Industry Setup Relevance:

ABMS could be a twist on traditional manufacturing by using software agents to control different parts of the process. Imagine a factory where machines, workstations, and even software programs aren’t just following instructions but can somewhat act and decide independently. This helps in faster problem-solving mechanisms and could help reduce human intervention in automated systems.

A little about our studio project:

Aim:

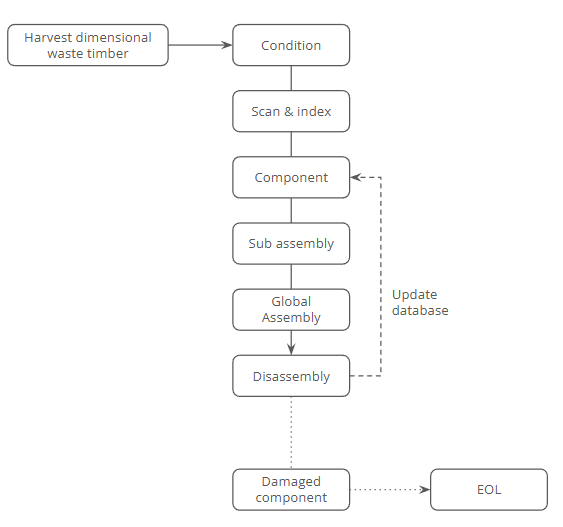

“To develop an efficient processing strategy for end-of-life dimensional timber so that it can be repurposed in a design for disassembly workflow for temporary structures.”

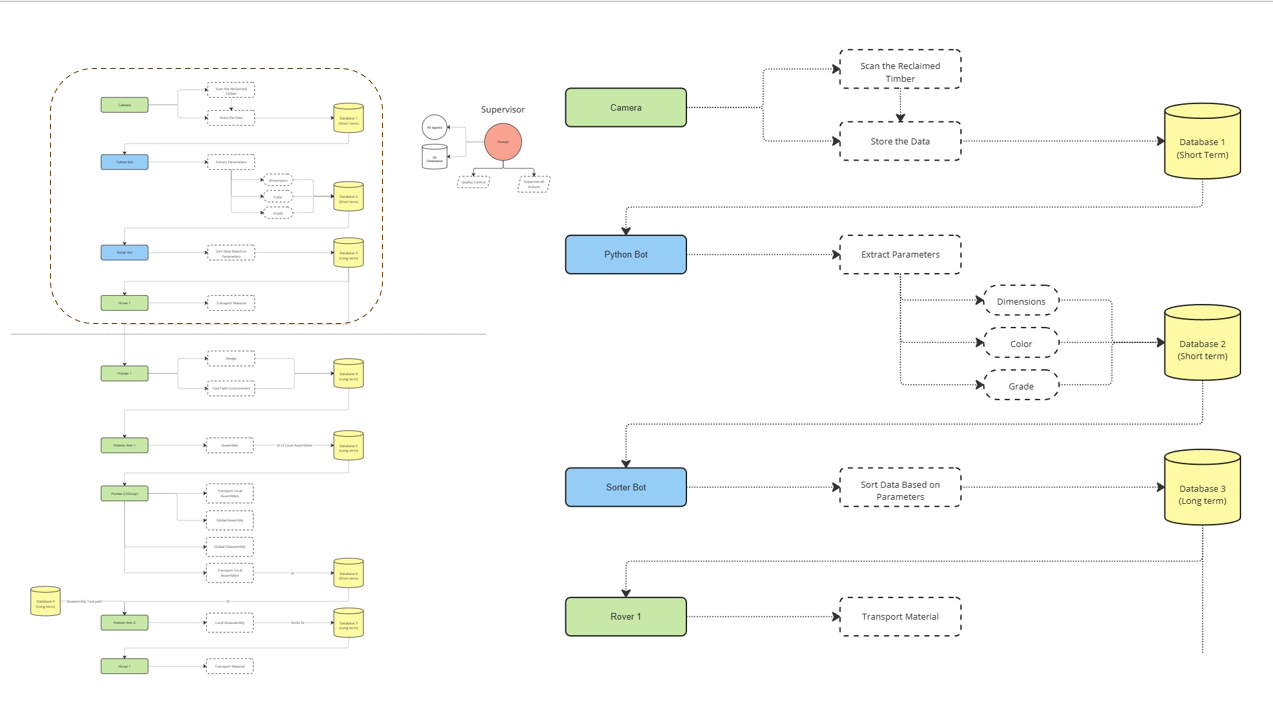

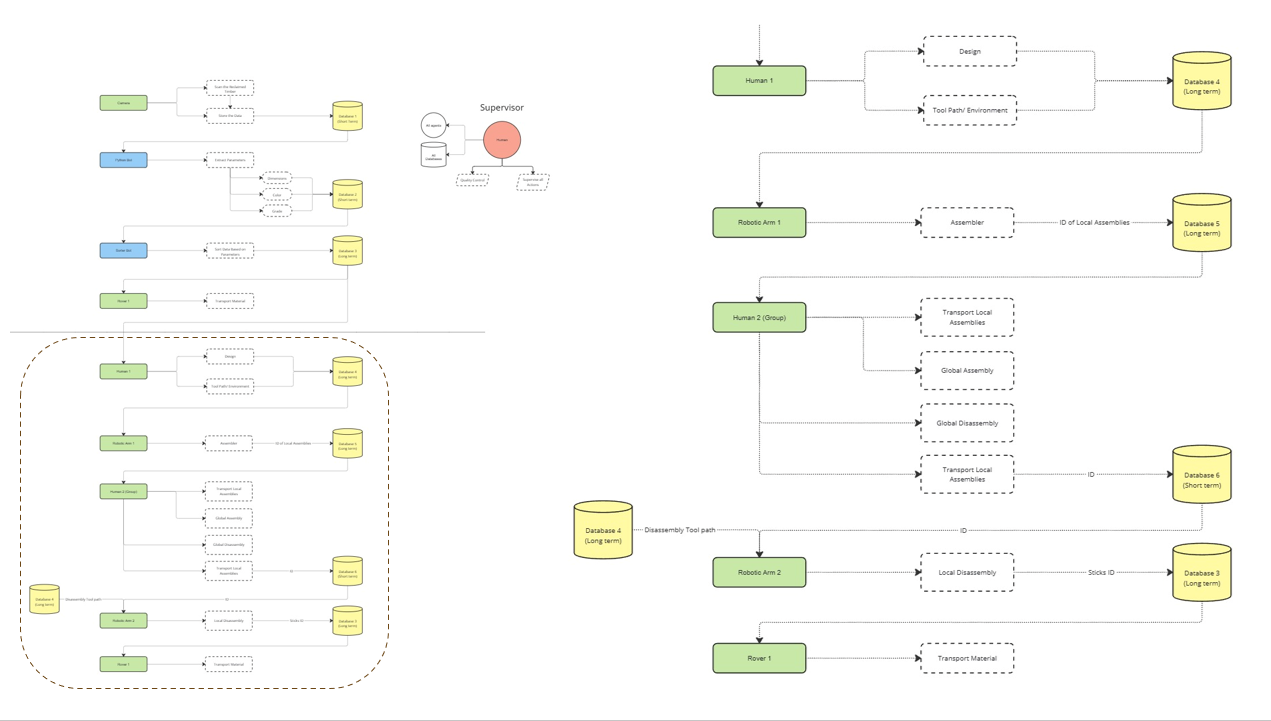

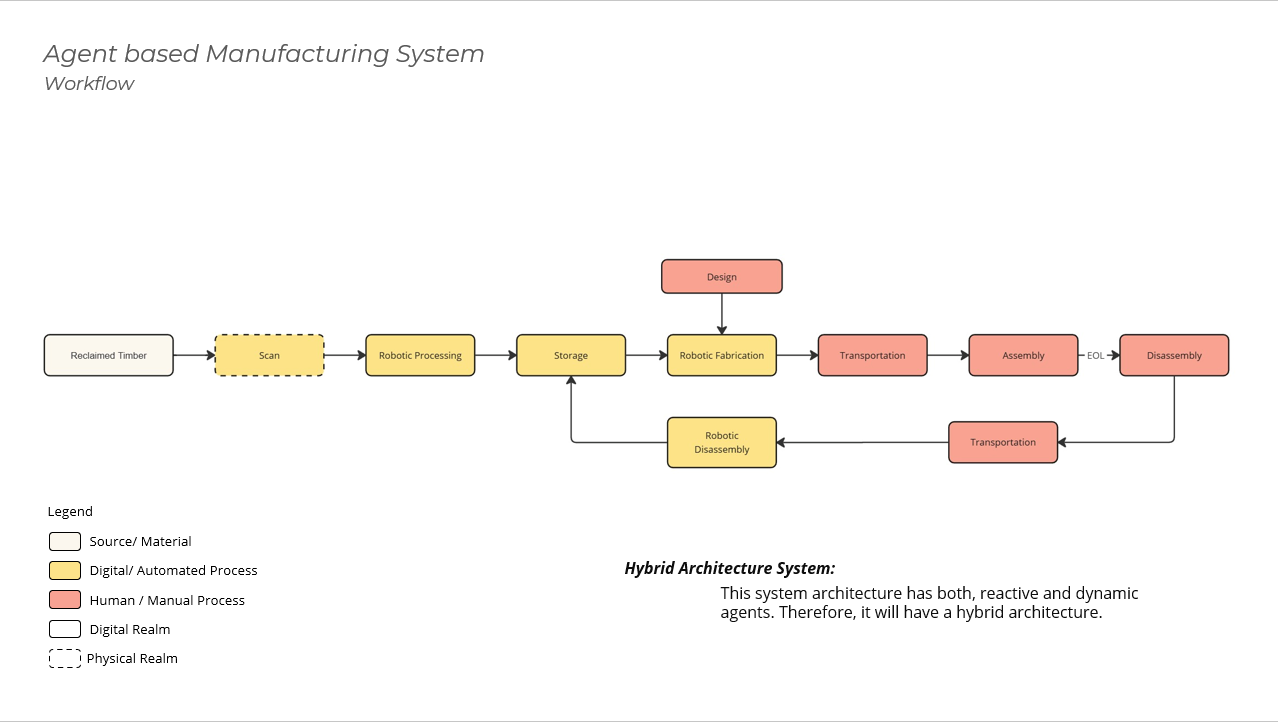

Agent-based Manufacturing System

Overview

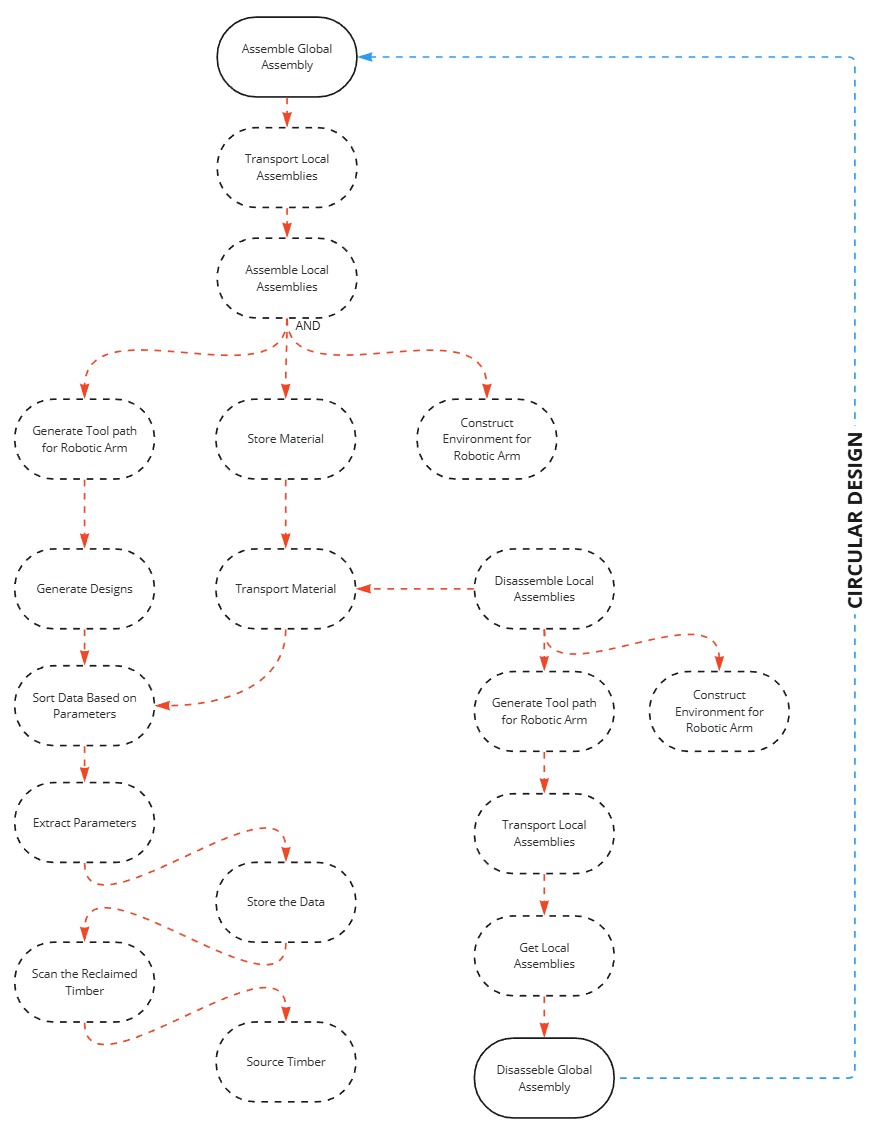

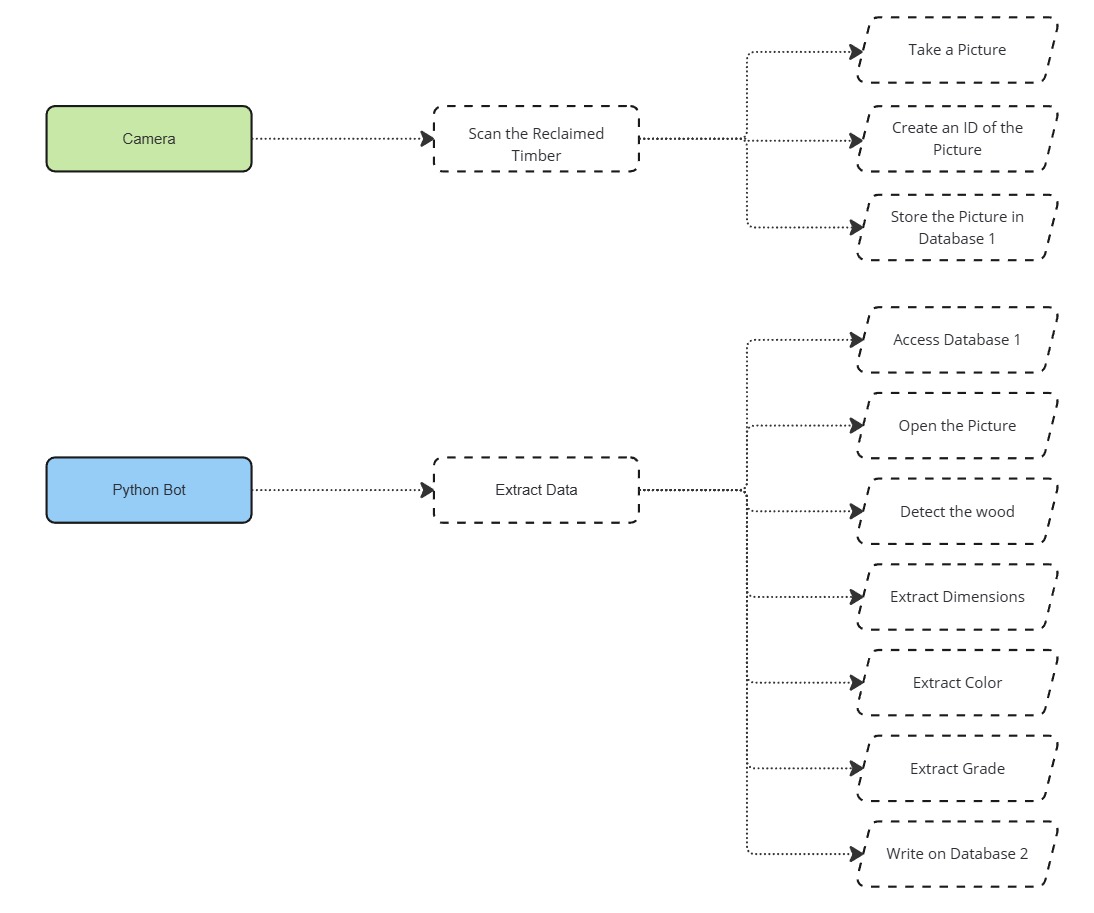

Goals and Sub-Goals

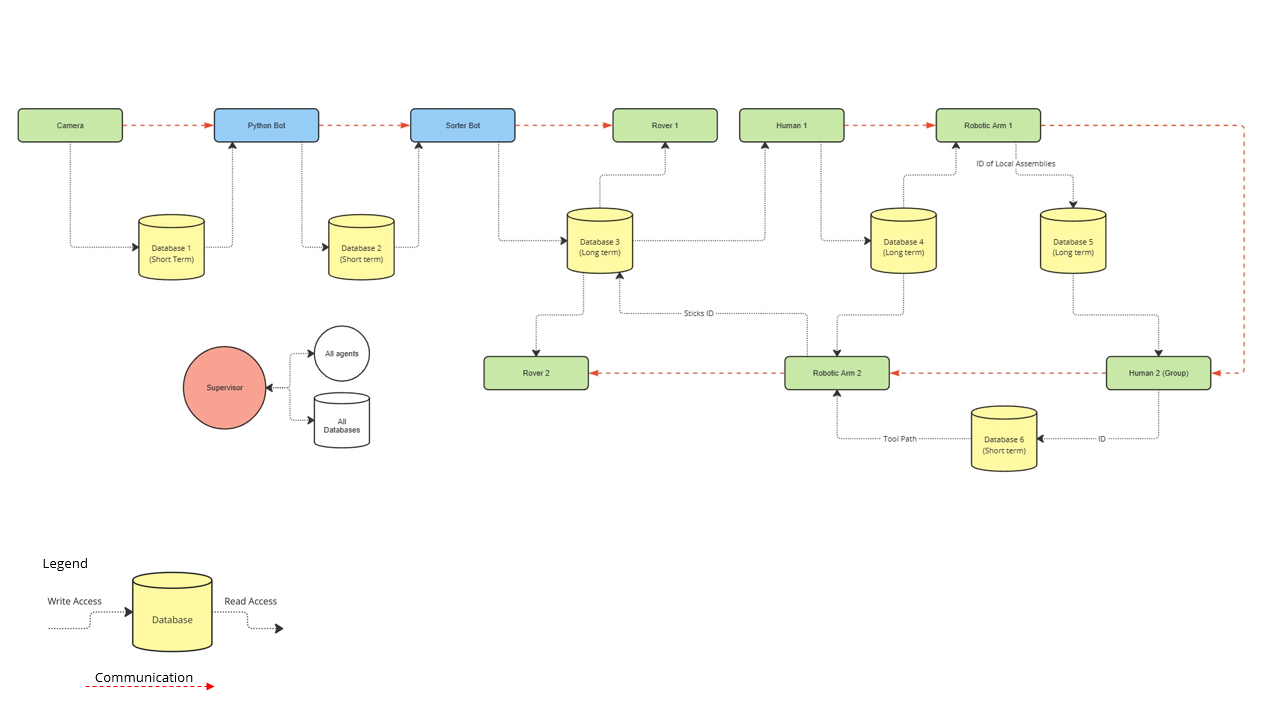

Communication between agents

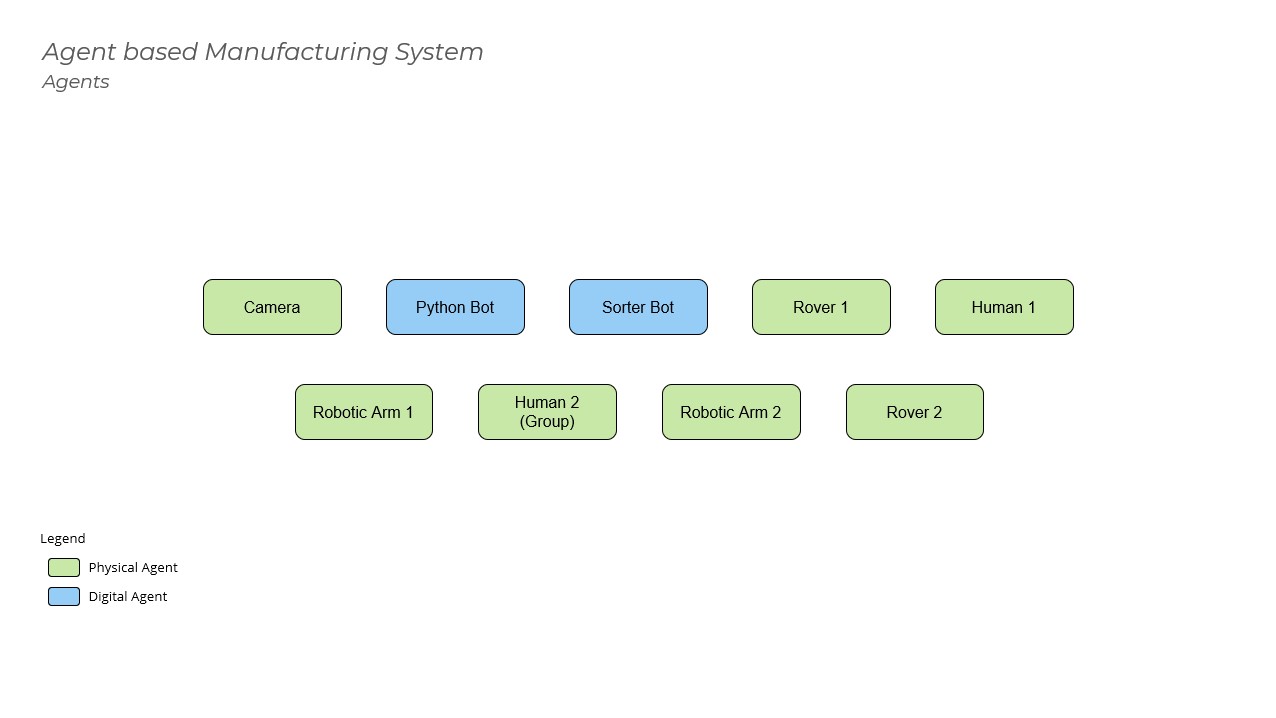

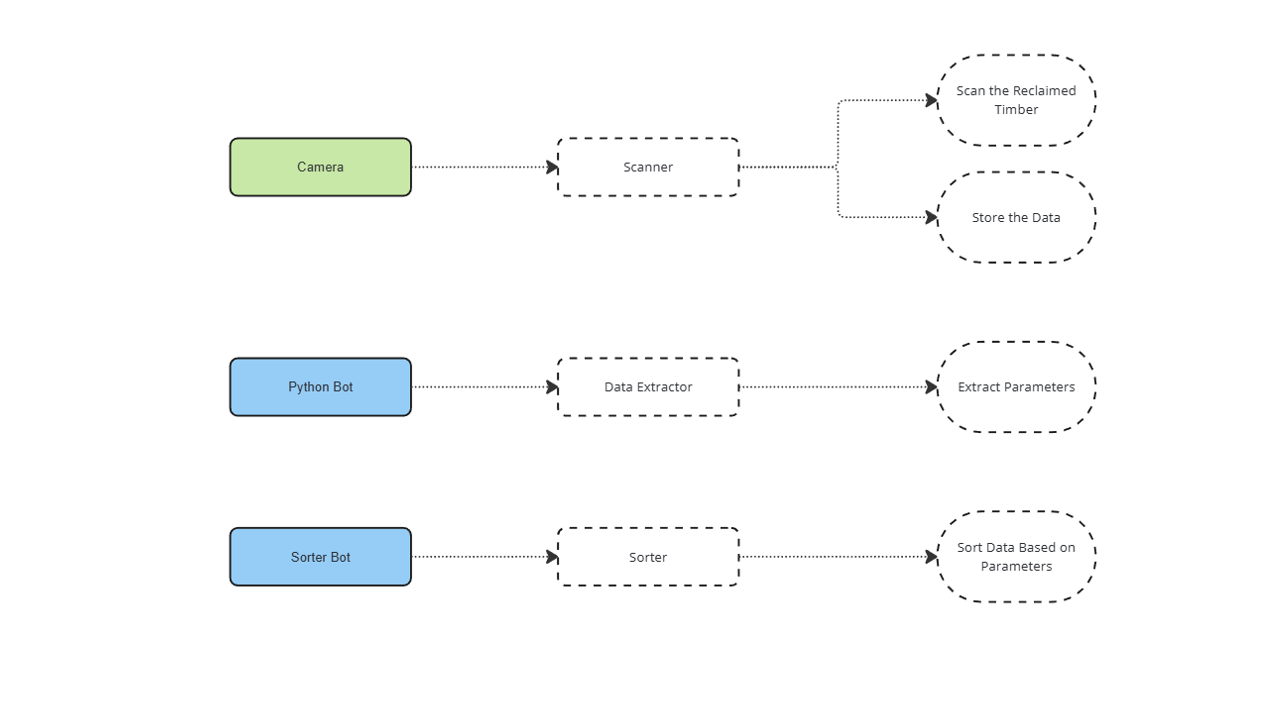

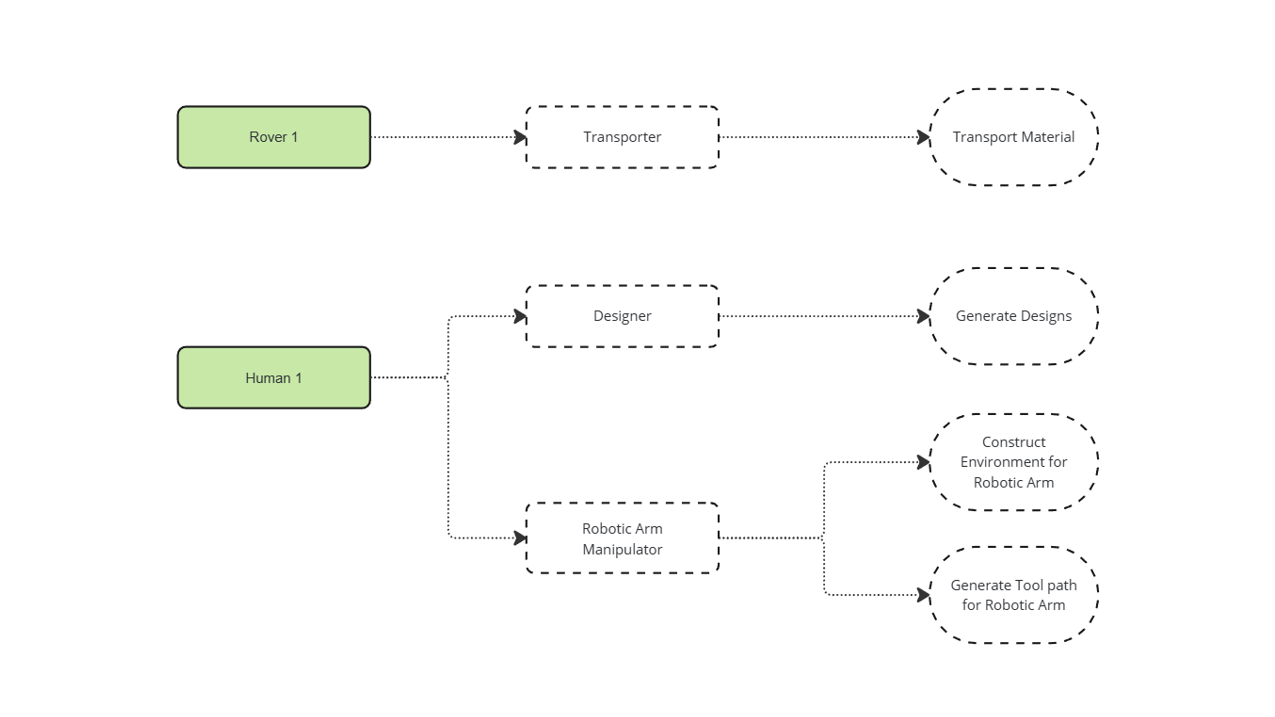

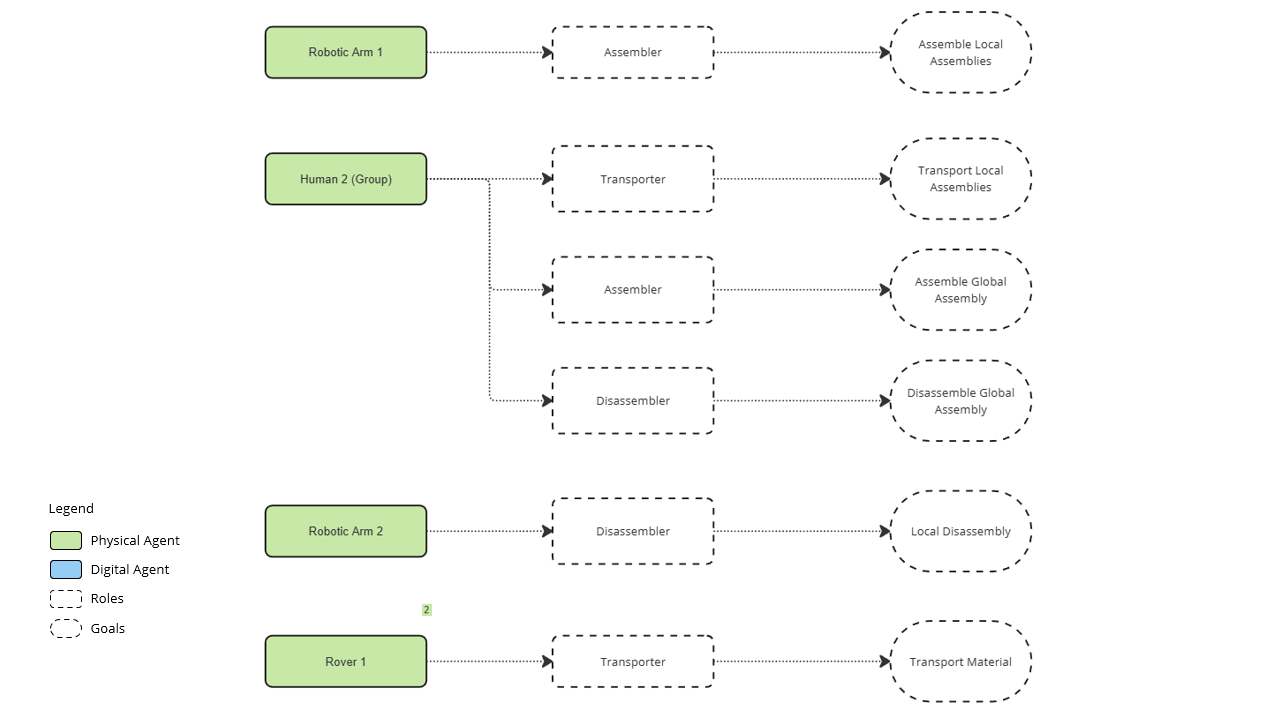

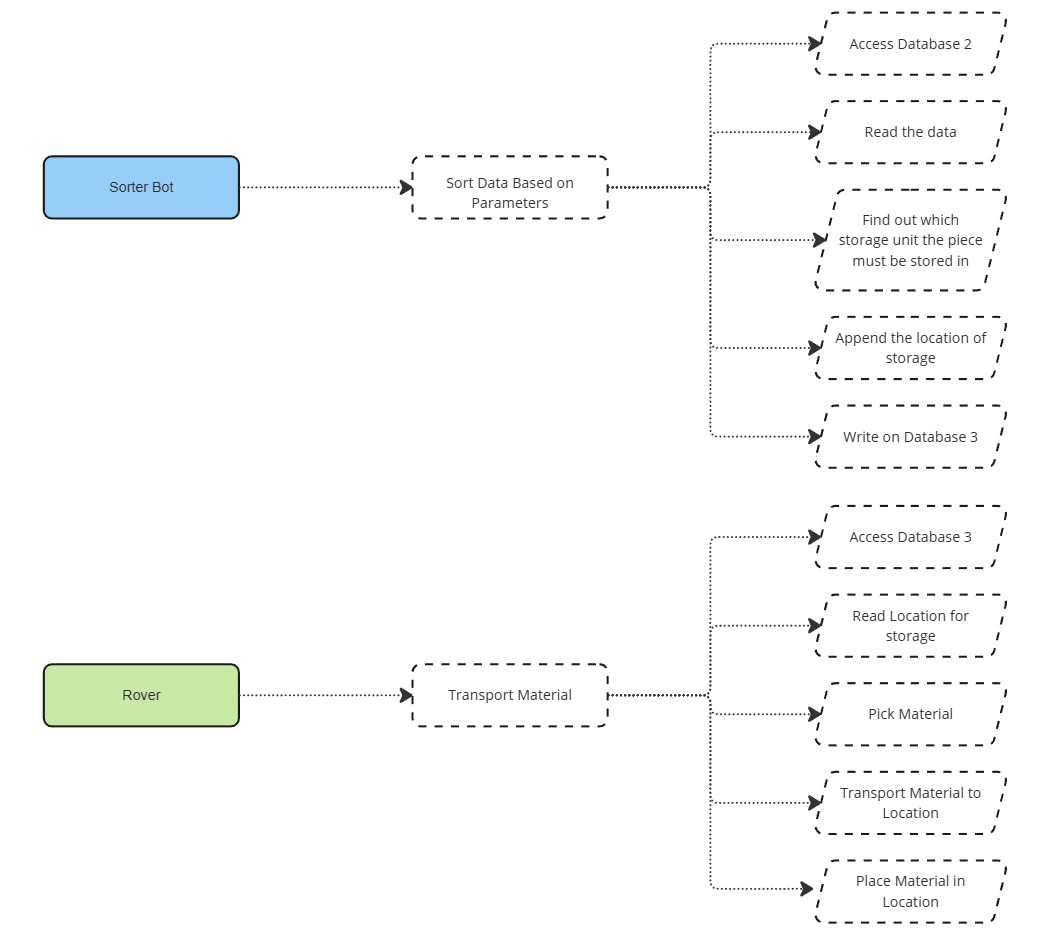

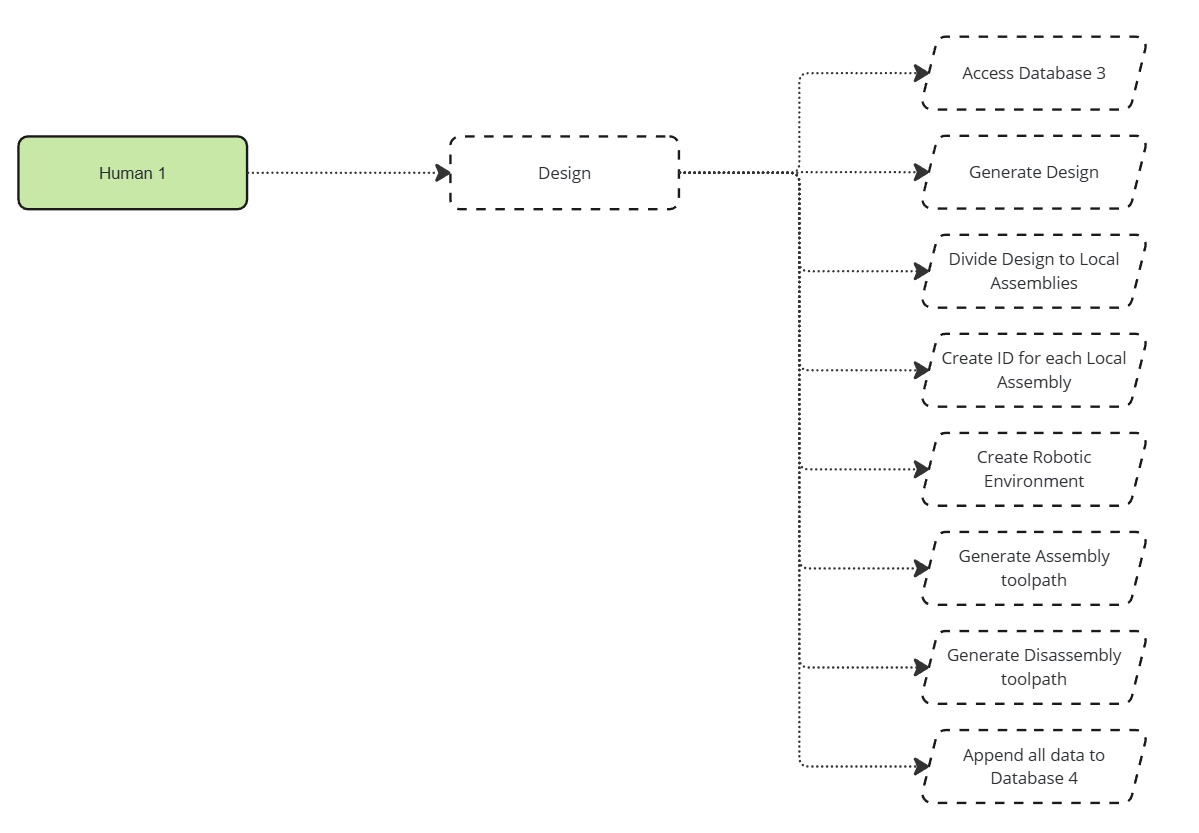

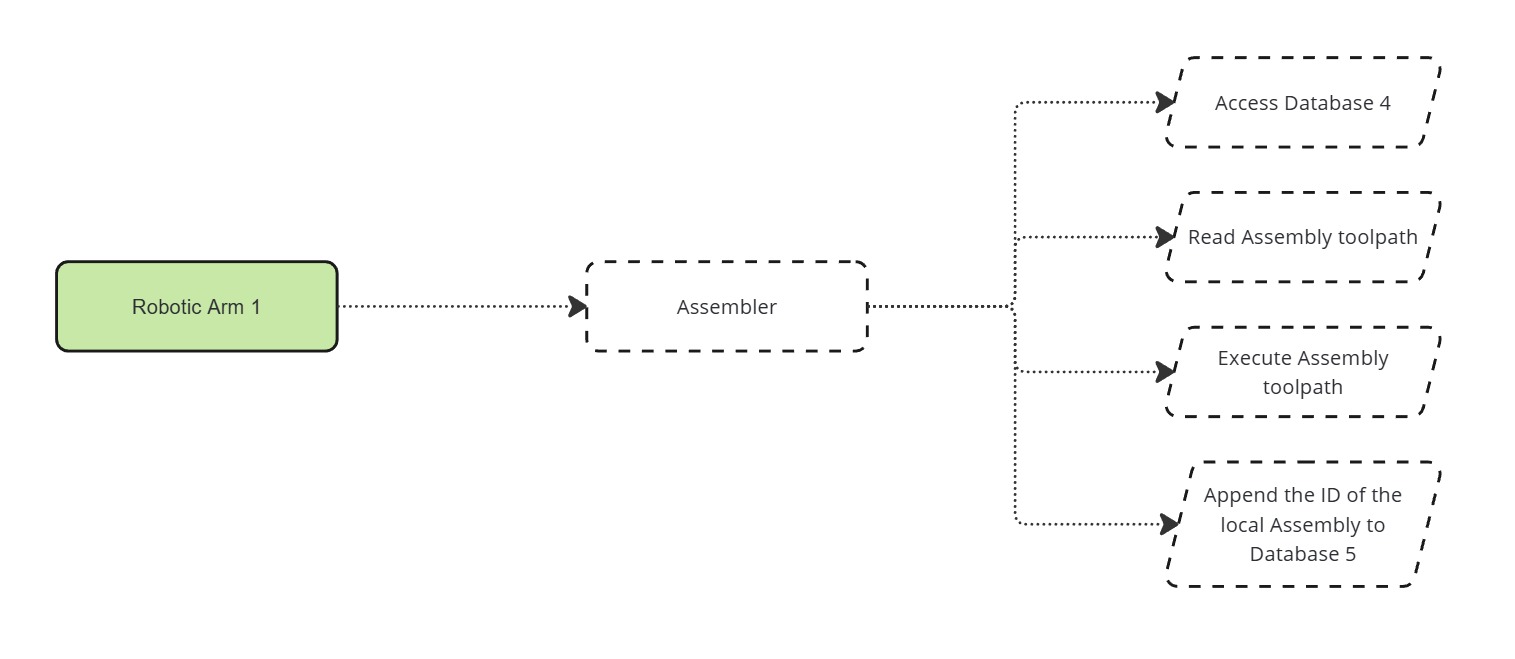

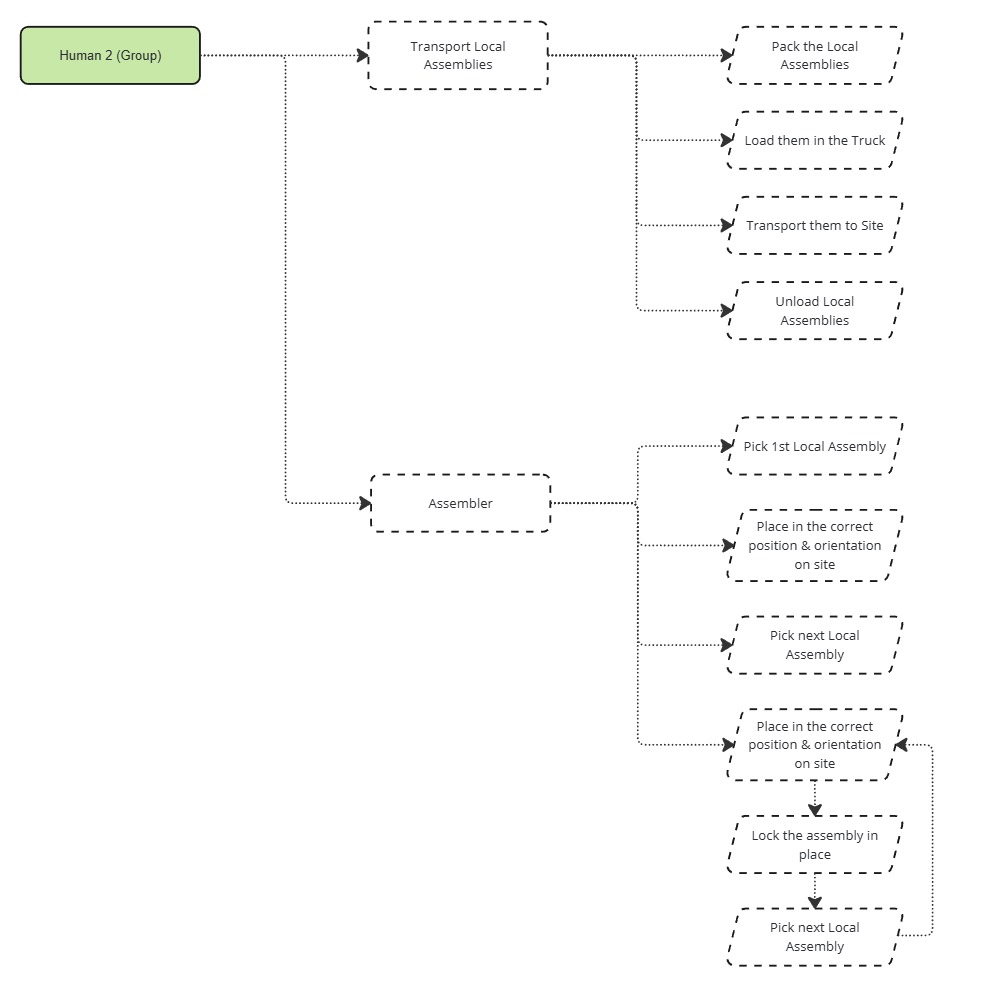

Agents – Roles – Goals

Rules/Norms

Linear Workflow: Do not start until the last one finishes.

Proxy Leader: If one of the processes malfunctions, the next one takes over for all the data already available until the supervisor fixes the process.

Deadlines: Agents must complete tasks and achieve milestones within the set timeframe, prioritizing safety and precision throughout.

Conflict communication

Negotiation: This will be based on a weighted average of all the parameters and priority of the agent’s action. The higher one takes priority.

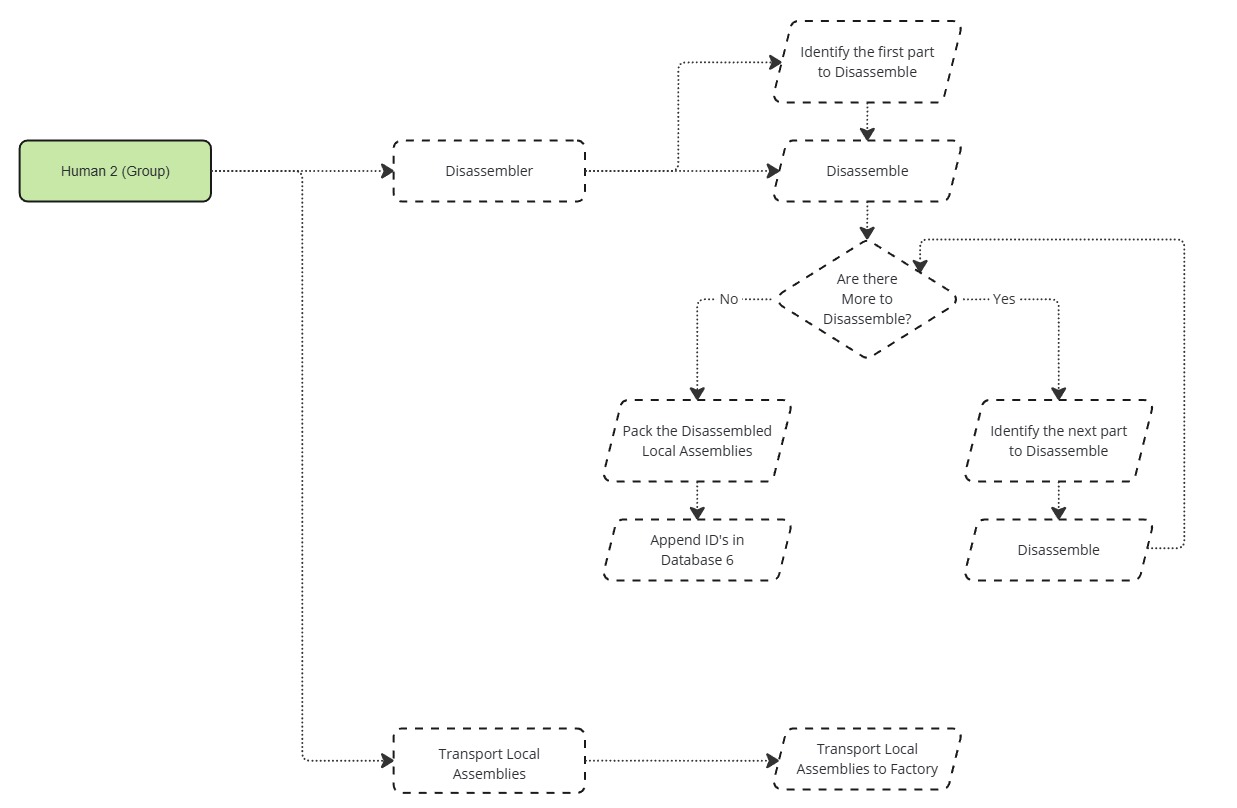

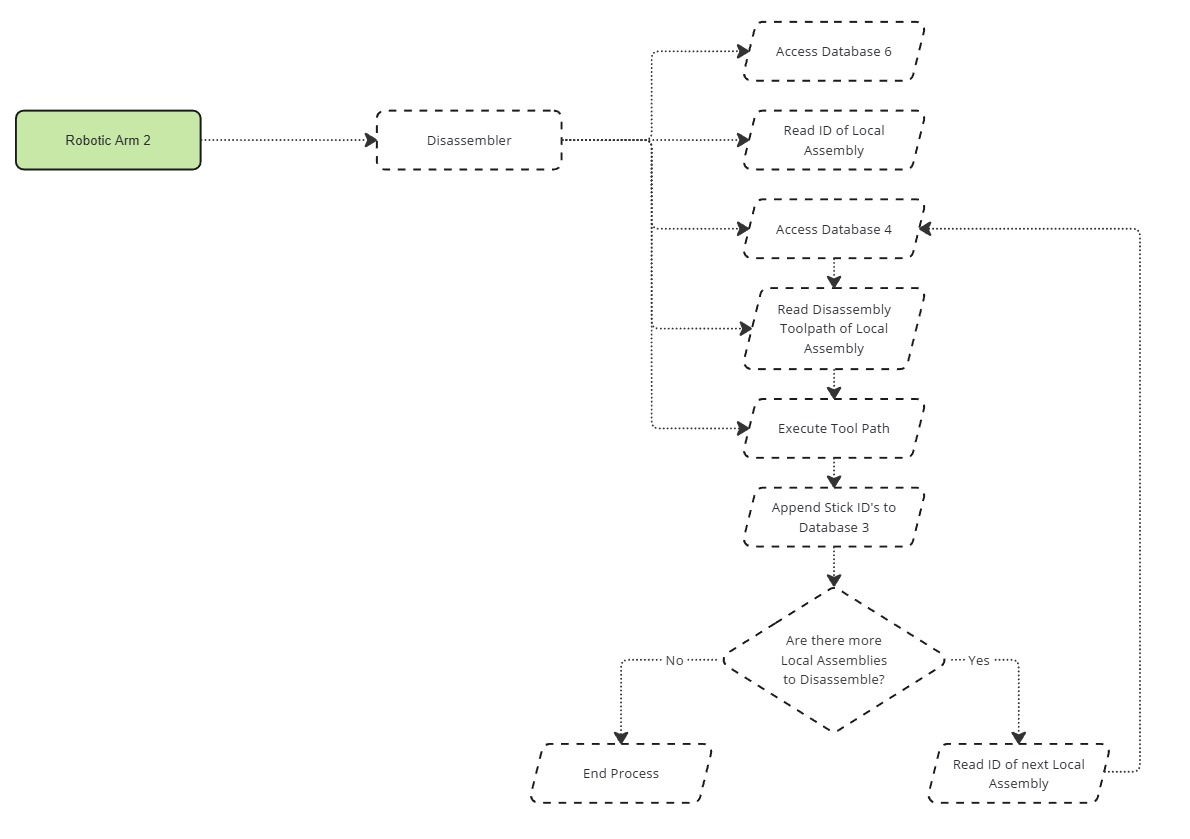

Agents – Roles – Actions

System Overview