A SYSTEM FOR URBAN DECARBONIZATION

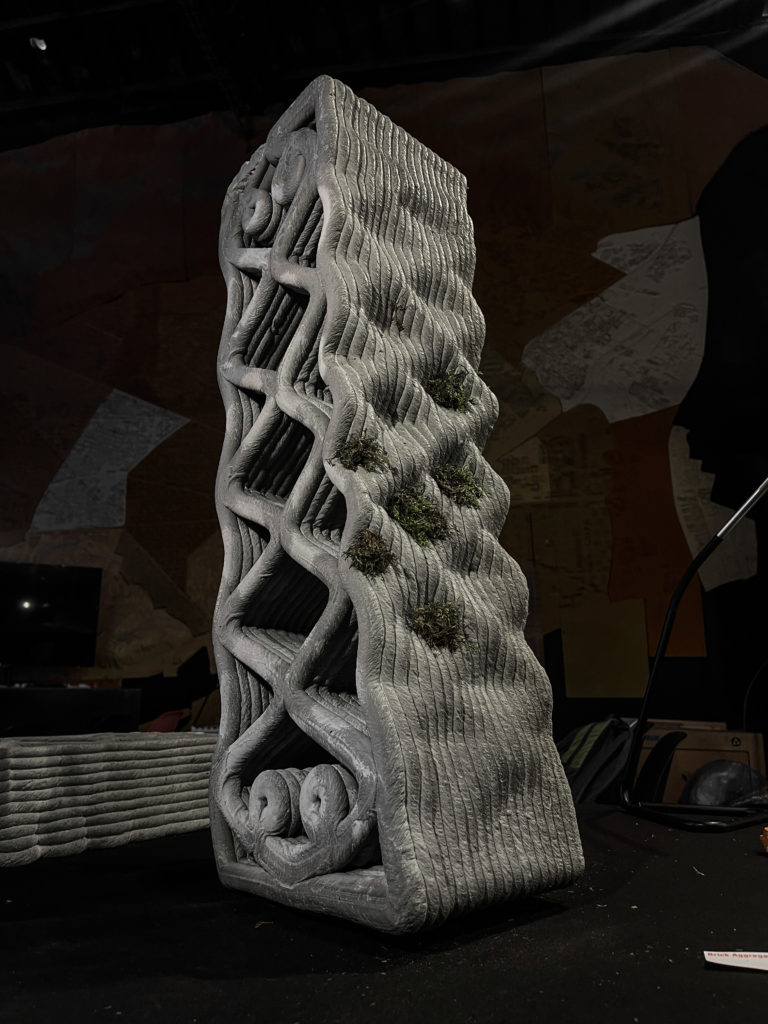

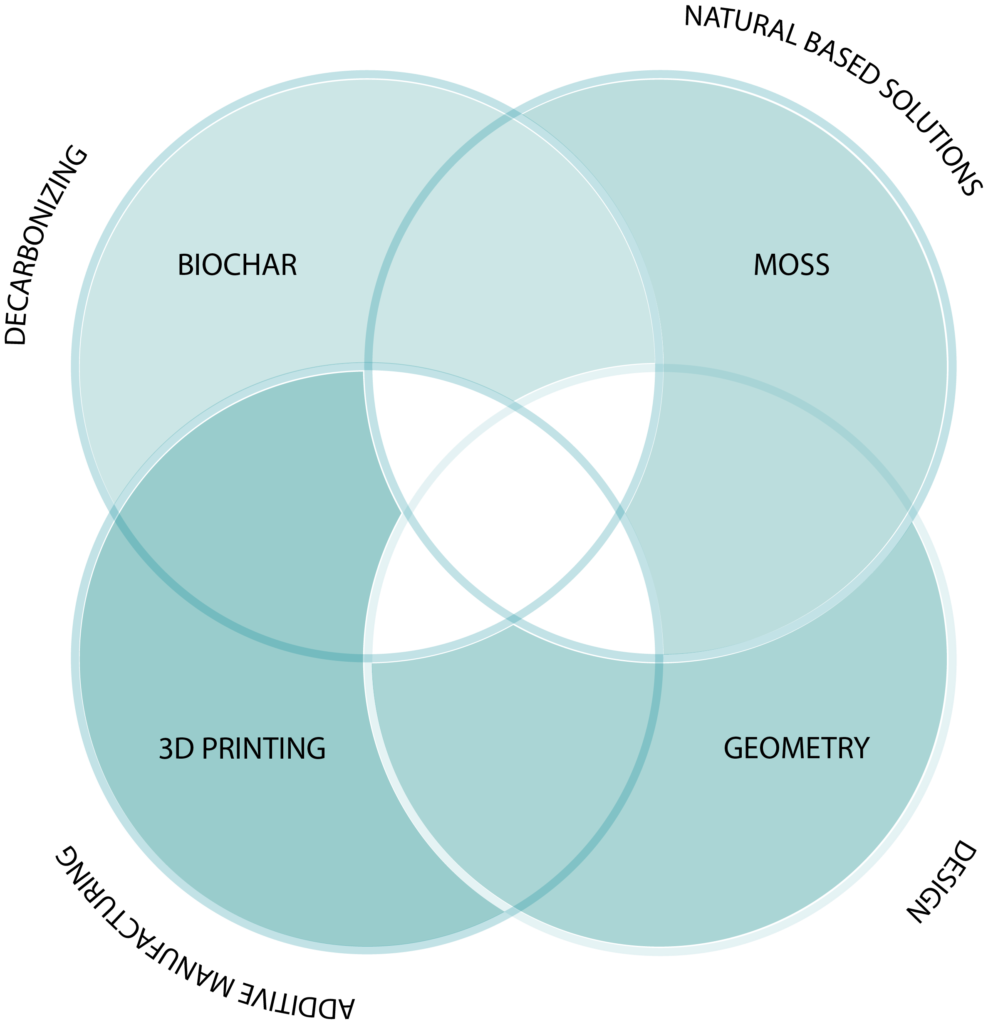

Breathing Carbon emerges as a response to the pressing need for sustainable urban infrastructure that addresses climate change and promotes ecological resilience. By integrating biochar, a carbon-rich material derived from biomass waste, into the concrete mixture, we aim to harness its carbon sequestration properties, thus contributing to global efforts in mitigating carbon emissions and combating climate change.

At the heart of our project lies a commitment to ecological restoration and biodiversity enhancement. The incorporation of living systems into the structure serves as a catalyst for creating an urban ecosystem. The moss not only acts as a natural air purifier, improving air quality, but also provides habitat and sustenance for diverse flora and fauna, fostering a resilient and balanced ecological community within the urban landscape.

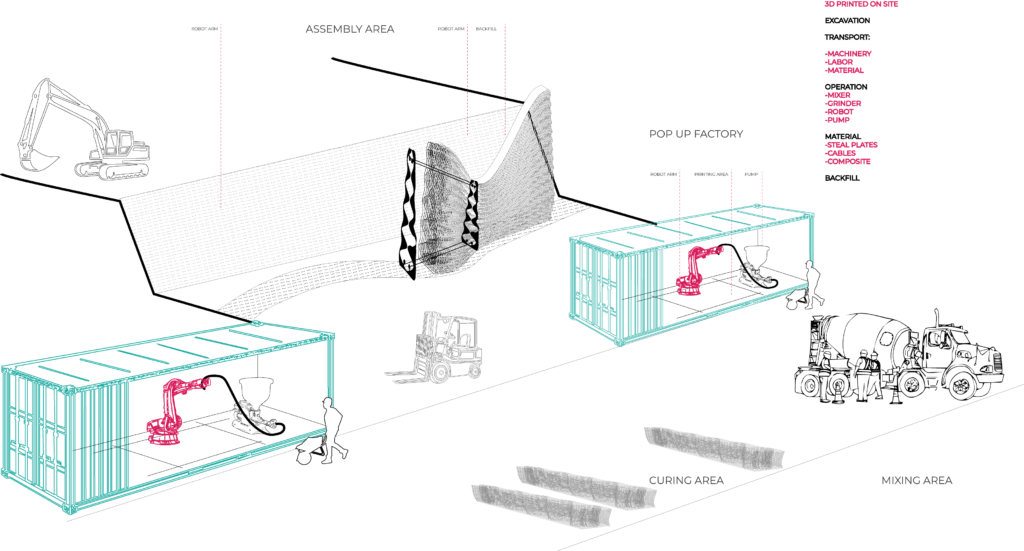

In alignment with the principles of sustainable construction, Breathing Carbon advocates for on-site fabrication techniques, such as 3D printing, to minimize transportation emissions and waste. This approach ensures a more efficient and environmentally friendly construction process, while adhering to the principles of a circular economy.

We aspire to transform the urban landscape into an ecosystem that not only addresses the challenges of climate change but also fosters ecological harmony and promotes the well-being of both human and non-human inhabitants. Breathing Carbon is a testament to our dedication to advancing sustainable urban design and construction practices.

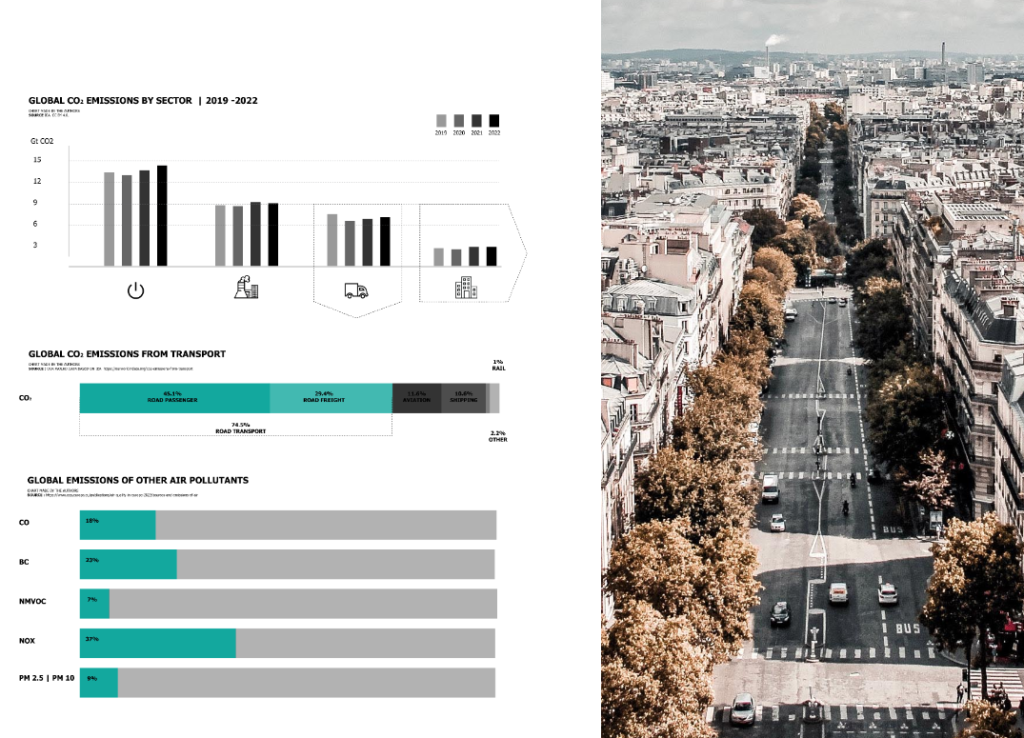

PROBLEMATIC

The rise in carbon dioxide (CO2) emissions has emerged as a worldwide issue, with a direct connection to climate change and rising temperatures. In 2022, global CO2 emissions experienced a 0.9% increase, reaching a new high of more than 36.8 billion tonnes.

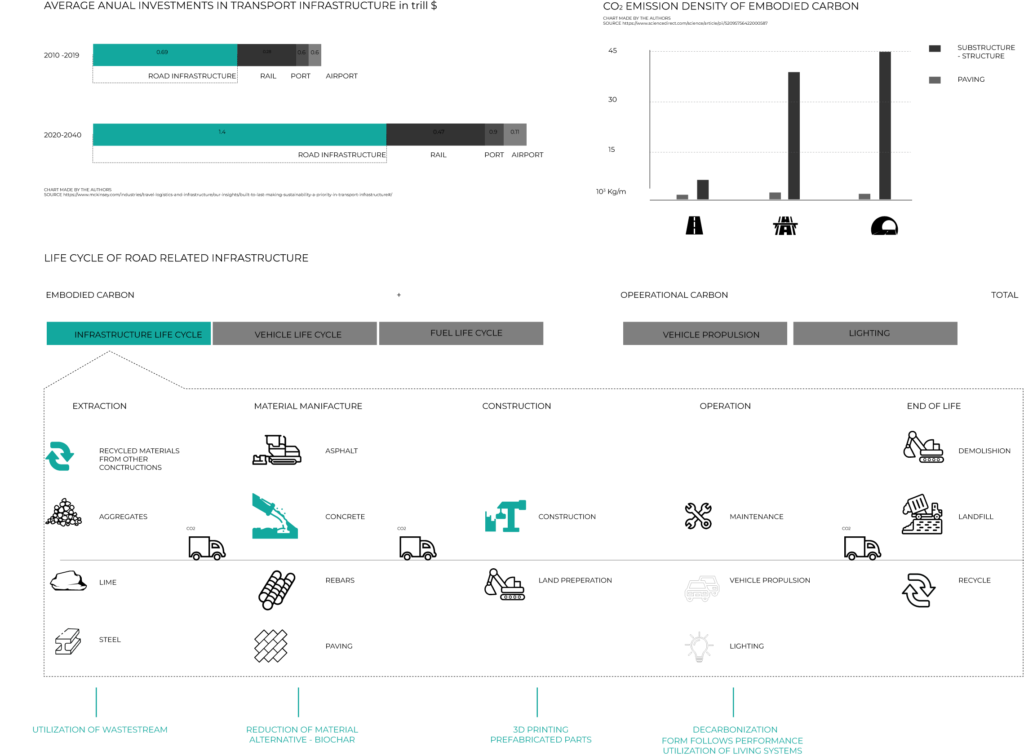

The burning of fossil fuels stands as the main contributor to these emissions. In 2019, the transportation sector was responsible for emitting 8.49 billion tonnes of greenhouse gasses, while the construction sector followed with 6.3 billion tonnes

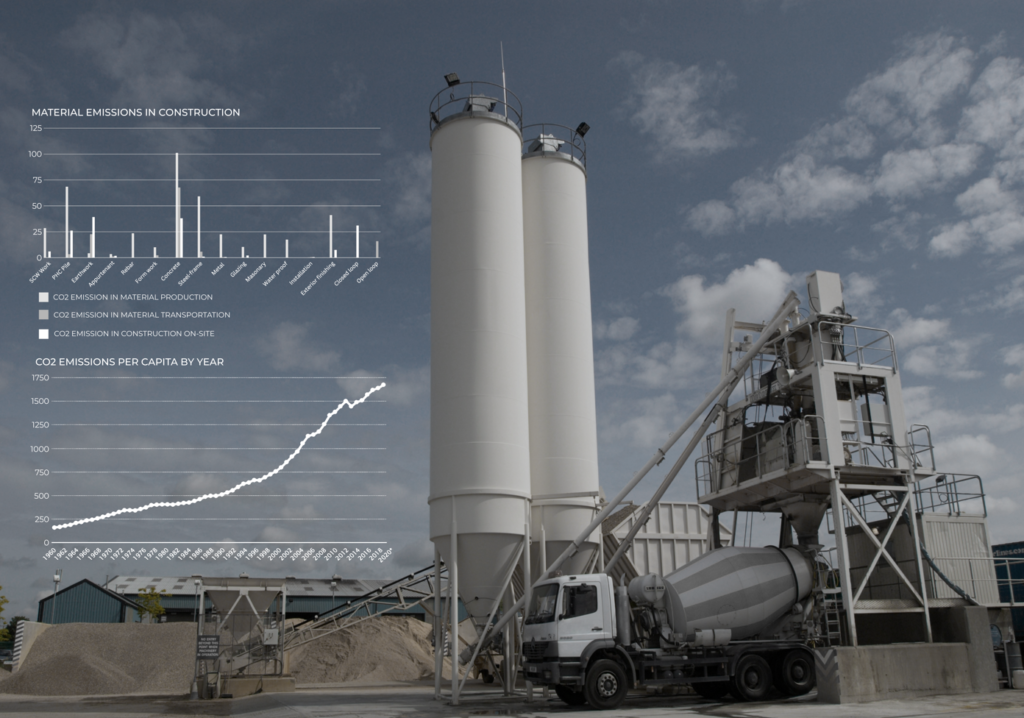

The built environment significantly contributes not only to CO2 emissions but also to the depletion of resources. Within the construction industry, the usage of energy in the final stages accounts for 36%, and energy and process-related CO2 emissions comprise 39% of the total. A notable 11% of these emissions result from the manufacturing of building materials.

Among those construction materials concrete has the highest production rate, being the most used material in the world w?th the h?ghest co2 em?ss?ons. The production of one ton of cement results in the emission of approximately 900 kg of CO2 into the atmosphere, making the cement industry alone accountable for almost 5% of global anthropogenic CO2 emissions.

However a range of initiatives to decarbonize the environment are taking place. Efforts like the European Green Deal, which aims for climate neutrality by 2050, are promoting measures such as alternative cement materials, exploring carbon capture technologies, improving energy efficiency, and encouraging circular economy practices in the cement sector. When it comes to decarbonization utilizing the photosynthetic mechanism of living systems is the most credible method so far.

When it comes to the urban environment , due to the global urbanization trend, it is estimated that infrastructure projects will double by 2040, resulting in significant CO2 emissions primarily attributable to the construction of structures and substructures for this massive projects. We see here an opportunity to intervene in the life cycle of these infrastructures with respect to the decarbonization efforts already in progress to develop novel methods and approaches in regard to materiality, manufacturing and operation.

RESEARCH PROPOSAL

We focus on the development of mitigation strategies to control CO2 emissions from the cement manufacturing sectors while retaining concrete’s performance introducing additive manufacturing as a more effective construction approach. At the same time we explore the impact of the incorporation of living systems in the decarbonization efforts. All of these under the umbrella of design as a median which adds value to structures and can create the conditions for optimized performance based solutions.

MATERIAL SYSTEM

A promising option for concrete admixtures, with demonstrated potential, is the utilization of biochar cementitious composites that can be used to effectively decrease the carbon footprint associated with structural building components

BIOCHAR

INTRODUCTION

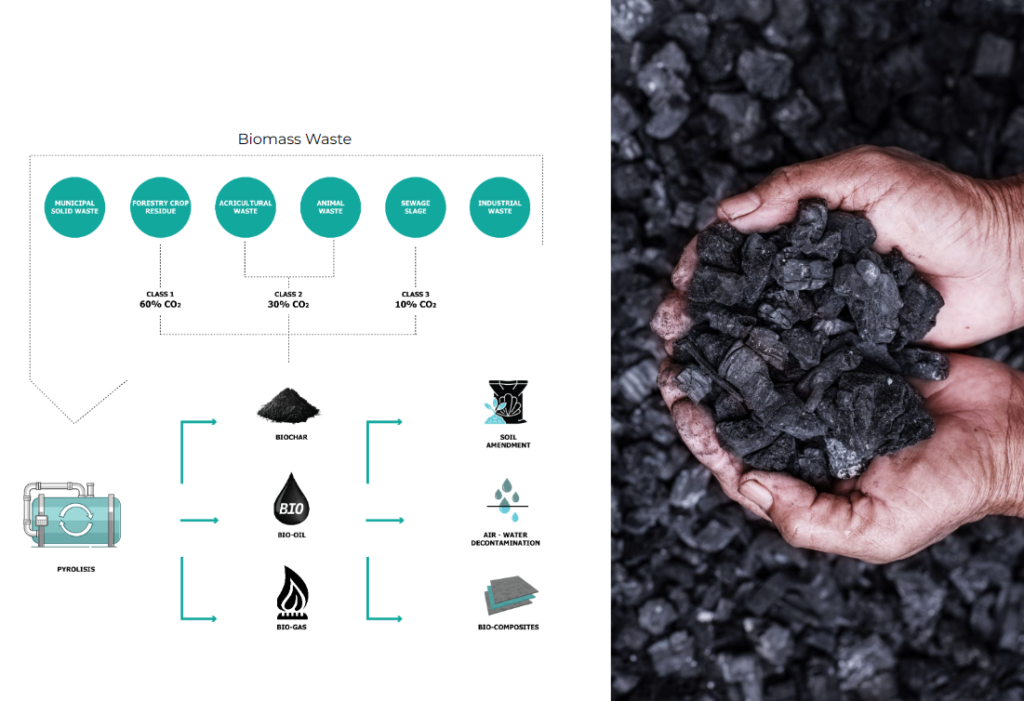

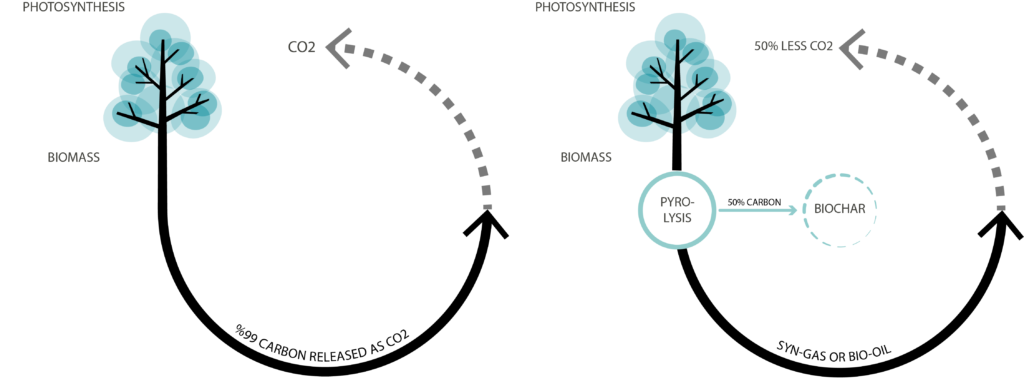

Biochar is the solid residue obtained from pyrolysis and gasification of biomass under limited oxygen. The other products are biogas and bio-oil. Traditionally, biochar has been used as a soil amendment. As a substitute for cement in concrete, it not only sequesters carbon but also reduces cement consumption. This leads to energy savings and a decrease in CO2 emissions during cement production.

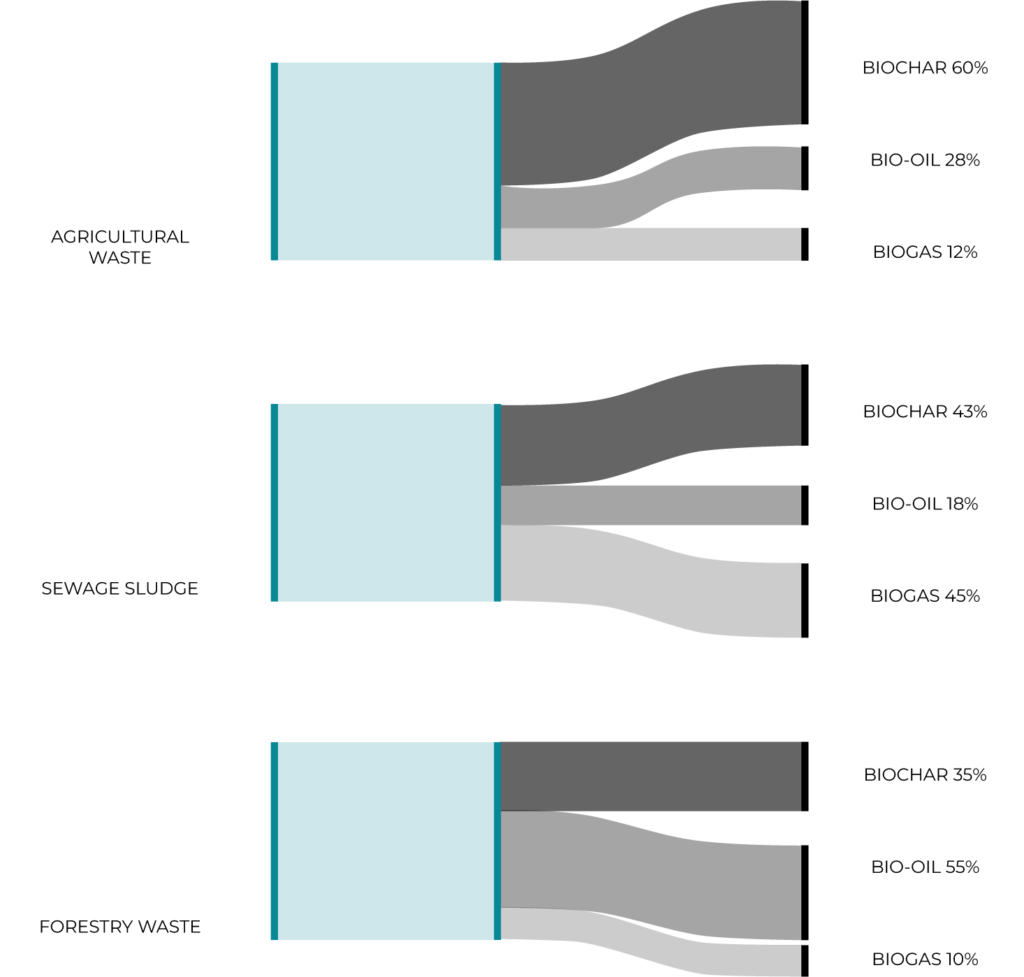

WASTE STREAM SANKY

According to the source of biomass biochar is originated from, the percentages and carbon content of the resulting biochar vary. Biochar from woodstock is 35% of the total amount of pyrolysis products with a 60% carbon content

CO2 SEQUESTRATION

Biochar is a very stable carbon rich material, which can sequester carbon for thousands of years. It is a carbon negative material, as the carbon present in the source biomass is trapped inside the biochar instead of being released into the atmosphere.

PROPERTIES

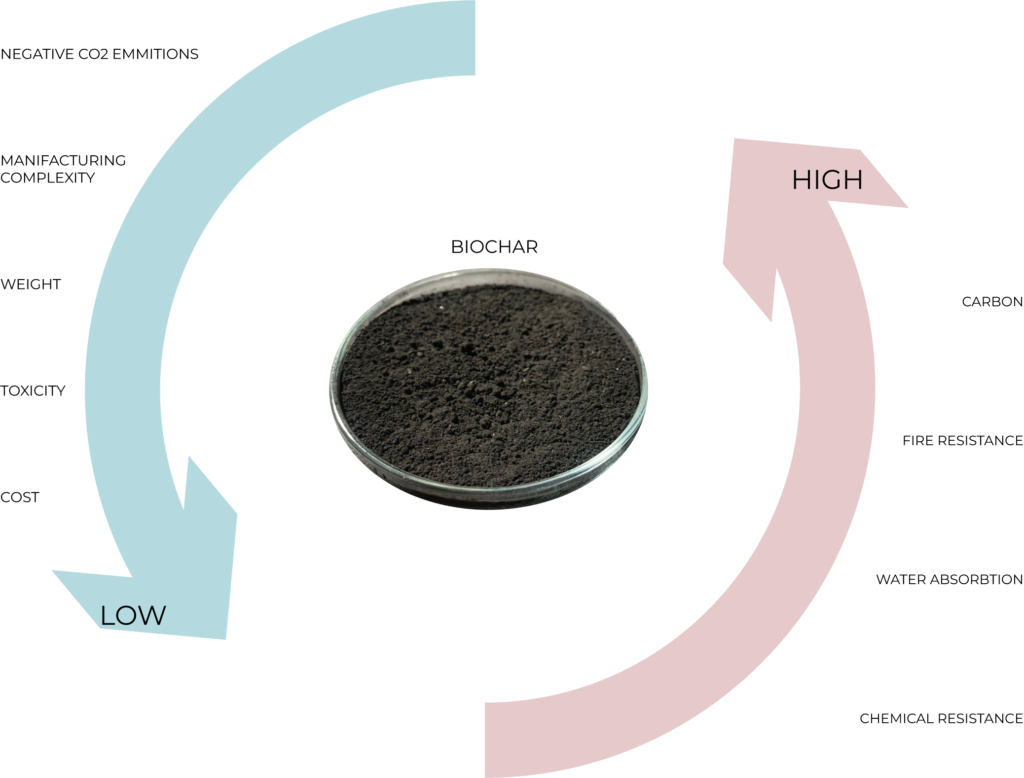

It is black in color, rich in carbon, has a large specific surface area, and has a porous structure. Thus its lightweight and absorbs humidity. It also can prolong the evaporative cooling effect, which could potential help reduce the heat island effect of urban spaces. Biochar is produced throughout the globe by the local agricultural industries making them an abundant and cost effective product. Additionally, within a cementitious composite due to its carbon content and humidity absorption can enhance its bioreceptive properties of the material.

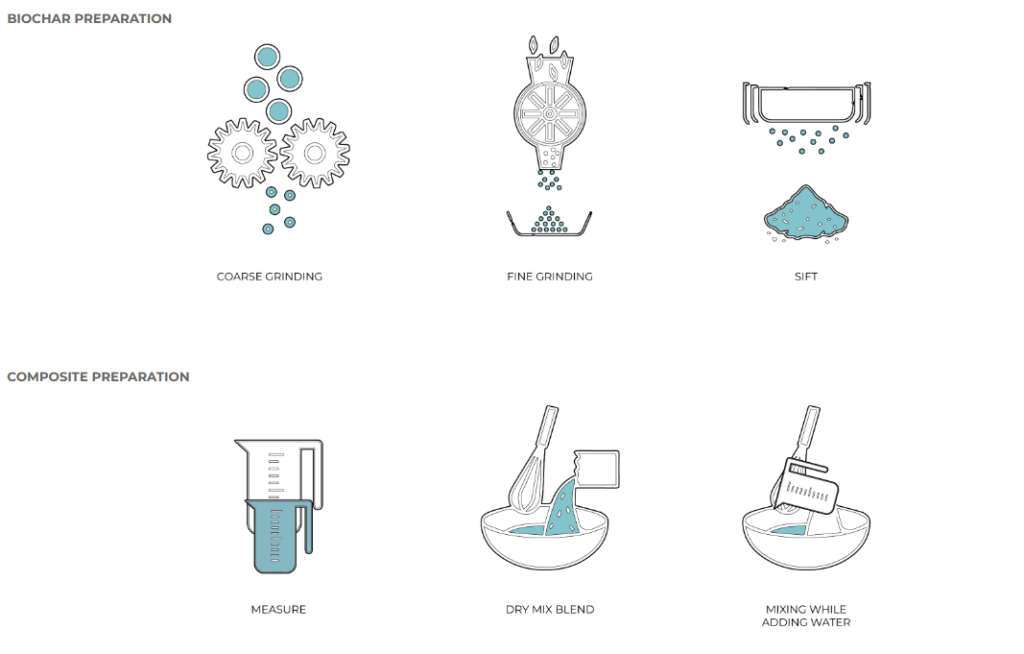

PREPARATION

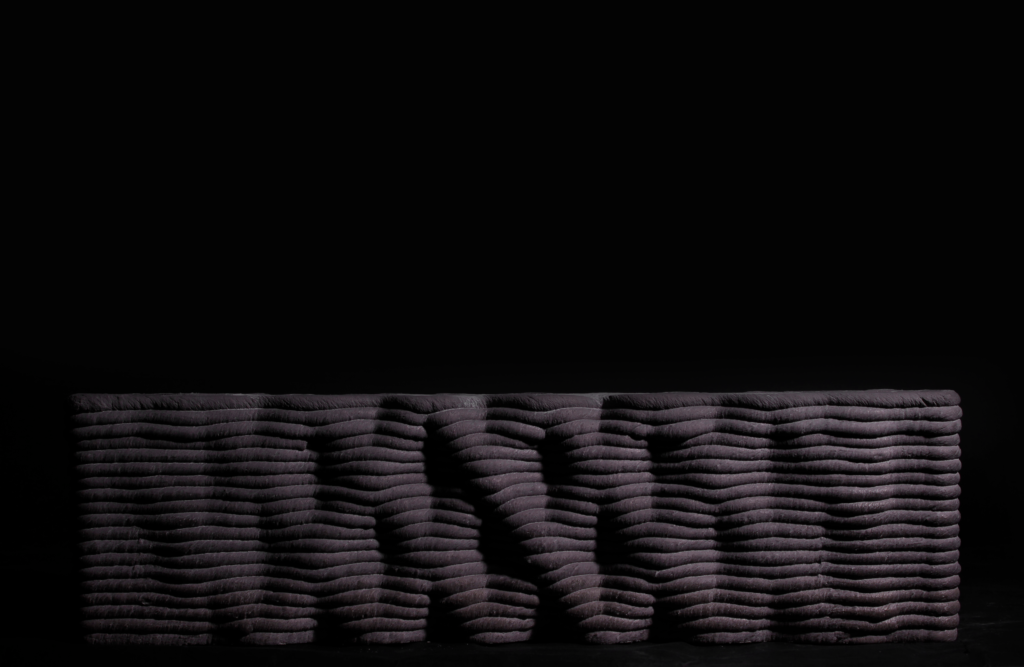

The below mentioned steps are required to produce the composite: Coarse and fine grinding of biochar, sift to obtain the finest powder. Measurement of the dry material which includes 20% sand concrete and biochar, mixing of the dry mixture and mixing while water is added.

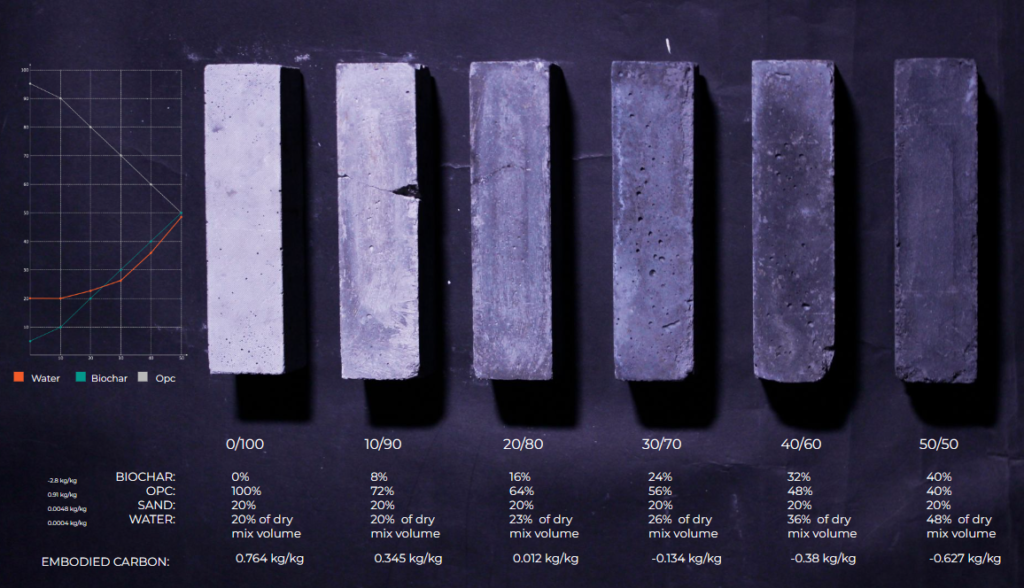

COMPOSITE INITAL EXPLORATION

During the initial material composite experimentation, it was noticed that the higher the amount of biochar in the mixture the more water the mixture is requiring. It has been proven that 5% of biochar in cement can increase its structural performance. In the 20% composite we can obtain an almost carbon neutral material which performs structurally as well as standard cement.

NATURE BASED SOLUTION

In the field of architecture, the biophilic properties of biochar have not been widely explored; however, there are some studies that demonstrate that biochar improves the vegetation compatibility of concrete. Biochar can accelerate plant growth and provide a healthy microbial & nutritious environment.

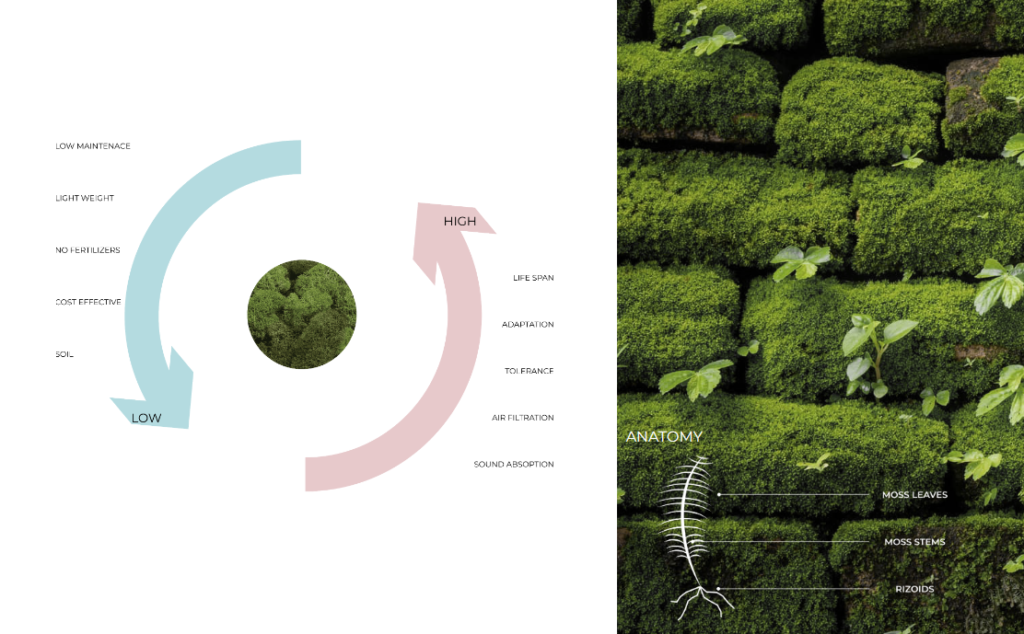

MOSS

The 3rd element of the material system is moss. Moss was chosen as reference of the impact that living systems can have on the operation carbon of structures. The choice was led by its adaptability and resistance to urban environments. Additionally, it can grow without soil and acts as an efficient air filtration system, reducing particulate matter. Mosses are nonvascular plants which instead of roots carry rhizoids Mosses are non-invasive plants, attaching to structures without compromising their integrity.

INTRODUCTION | PROPERTIES

CARBON CAPTURE

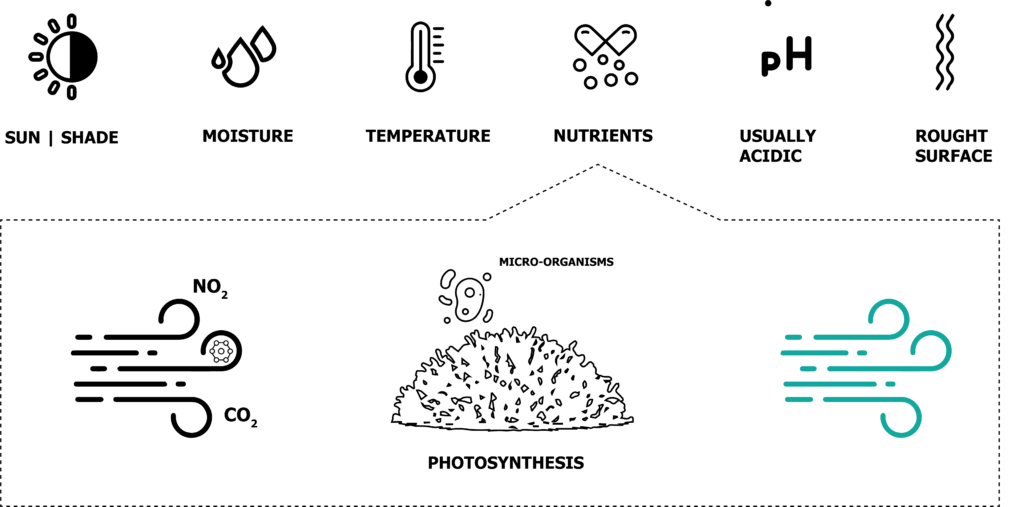

Although moss prefers shady environments, it still requires light for photosynthesis and can tolerate low light intensities. Mosses generally thrive within a temperature range of 15-25°C. Moisture must be kept more than 30% they need a Moss colonies exhibit peak photosynthetic activity in the early morning and late evening when moisture is abundant. Mosses derive nutrients from the atmosphere and can filter pollutants like nitrogen oxides and carbon dioxide, making them efficient air purifiers. The capture carbon as any living plant by photosynthesis. 1 square meter of moss sequesters 1 to 2.5 micro mol of CO2 per second*. which is equivalent to 0.032 – 0.079 kg of molecules per year. This may seem small (fuck its small!) but photosynthesis by moss accounts for 10 to 50% of whole-forest gross CO2 uptake. Sphagnum moss sequesters more CO2 than any other plant. This aptitude for absorption is partly because moss’s surface area is 30 times its size.

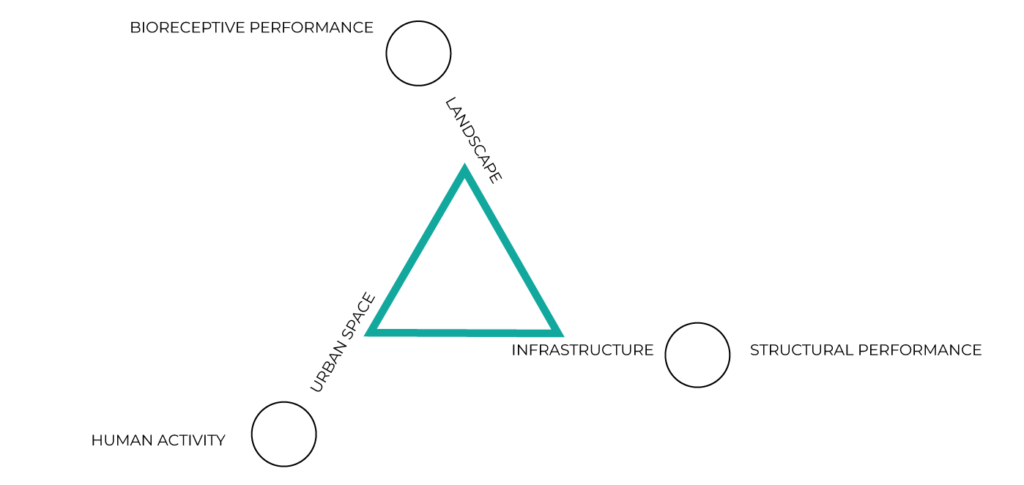

DESIGN & GEOMETRY

Concerning design as a median which adds value to structures, as well as considering the vast area that infrastructures occupy the decision was made to place our design somewhere between landscape -urban space and infrastructure, to utilize the area infrastructures occupy, creating a hybrid which can accommodate both the human and the non human.

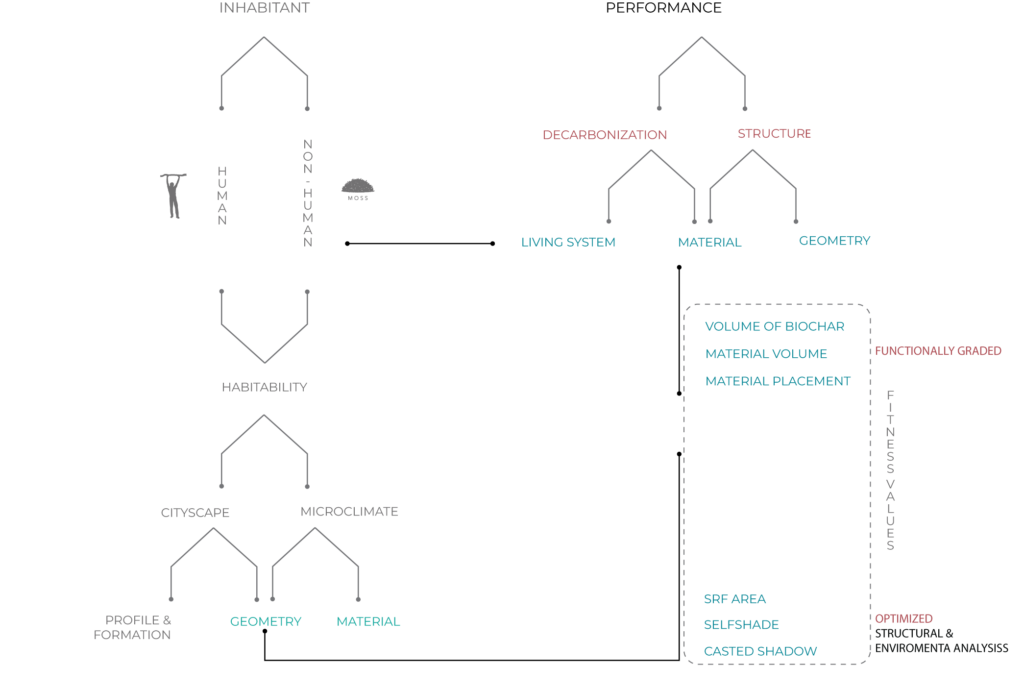

DESIGN METHODOLOGY | HABITANTS

As already mentioned, within the material system there is a living system with carbon capture capabilities. This living system has some predetermined needs in order to grow and populate what we can call a microclimate. And on the other hand we have the user-habitat, the human which also comes with conditions for inhabitants which are what we call the cityscape, all the activities, objects, spaces, history meanings and images, that create what human inhabits.

NON HUMAN

Moss was mentioned to be a very adaptable and resistant organism. However, controlled growth is crucial, as moss can enter a dry state where it does not absorb CO2 without the appropriate microclimate. There are 3 basic factors that are determinant Moisture Shade and griping. Moss needs minimum 30% moisture, 5 hours sunlight per day and a protected space from high speed wind with a rough surface to grip on.

MICROCLIMATE

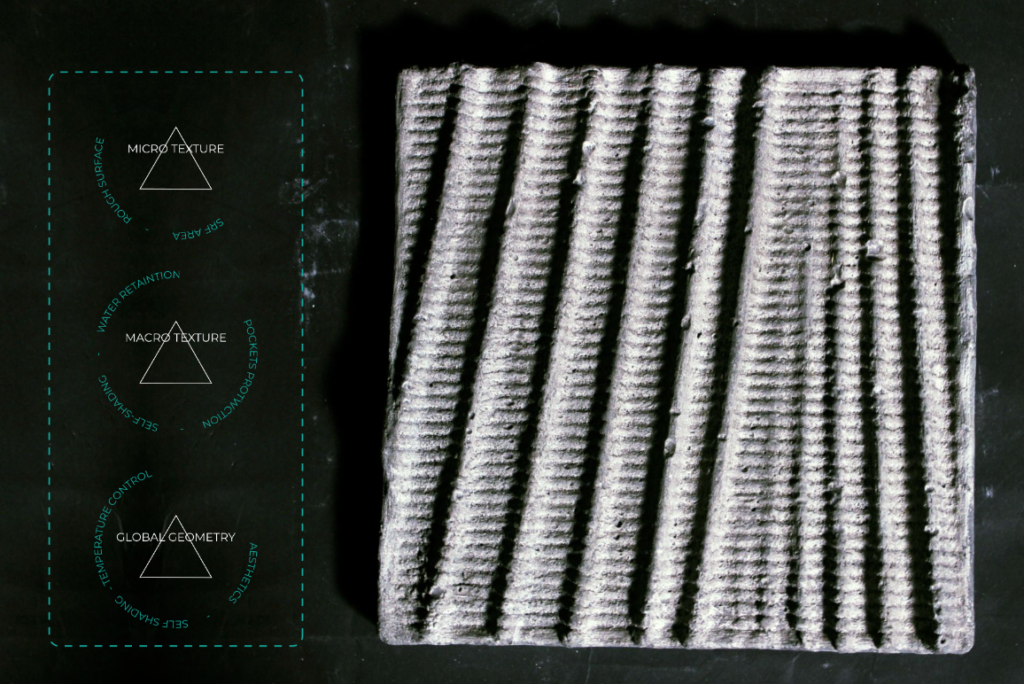

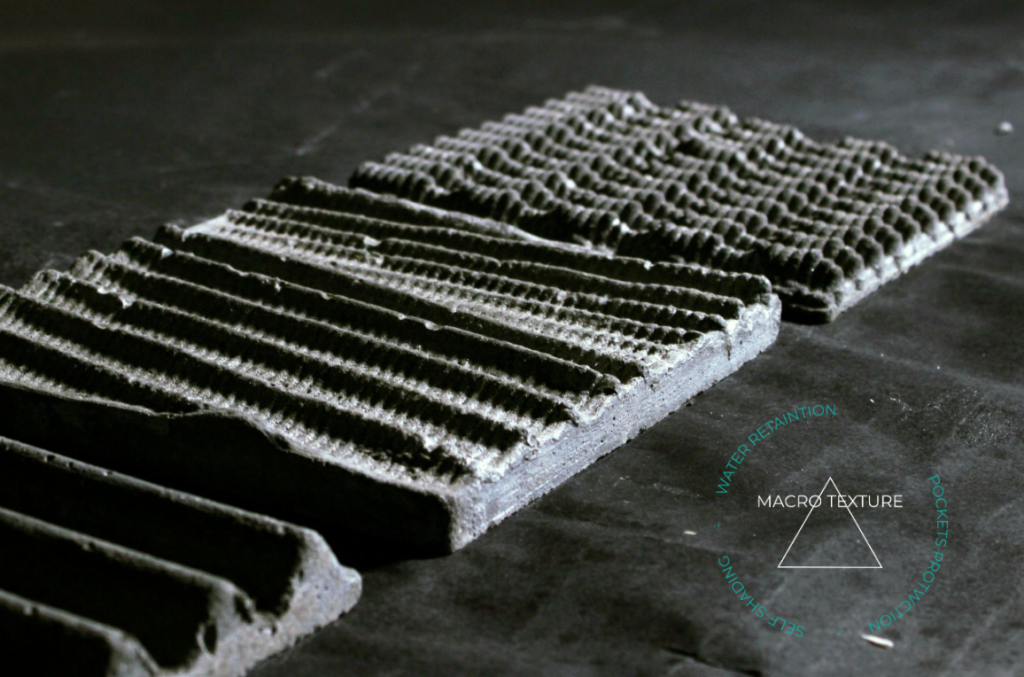

The Microtexture provides griping and water retention increases the surface area so consequently increases the water absorption and thus the moisture-water content of the structure.

The Macrotexture provides the living pockets to protect from wind, self shade and water distribution.

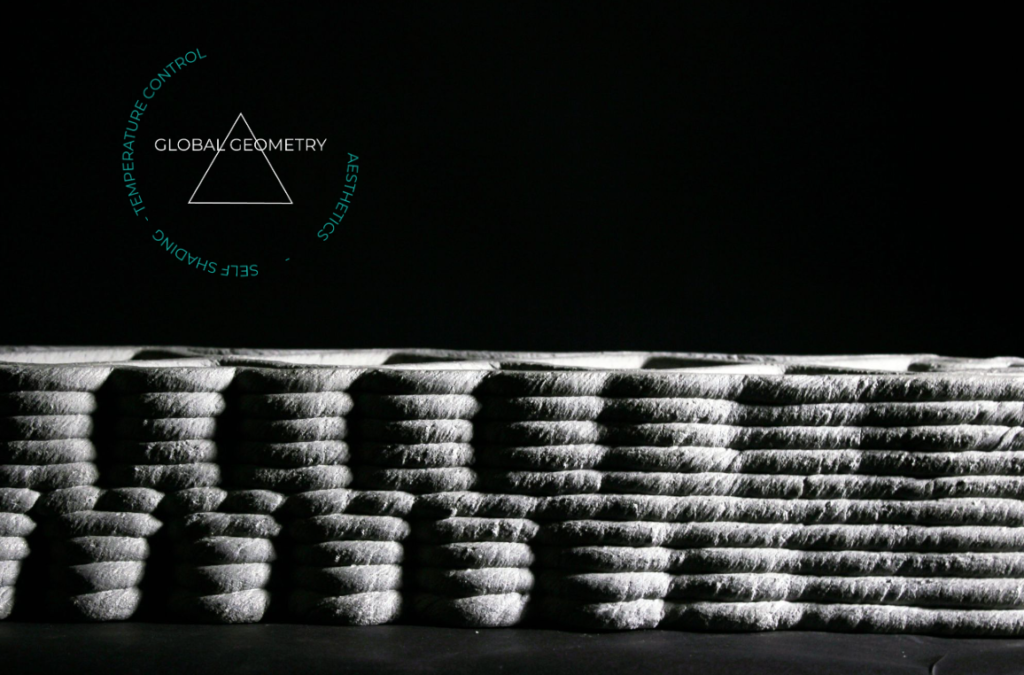

The Global Geometry controls as well the sun and shade on a bigger scale.

HUMAN

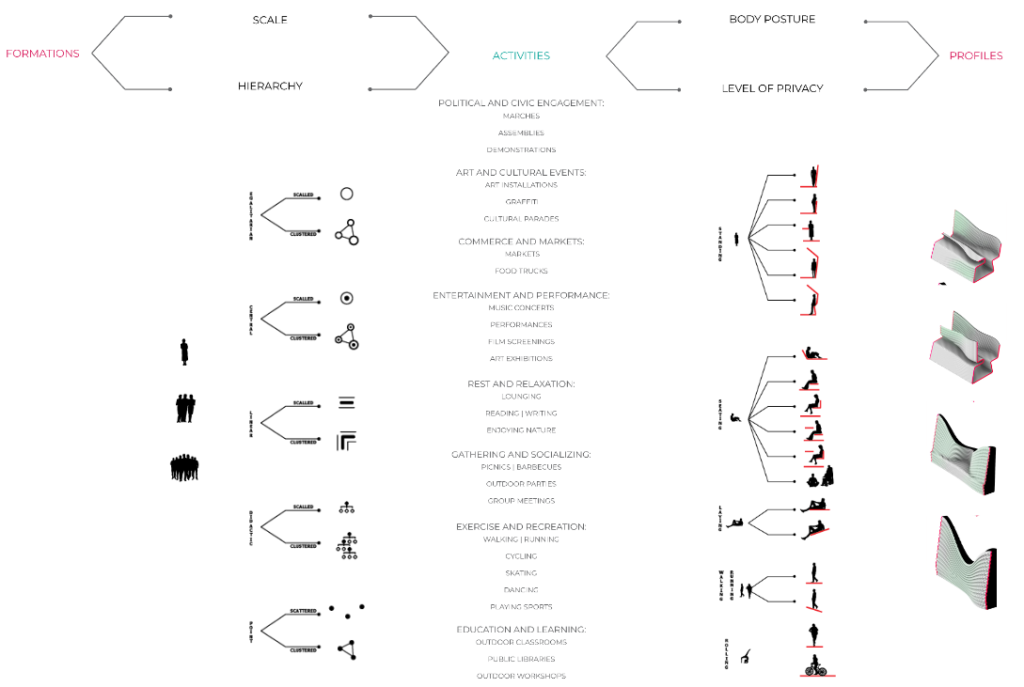

On the other hand, to define the parameters for human habitation we are focusing on different activities occurring in an urban space, on two different levels. On one level of the activities in regard to body posture, that will inform the PROFILE of the structure and on another level, scale and hierarchy of space needed that will inform the global geometry- the space formation.

ACTIVITIES & POSTURES

DESIGN OBJECTIVES

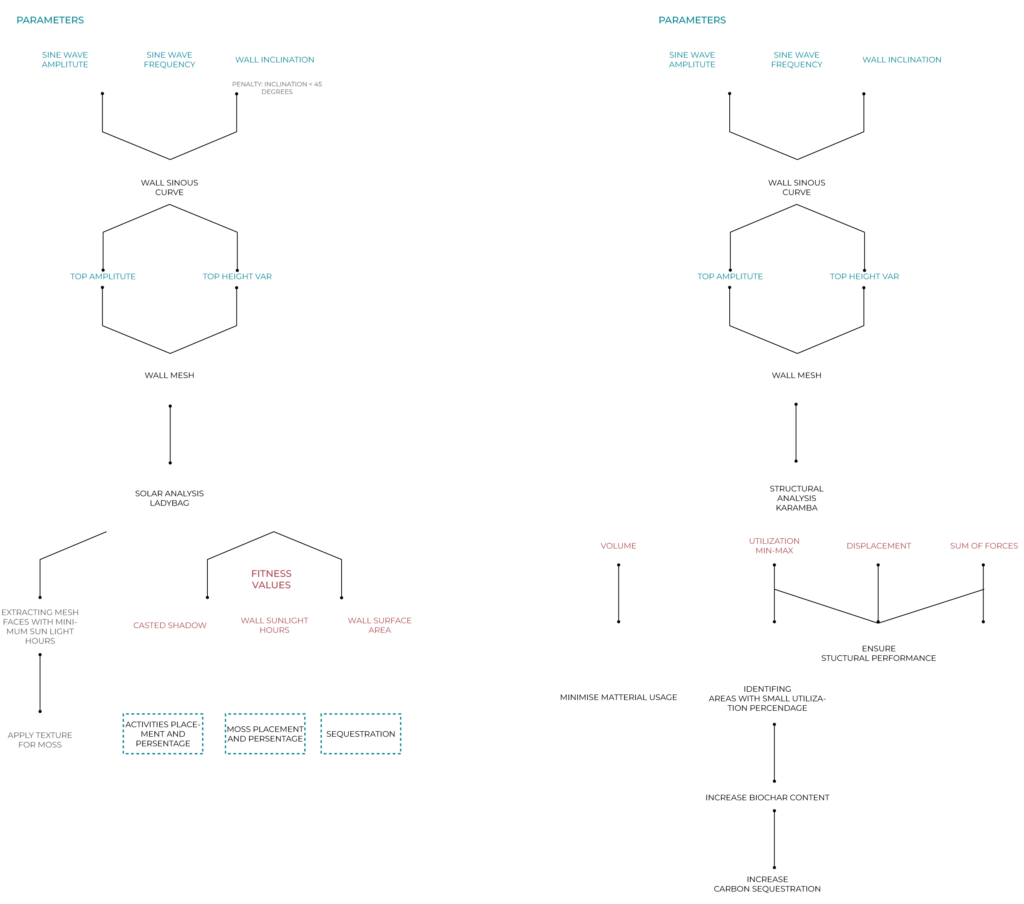

Alongside the habitant the performance of the structure is considered. As already defined, the performance is driven by 2 main characteristics. Carbon sequestration which is provided both on material level and during operation and structural performance as the necessary condition. In this way we can describe all the parameters and fitness values that will control our geometry.

CASE STUDY

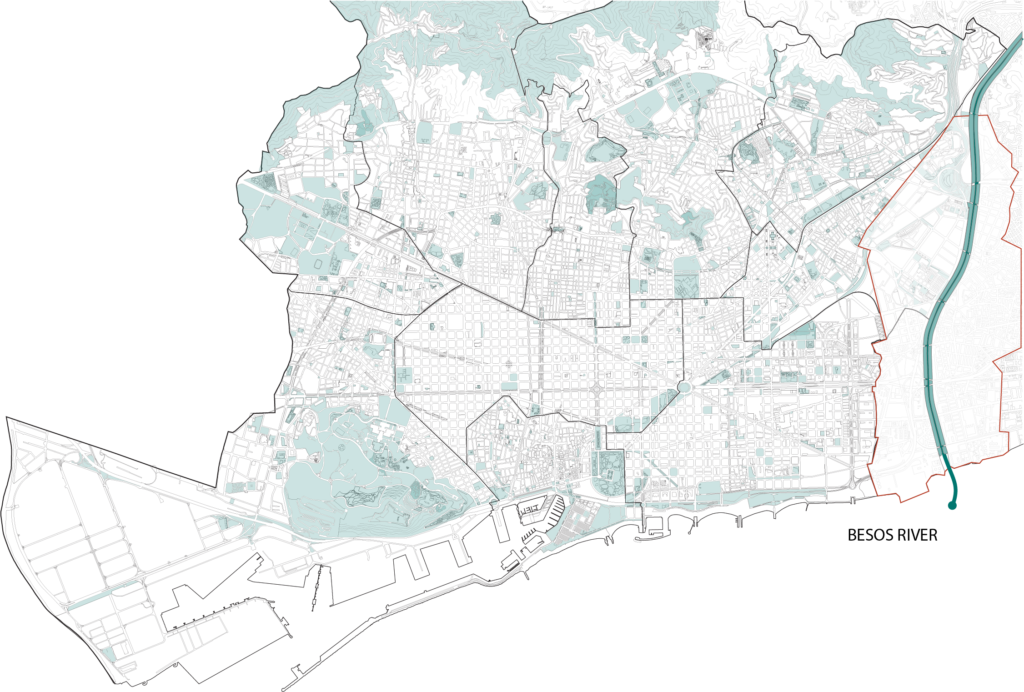

To demonstrate the potential of the system, the banks of Besos river in Barcelona were chosen as a case study. Besòs River has played a significant role in the urban and industrial development of the region, and efforts have been made to improve its water quality and restore its natural ecosystems.

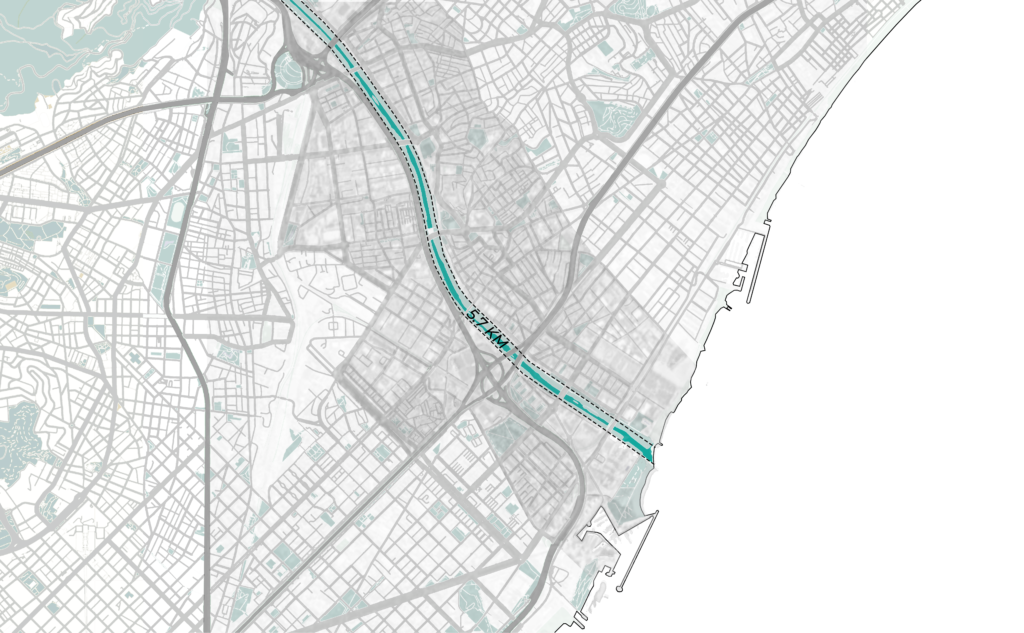

BESOS RIVER

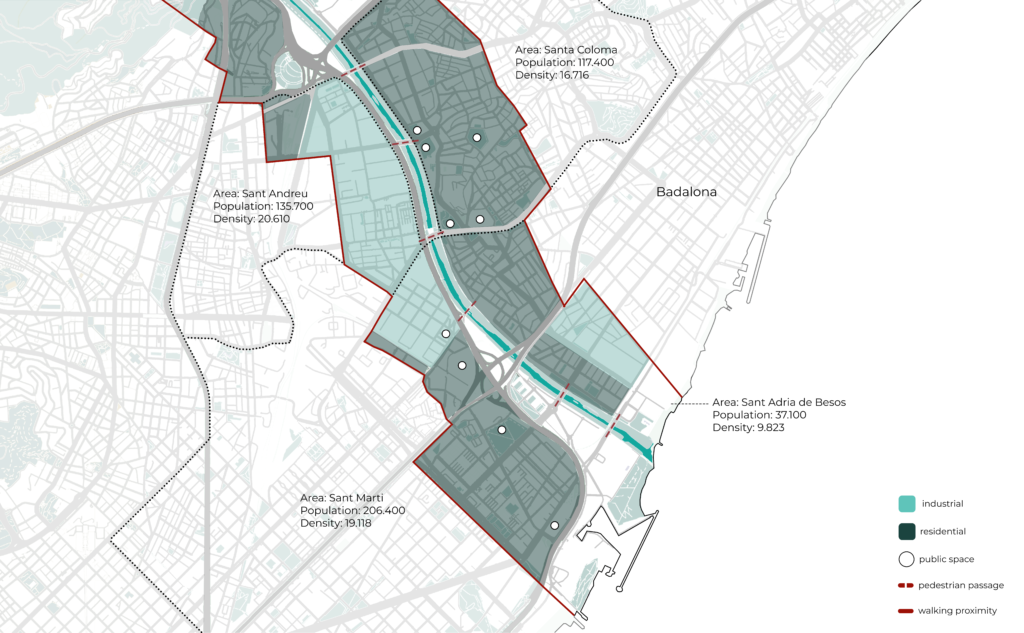

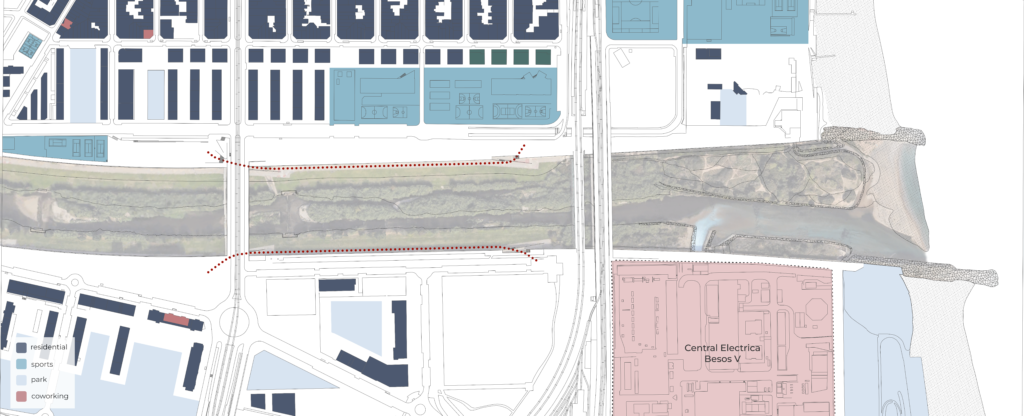

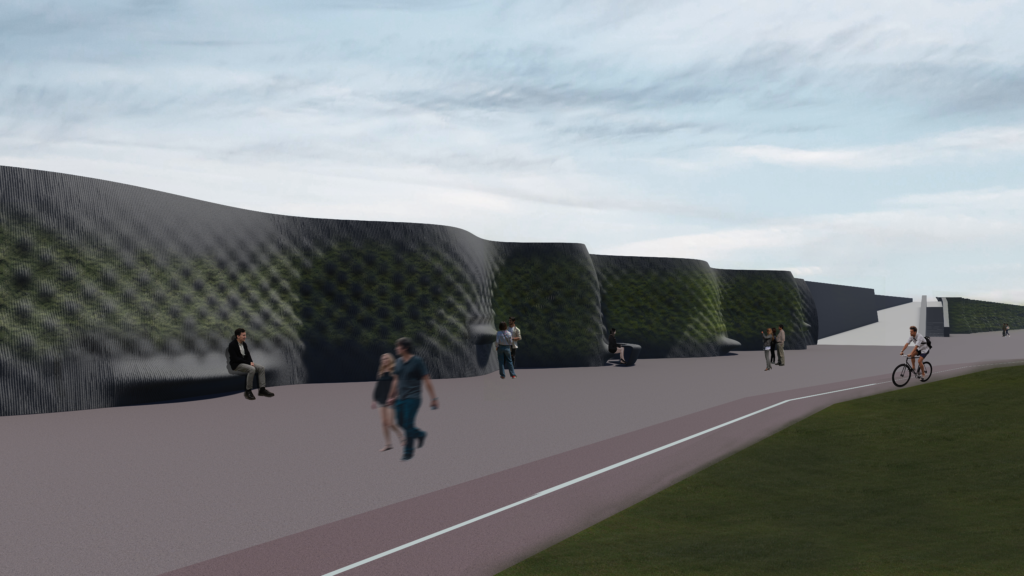

The river runs approximately 25 kilometers. Through Barcelona, along the riverbed a 5.7km long concrete wall is used to retain the soil. Our effort is to propose an alternative structure as a demonstrator of the carbon sequestering ability of our system and to create a spatial configurations that can accommodate the needs of the neighboring areas

The section of the Besòs River that runs through Barcelona traverses a diverse range of land uses. The immediate surroundings of the river include a mix of residential, commercial, and industrial areas.

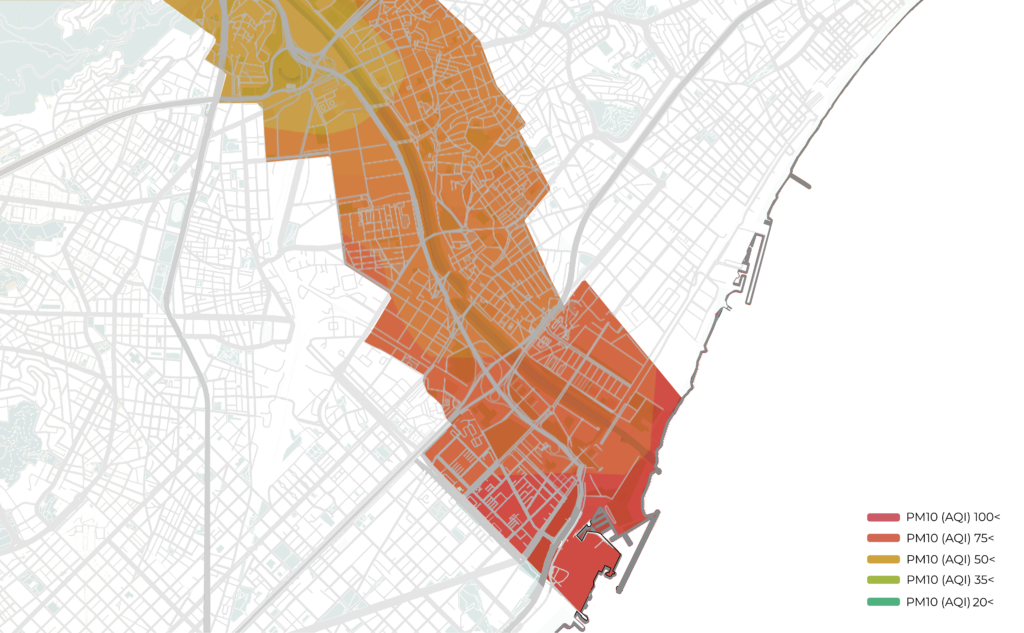

This map demonstrates the air quality in a area of around 1km distance from the river. Port activity generates emissions which, together with the rest of the metropolitan area, contribute to air pollution in both port and city. The air is more contaminated near by the sea. Port activities represent between 15 and 20% of total emissions of the Barcelona metropolitan area .But contribution of port emissions to the city’s pollution levels is proportionally lower, less than 10%, since half of those emissions is dispersed to the sea.

CONTEXT

From this data we derive to a program of specific activities for each area that from our general design drive take now specific formations according to hierarchy and specific profiles.

DESIGN & GEOMETRY APPROACH

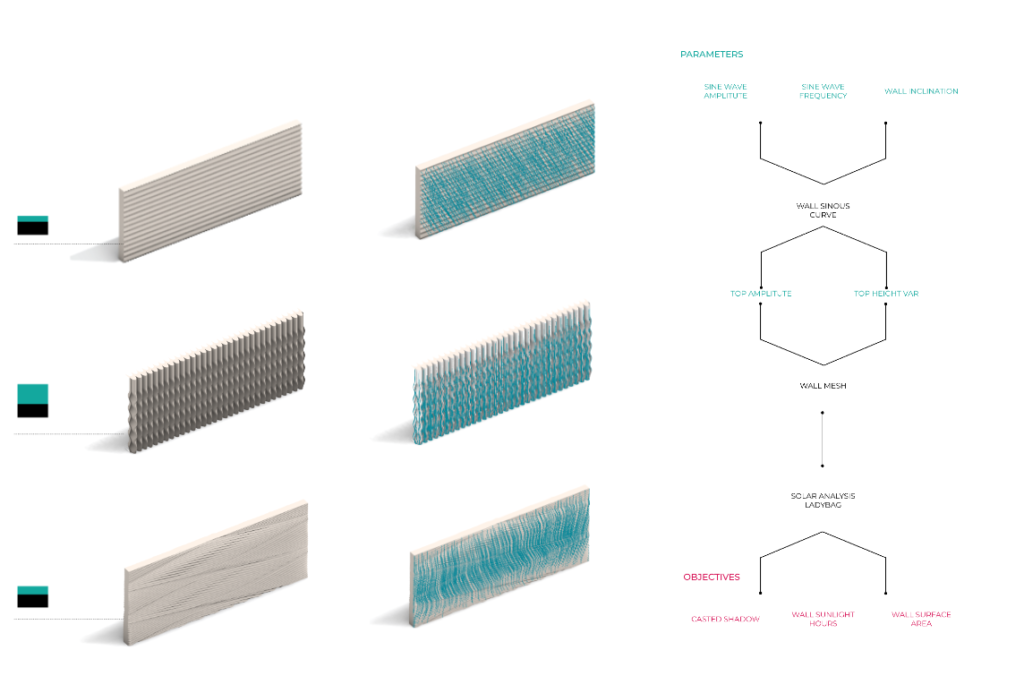

Under these considerations the design is based on the hypothesis or “main idea”, that sinuous geometries can exhibit enhanced structural performance and better performance in terms of self-shading, casting shadows, and water retention characteristics. And in parallel a main concept is this conjunction between the human and non human and between the different performances that are being explored as a gradient. This gradient helps identify points of interest and strategically place different geometries and percentages of biochar content on the structure in order to obtain optimal performance.

OPTIMIZATION

In order to achieve the needed performances, a series of optimization studies has been done with multiple objectives.

Sunlight hours

Manufacturing

Using additive manufacturing to achieve the customization needed in material and geometry.

RENDER

PROTOTYPE