Introduction to Digital Fabrication Seminar

Faculty: Ricardo Mayor, Hamid Peiro, Shyam Francesco Zonca

Faculty Assistant: Sheikh Rizvi Riaz, Federico Caldi, Vivek Venkateshappa

In our Introduction to Digital Fabrication course we developed a small ecosystem of “bio” prototypes that test how code, machines and matter can co-evolve. Across four exercises we treated each fabrication tool as a way to grow architecture rather than just draw it. BioJoint uses the laser cutter to turn flat sheets into an interlocking, organism-like structure that plays with light and shadow. BioPixel translates a digital height map into a CNC-milled relief, where each wooden “pixel” can host micro-greens and micro-shadows. With BioMesh, 3D printing becomes a way to weave porous, load-bearing skins in which structure and opening are one continuous geometry. Finally, BioCup brings in robotic clay printing, using an ABB arm to coil a simple vessel from wet earth, layer by layer. Together, these four pieces trace a trajectory from 2D to 3D, from grid to mesh, from inert material to potentially living surface, an early catalogue of how digital fabrication can prototype future bio-informed architectures.

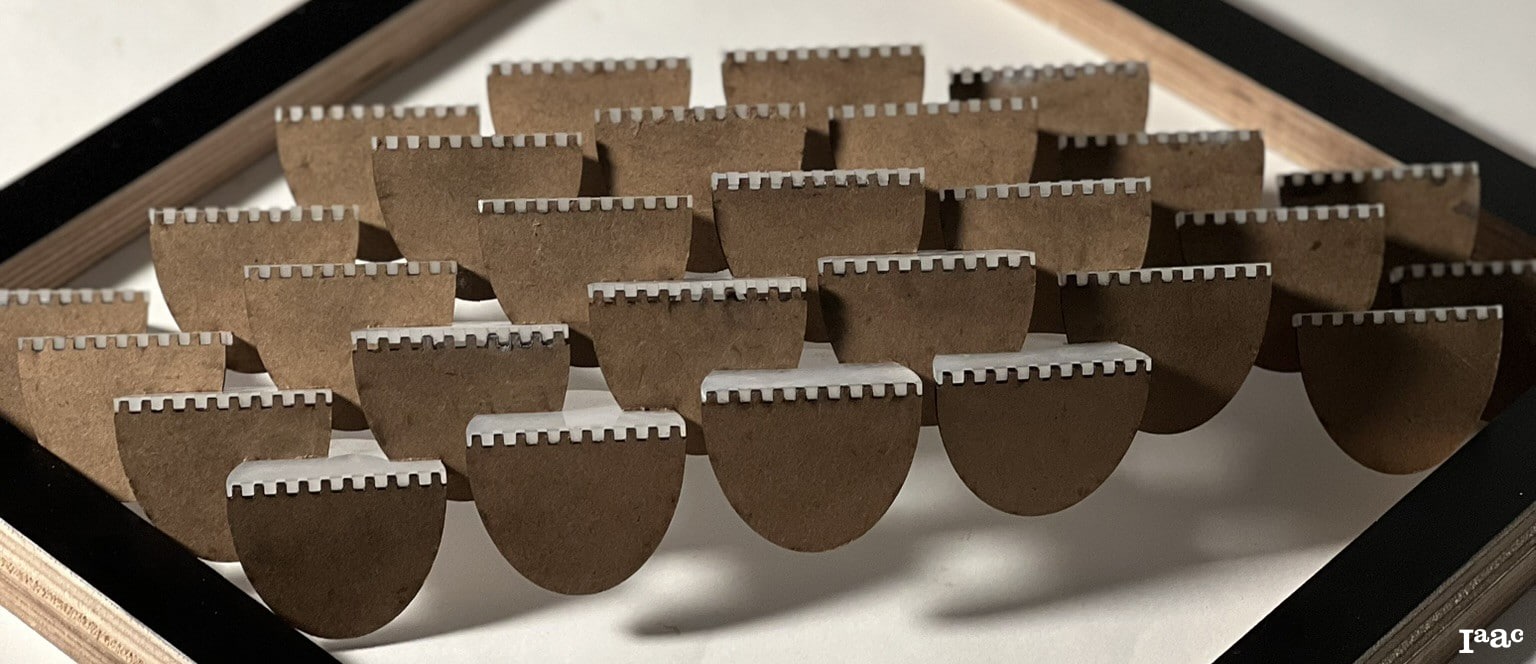

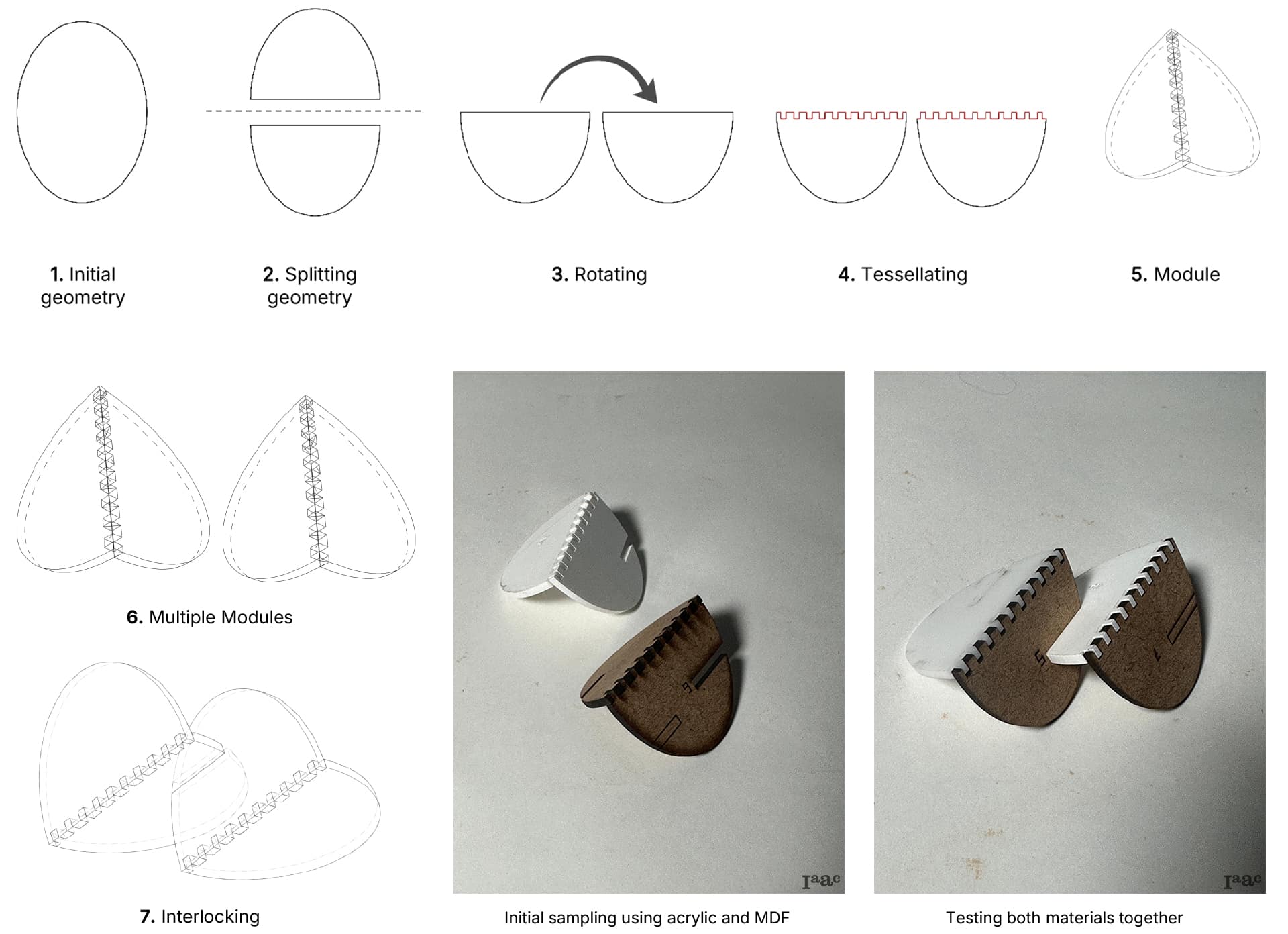

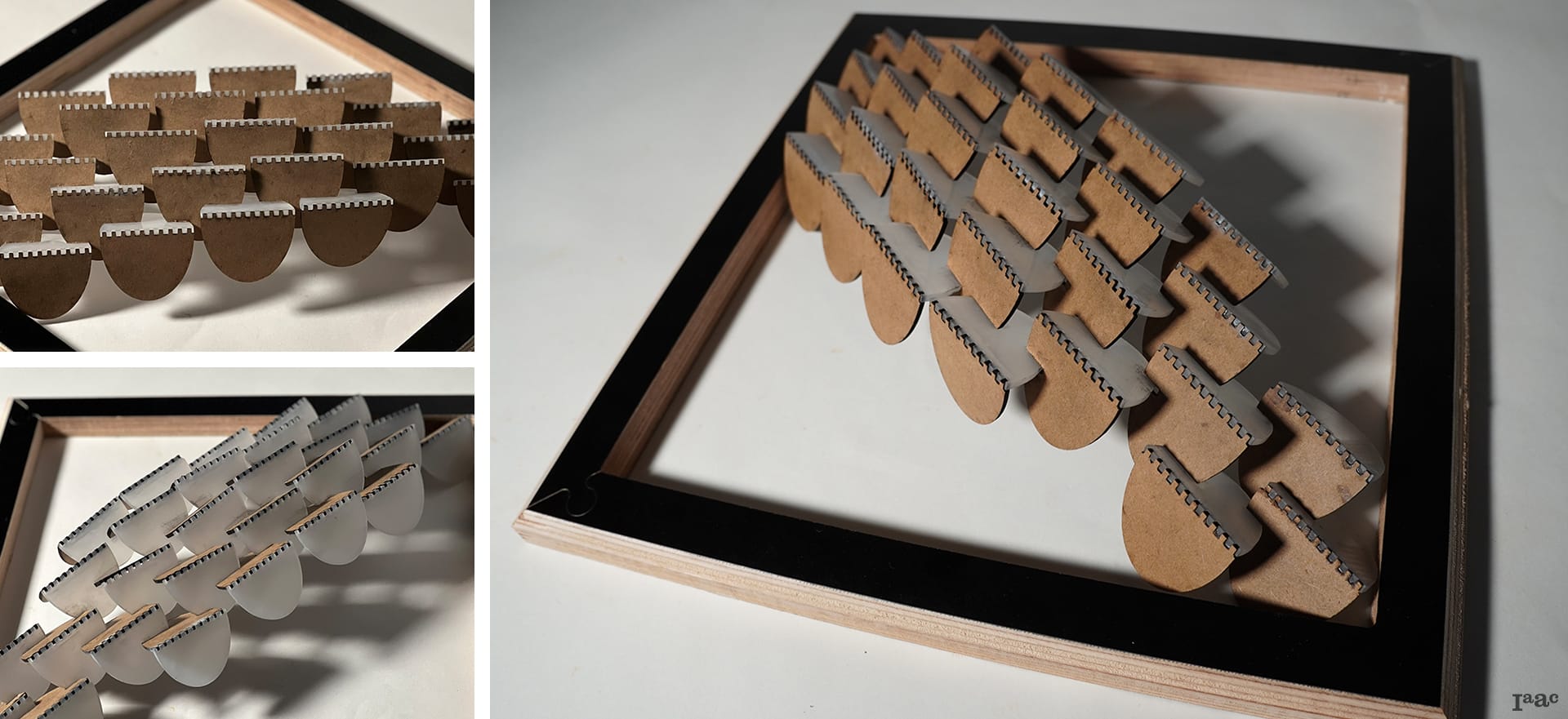

BioJoint – Laser Cutting

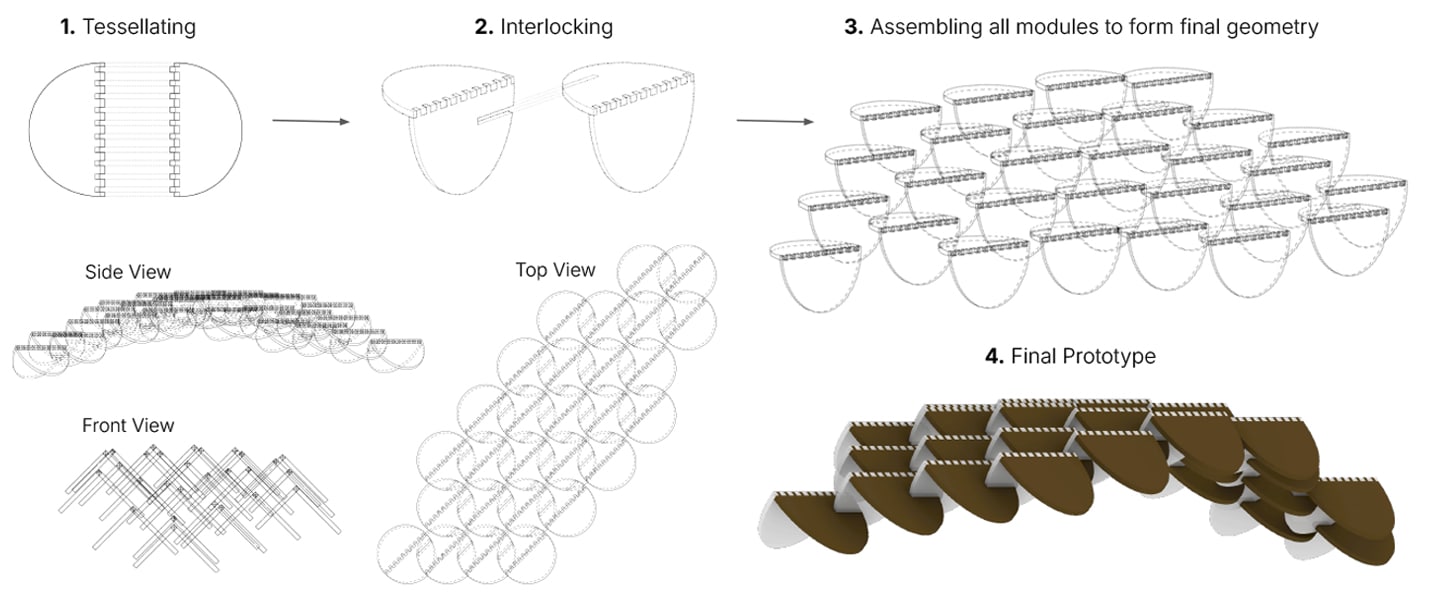

BioJoint is an experimental interlocking system that utilizes two laser-cut materials to create a sculptural 3D volume from flat 2D components.

The design, which resembles natural organisms and combines acrylic with MDF wood, promotes a dynamic interplay of transparency, light, and shadow. Its structural porosity and organic geometry make it suitable for diverse uses, such as partitions, pavilions, or shading devices, showcasing the potential of digital fabrication in nature-inspired architecture.

Process and Design

Project Diagrams and Final Design

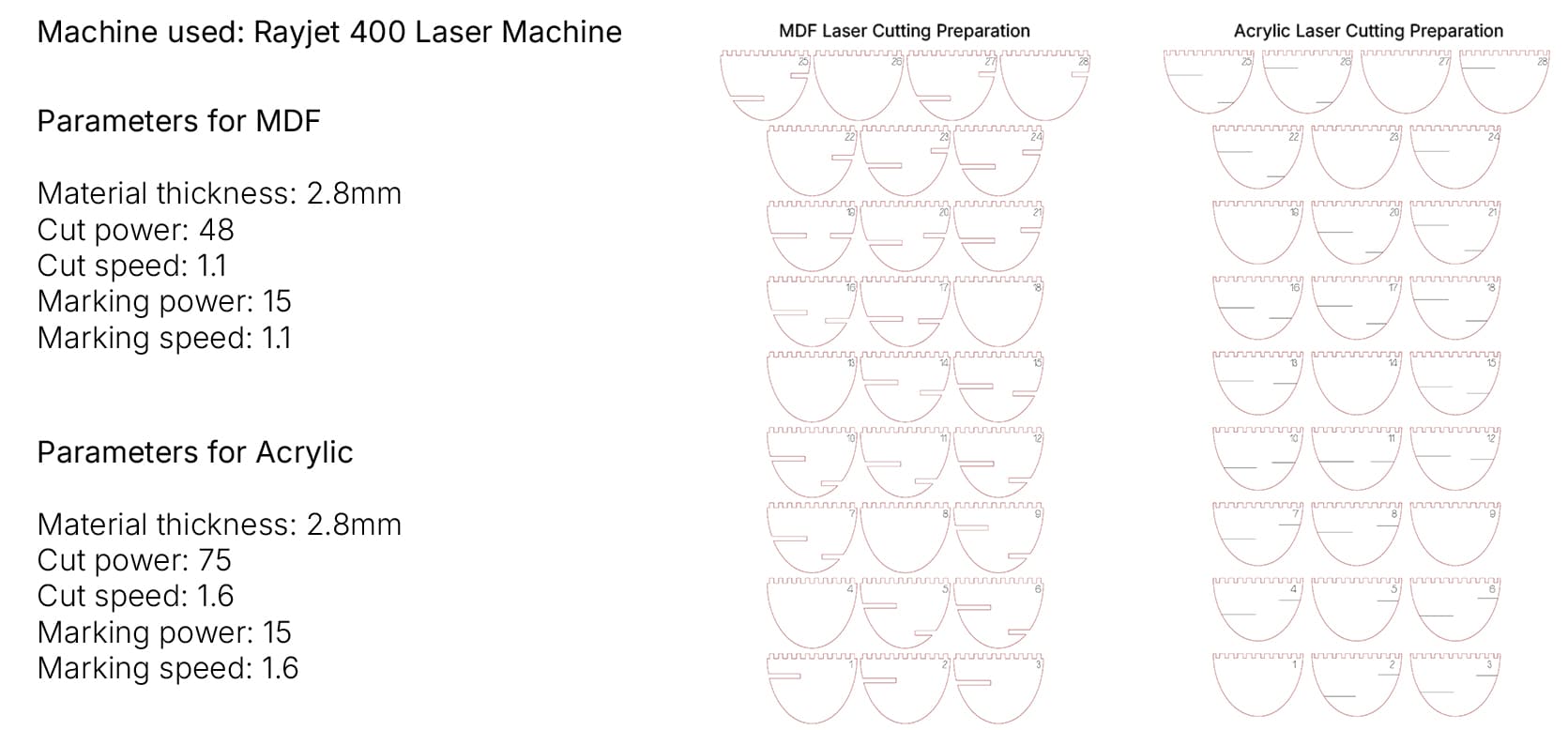

Fabrication Strategy

Prototype Pictures

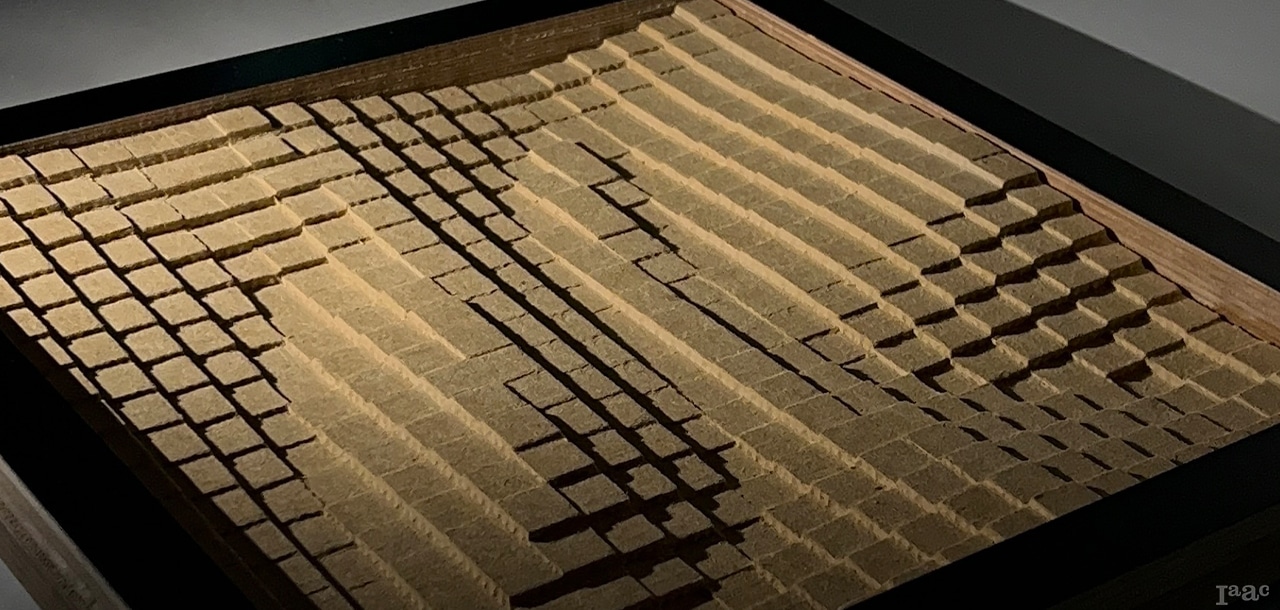

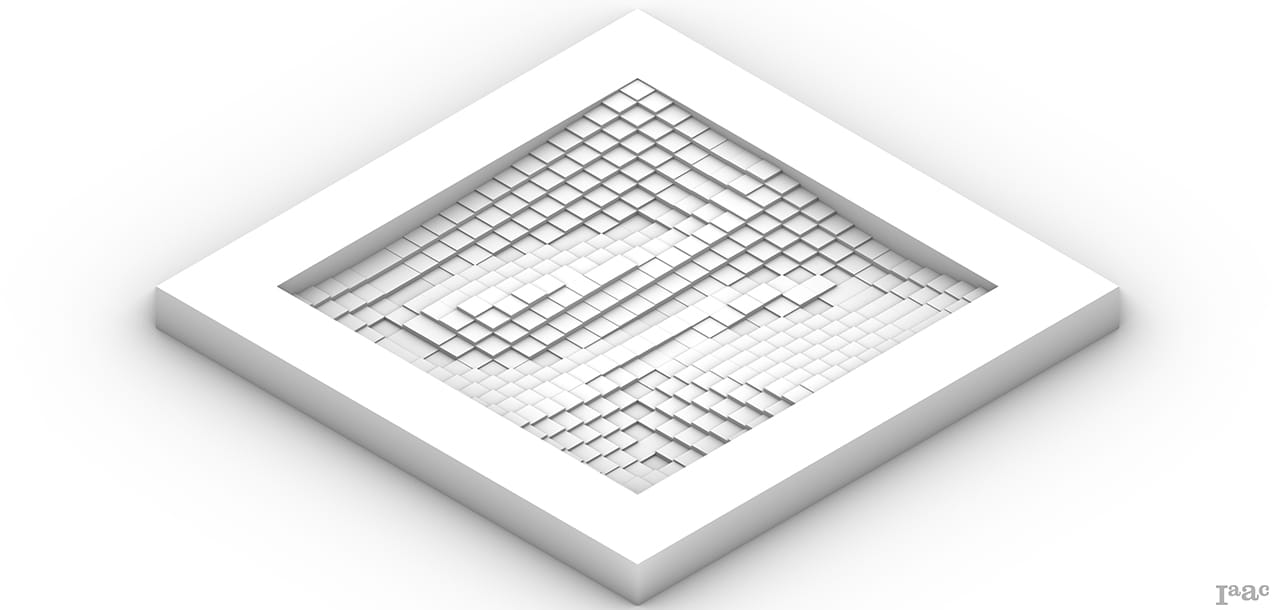

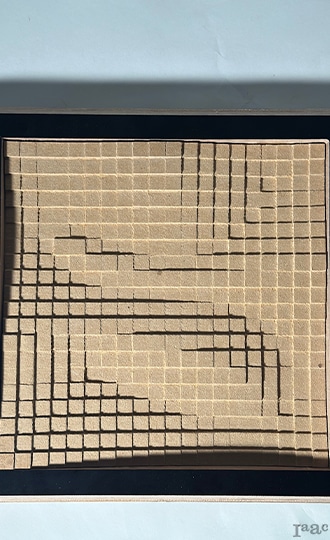

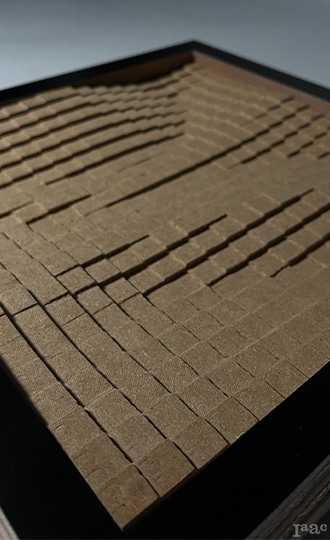

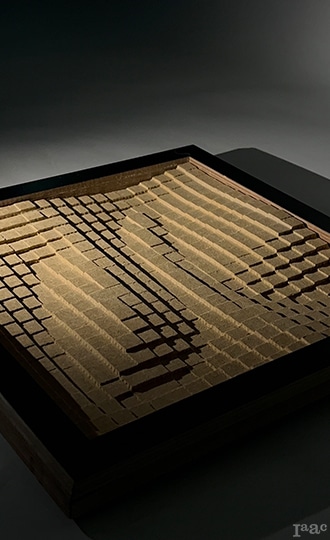

BioPixel – CNC Milling

BioPixel explores the intersection between digital fabrication and ecological design.

The panel translates a pixelated digital pattern into a physical, three-dimensional surface that can host micro green pockets and dynamic light effects. Each pixel’s depth variation generates texture, shadow, and potential for natural growth, transforming a rigid digital grid into a living architectural skin. Chosen as our CNC project, BioPixel demonstrates how computation and material fabrication can merge to create adaptive, responsive facade systems.

Our project is an inspiration from the “Pixel Facade” system. This system is an adaptive scalable and repeatable building system that can be applied to various building typologies.

Project Diagram- Technical Drawing

We generated a grid of points, used curve attraction to define height variation, and extruded each pixel based on proximity values. The resulting surface translates digital data into a dynamic facade pattern.

Fabrication Strategy

Biopixel was created using a 30 mm MDF panel as the primary material. The machining was carried out on a CNC ShopBot, using the ShopBot_MTC post processor to ensure accurate toolpath execution. The workpiece measured 400 × 400 × 30 mm, providing a compact yet solid volume suitable for detailed CNC operations. Since the project has already been completed, this information serves as a technical summary for documentation and blogging purposes.

01 – Engraving

Flat Mill

Flute: 2

Diameter: 6

Spindle Speed: 12000

Cut Direction: Natural

Total Cut Depth: 3mm

Total mill time: 0.3 min.

02 – Horizontal Roughing

Flat Mill

Flute: 1

Diameter: 8

Spindle Speed: 12000

Cut Direction: Downcut

Stepdown Control (dZ): 50%

Stepover Distance: 60%

Total mill time: 35 min.

03 – Parallel Finishing (1)

Flat Mill

Flute: 2

Diameter: 6

Spindle Speed: 12000

Cut Direction: Mixed

Stepover Distance: 3.175 (60%)

Angle of Cuts: 0

Total mill time: 15 min.

04 – Parallel Finishing (2)

Flat Mill

Flute: 2

Diameter: 6

Spindle Speed: 12000

Cut Direction: Mixed

Stepover Distance: 3.175 (60%)

Angle of Cuts: 90

Total mill time: 15 min.

05 – Profiling

Flat Mill

Flute: 2

Diameter: 6

Spindle Speed: 12000

Cut Direction: Upcut

Number of Bridges: 5

Total mill time: 6 min.

Prototype Pictures

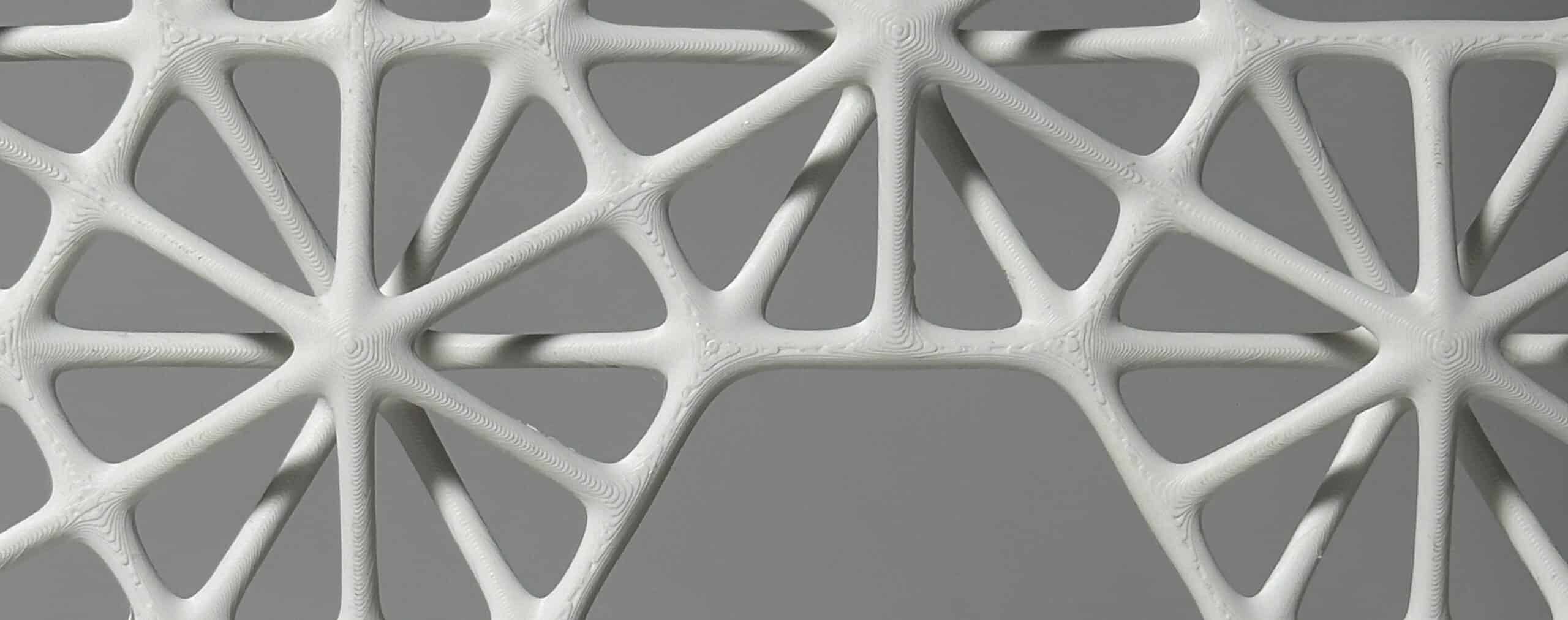

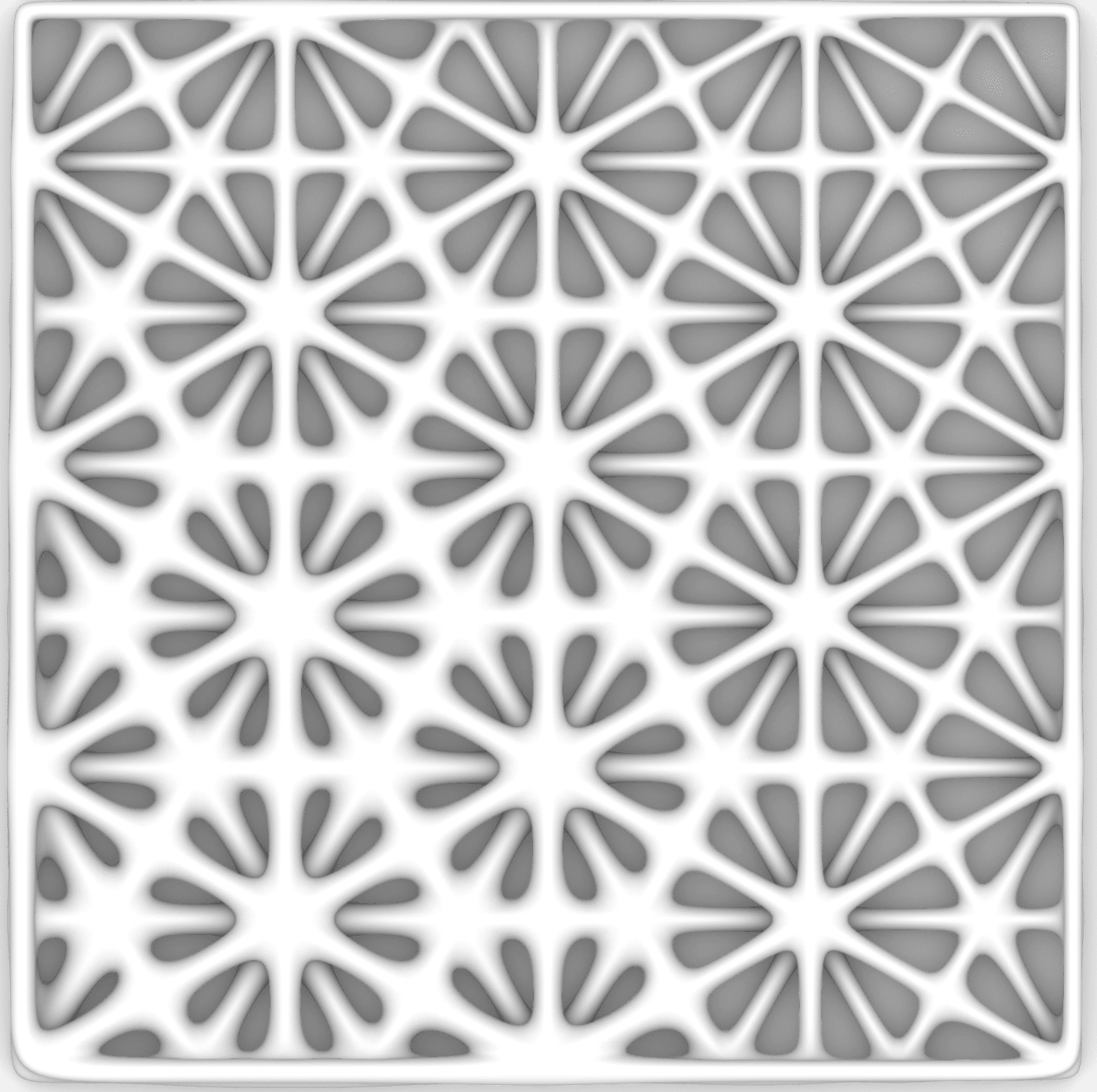

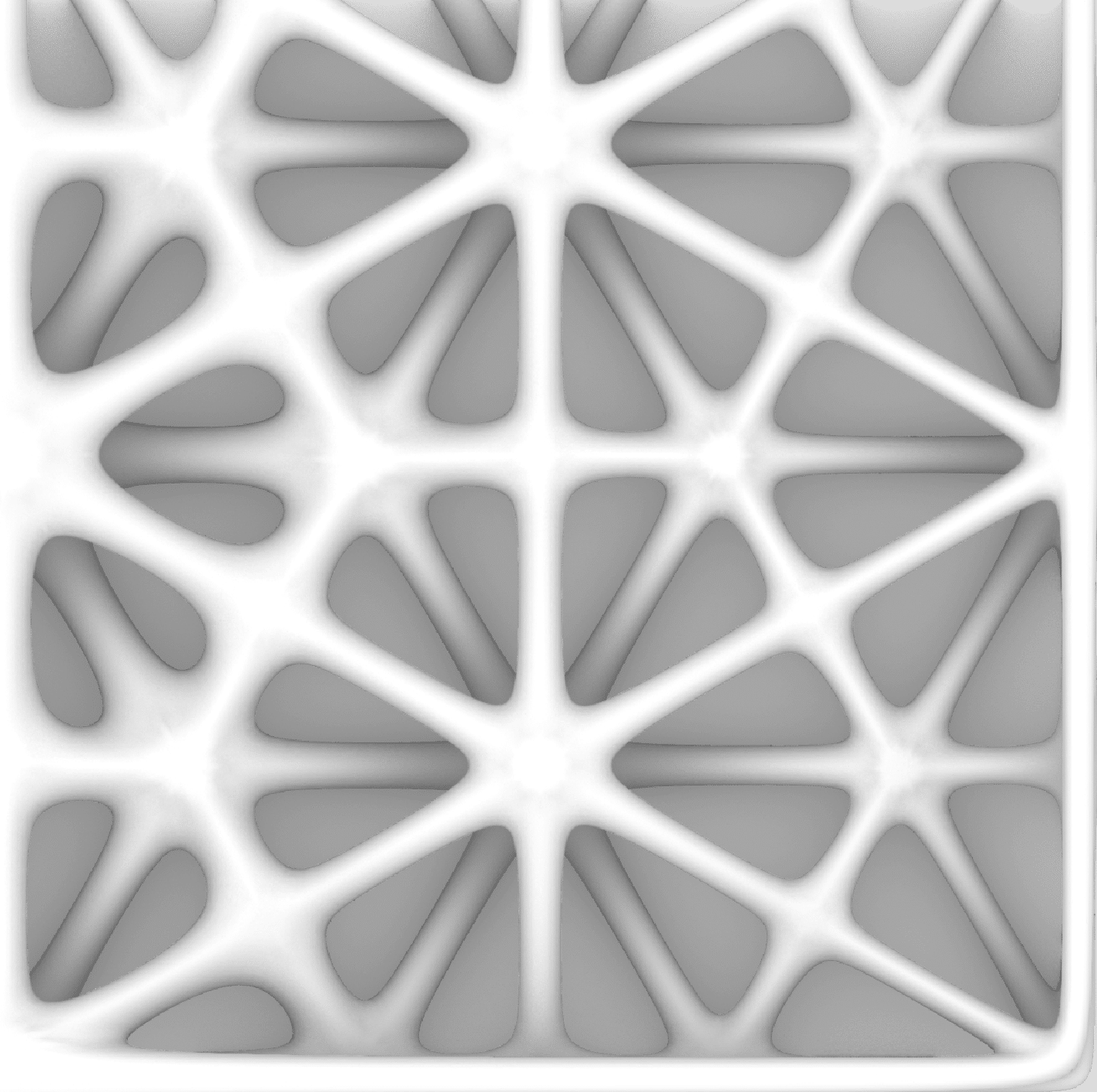

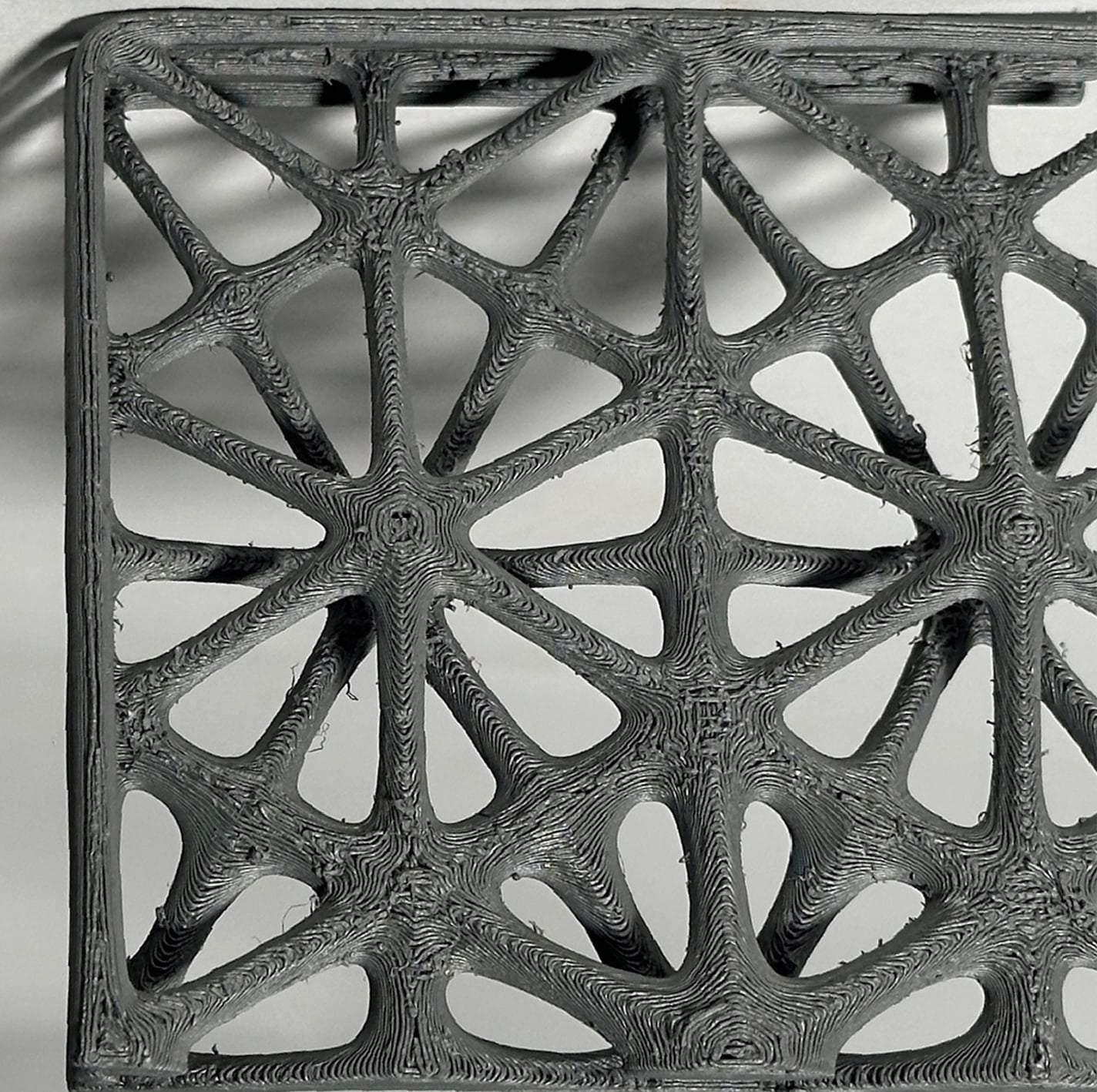

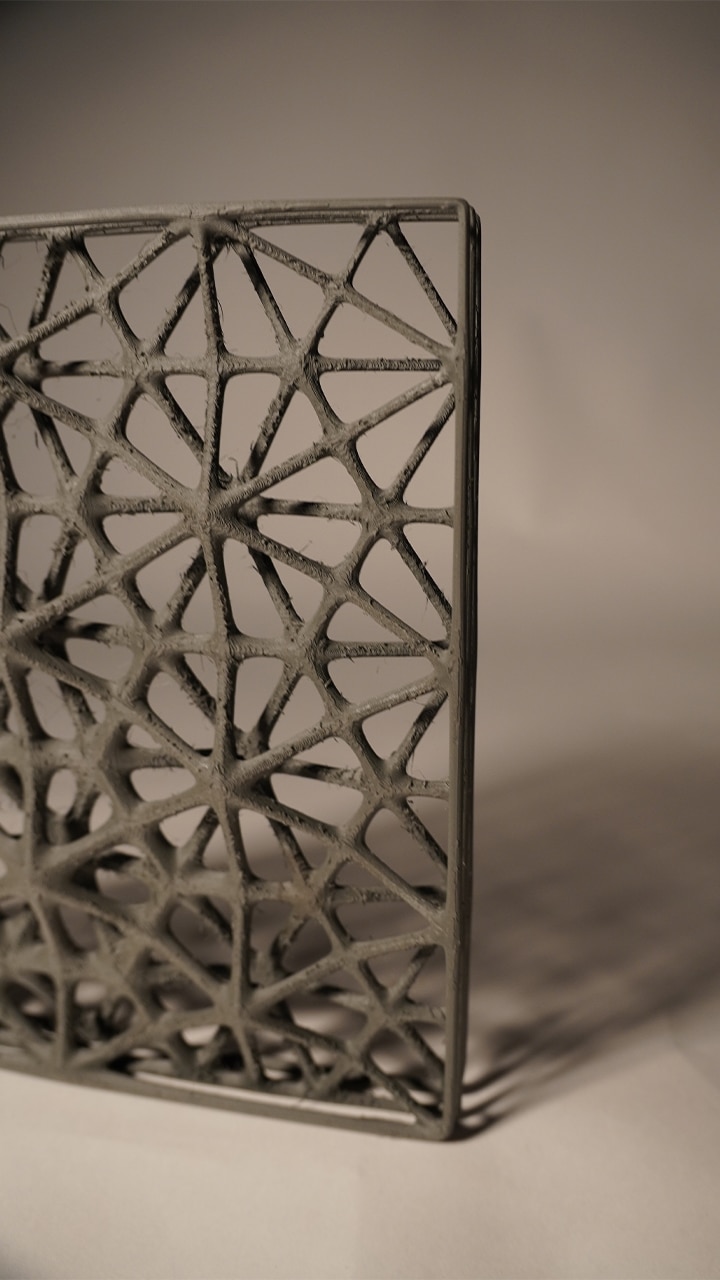

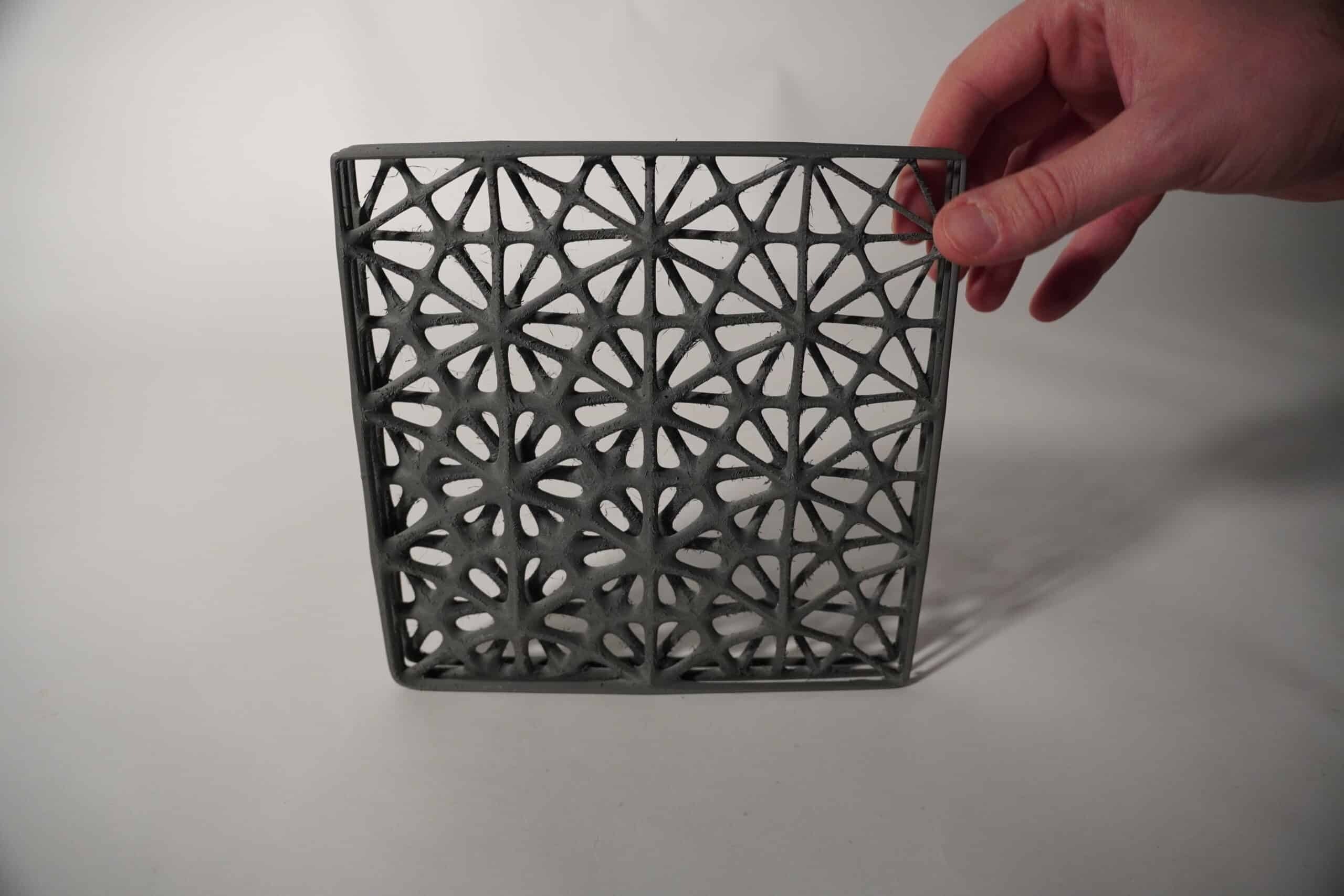

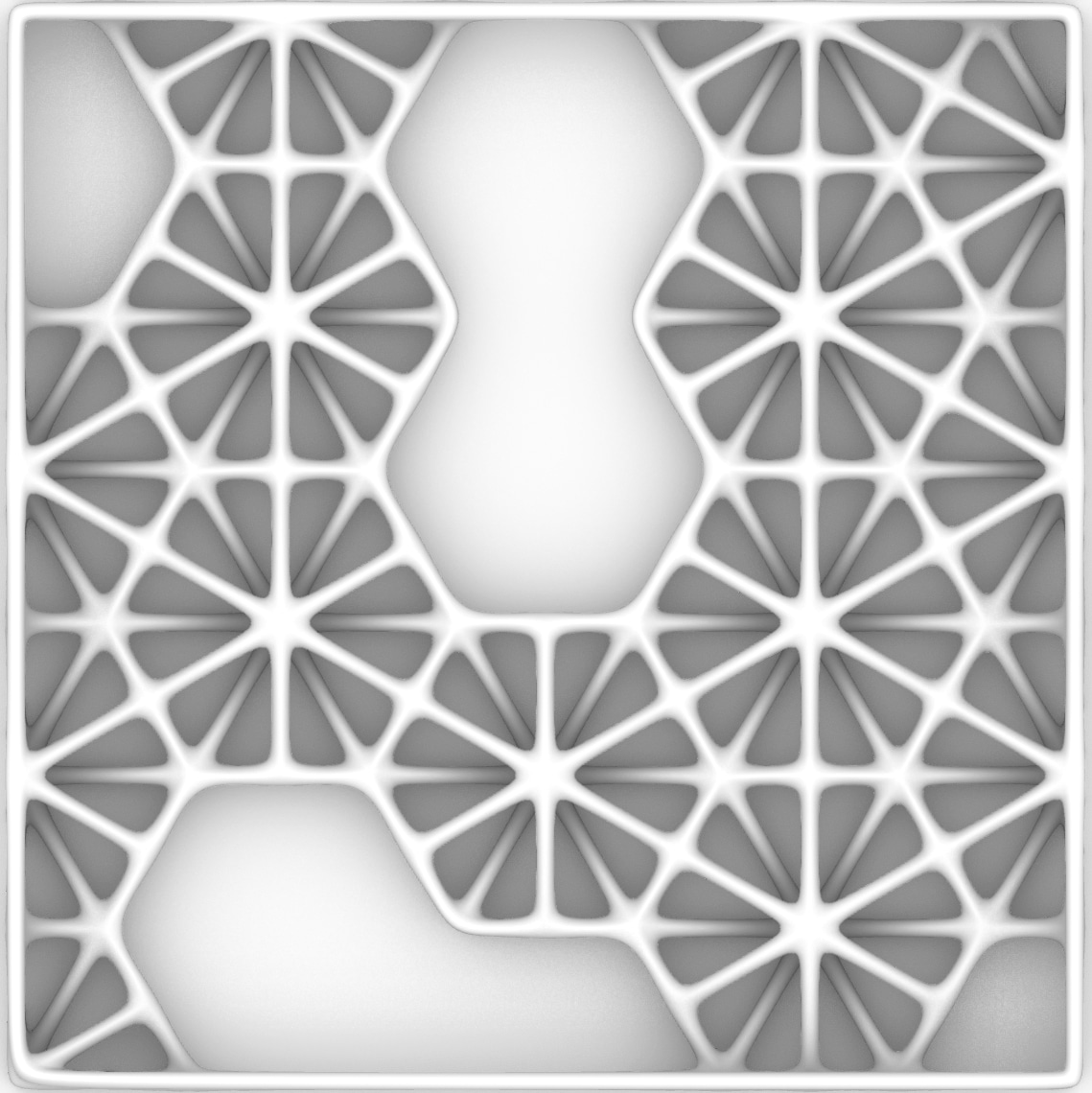

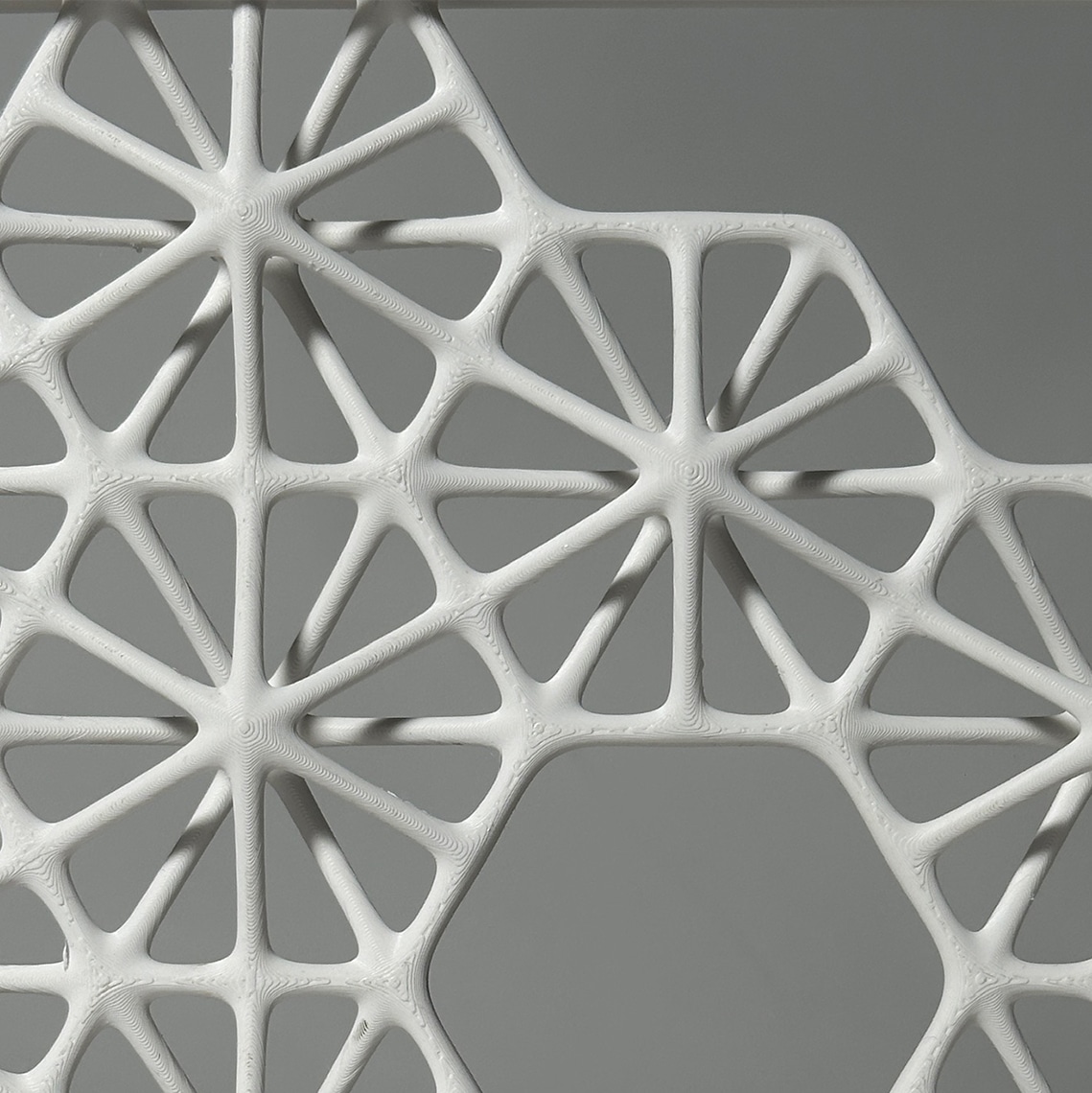

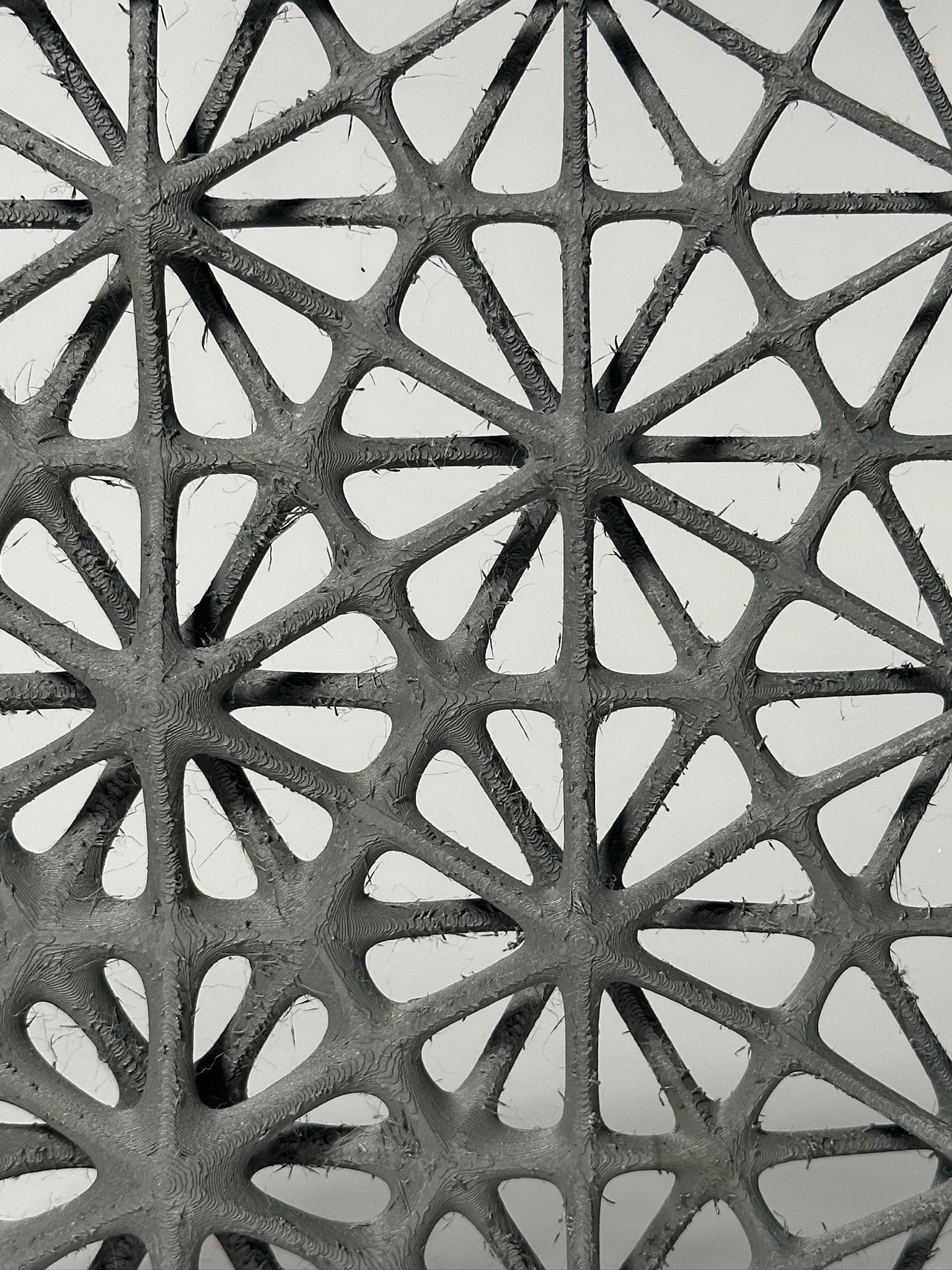

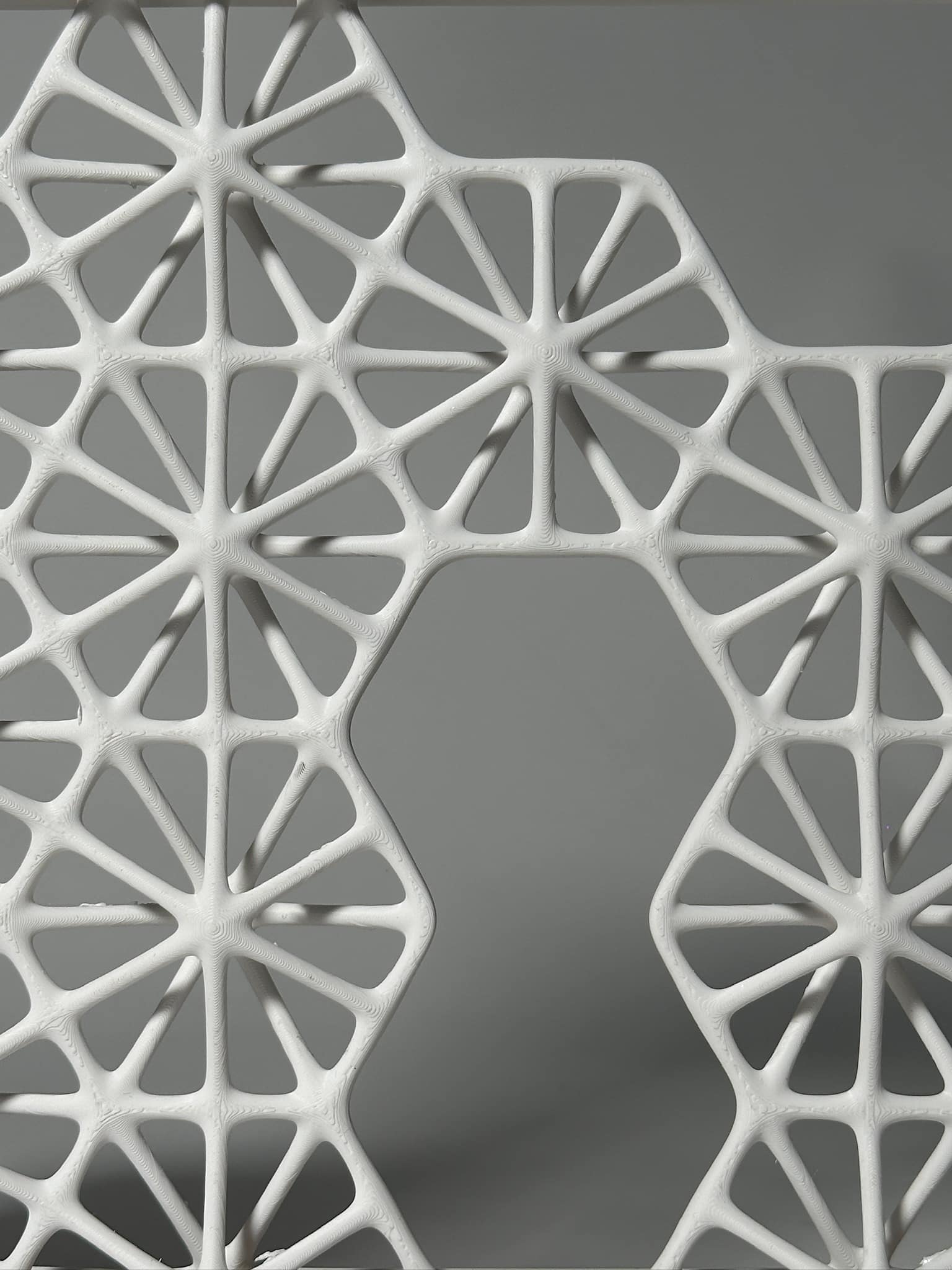

BioMesh – 3D Printing

BioMesh is a modular pattern where structure and opening are the same thing. A network of ribs forms graded holes that steer light, air and views while carrying load. One unit reads as a frame; many units join into screens, façades or light cores. The geometry can thicken into columns or flatten into panels, scaling from furniture to building skin. It is a simple kit for breathable, lightweight architecture.

Process and Design

We divided our model into four sections and printed the section with the thinnest lines as a sample before beginning to print our final model.

Prepare Time: 6m 14s

Model printing time: 2h 35m

Total time: 2h 41m

First Design

Material: PLA

Machine: Bambu Lab A1

Workpiece volume: 200mmx200mx30mm

Total Filament: 146.11 g

Model Filament: 65.90 g

Support Time: 8h53m

Top Z Distance: 0.23

Model Printing Time: 17h50m

Total Time: 21h39m

Final Design

In order to create a more parametric and potentially flexible design, we are recreating the current digital model in Grasshopper with additional forms, gaps, and shadows.

Prepare Time: 6m 30s

Timelapse Time: 4m 32s

Model printing time: 17h 50m

Total time: 18h 1m

Project Diagrams- Technical Drawing

Fabrication Strategy

Prototype pictures

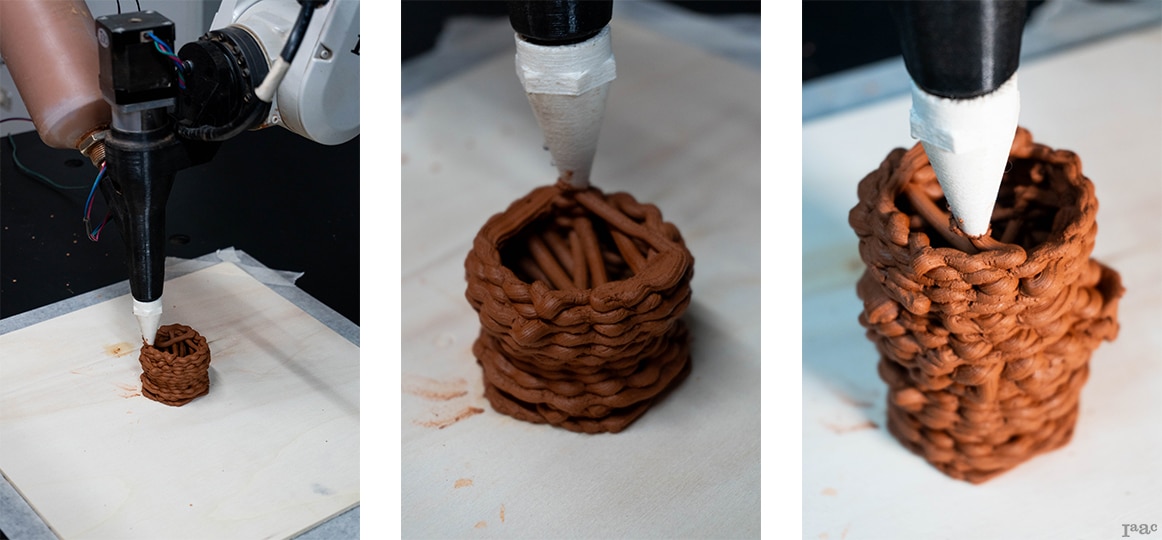

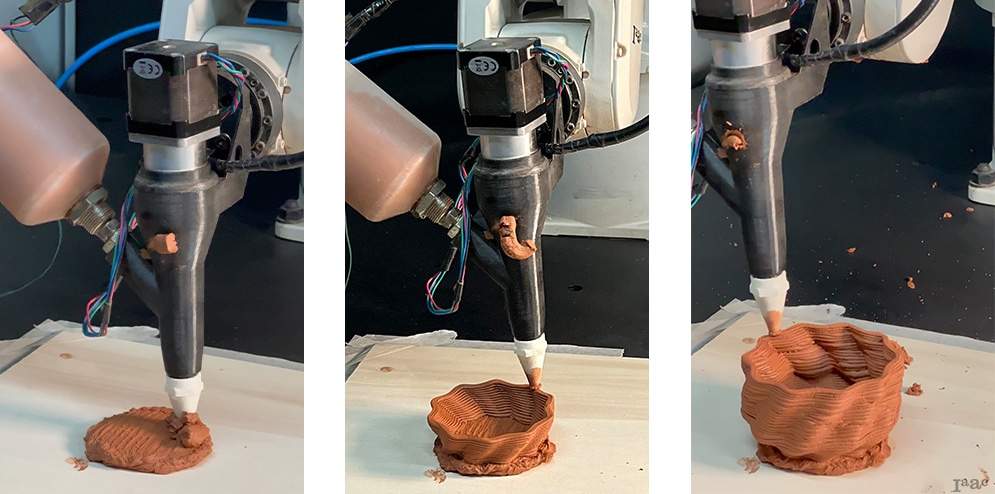

BioCup – Introduction to ABB Robotics

Project Description

First Sample

In the first sample, we had some issues with our first example since we did not approach the model as a system of external lines, which resulted in the incorrect creation of many lines. The way the cartridge is filled is important because too many air spaces can lead to the formation of clay bubbles, which would undermine the design.

Second Sample

In the second sample, we addressed the issues from the first example by adjusting the lines and layer height, but increased the printing arm speed from 15% to 38%. This change caused our design to collapse. For the final model, we implemented a two-layer base while maintaining the same speed throughout the process.

Fabrication Strategy

We optimized project geometry in Grasshopper for the ABB 120 robotic arm, integrating our script with the staff’s to conduct tests for system calibration and establish an effective fabrication workflow.

To begin the process, we prepared the robot by setting up a base for the product, filling the cartridge with clay, and securing it to the end effector. Additionally, prepare and test the digital code to ensure functionality before starting the modeling process.

Speed: 15%

Approximate time: 20m

Material: Premixed clay

Prototype Video

Prototype Pictures