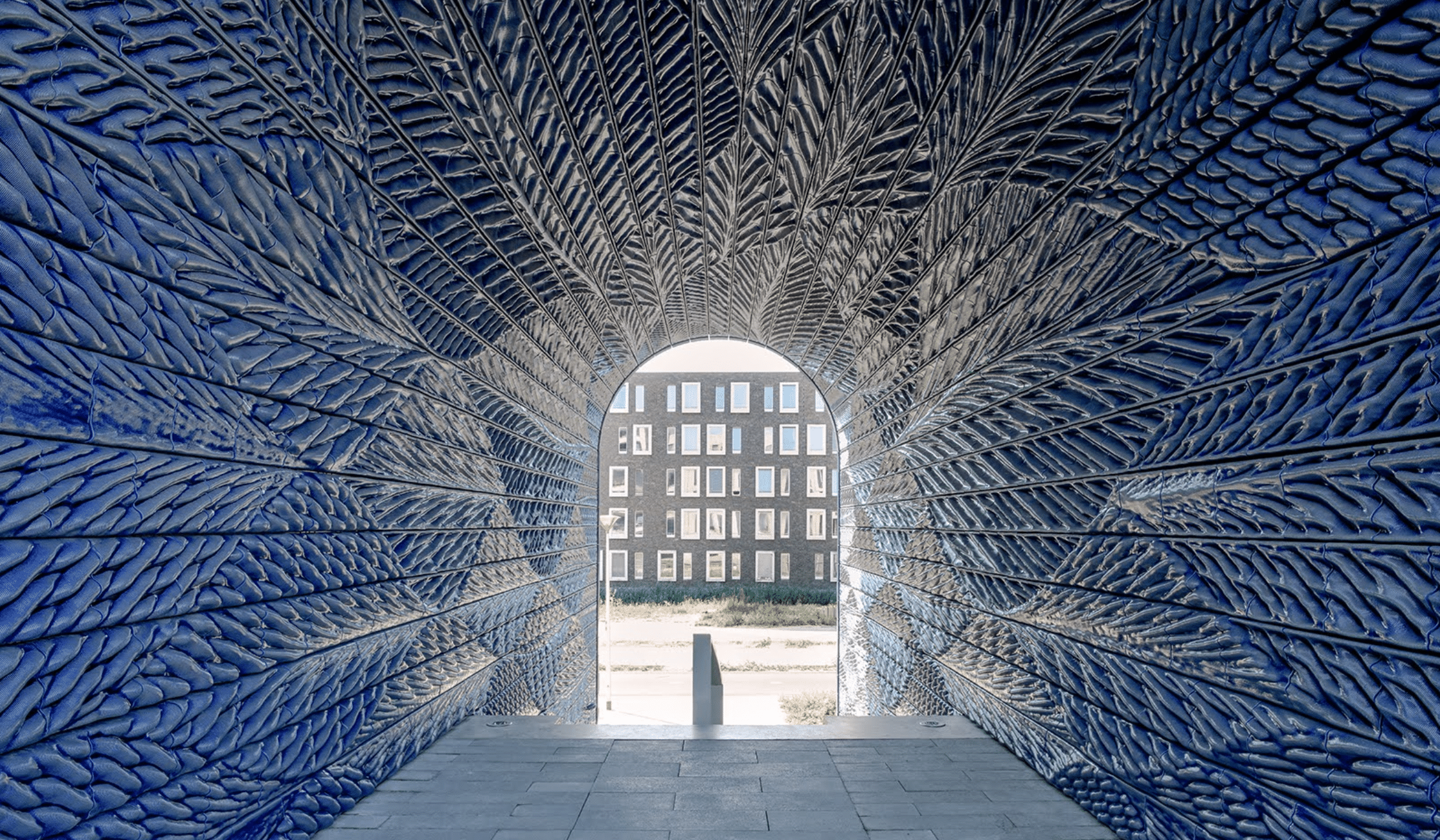

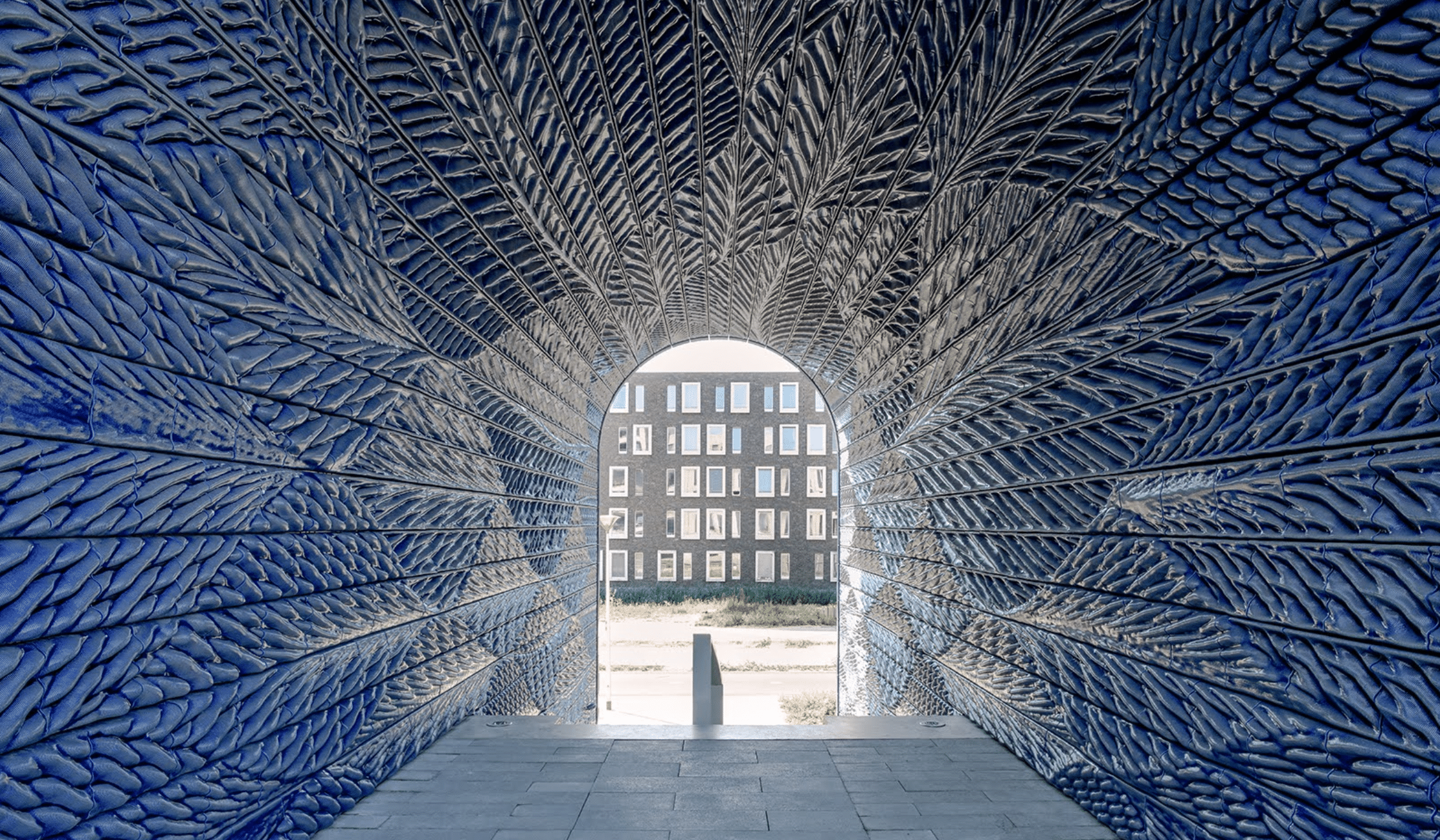

Credits: New Delft Blue, Studio RAP 2019

Digital Fabrication is an introductory course on new production techniques through the relation between computer data and machine-oriented fabrication.

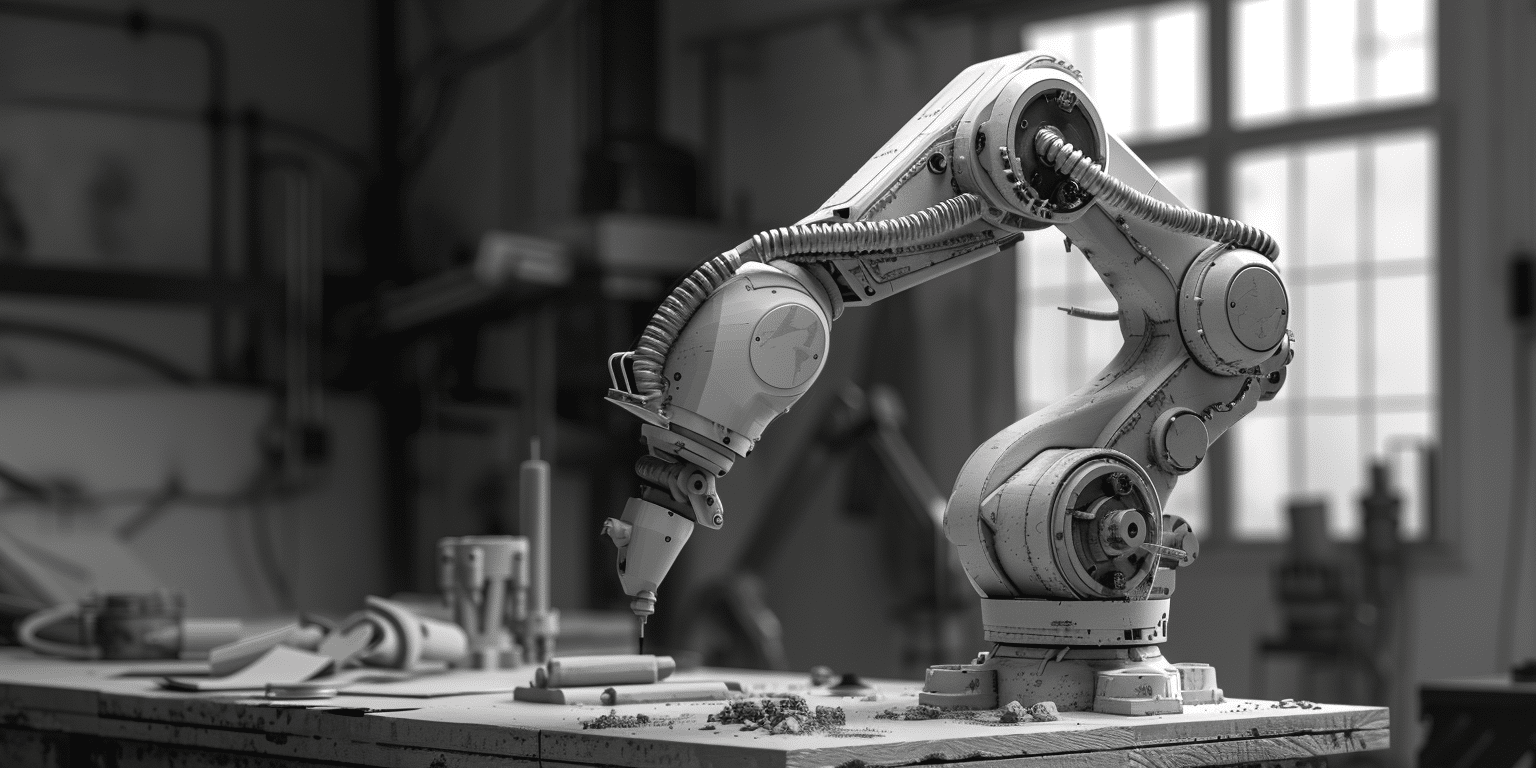

CNC machines were introduced in the middle of the 20th century into industry, changing the conception of the production of objects and parts (mainly in the automotive and military industries, and then into mass-consumed products). The relationship between architecture and digital fabrication CAD / CAM processes in architecture is not new anymore, it started during the last two decades of the XXth century, bringing in a new relationship that is not only affecting the way architecture is produced but is changing the way machines are constructed and conceived for the production of architecture.

At first, the relationship between architecture and digital fabrication has been focused on the production of non-standard parts/components and on the speculation of forms as an end itself. Instead, the seminar will focus on geometry and machines as a means to develop a performance-based design with efficient fabrication methods.

Learning Objectives

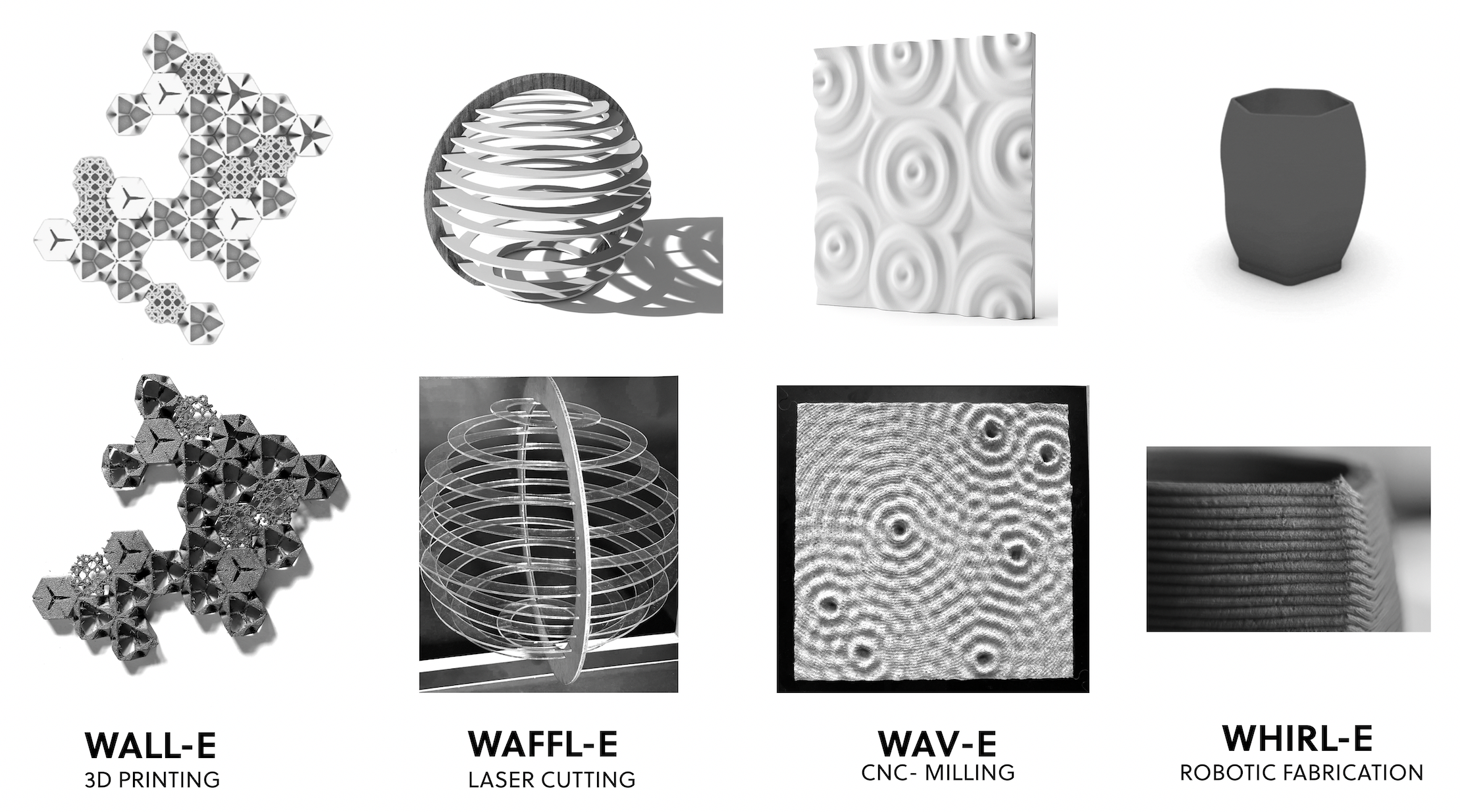

This seminar will be structured in weekly phases to reflect a different technology per phase.

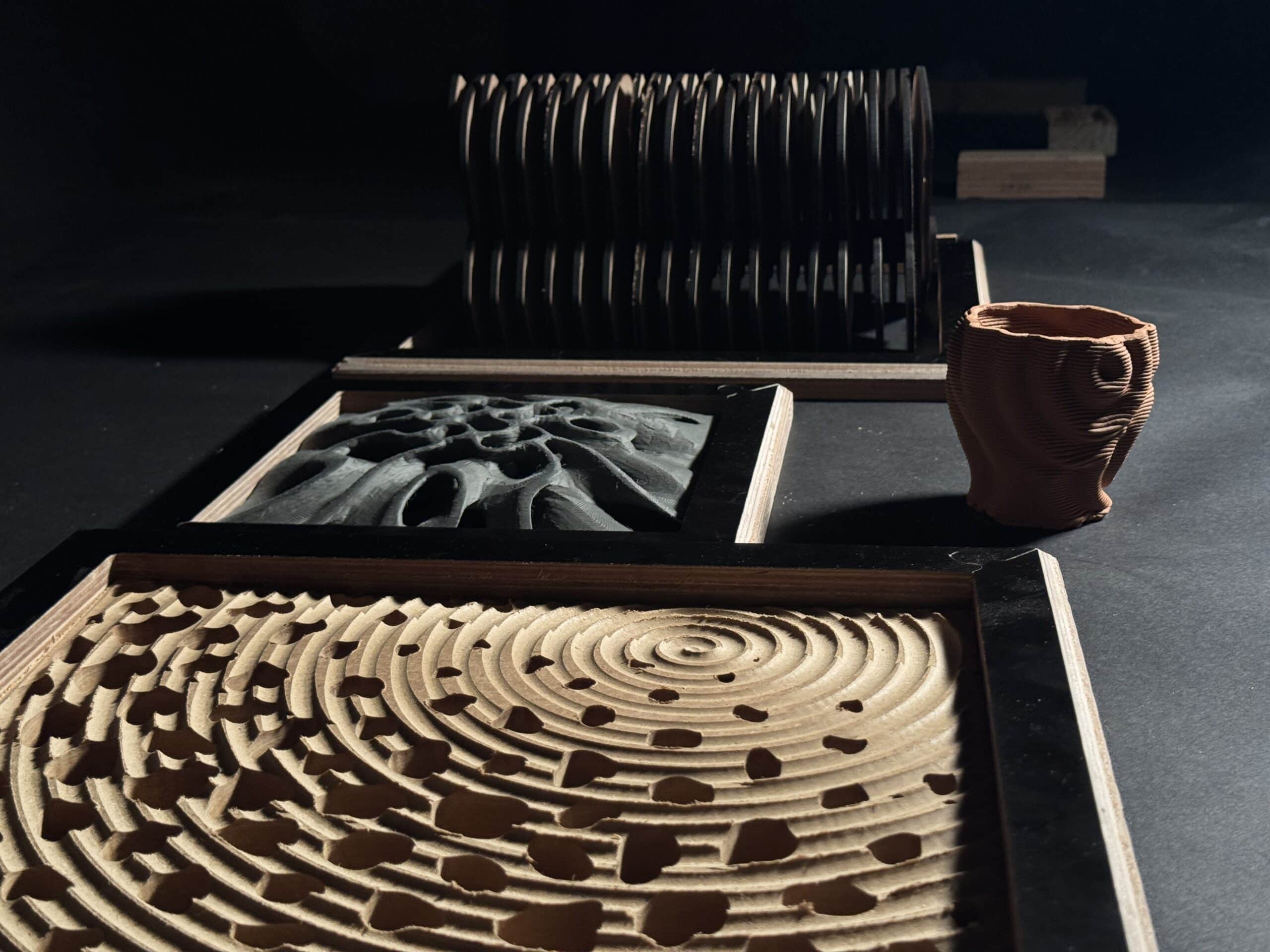

Through digital fabrication, tackling architecture details becomes an exciting new field of exploration for designers. The central theme of the weekly exercises revolves around the development of modular components of vertical building elements. Every week, teams are requested to bring new iterations of their work, incorporating novel aspects from three common digital fabrication processes: Laser Cutting, CNC milling and 3D Printing. You have both weekdays and weekends to collaborate on your projects, both digitally and physically (a lot can be explored and learn about matter behaviour without the use of digital machines).

Throughout the seminar, the first day of each phase will include an introductory lecture. Subsequently, students will explore fabrication parameters along with practical sessions with the goal of designing and prototyping their object. Each team will be provided with fabrication slots with the opportunity to use the machines in the lab to materialise their design. Students are requested to bring their files ready for production. Any doubt should be resolved previously.

Additionally, each week will include a “Fabrication Review” where students will have the opportunity to analyse the final object, review the design and learn about new processes and techniques under the guidance and support of tutors. The review will mainly be based on physically developed work. Students can show fabrication explorations, photos or diagrams during these reviews. Digital 3D models will not be allowed in the review.

By the end of the course, every student should be familiar with digital modelling, fabricating, documenting and assembly of a structure. Students should be able to devise strategies to translate geometries into articulated constructible solutions, produce the CAD-CAM files for production and use the CNC machines independently. During the course, students will also learn the principle of a FabLab and learn how to use this collaborative maker space in a safe, clean and respectful way.