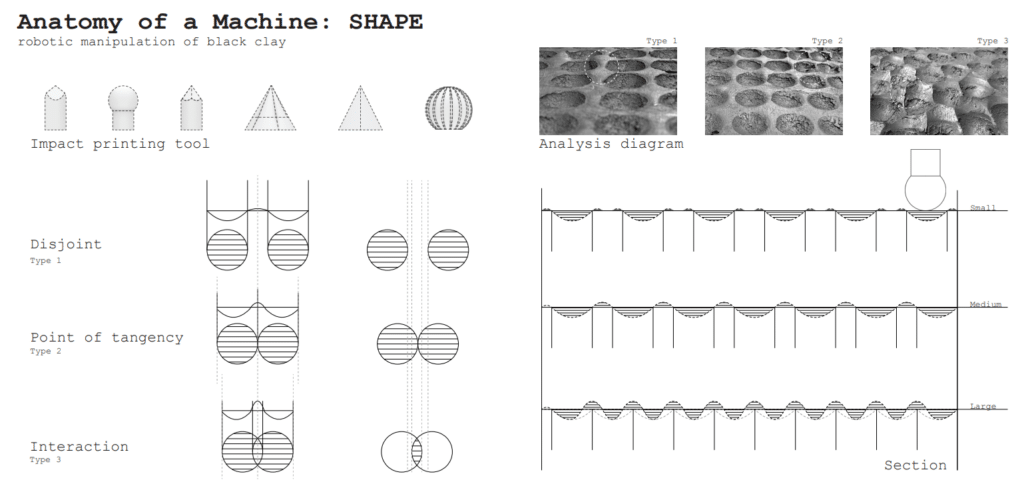

“Anatomy of a Machine: SHAPE” is a research project from the MRAC program that seeks to integrate knowledge from previous explorations in spill and strokes. To achieve shape, clay stamping was selected as the primary fabrication tool, establishing a 40x40cm working area as the base for experimentation. The project investigates how precise robotic movements—varying position, orientation, and height—can create diverse patterns and textures on clay surfaces through systematic stamping operations.

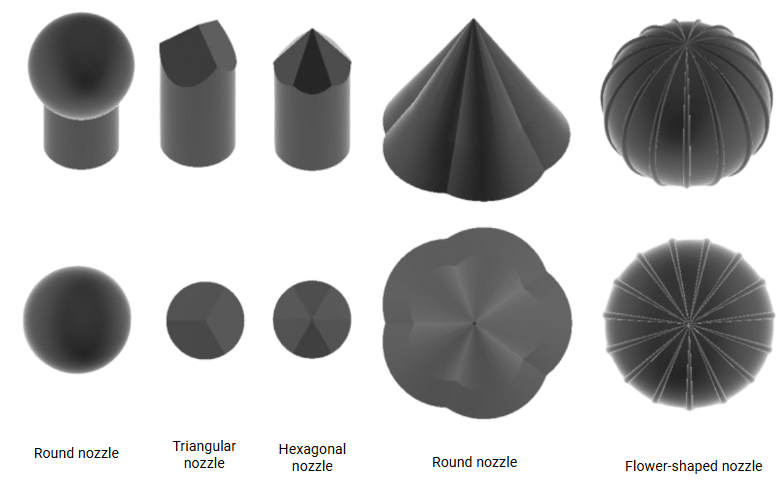

Terminal Nozzles: Design and Fabrication

The first step in the project involved designing a series of interchangeable terminal nozzles, each with distinct geometric profiles. Five different end effector tips were developed: triangular, round, hexagonal, and flower-shaped nozzles. These tools serve as the interface between the robotic arm and the clay surface, each geometry producing unique imprints and textural qualities. The variety of shapes allows for exploration of how different forms interact with the material properties of clay during the stamping process.

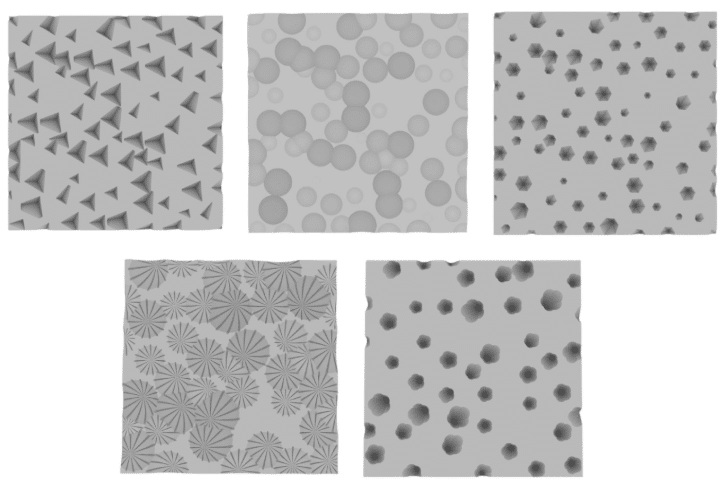

Motion Simulation

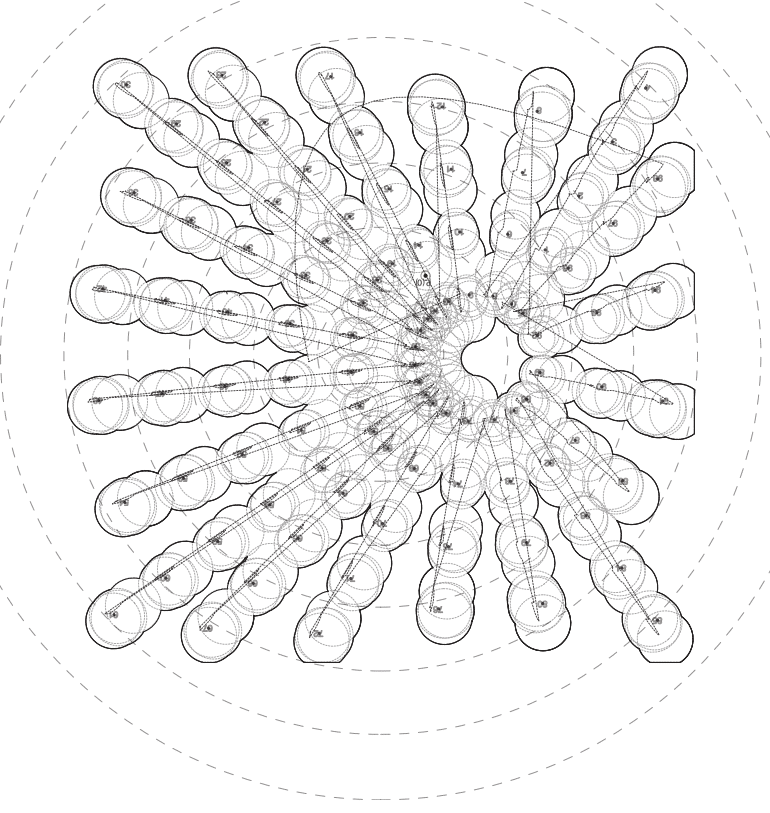

Before physical testing, motion simulations were conducted to plan and visualize the robotic operations. This digital phase allowed for the programming of toolpaths that would vary position, orientation, and stamping depth across the working surface. The simulation phase was crucial in understanding the robot’s movement capabilities and in predicting how different parameters would affect the final outcome.

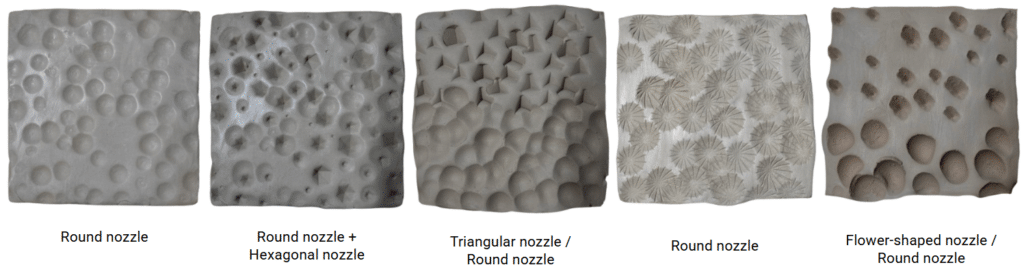

Clay Stamping Results: Initial Exploration

The initial testing phase focused on exploring the system’s capabilities through randomized stamping patterns. Different nozzle combinations were tested at varied positions, orientations, and heights to understand the range of textures and patterns achievable. Key test combinations included:

- Triangular and round nozzles creating angular and soft contrasts

- Exclusively round nozzles for uniform pattern studies

- Round and hexagonal nozzles combining circular and polygonal geometries

- Flower-shaped and round nozzles exploring organic and geometric intersections

These early experiments revealed how depth variation, nozzle geometry, and stamping density could generate vastly different surface qualities—from subtle textures to pronounced three-dimensional reliefs.

Prototype Development

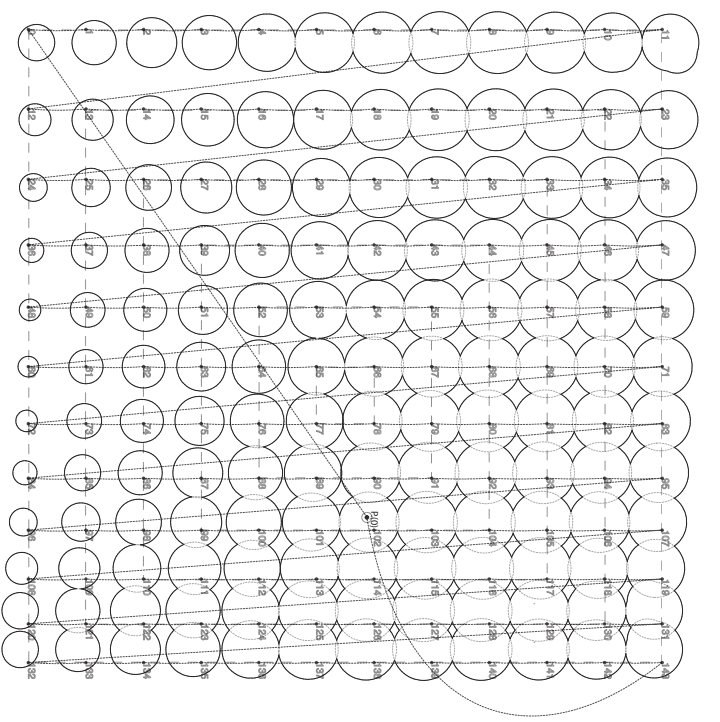

The project evolved through three main prototype iterations, each refining the relationship between point distance and Z-axis control.

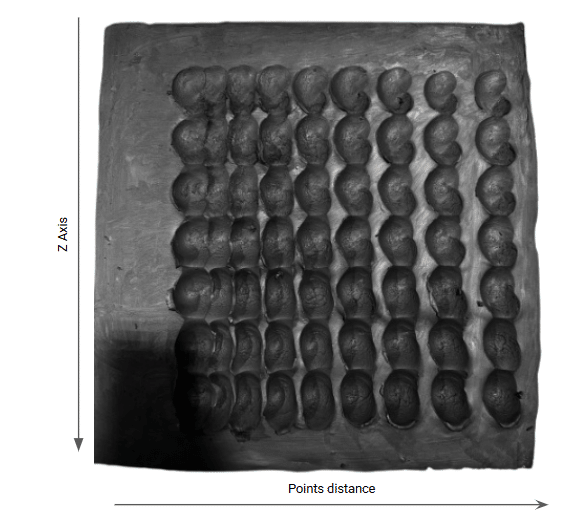

Prototype 1

The first prototype established the baseline parameters, experimenting with the relationship between stamping point distances and vertical displacement along the Z-axis. This initial iteration focused on understanding how spacing between stamps affects overall pattern coherence and surface continuity.

.

.

.

.

.

.

.

.

.

.

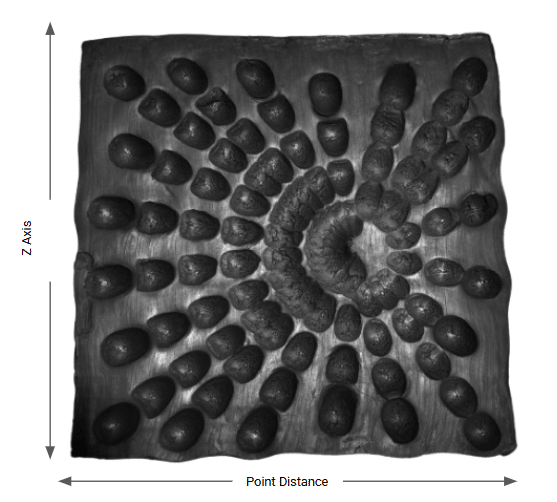

Prototype 2

Building on the first iteration, Prototype 2 refined the control over point distance and Z-axis movement. The adjustments allowed for more precise manipulation of pattern density and depth variation, leading to more controlled and intentional surface articulation.

.

.

.

.

.

.

.

.

.

.

.

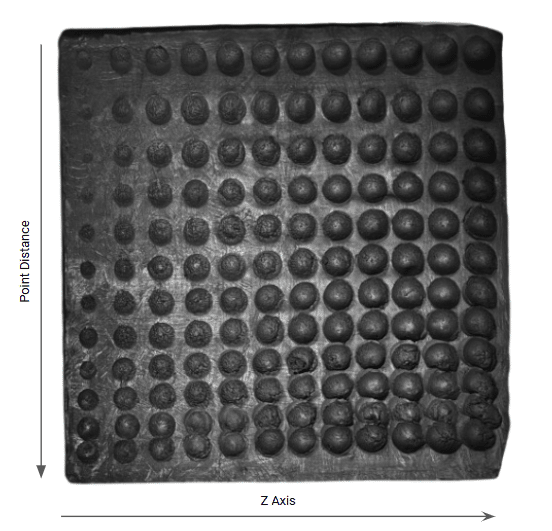

Prototype 3

The final prototype iteration further optimized the parameters of point distance and Z-axis control. This version demonstrated the most refined understanding of how computational parameters translate into physical surface qualities, achieving a balance between systematic order and expressive variation.

.

.

.

.

.

.

.

.

.

.

.

Conclusions

“Anatomy of a Machine” demonstrates how robotic fabrication can extend traditional ceramic techniques into new territories of form and texture. By systematically exploring the variables of movement, geometry, and material interaction, the project reveals a methodology for computational craft that maintains material sensitivity while leveraging digital precision. The iterative prototype development shows a clear progression toward more nuanced control over the relationship between digital input and physical output, opening possibilities for future applications in architectural ceramics and beyond.