KINXA aims to bring vernacular construction back into contemporary architecture by systemizing traditional “quincha”. At the same time, through a redesigned material system, KINXA seeks to take advantage of local resources and lower even more its precedent carbon footprint.

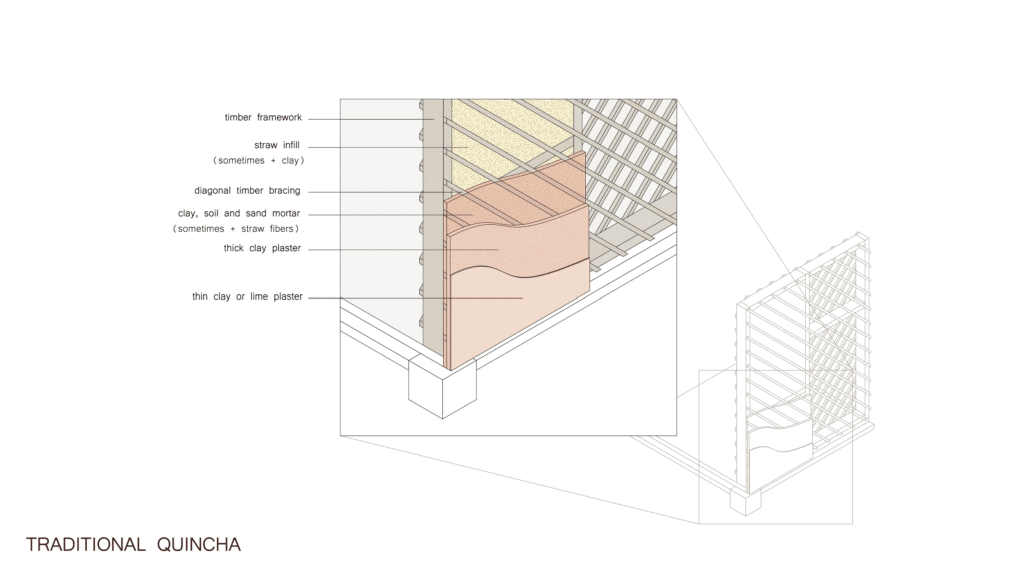

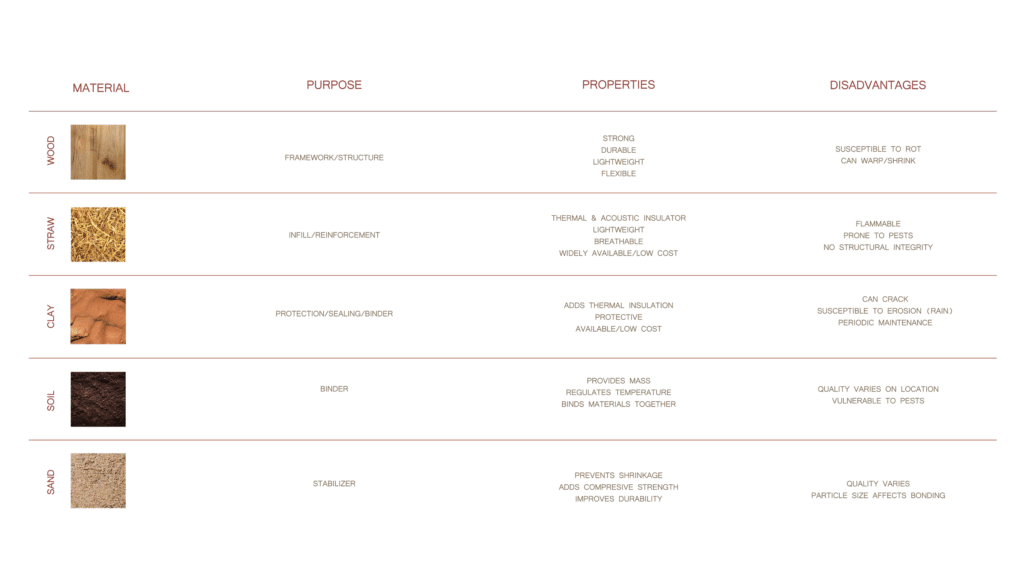

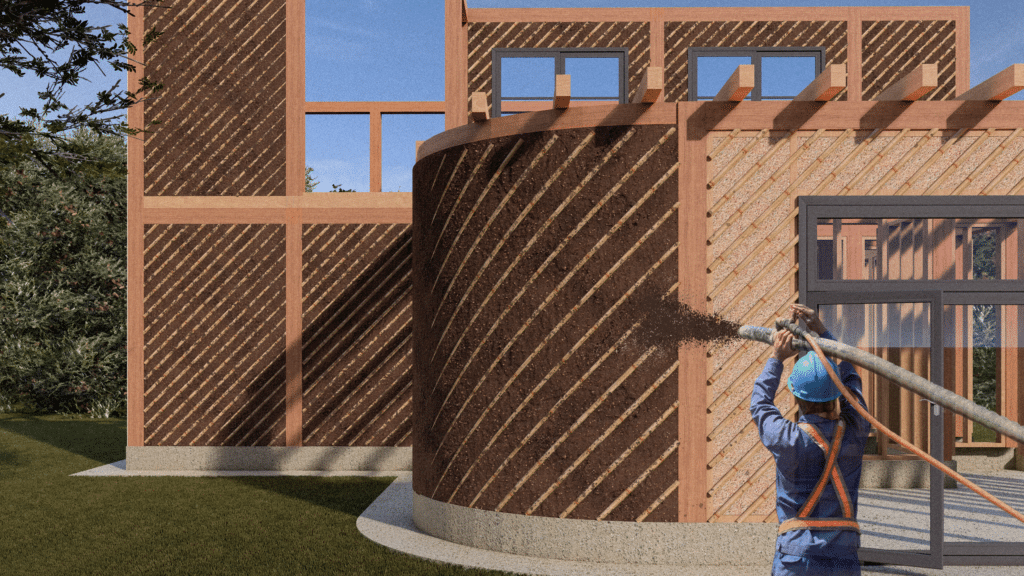

Quincha is a technique prevalent in Latin America which consists of the use of a wood or cane frame, with a fiber infill which is then covered with a soil and clay mixture.

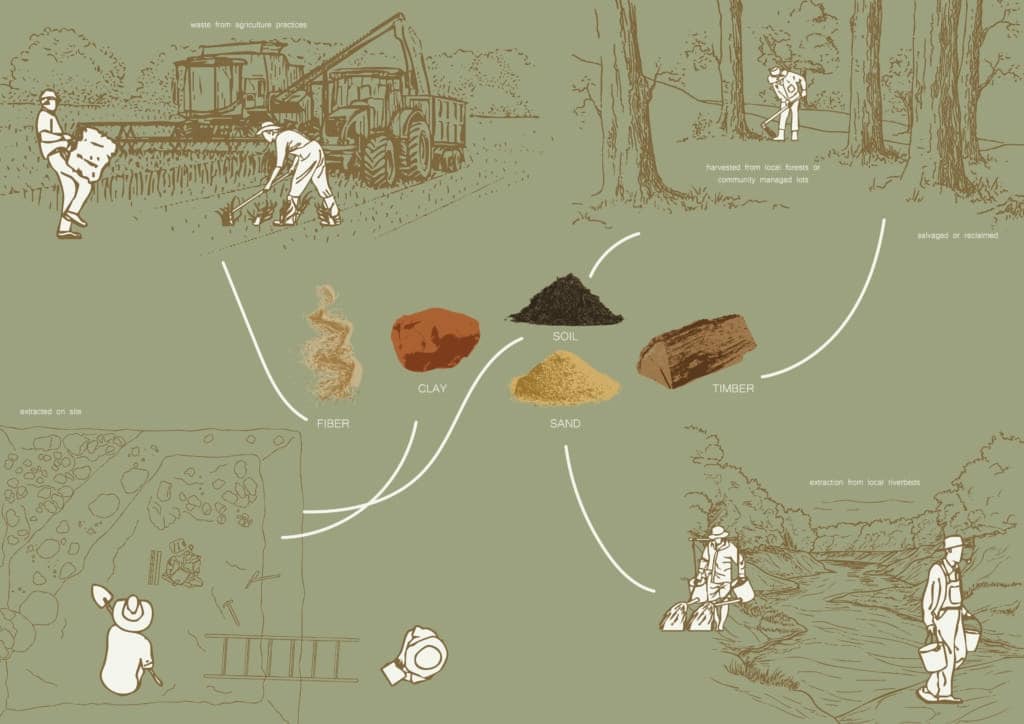

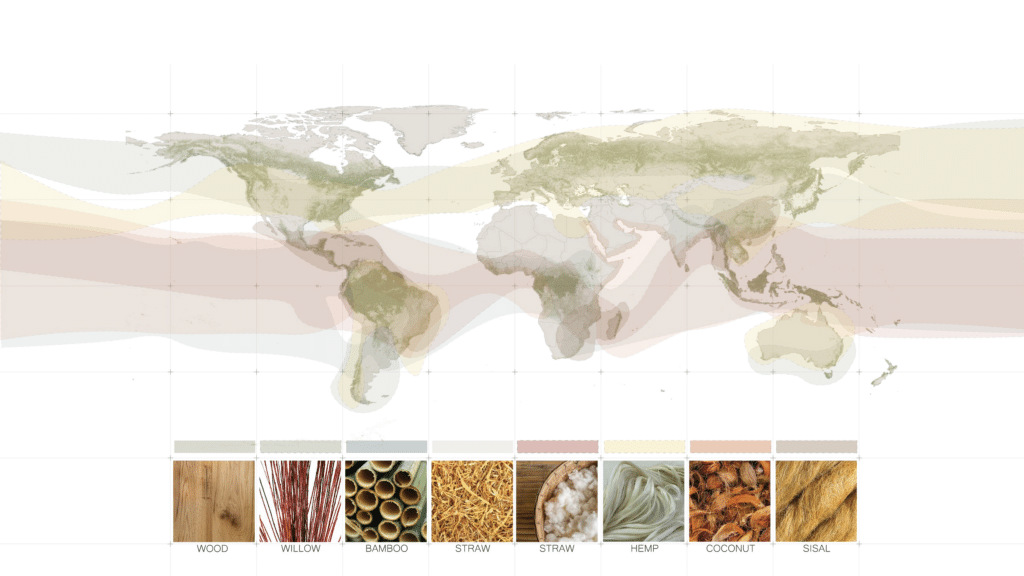

Quincha materials are typically locally sourced, natural, and renewable. Wood or bamboo comes from managed forests, plantations, or reclaimed timber. Straw, a common infill, is an agricultural byproduct, though other regional fibers can be used. Clay and soil are often dug on-site or bought locally, while sand comes from riverbeds, quarries, or suppliers.

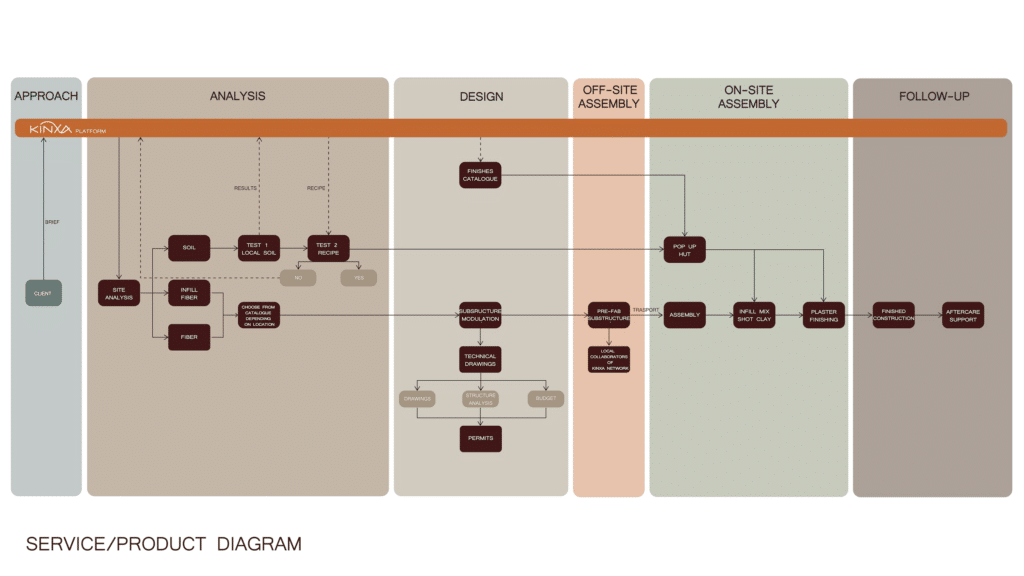

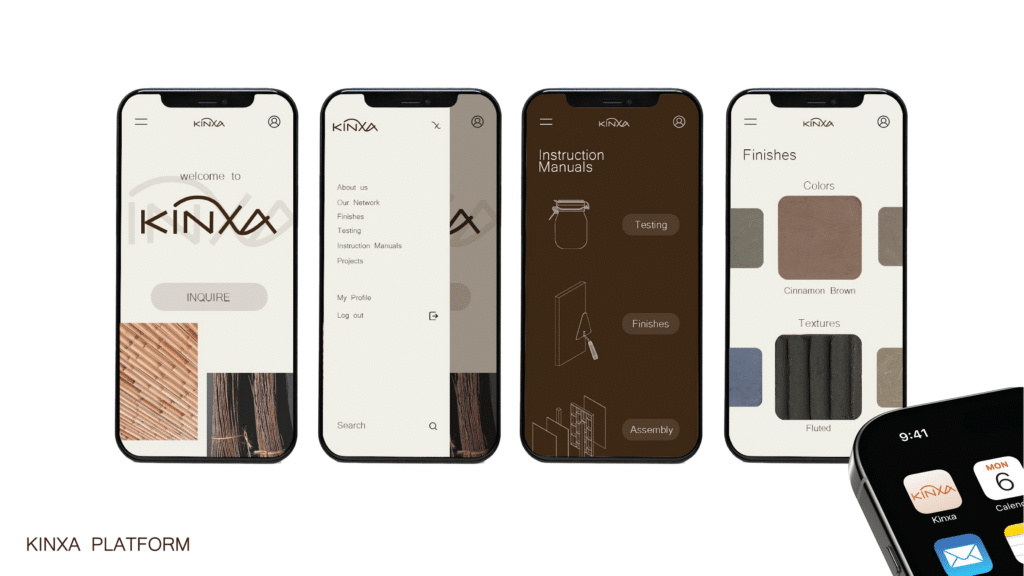

KINXA is a service that aims to bring vernacular construction back into contemporary architecture by systemizing traditional “quincha”. It is a platform that bridges the company to the client in every stage of the process.

On the platform our clients can find the construction manuals, catalogues, and chat with our team at any given time.

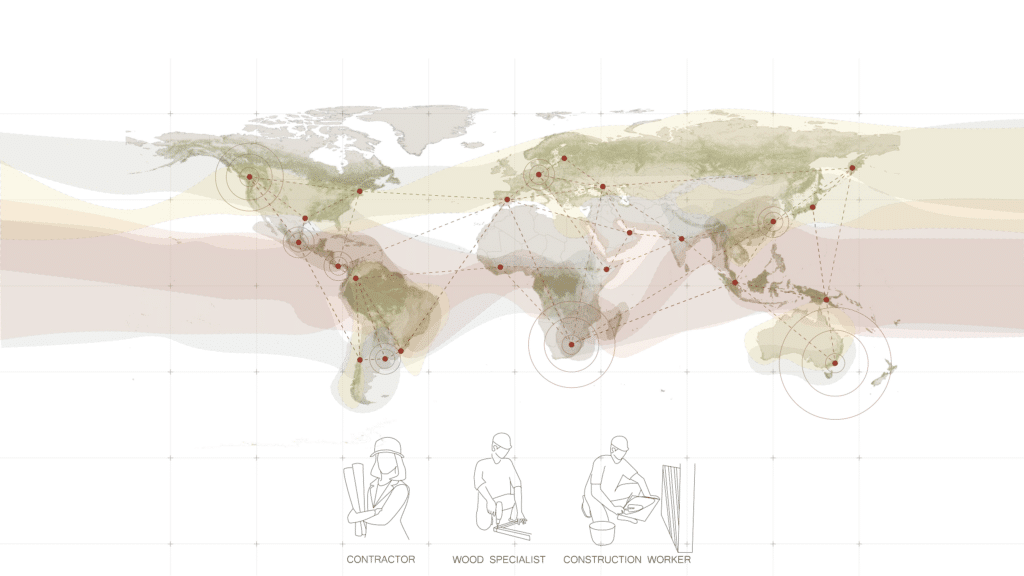

As with traditional quincha, we want to continue sourcing local materials for our projects. Therefore each project will vary depending on your location and material availability.

KINXA will be able to work on a global level thanks to our network of collaborators, including contractors, wood specialists and construction workers.

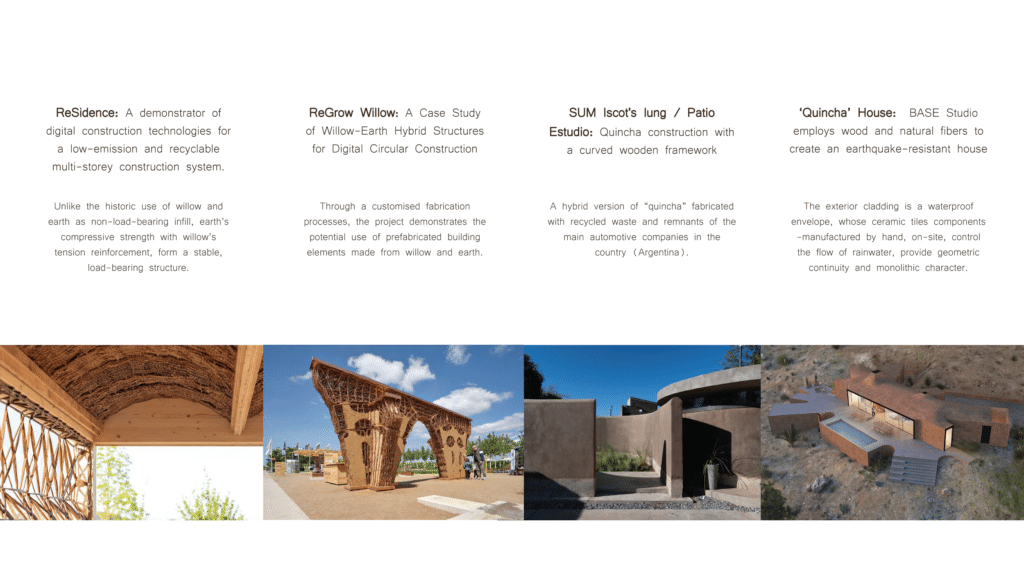

State of the Art – In designing our own version of this technique, we drew inspiration from some projects that implement fiber weaving or novel ways of working with wood and clay.

OUR PROPOSAL

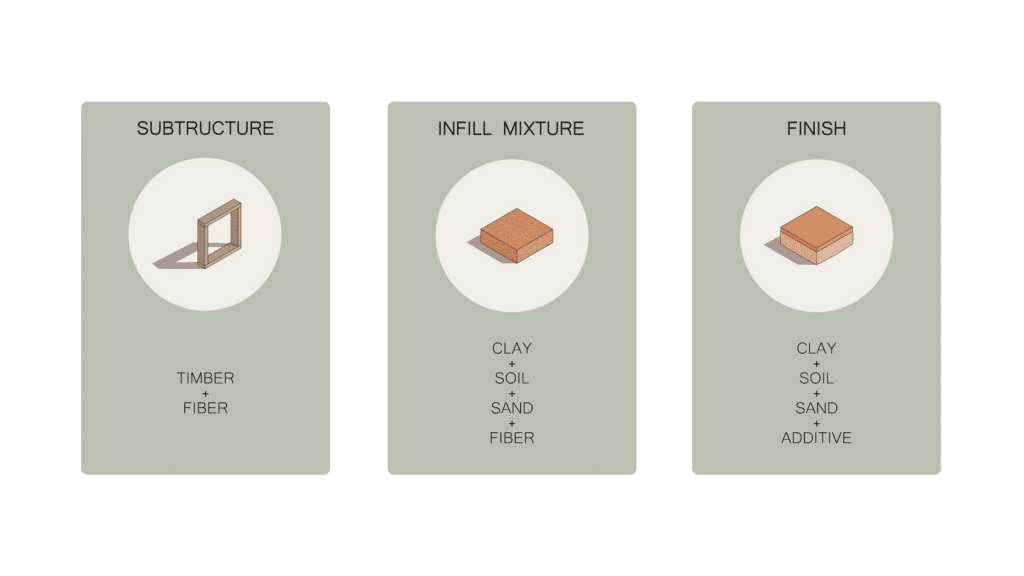

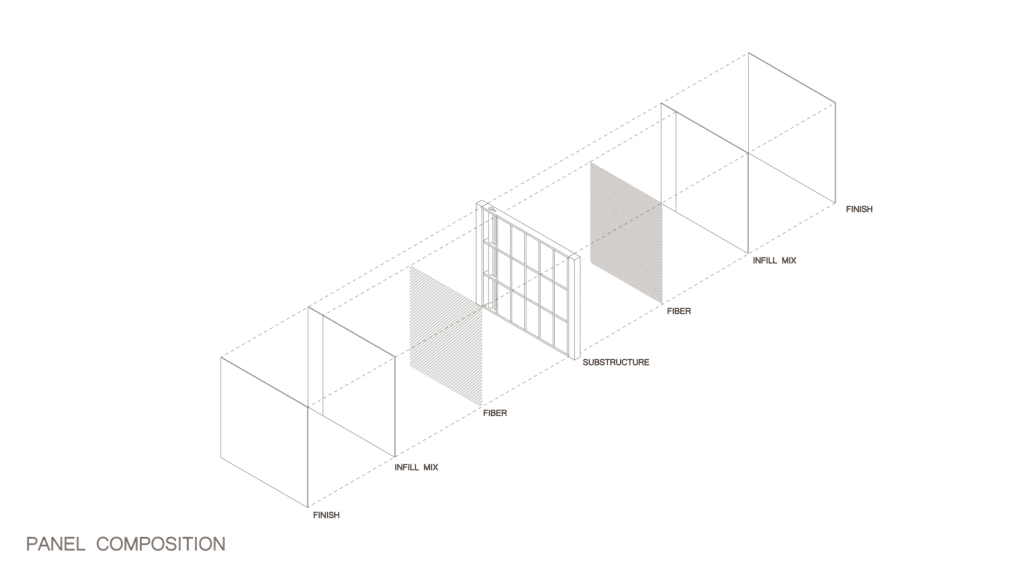

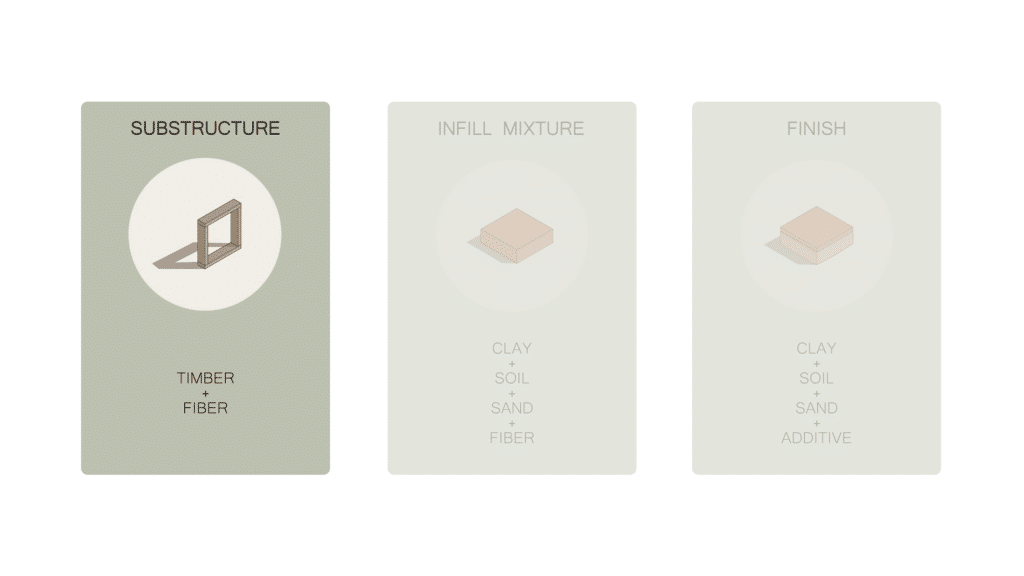

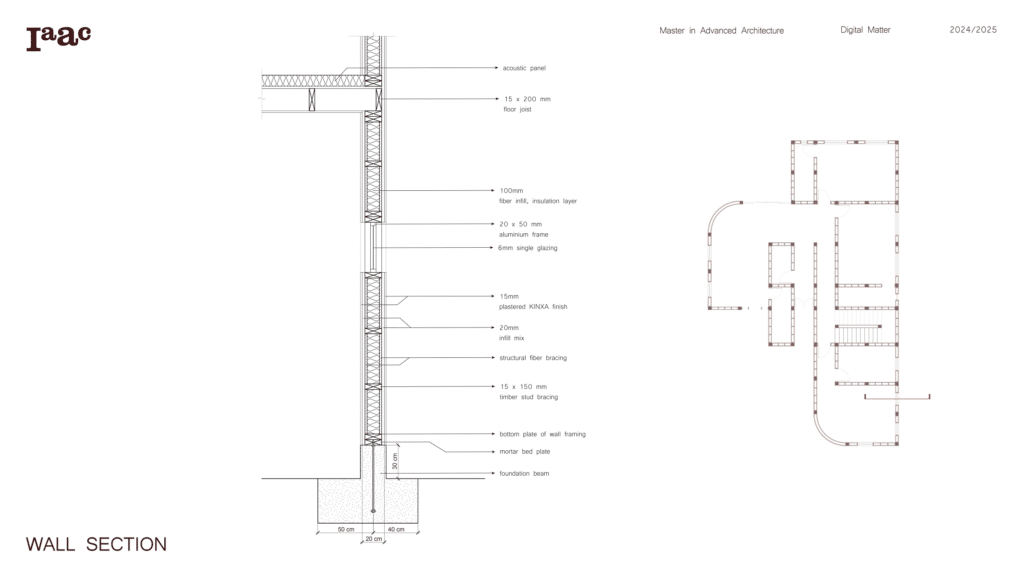

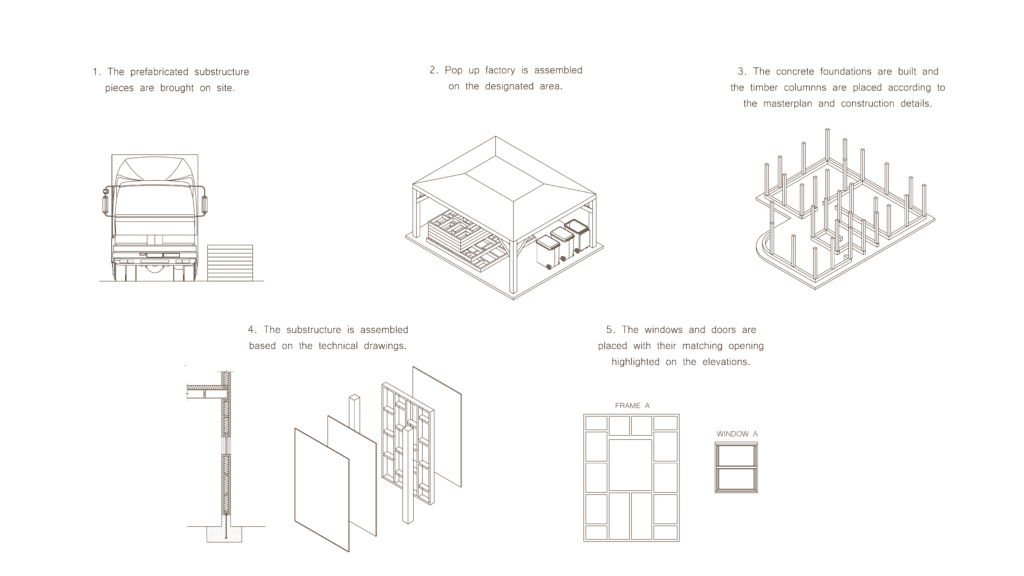

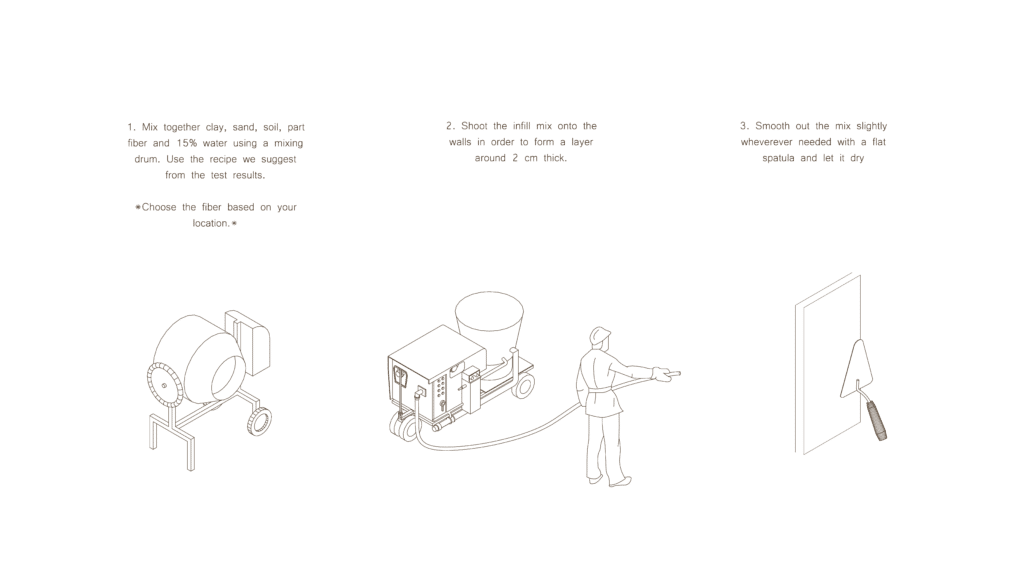

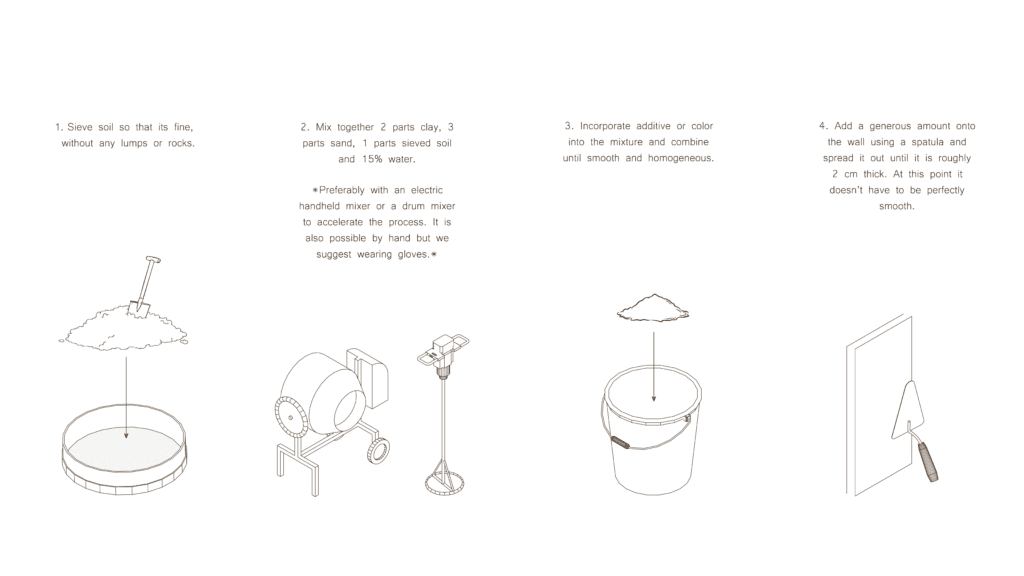

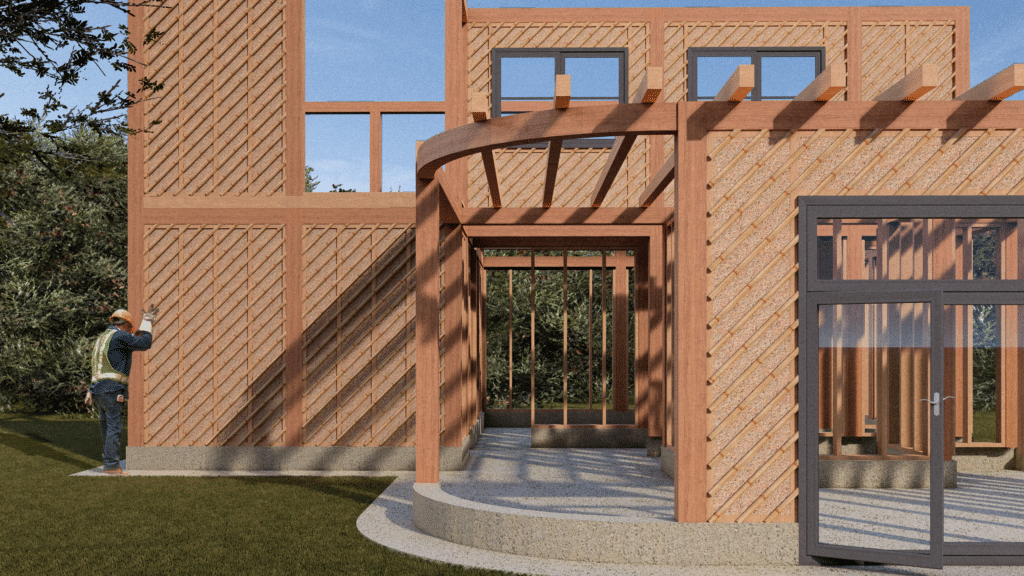

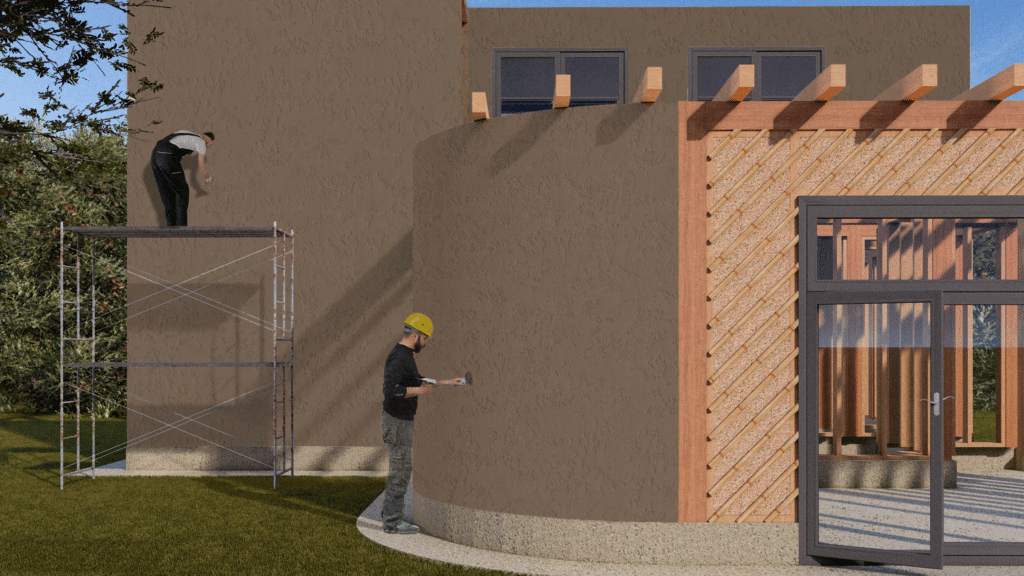

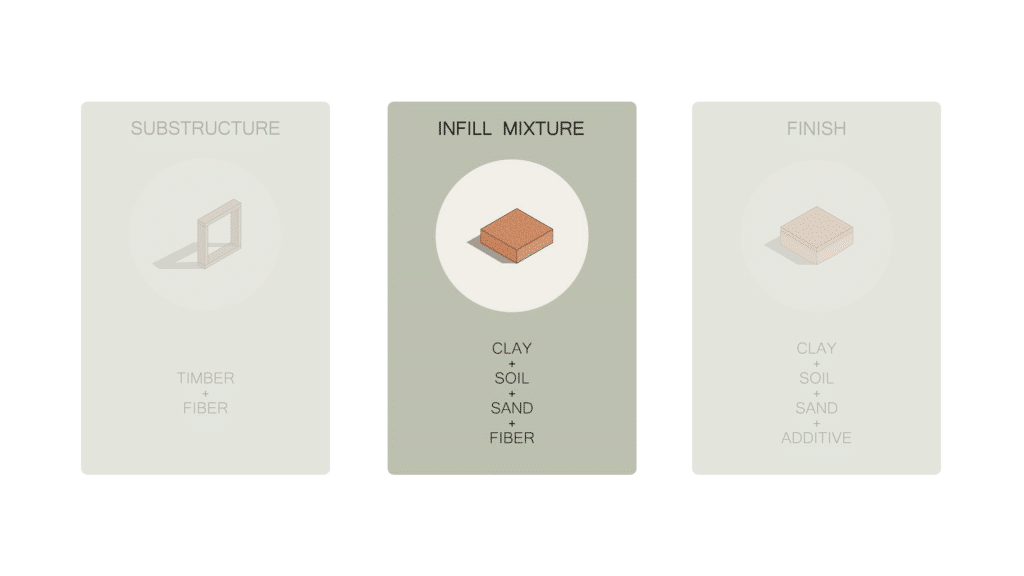

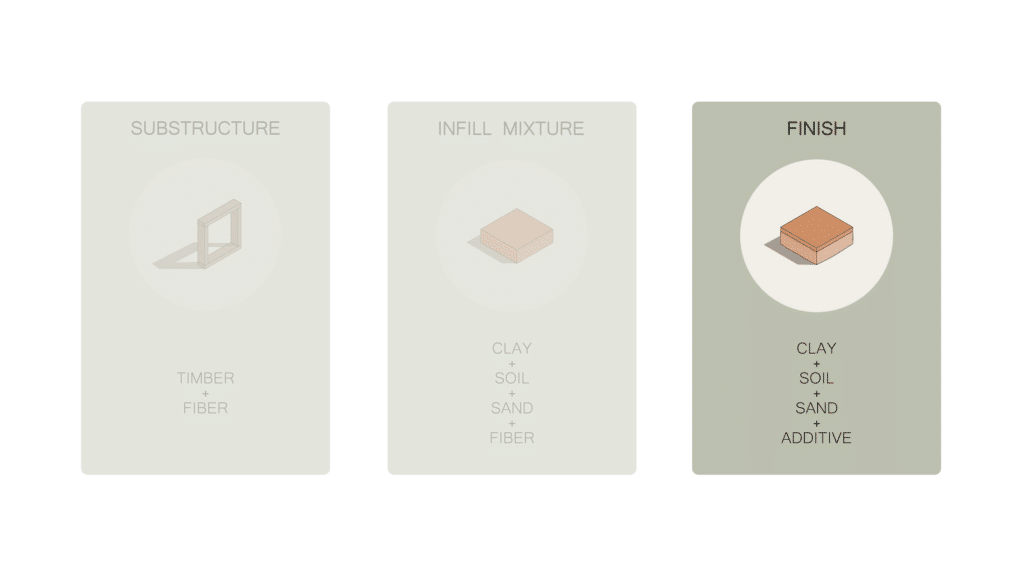

We then stepped into the creation of our own material system: Customized prefabricated panels which are plastered on site. The entire system consists of 3 main elements: a substructure, an infill mix and a finish.

Although each panel can be unique, they all have the same composition.

SUBSTRUCTURE DESIGN

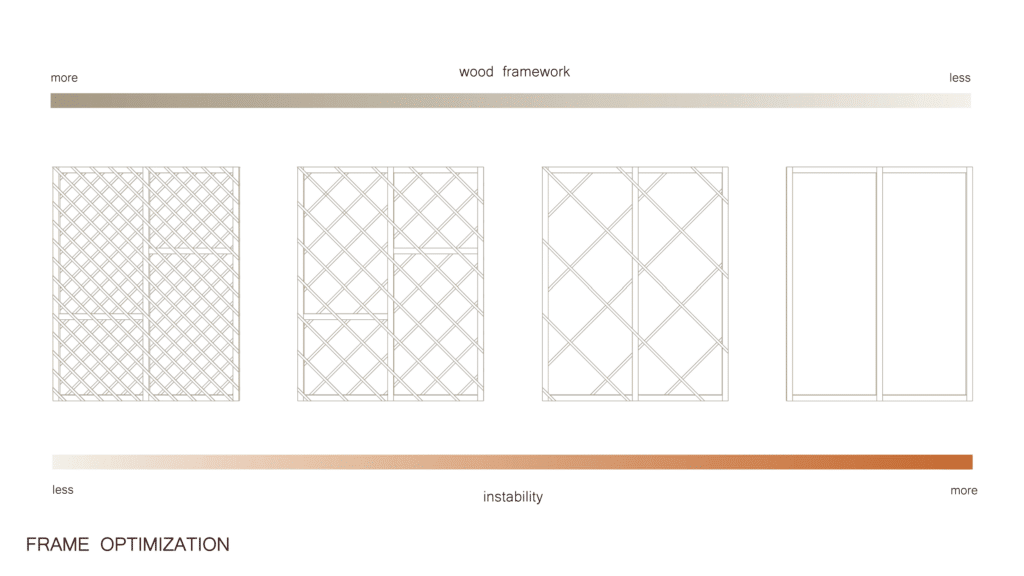

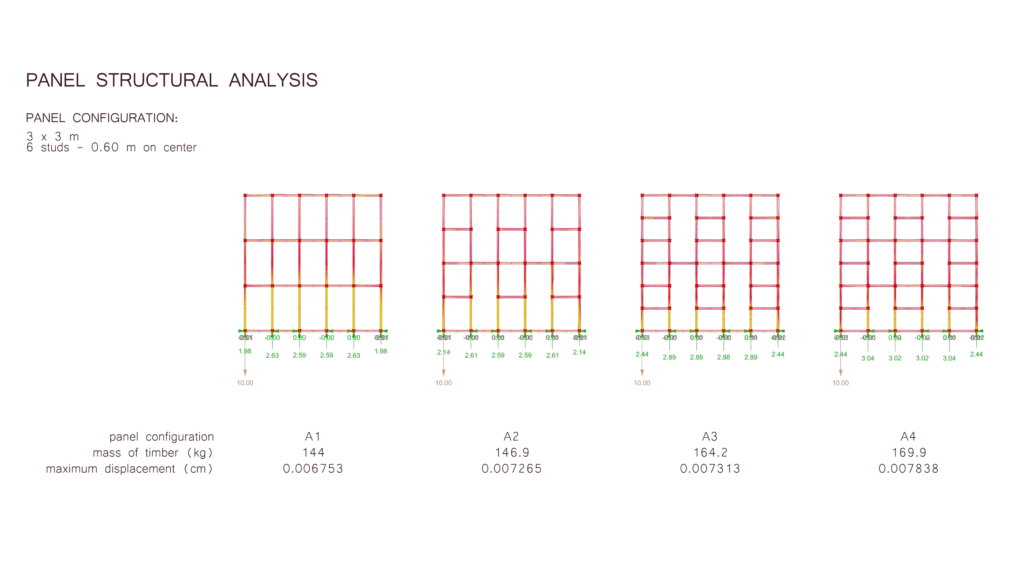

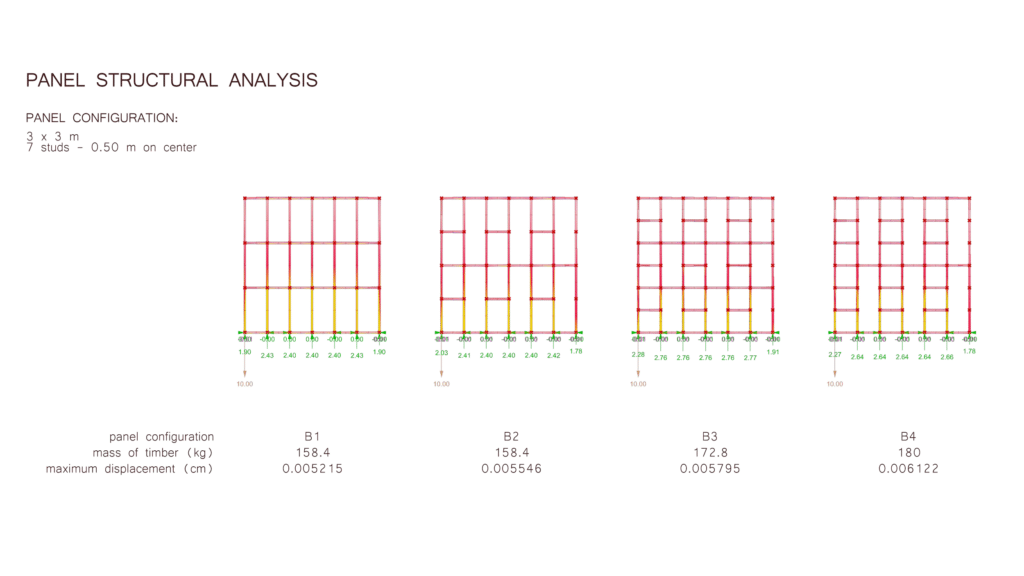

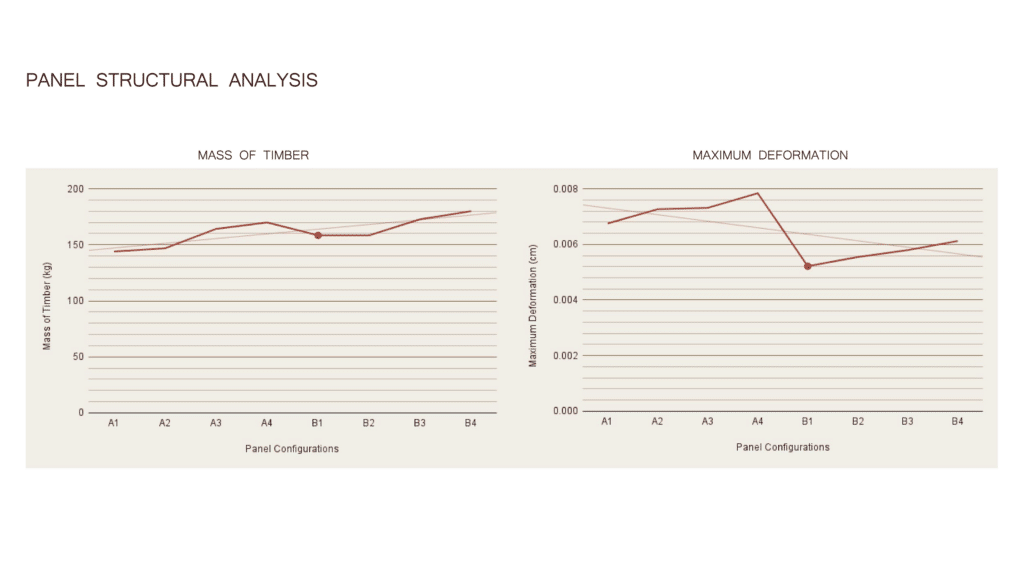

For the substructure, one of our goals is to optimize the use of timber

Using Karamba we carry out a structural analysis to obtain panels that use the least amount of wood without compromising any structural performance.

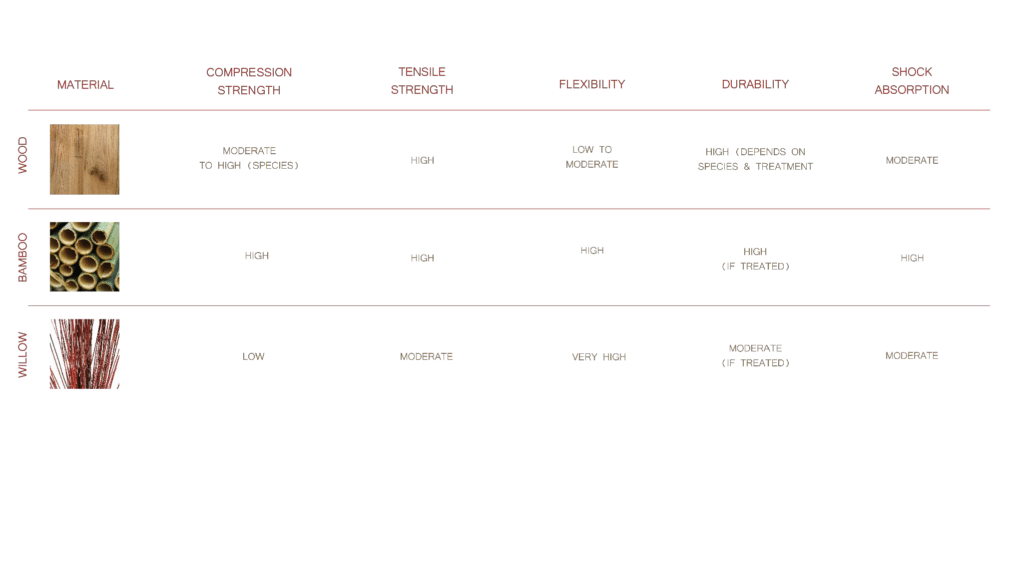

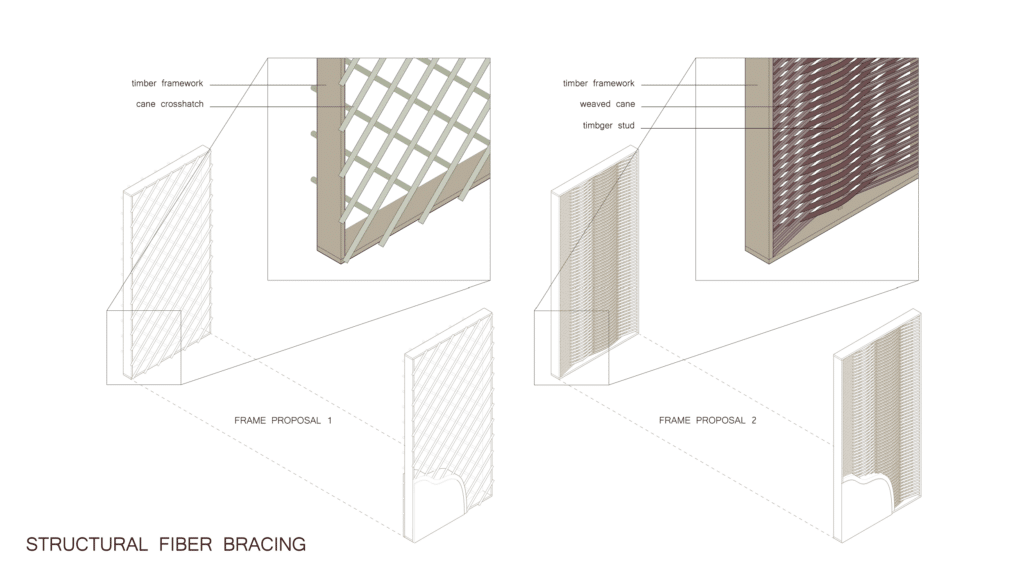

Based on your region the substructure will always have timber, but its bracing can be made of timber, bamboo, willow.

We came up with different bamboo and willow bracing strategies.

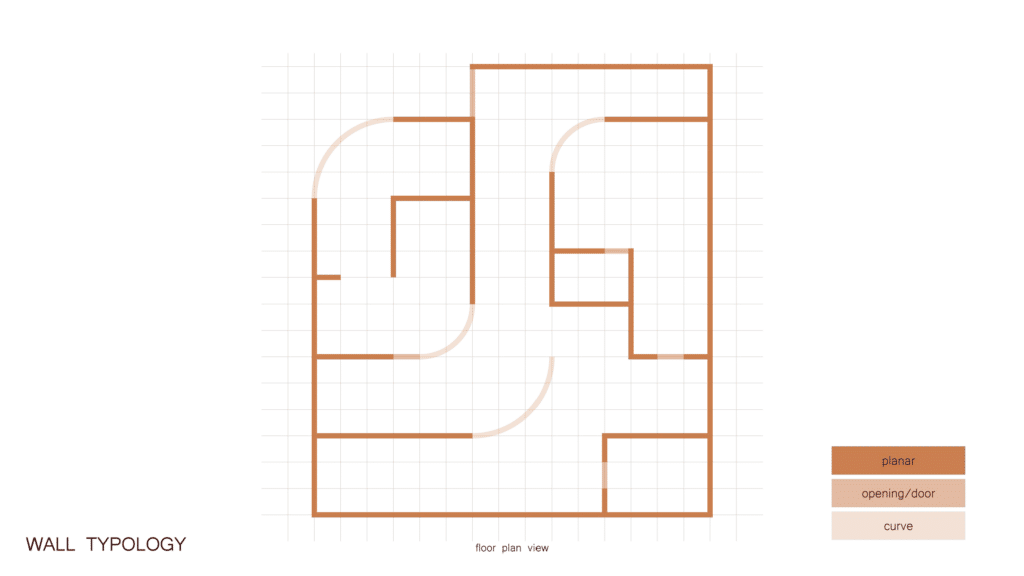

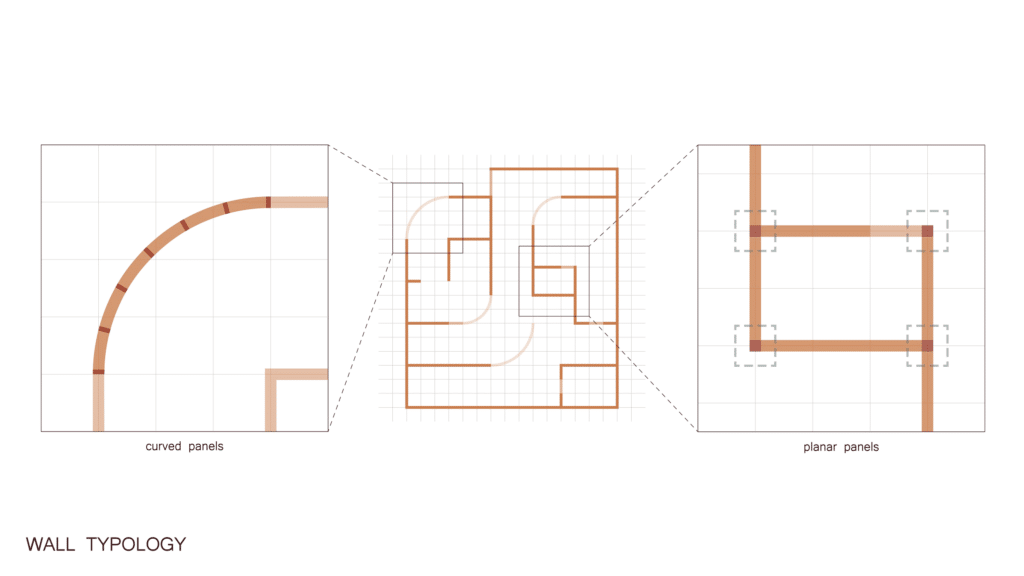

Another of our goals is to be able to achieve curved forms. Usually quincha houses are rectilinear and offer little room for unique designs.

We offer the possibility of having both curved and planar panels, which combined can create new and more interesting spaces.

CASE STUDY

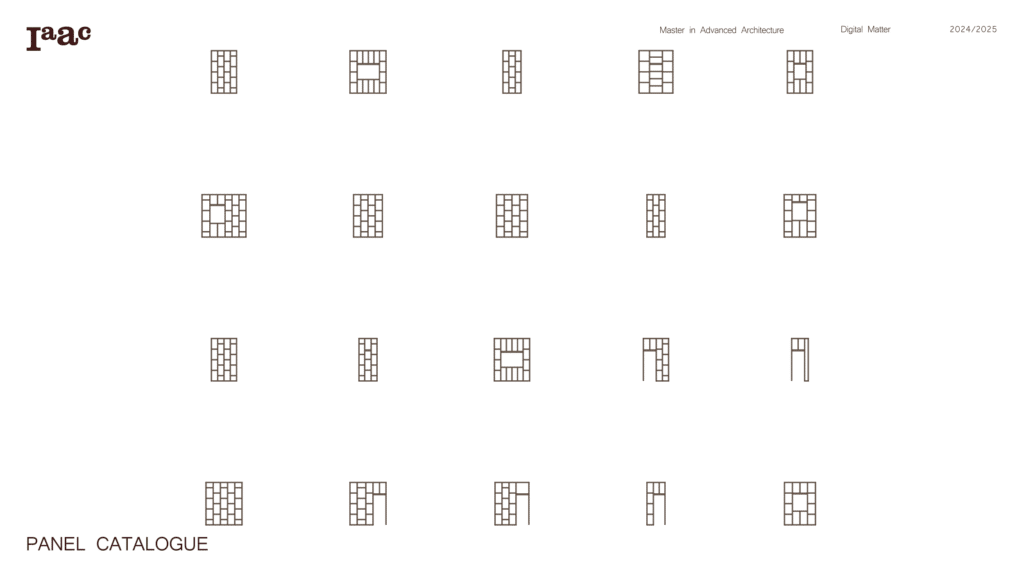

We kinxafied one of our homes and developed some technical drawings to show the modulation and the constructive system. Generating a catalogue of all the panels necessary to built it

KINXA CLIENT MANUAL

The substructure is the only part of the system that is prefabricated offsite. The rest of the process happens in conjunction with the client and our network of collaborators through the KINXA app.

All the construction manuals and material catalogues can be found in the KINXA client manual.

PERFORMANCE TESTING

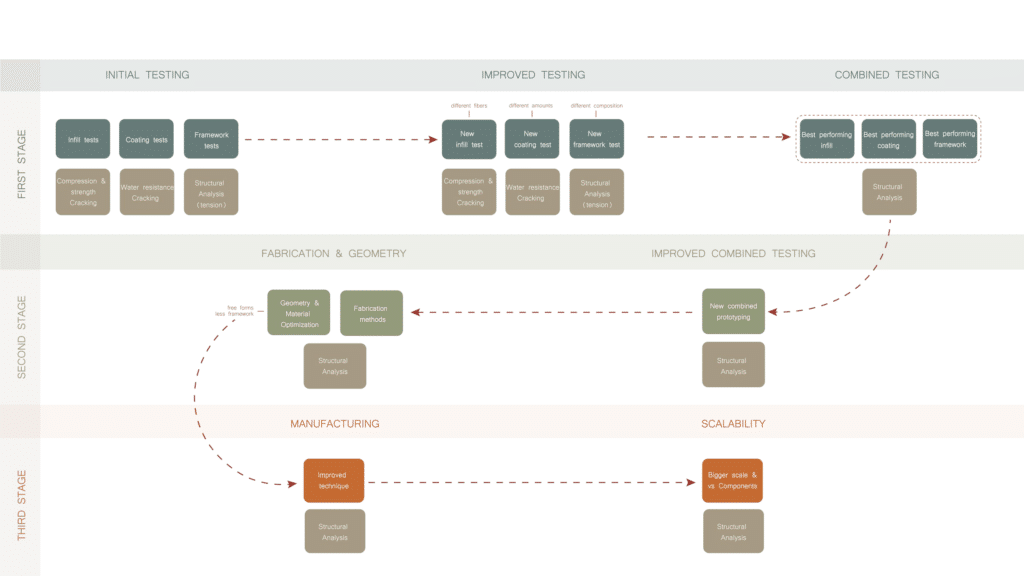

We had a clear strategy stepping into our project, which allowed us to be very methodical about our testing.

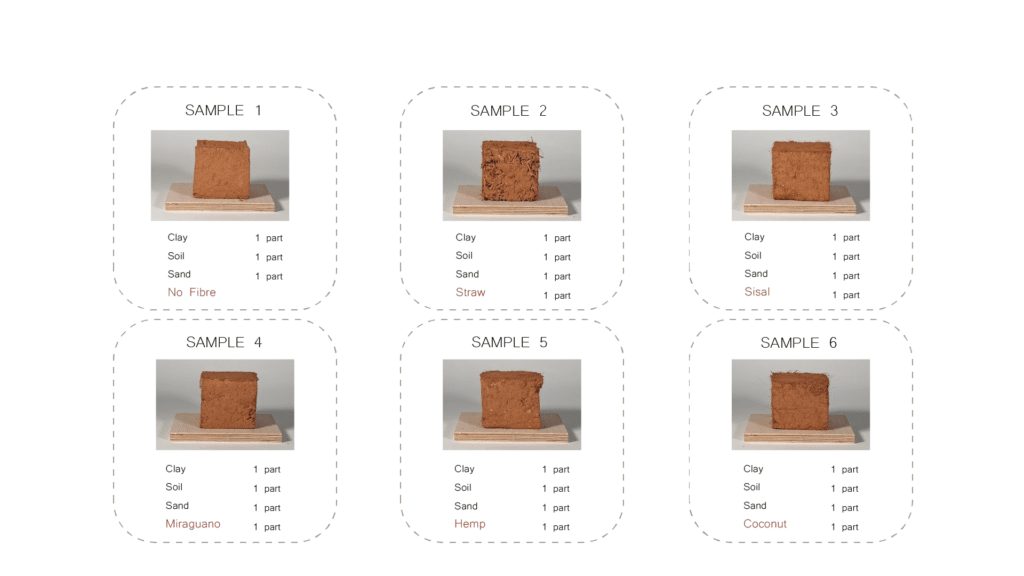

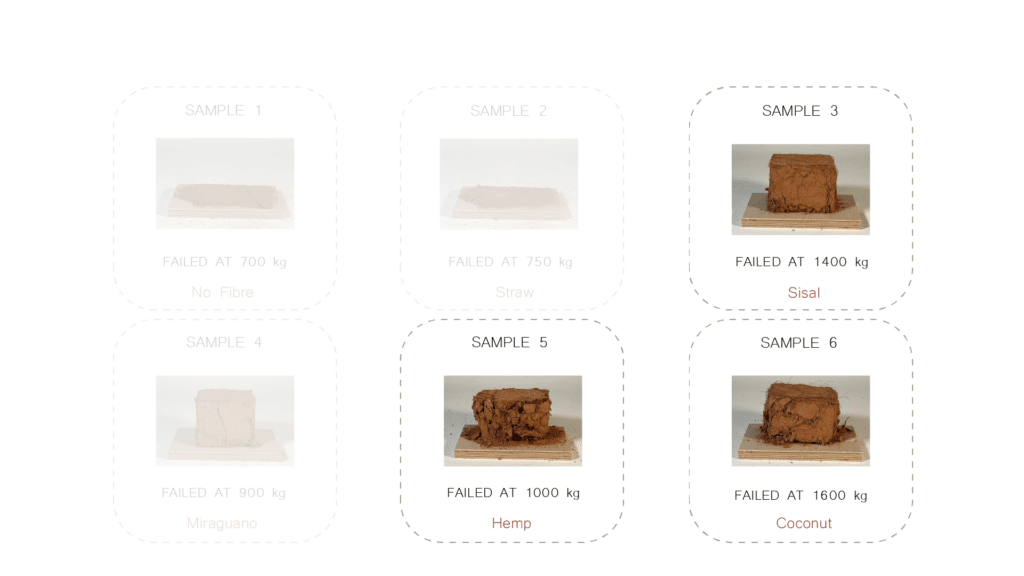

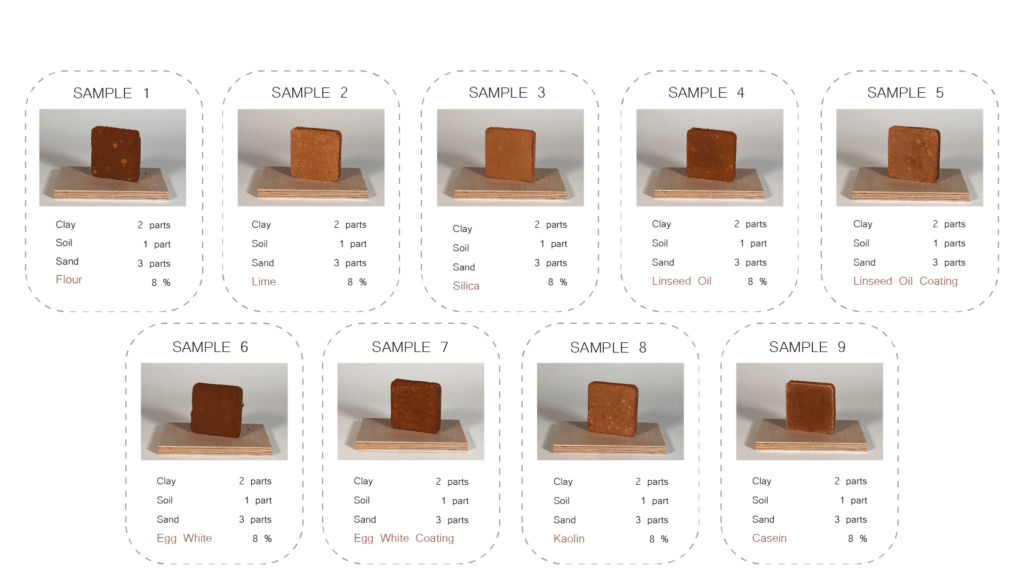

We started by creating recipes for our infill mixture with different fibers and testing them for compression. The ones that performed the best were sisal, coconut coir and hemp.

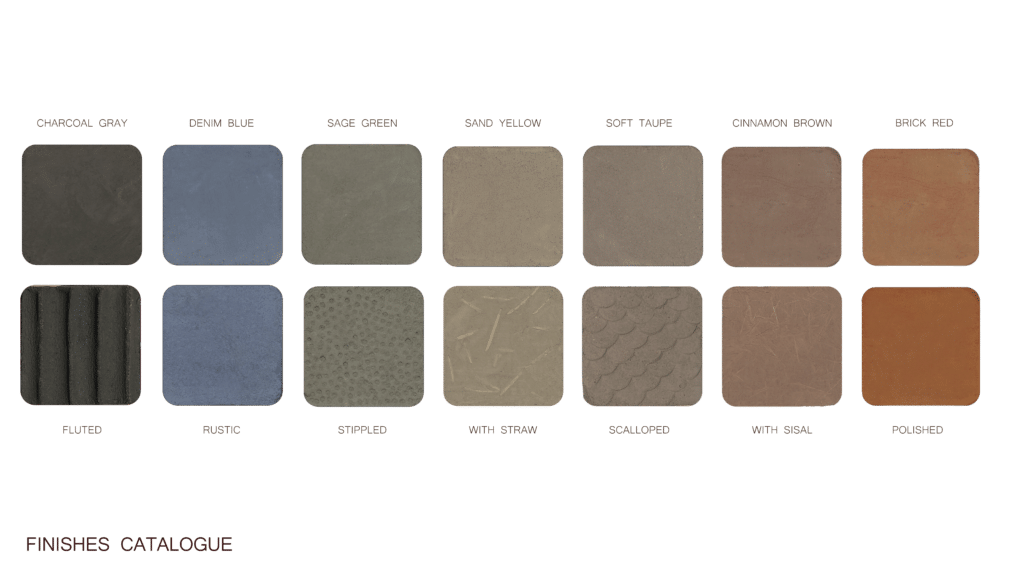

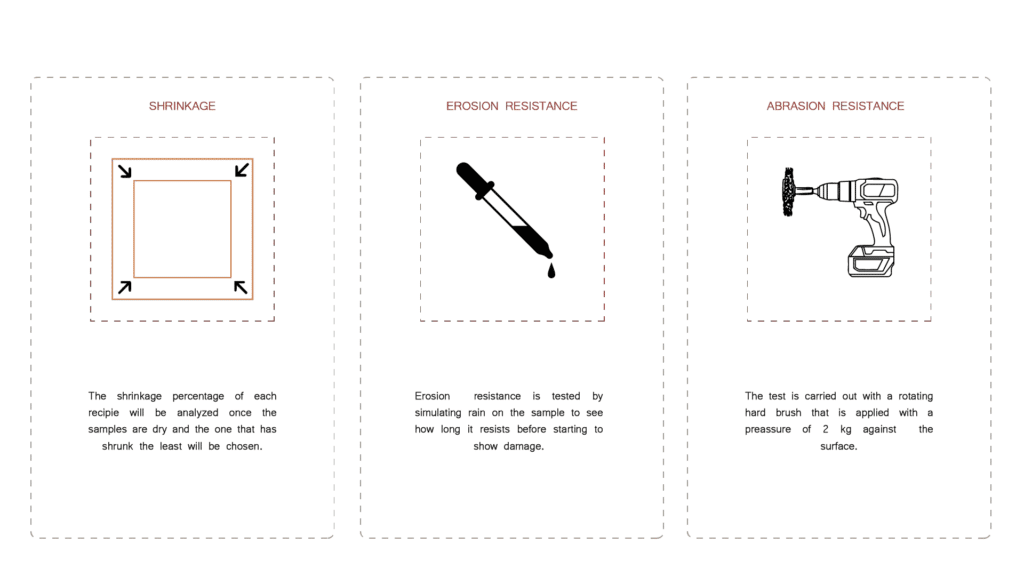

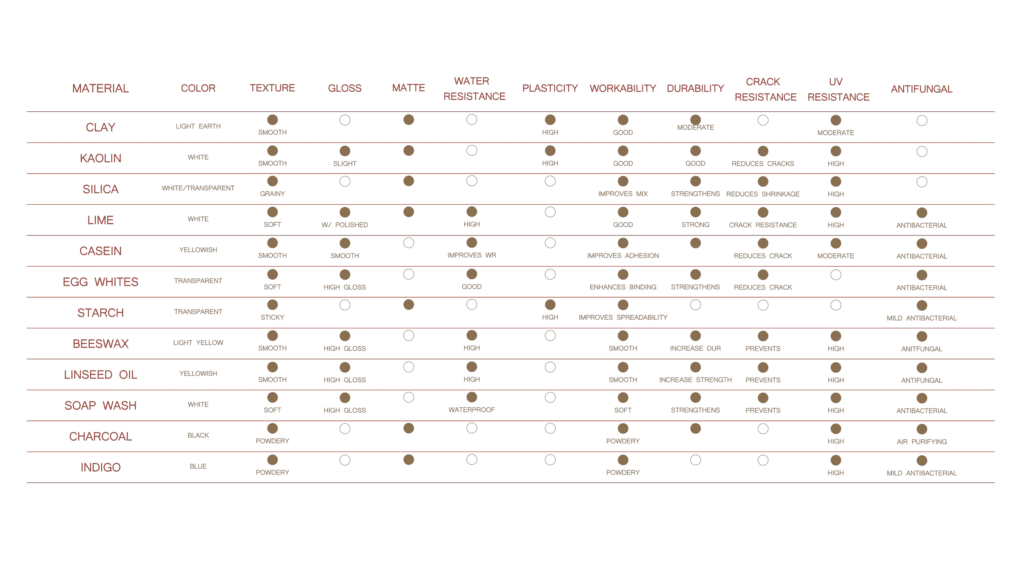

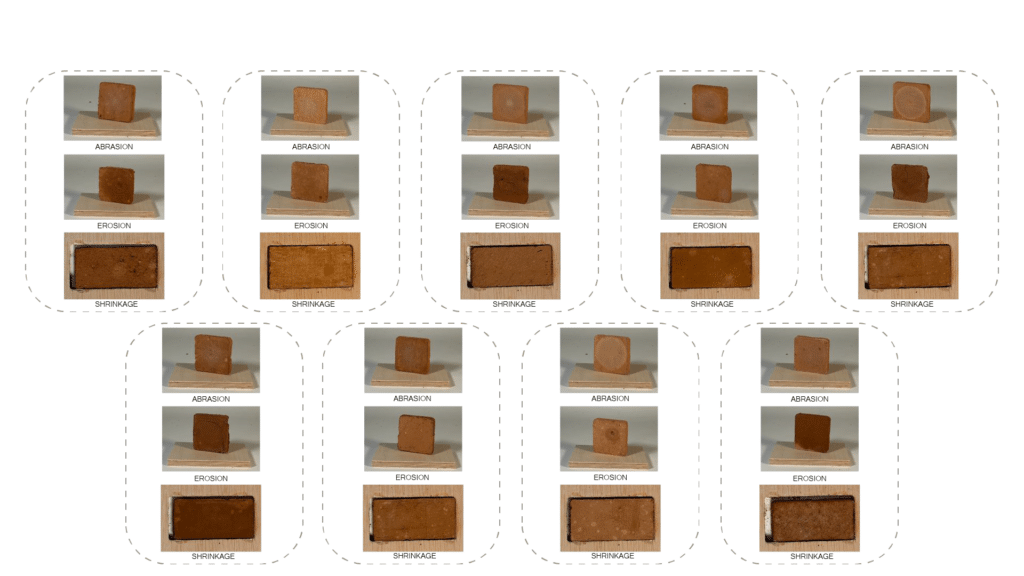

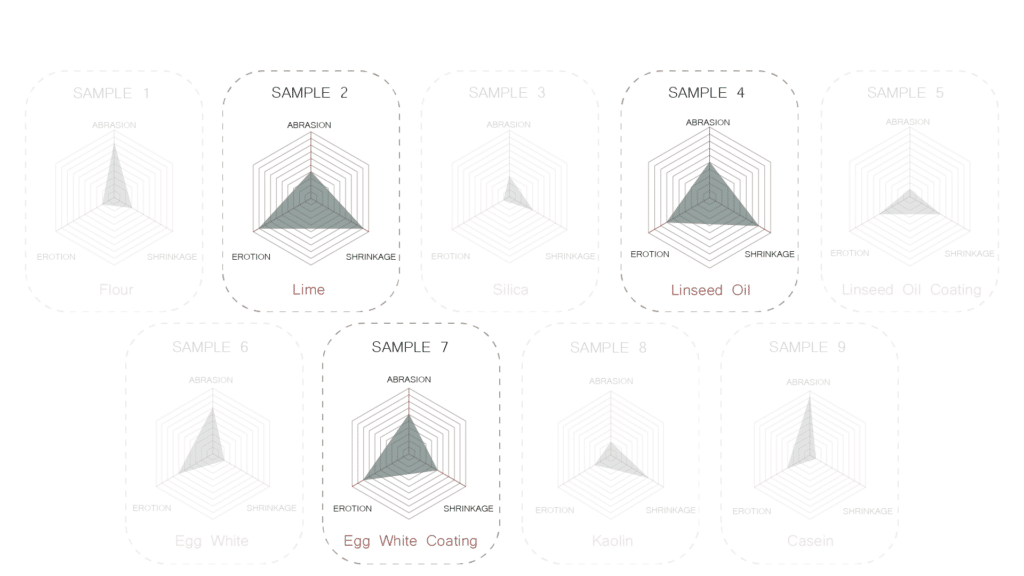

We also tested our finish recipes for shrinkage, erosion and abrasion.

The recipes for our finishes were all the same except for the additives.

From the testing we realized that the finishes with lime, linseed oil and egg white coating were the best performing.

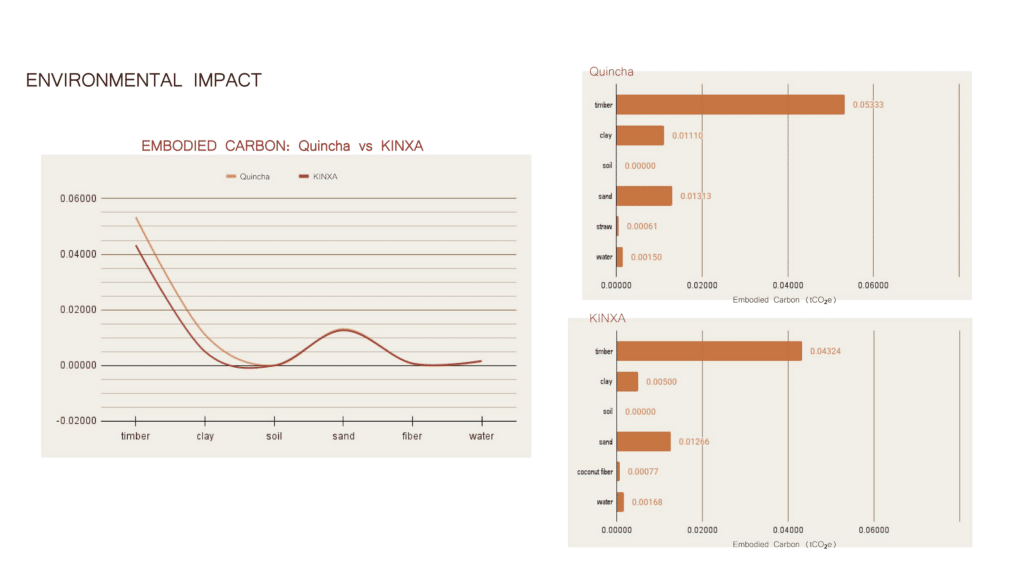

Part of our mission is to be conscious of our environmental impact, so we looked at all the materials that make up our system and did an analysis of its carbon footprint. We compared the embodied carbon of a 3 x 3 panel of traditional quincha and our KINXA and not only have we maintained its sustainable qualities but lowered some of its possible emissions

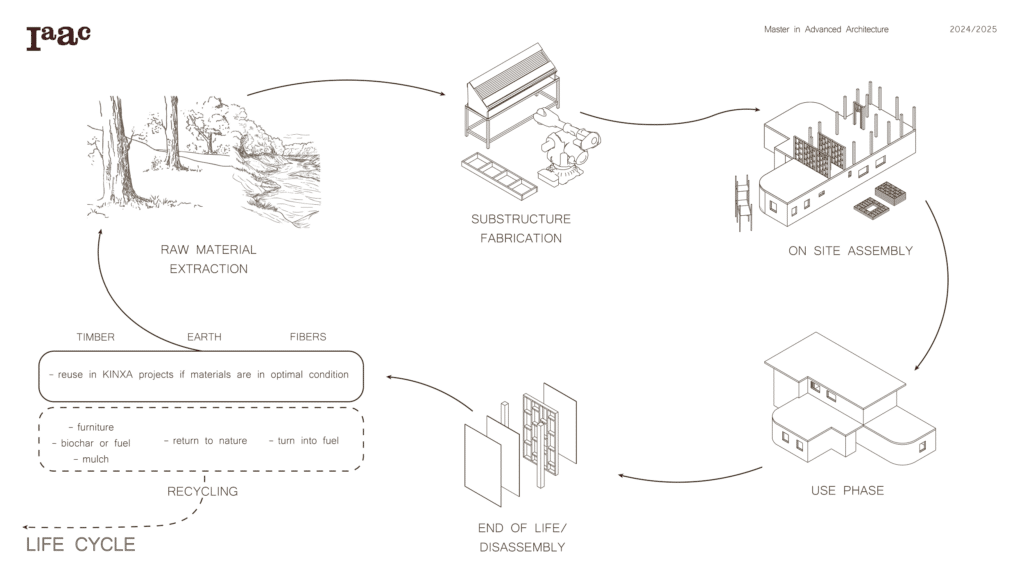

We also analyzed our project’s life cycle and created strategies for the end of its life, aiming to minimize waste.

BIBLIOGRAPHY

Embodied carbon and cement replacement: what are the alternatives? – Greengage Environmental. (2022, May 17). https://www.greengage-env.com/embodied-carbon/

Minke, G. (1994). Manual de Construcción con Tierra. BRC Ediciones.

Orr, J., Gibbons, O., & Arnold, W. (2020). A brief guide to calculating embodied carbon. The Structural Engineer, 98(7), 22–27. https://doi.org/10.56330/JZNX5709

Pérez, T. (2014). Re-visitando tradiciones constructivas: al rescate de la Quincha. ArchDaily. https://www.archdaily.mx/mx/02-333349/en-detalle-revisitando-tradiciones-constructivas-al-rescate-de-la-quincha/52f103bbe8e44eeed5000088-en-detalle-revisitando-tradiciones-constructivas-al-rescate-de-la-quincha-foto

Quincha House. (n.d.). Base Studio. https://basestudio.cl/portfolio-item/quincha-house/

ReGrow Willow. (n.d.). KIT – Projects. https://dos.ieb.kit.edu/english/361.php

ReSidence. (n.d.). DDF. https://www.ddf-kit.de/residence

Silva, L. (n.d.). Quincha Coating. Pinterest. https://uk.pinterest.com/pin/289919294780676625/

Straw. (2020). def – Deco con Alas. https://www.decorarenfamilia.com/2020/05/vivir-en-una-casa-de-paja.html

SUM Iscot’s lung / Patio Estudio. (2021, December 3). ArchDaily. https://www.archdaily.com/972830/sum-iscots-lung-patio-estudio?ad_source=search&ad_medium=projects_tab