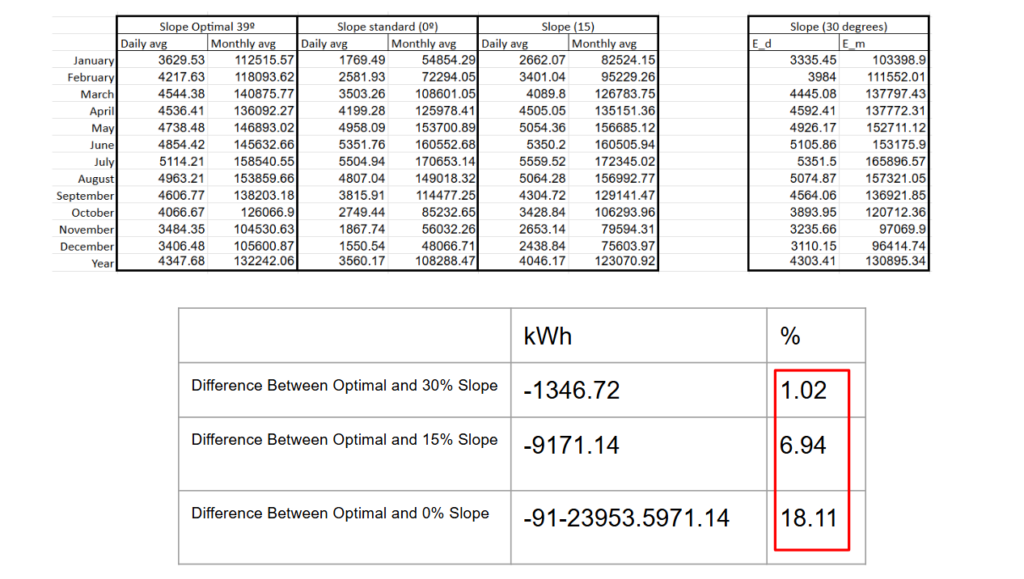

We compared the optimal slope (39°) for solar panels with the feasible installation angles on our curved roof (0° and 15°).

Sunny Design details

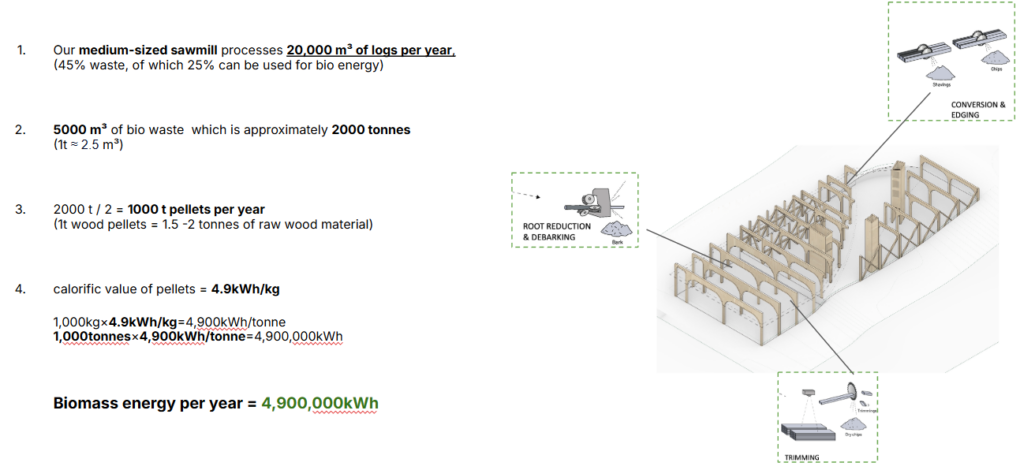

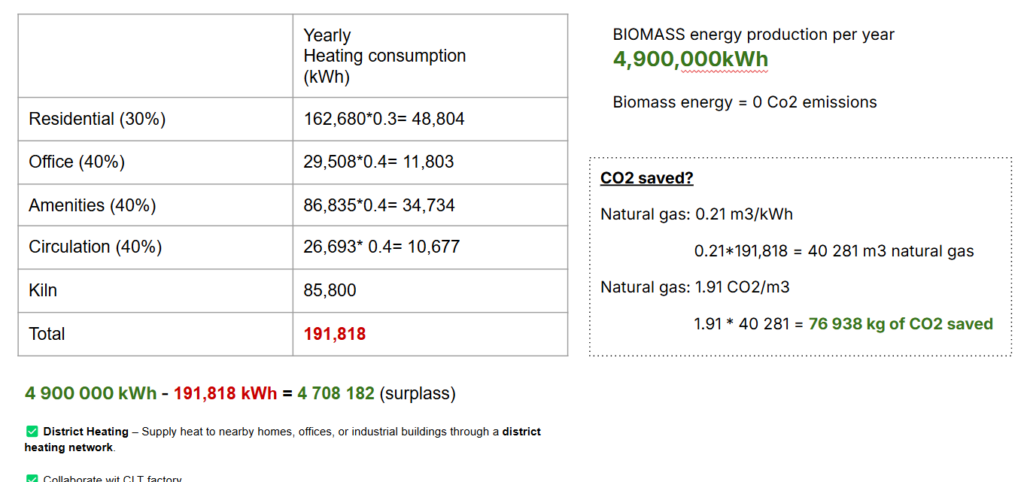

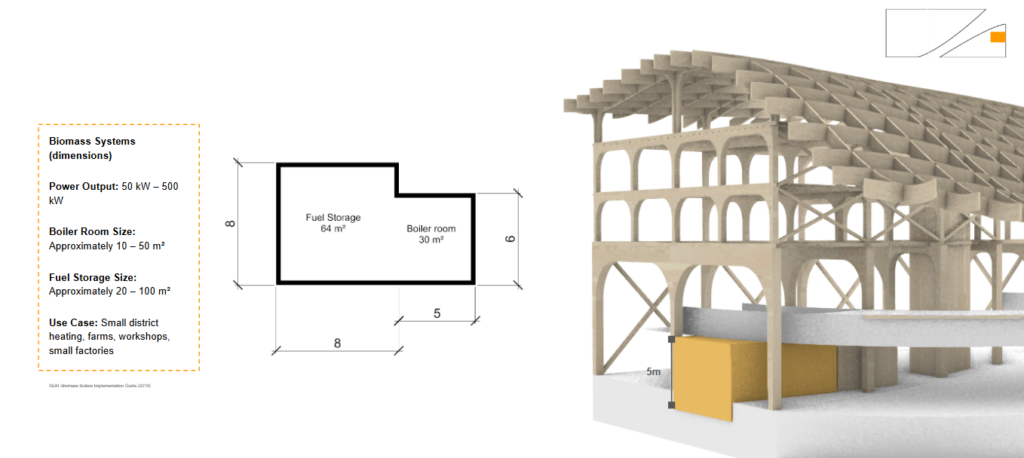

Biomass

Sawmills generate significant amounts of waste as part of the wood processing process, with up to 50% of the original material becoming byproducts. Interestingly, around 25% of this waste can be repurposed for biomass energy, providing a valuable resource to help power our building and machinery.

To ensure a sustainable energy supply, we plan to send our sawmill waste products to a specialized company where they will be processed into pellets. These pellets will then be used to fuel our biomass system, contributing to the energy needs of the project while minimizing waste and supporting a circular energy model.

With the 4,900,000 kWh of energy we generate, we are in a strong position to collaborate with the CLT factory located on the same plot. By using the energy produced from our biomass and heat recovery systems, we aim to create a self-sustainable industry, where the factory can process timber using its own generated energy. This collaboration not only reduces our environmental impact but also strengthens the circular economy within our operations, ensuring that both facilities contribute to each other’s energy needs.

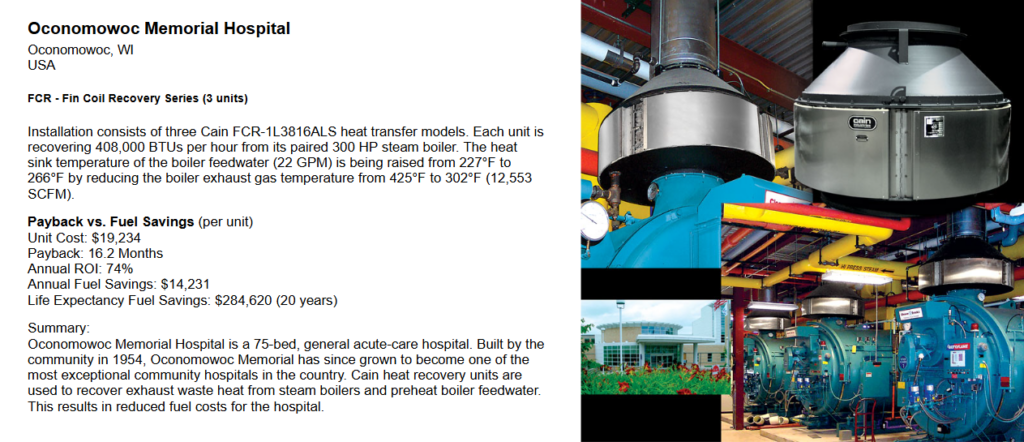

Heat Recovery System

We explored the possibility of implementing a heat recovery system for our project, recognizing that the machinery in our sawmill generates a significant amount of excess heat that could be repurposed. To better understand how to capture and reuse this energy, we researched various case studies where heat recovery systems have been successfully implemented using heat exchangers. This strategy not only reduces energy waste but also enhances the overall sustainability of our operations by making use of what would otherwise be lost heat. Finding precise number to understand how much energy we would generate is unclear.