- In this project, we explored the process of designing and fabricating a sub-D surface using 6-axis milling with a Cooper robot.

- Initially, we created a surface that was modulated using an image sampler. However, this approach produced an extremely dense mesh — our UV count was set to 400 by 400, resulting in 1.6 million UV points. This made it impossible to carry out any meaningful analysis or fabrication.

- To address this, we generated a new surface using WeaverBird, applying surfaces not as detection points but through an equation that allowed us to transition from the modulated WeaverBird surface to smoother surfaces with a flat seating area.

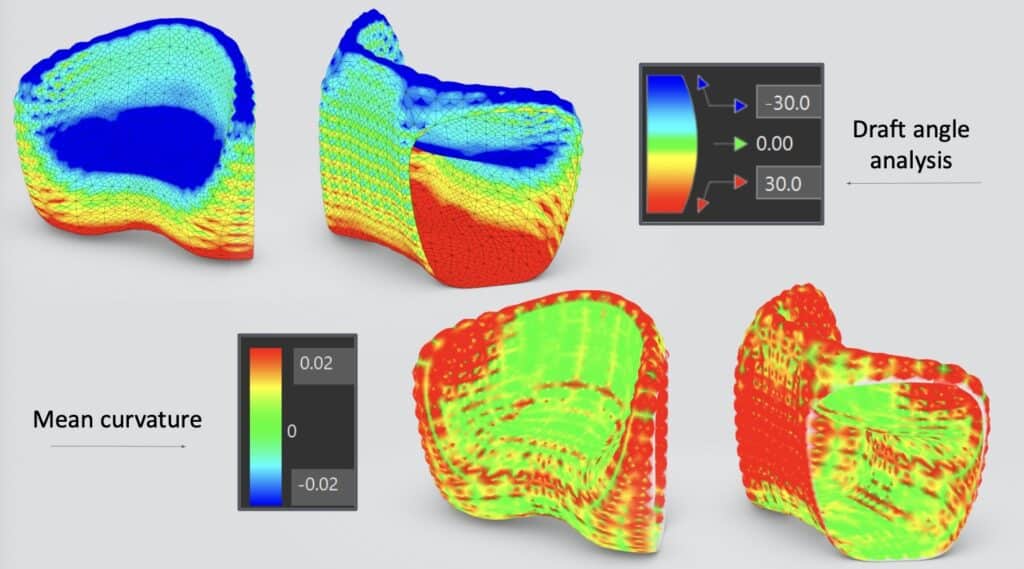

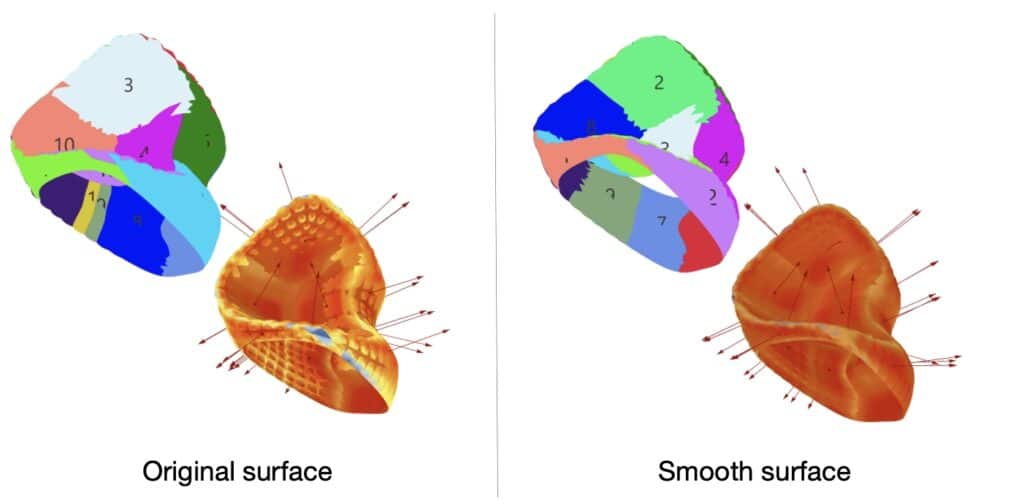

- After refining the geometry, we performed draft angle analysis and LSI analysis to identify problematic areas and better understand how to improve the surface continuity. Through this process, we divided the model into 11 patches, which we refined manually.

- Finally, we carried out two types of draft analyses: one with a single uniform angle, and another adjusted according to the direction of each patch. This helped us evaluate and optimize the geometry for fabrication accuracy and milling feasibility.

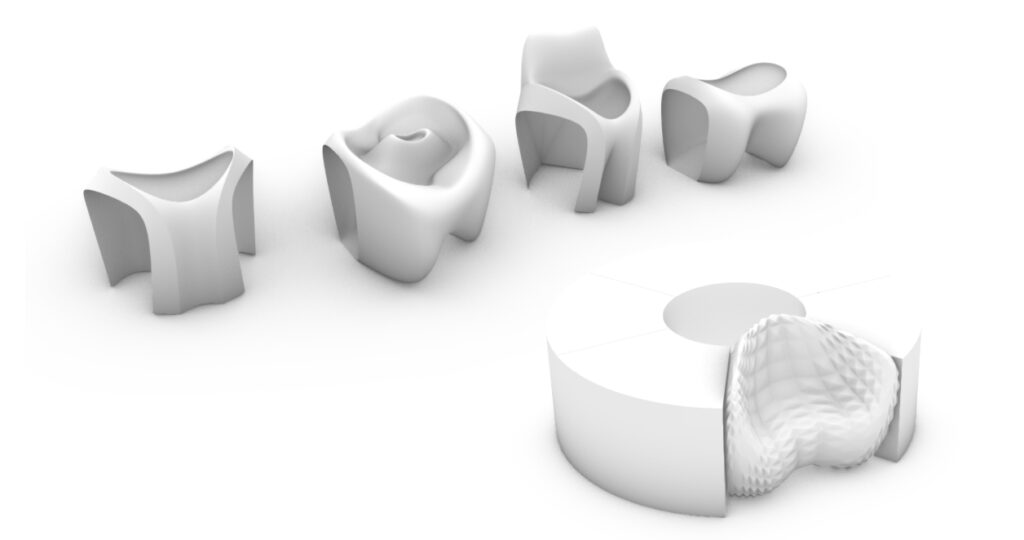

So basically, these are the iterations we made with the first day at the workshop. These are the many iterations of the different topologies and chairs we made using SubDs. In the end, we decided to go with a simple shape, yet with a complex textile texture.

For these diagrams, we conducted a draft angle analysis to evaluate the angularity of each bump and curve on the surface. We also performed a mean curvature analysis, with values set between 0.02 and –0.02, to examine the differences between smooth textures and rough mesh topologies. In another diagram, the geometry was divided into patches that the robot could modulate between, and ultimately, we decided to use 11 patches for the smooth surfaces. Following the patch analysis, a normal analysis was carried out to visualize the orientation and direction of the surface normals across the chair.