Overview

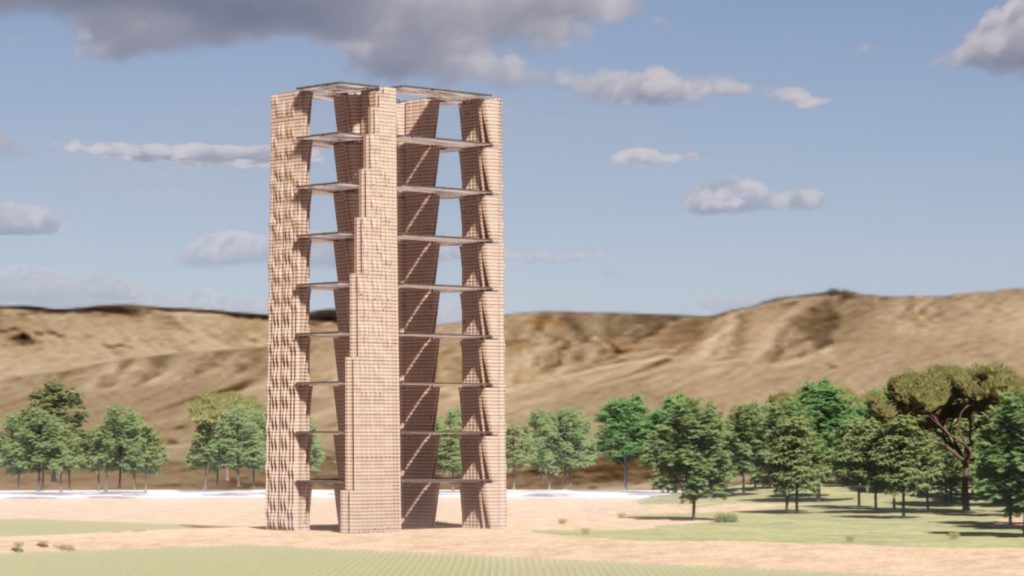

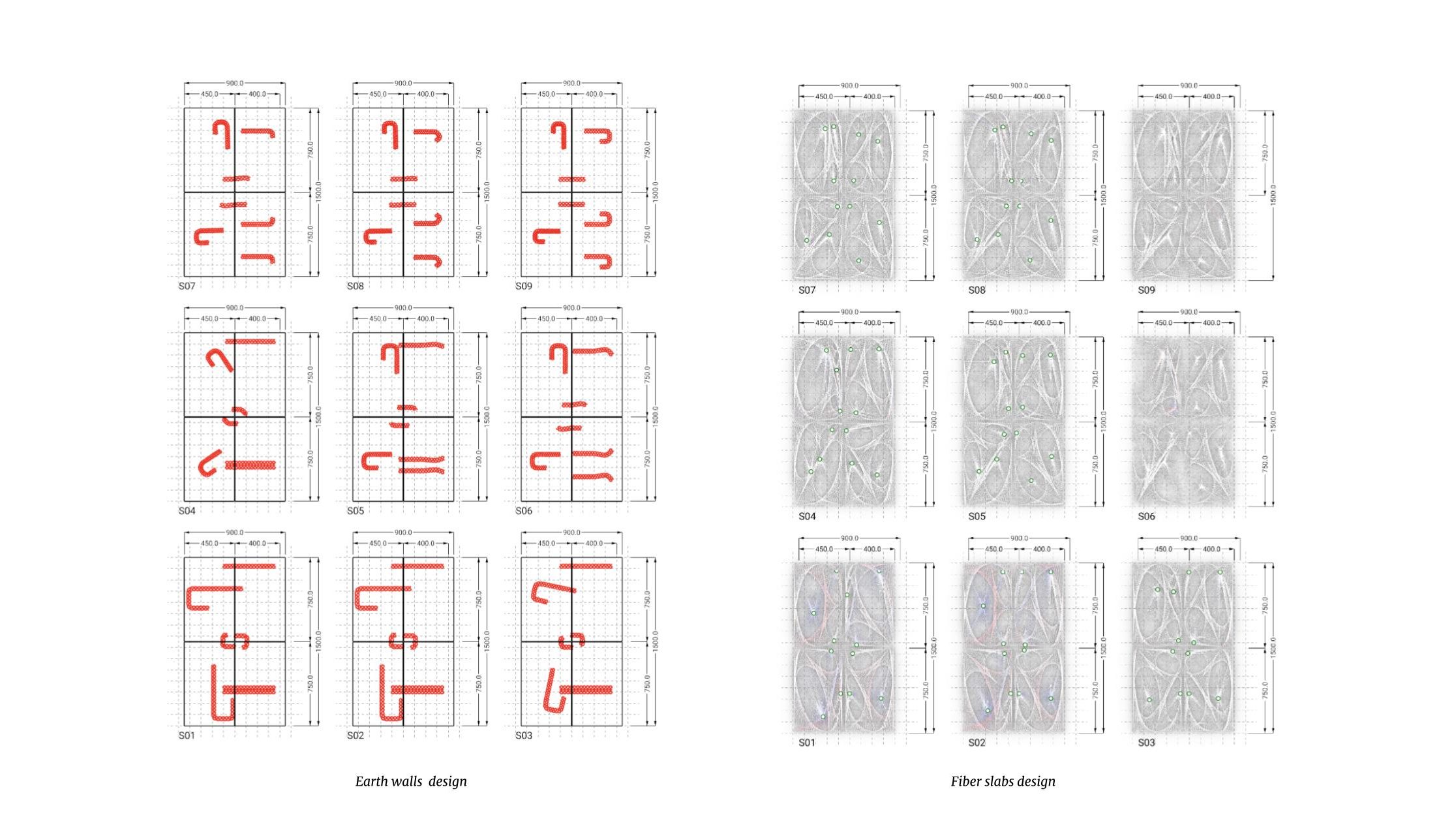

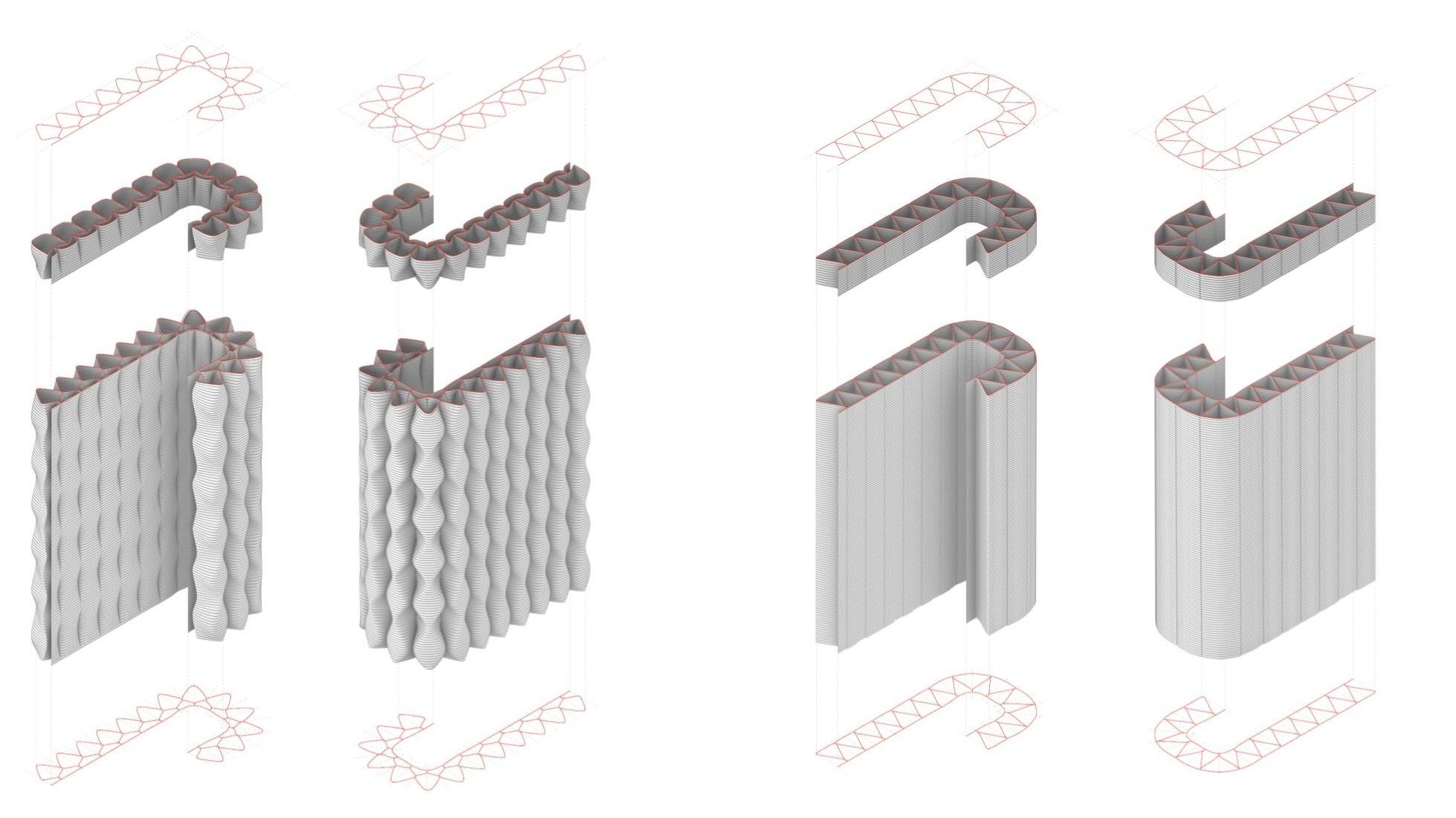

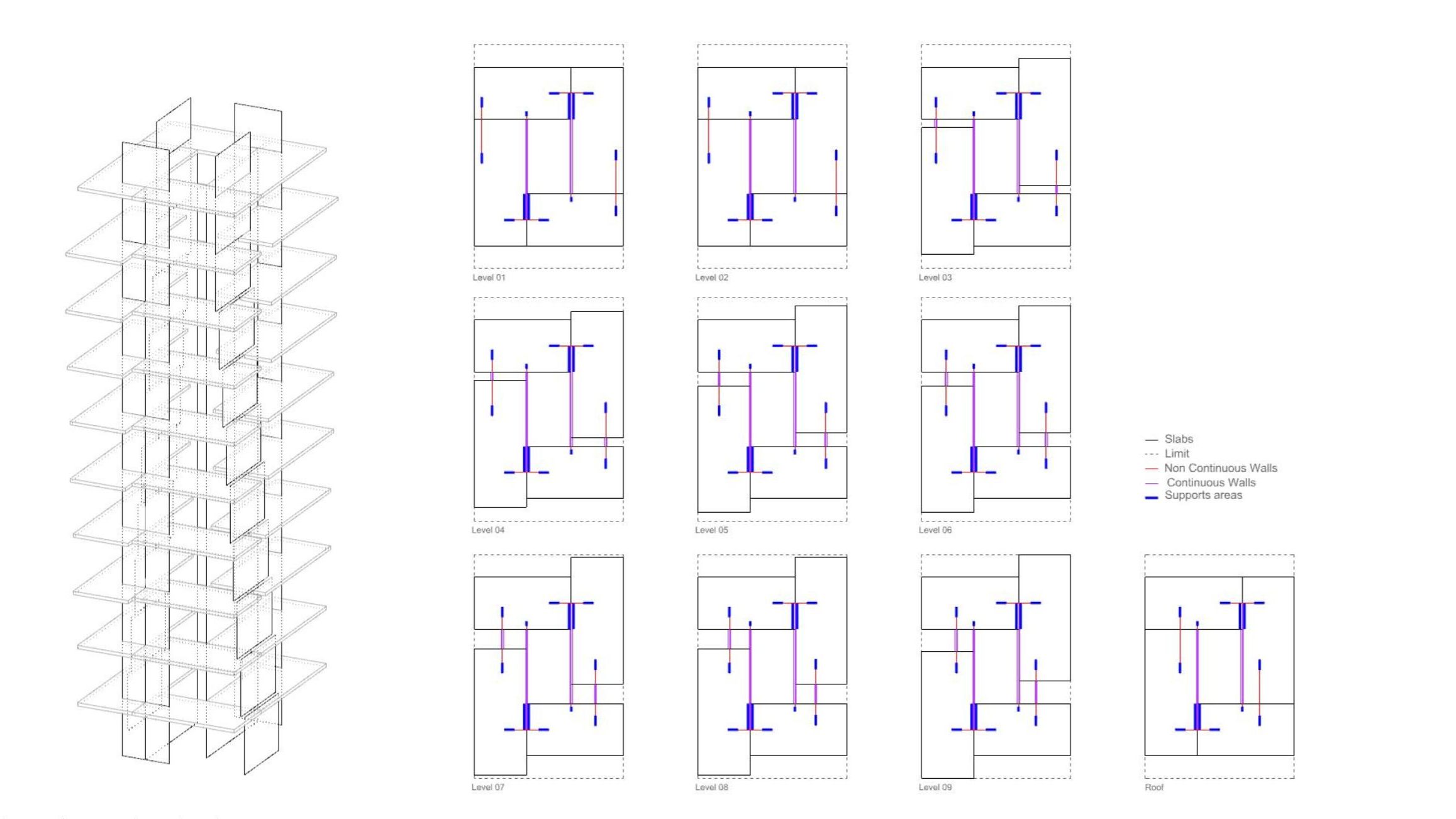

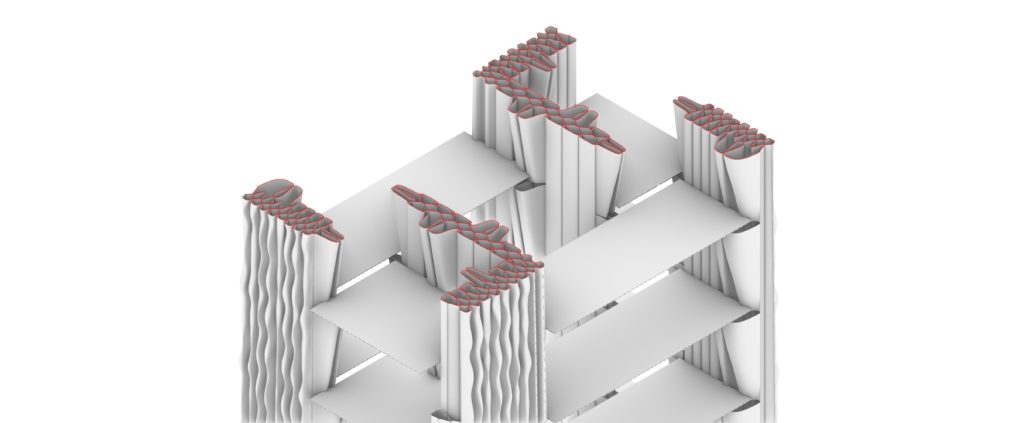

The last exercise of the Techne chapter is labeled ‘Architecture’ seeing the intersectionality of thematic from the previous workshops: structural understandings, detail, wall-design, performativity, and other architectural attributes. The requested 10m by 15m 10-storey clay building was expected to accompany ITKE’s flax-fiber reinforced slabs. This collaboration merged the knowledge of both methodologies in order to achieve a building design that was bottom-up. The designed conditions revolve around wall typology and positioning of slabs. The positioning of ITKE’s slabs was governed by structural strategies and strategically placed points for support. 3 types of walls and 2 types of wall infills were crossed into 6 combinations that were distributed to six groups, each illustrated in the following. The two wall infills were the TOVA pattern and the Living Prototype Pattern.

Single Polyline Walls + ‘Living Prototype’ Infill Pattern

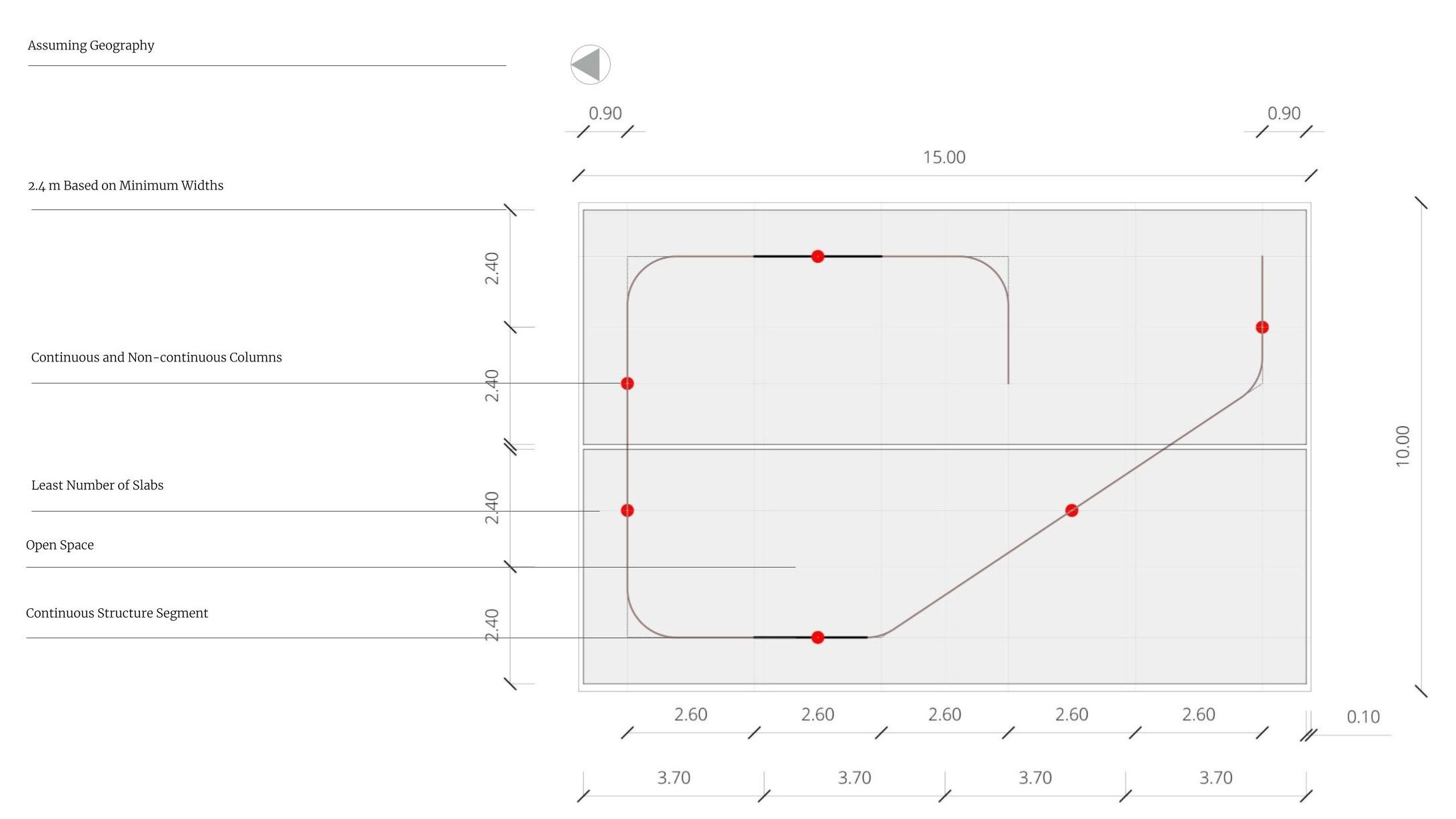

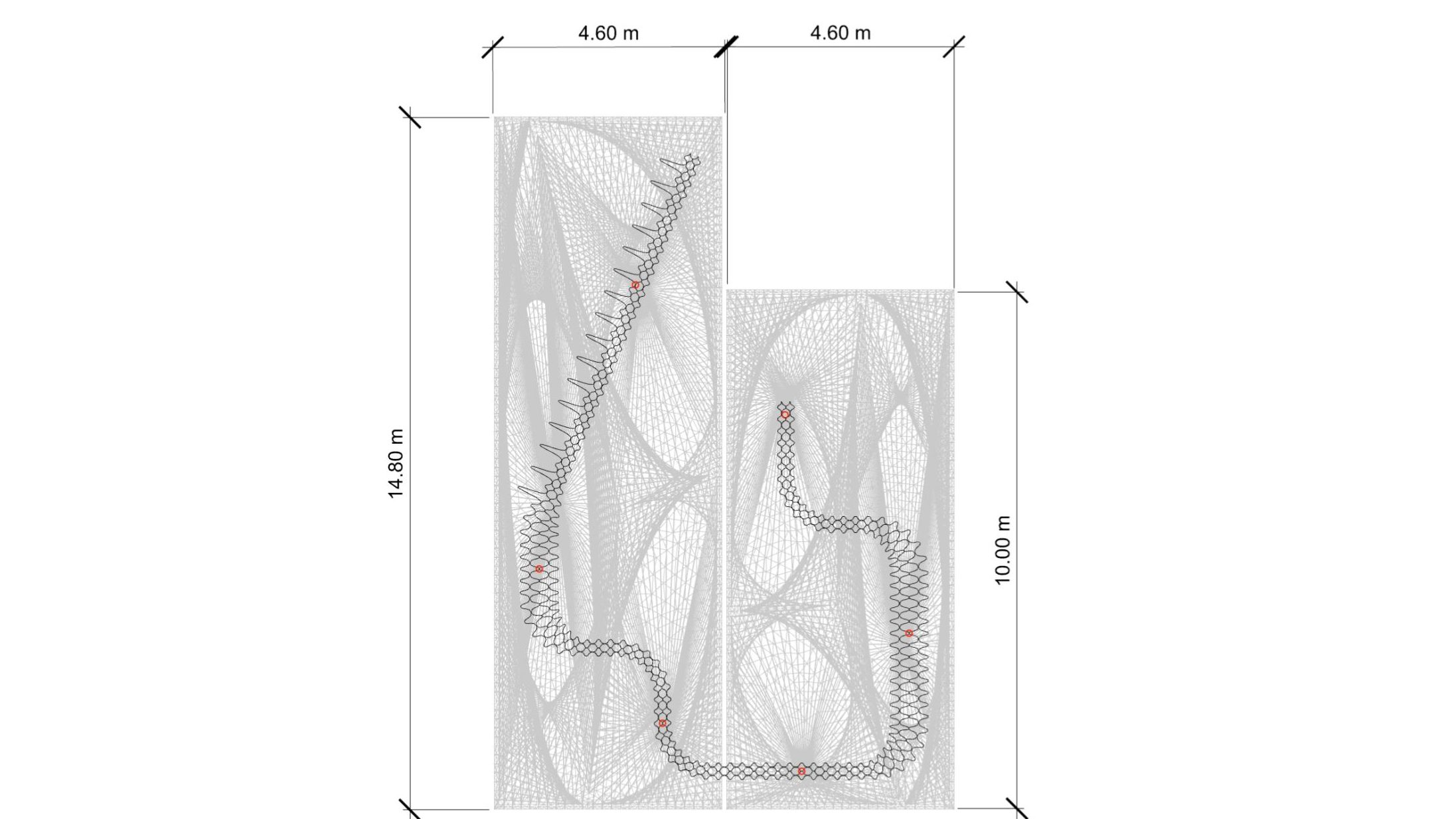

Since the context is hypothetical, geographical conditions were set in addition to the structural conditions that were planned as well. After assuming the north sign, the space was decided to be an open office space characterized by fileted walls, some of which shift position between one floor and the other. This achieves a coinciding versus non coinciding situation. The western wall rotates a little bit at every floor. The grid which was used to draft on was made to achieve the smallest number of slabs and the ensuring that the achieved spaces may be occupied.

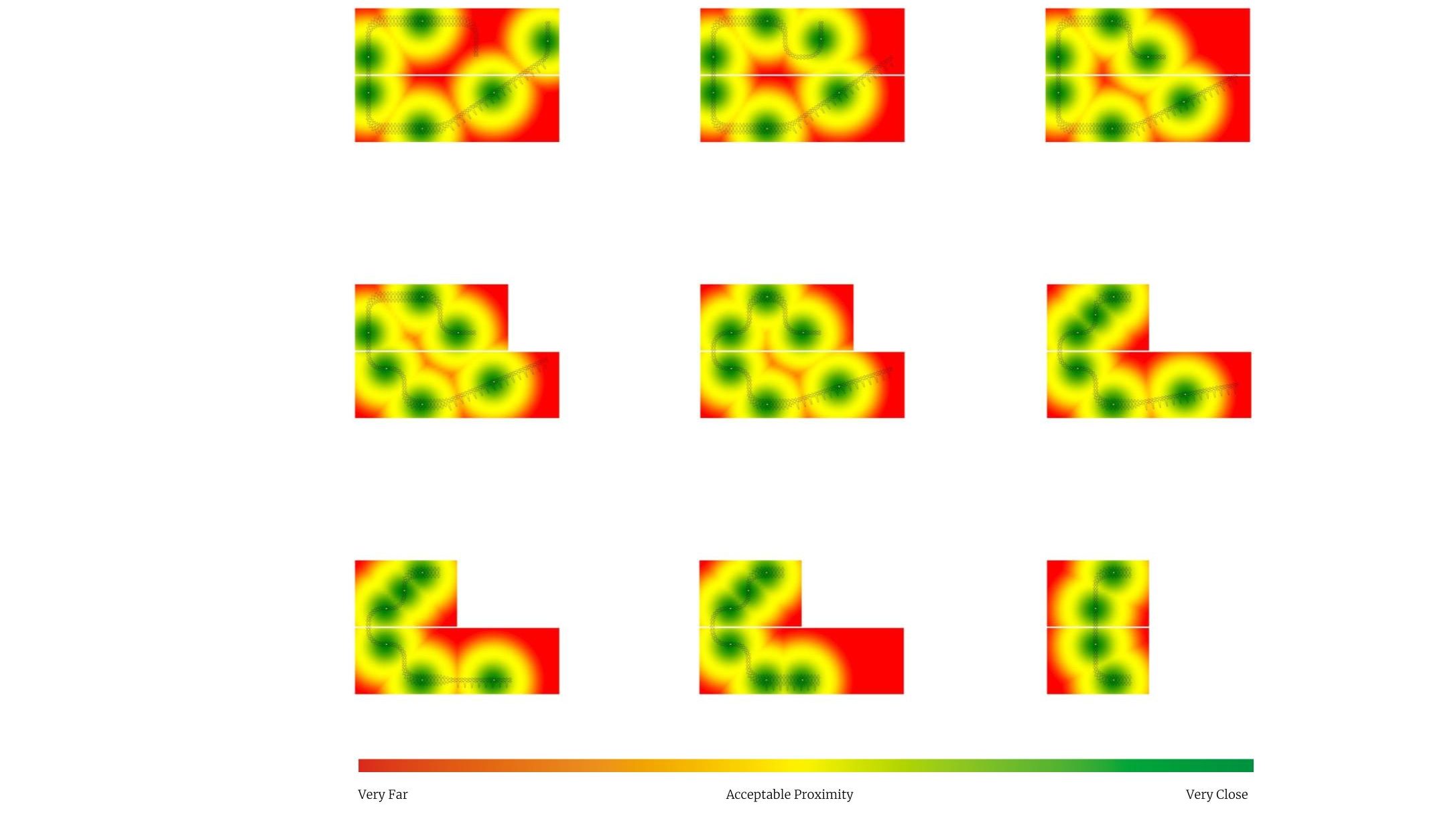

Several assessments were conducted to make a productive choice on where the support points may be placed. This structural analysis discloses the validity of support points position and the risk of overhang.

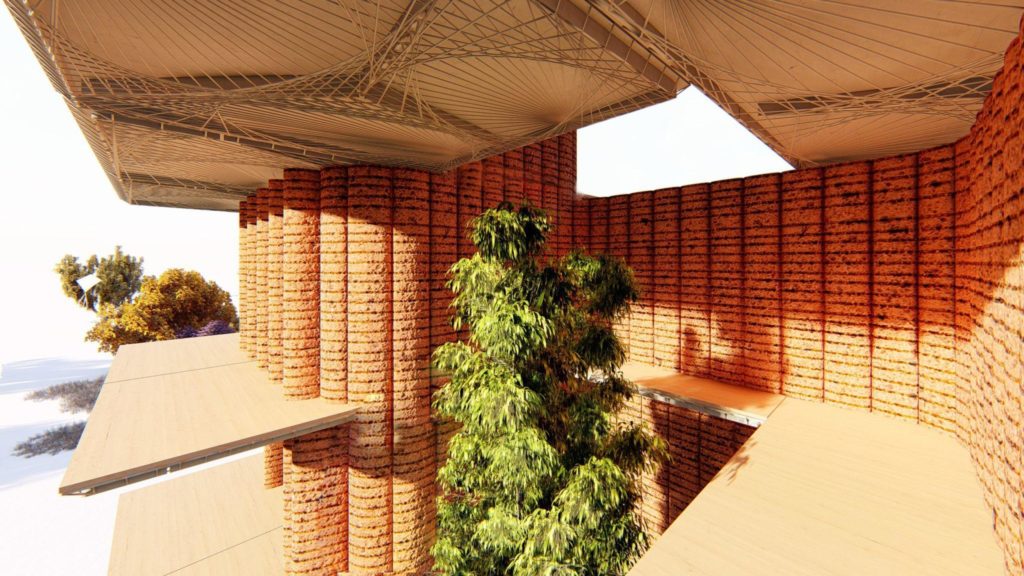

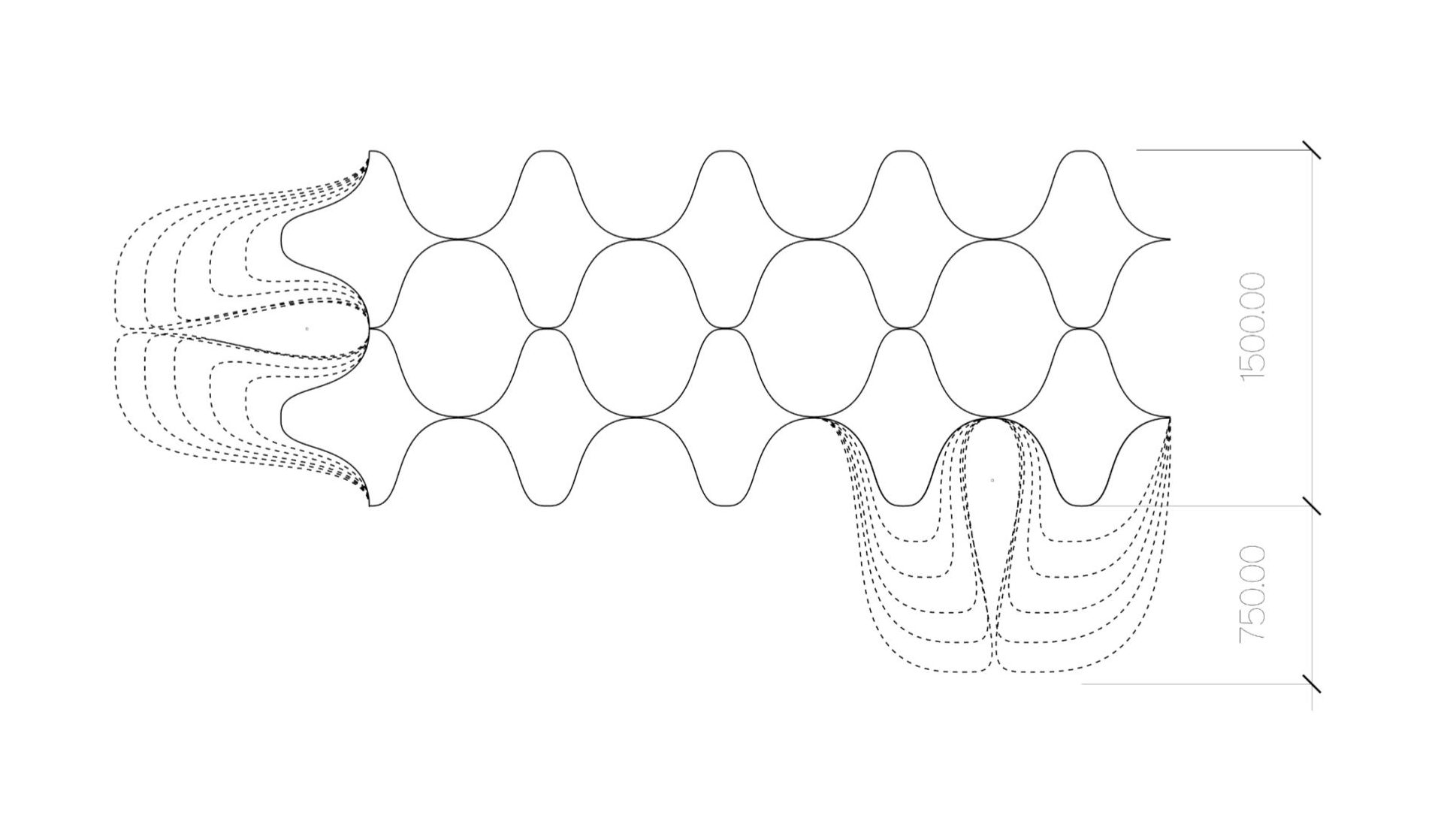

The infill of a fileted wall can give a lot of opportunities such as narrowing the wall thickness to optimize mass and weight. The western facade was designed in a way that creates vertical louvers for sun shading.

Single Polyline Walls + ‘TOVA’ Infill Pattern

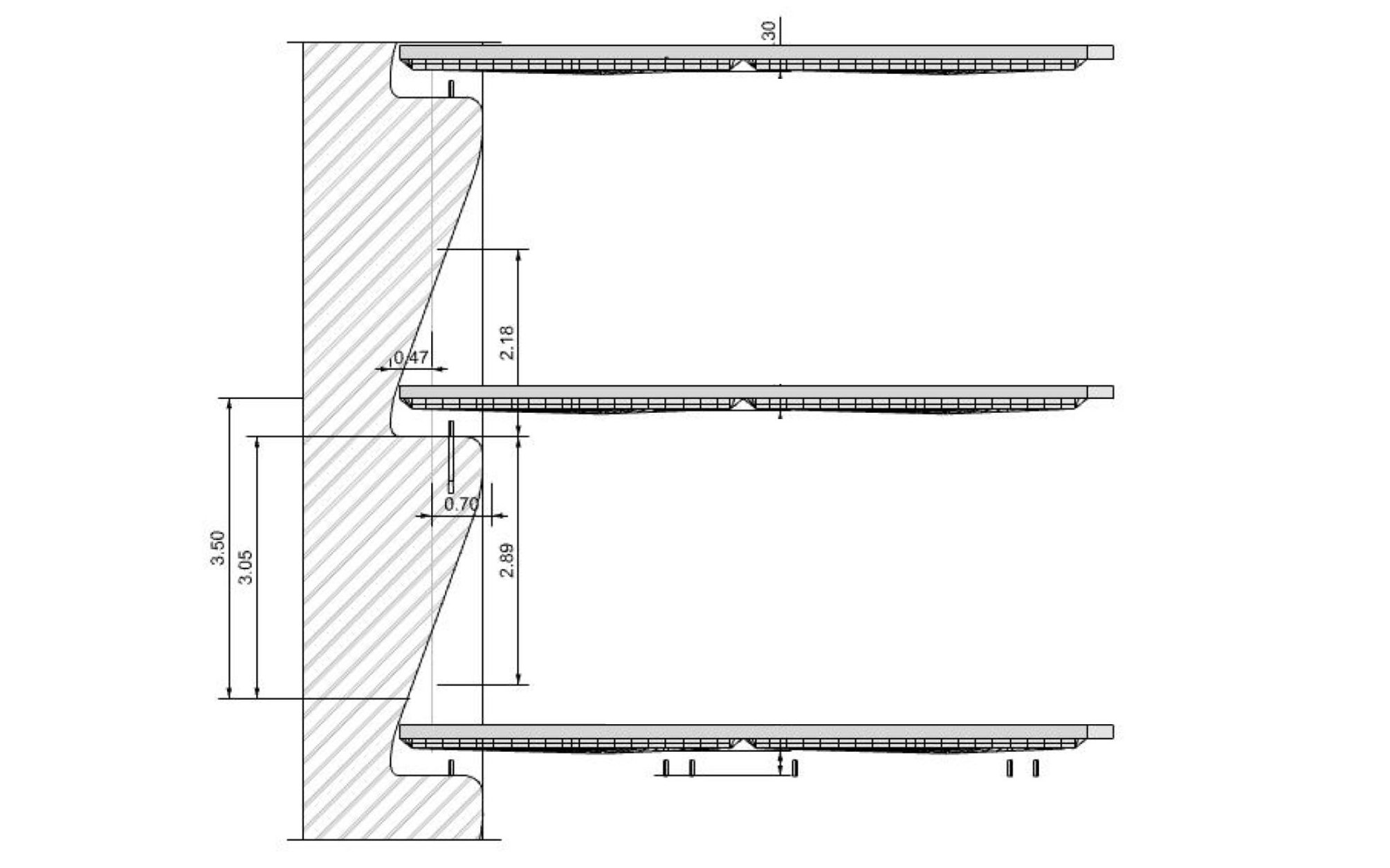

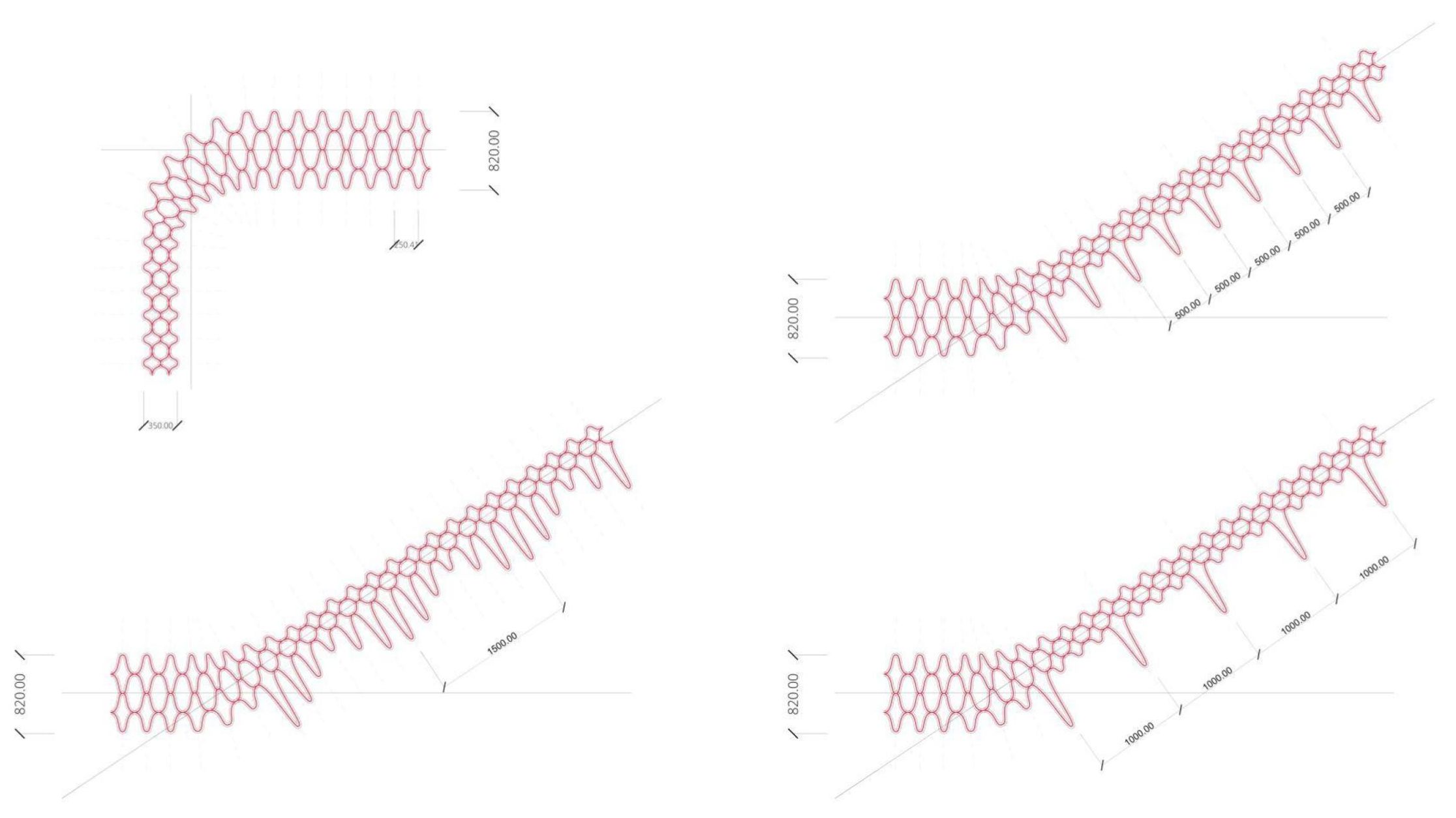

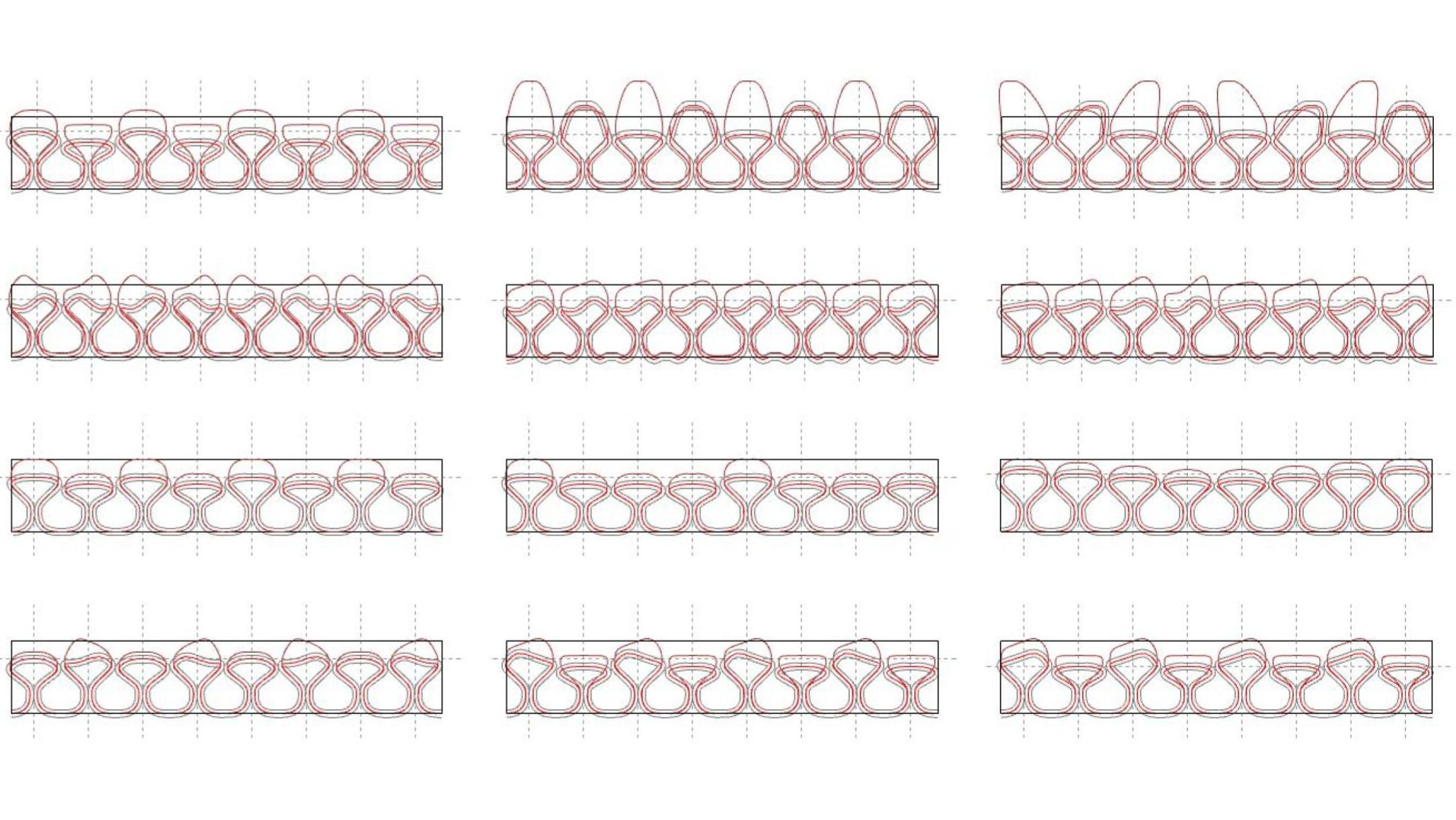

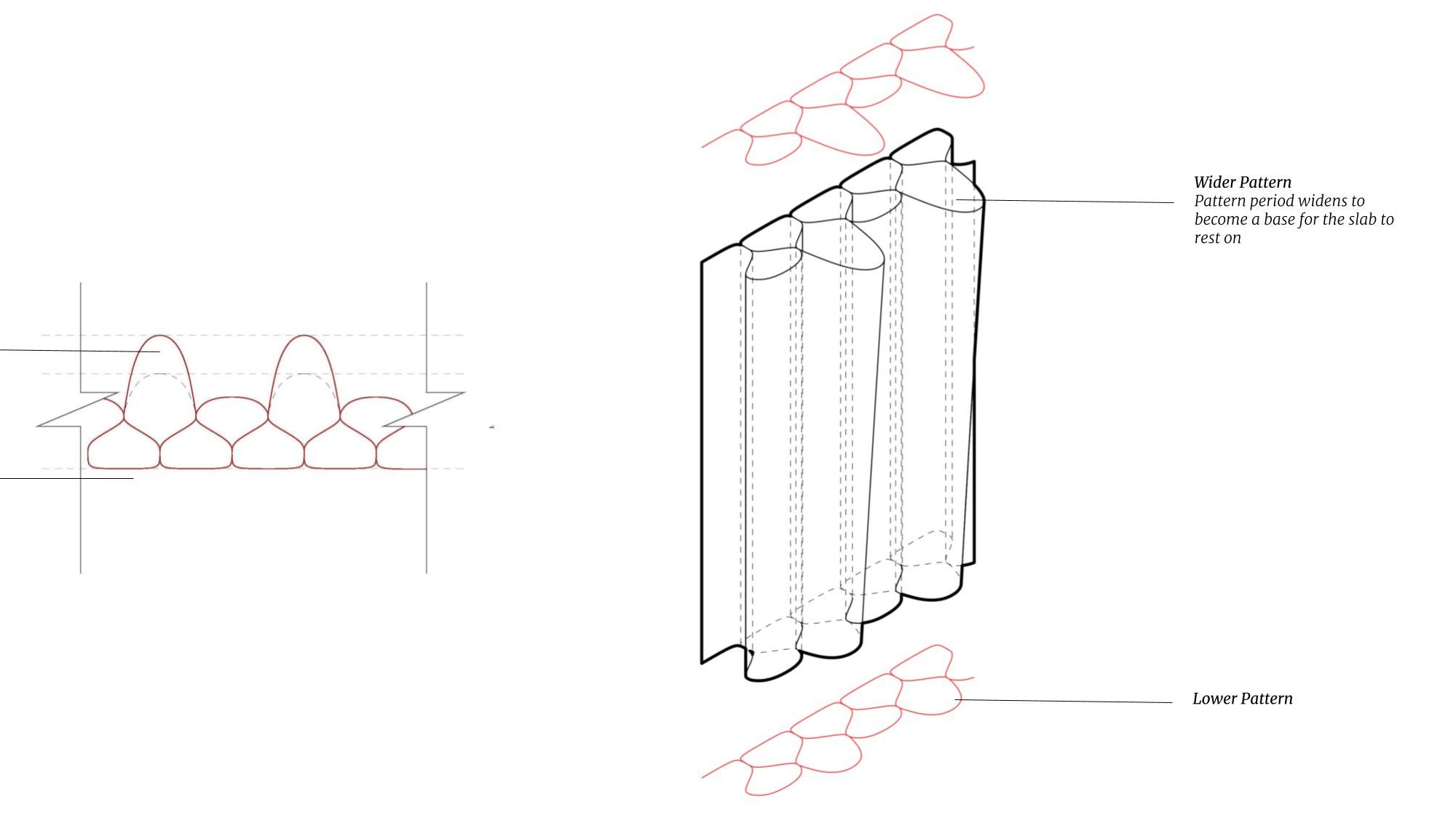

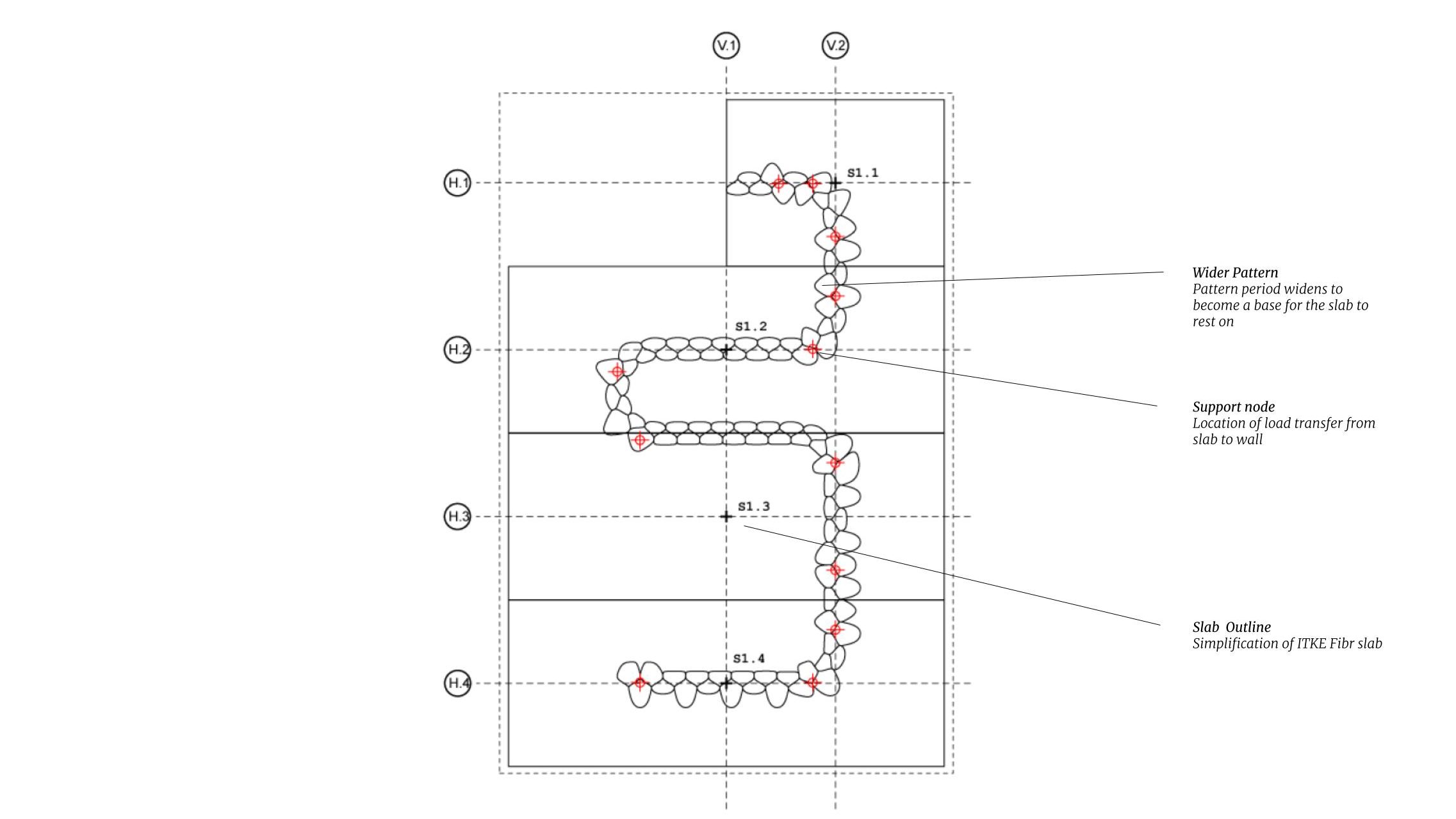

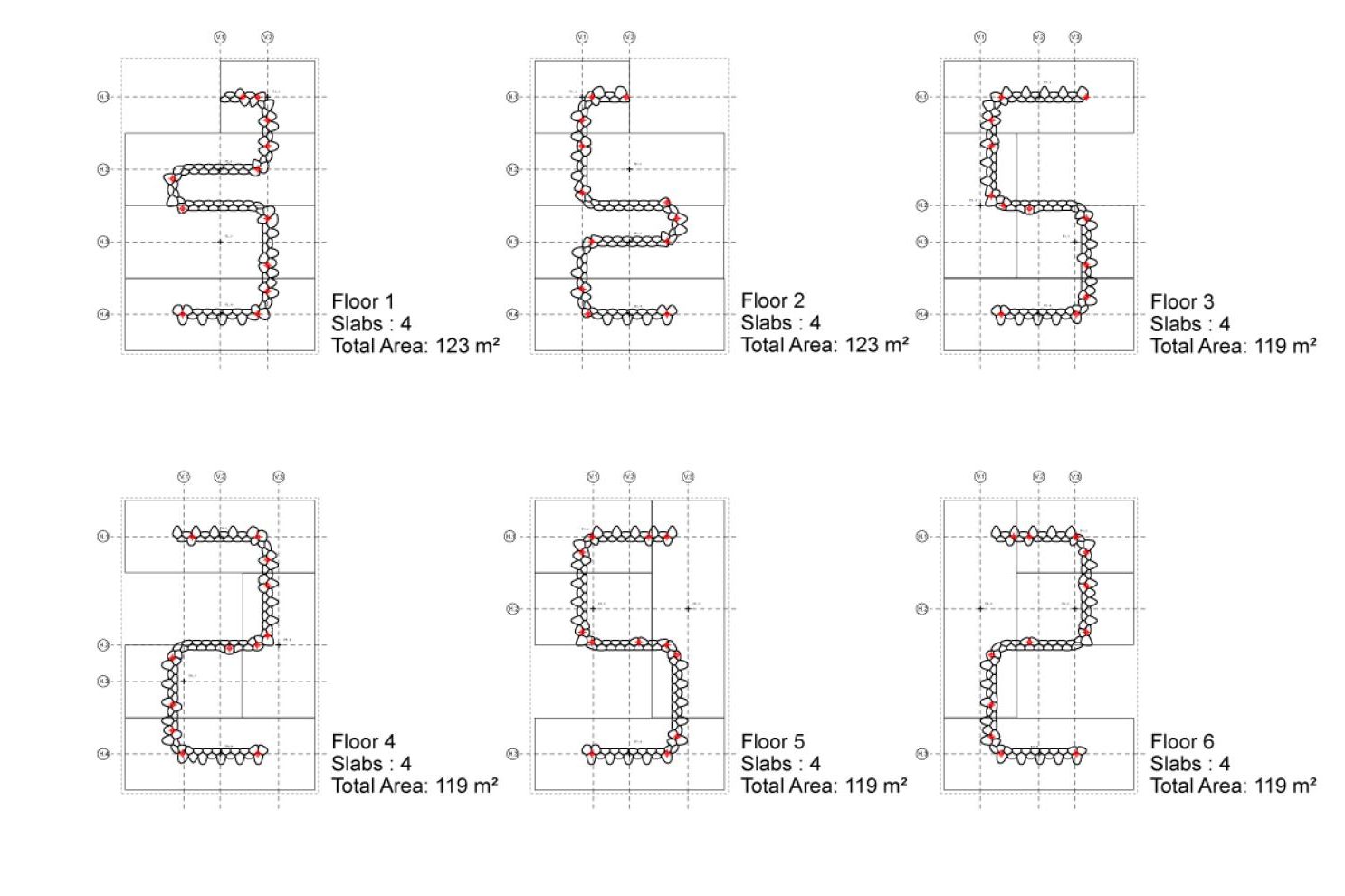

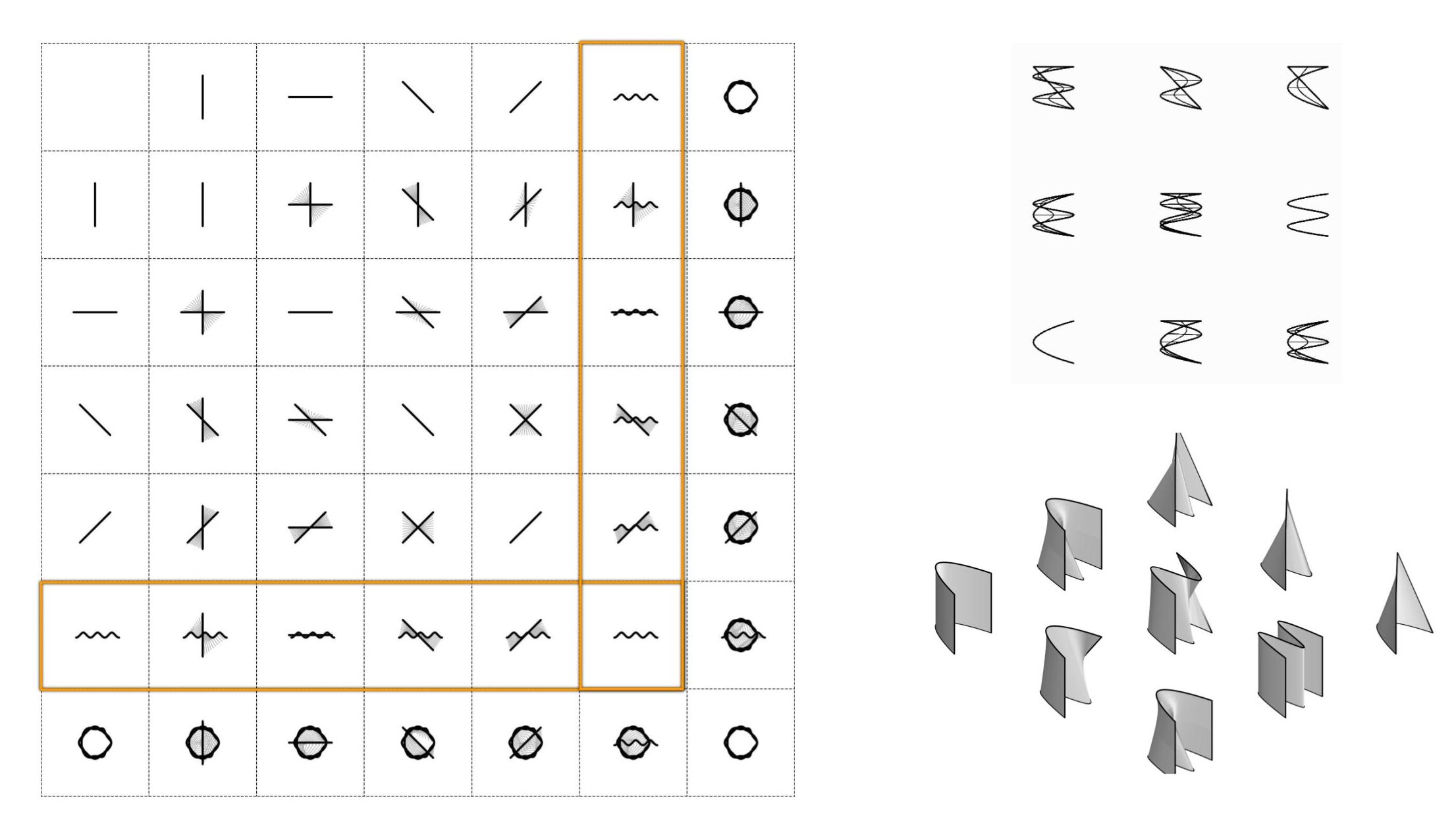

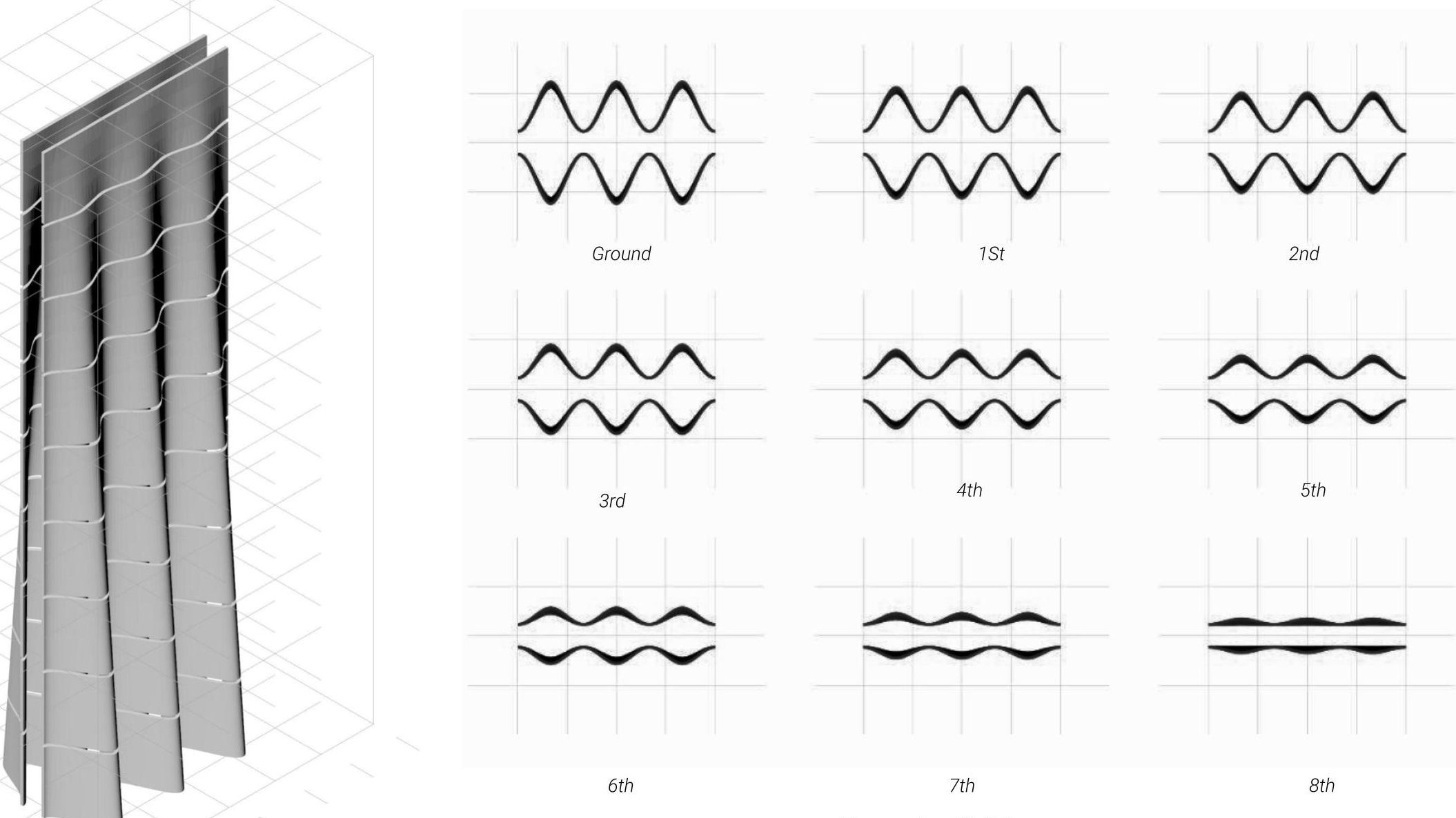

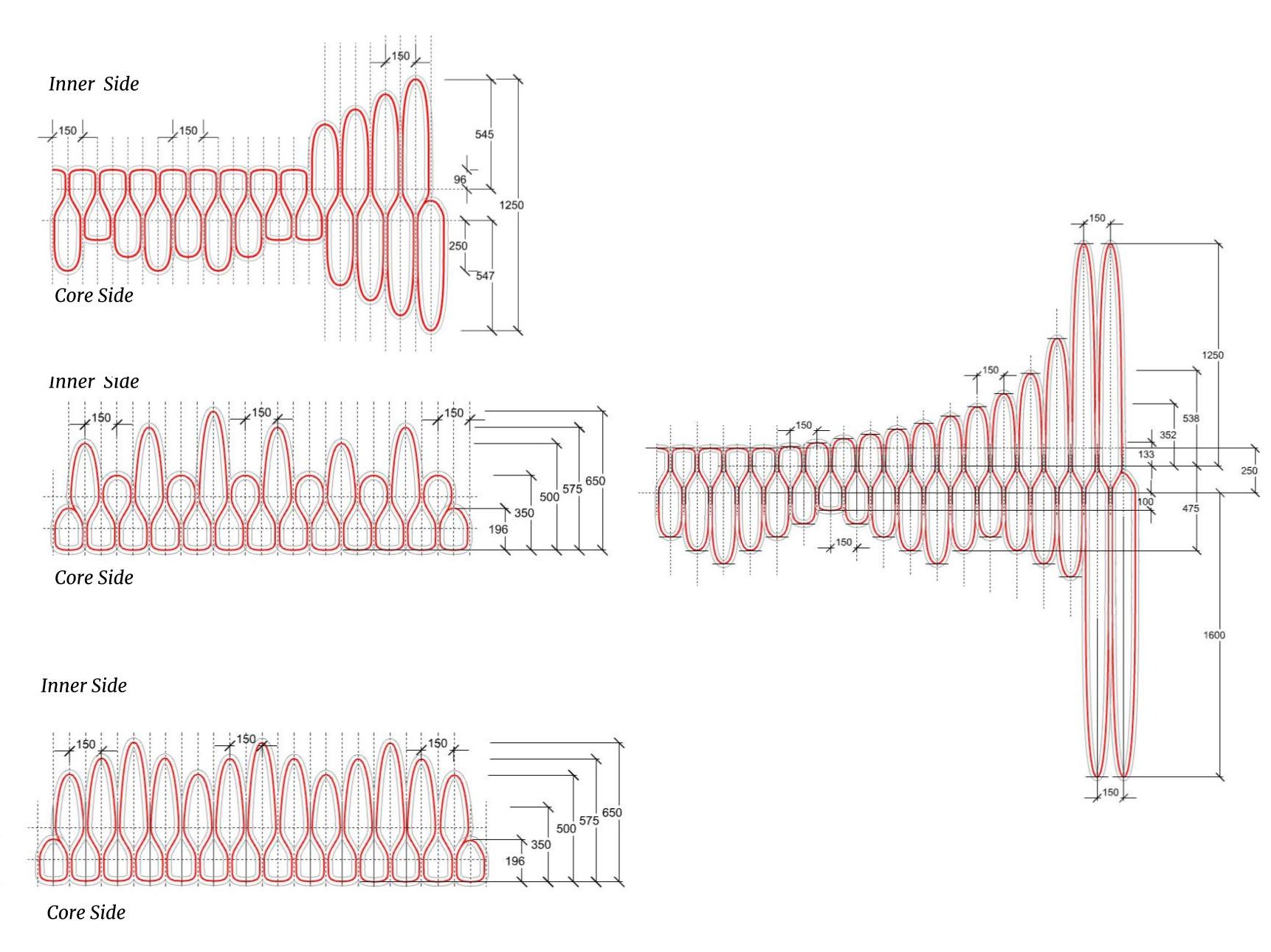

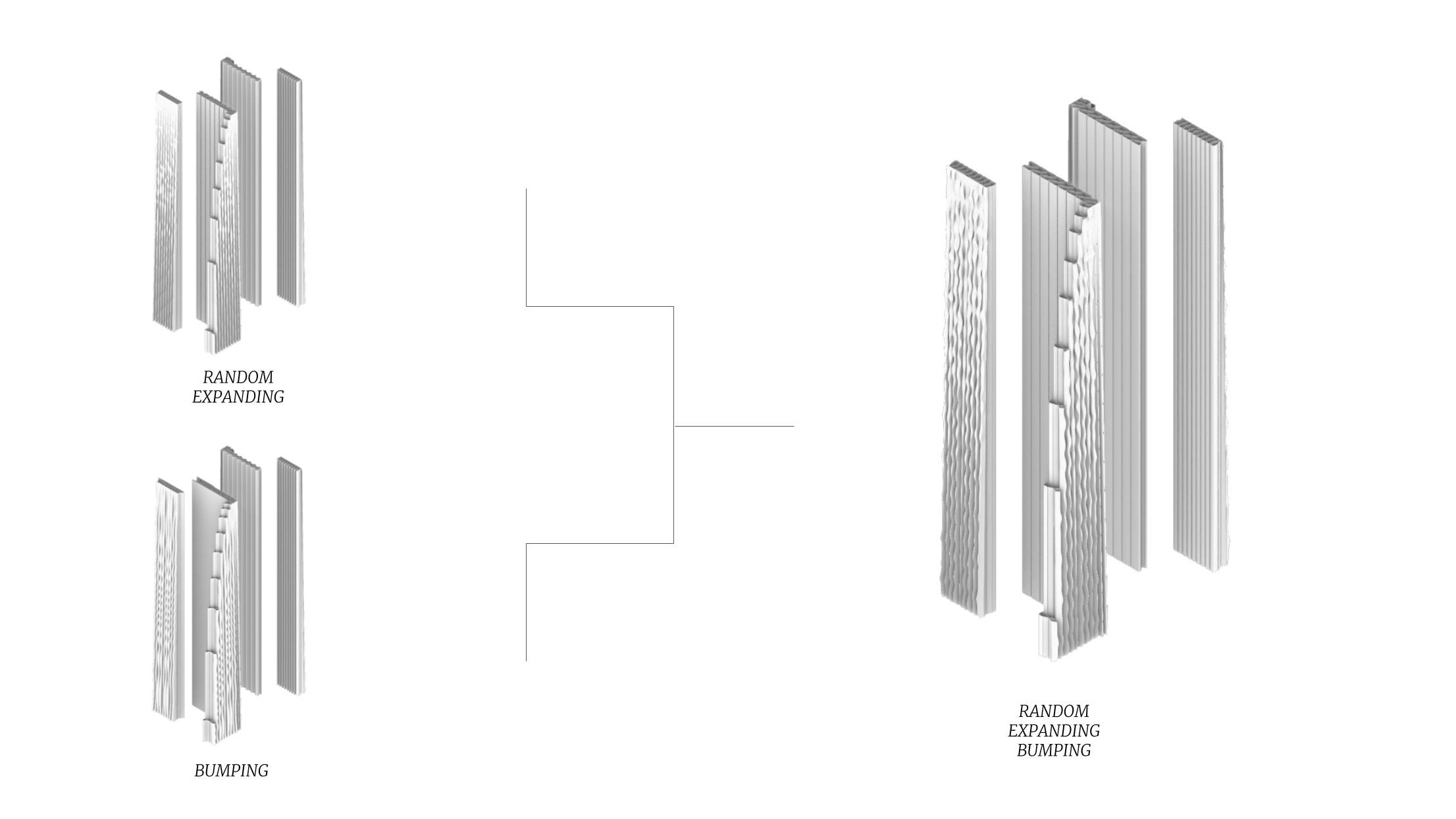

The texture catalog conveys explorations of the infill of the wall by moving, scaling, and/ or rotating points of tangents. The selected wall infill employs a flattened texture on one side, and a rhythmic texture for the exterior facade on the other side. The wider periods in the infill of the external facade are utilized as a base for the slab to rest on. The wall’s design was tapered from bottom to top.

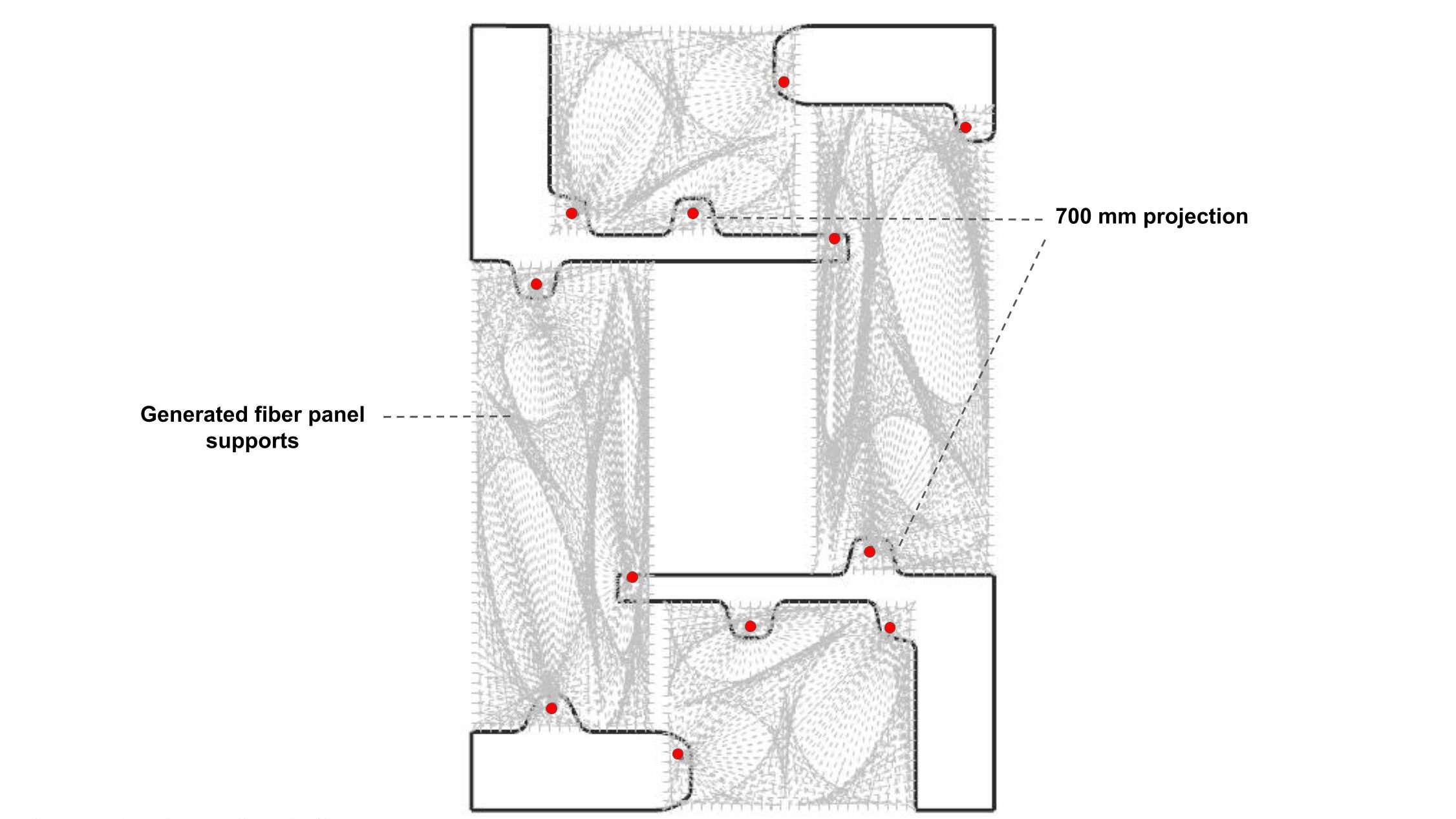

Points of support were placed along predetermined axis lines that simplify the realization of ITKE’s fiber slabs.

Bifurcation or Twist Walls + ‘Living Prototype’ Infill Pattern

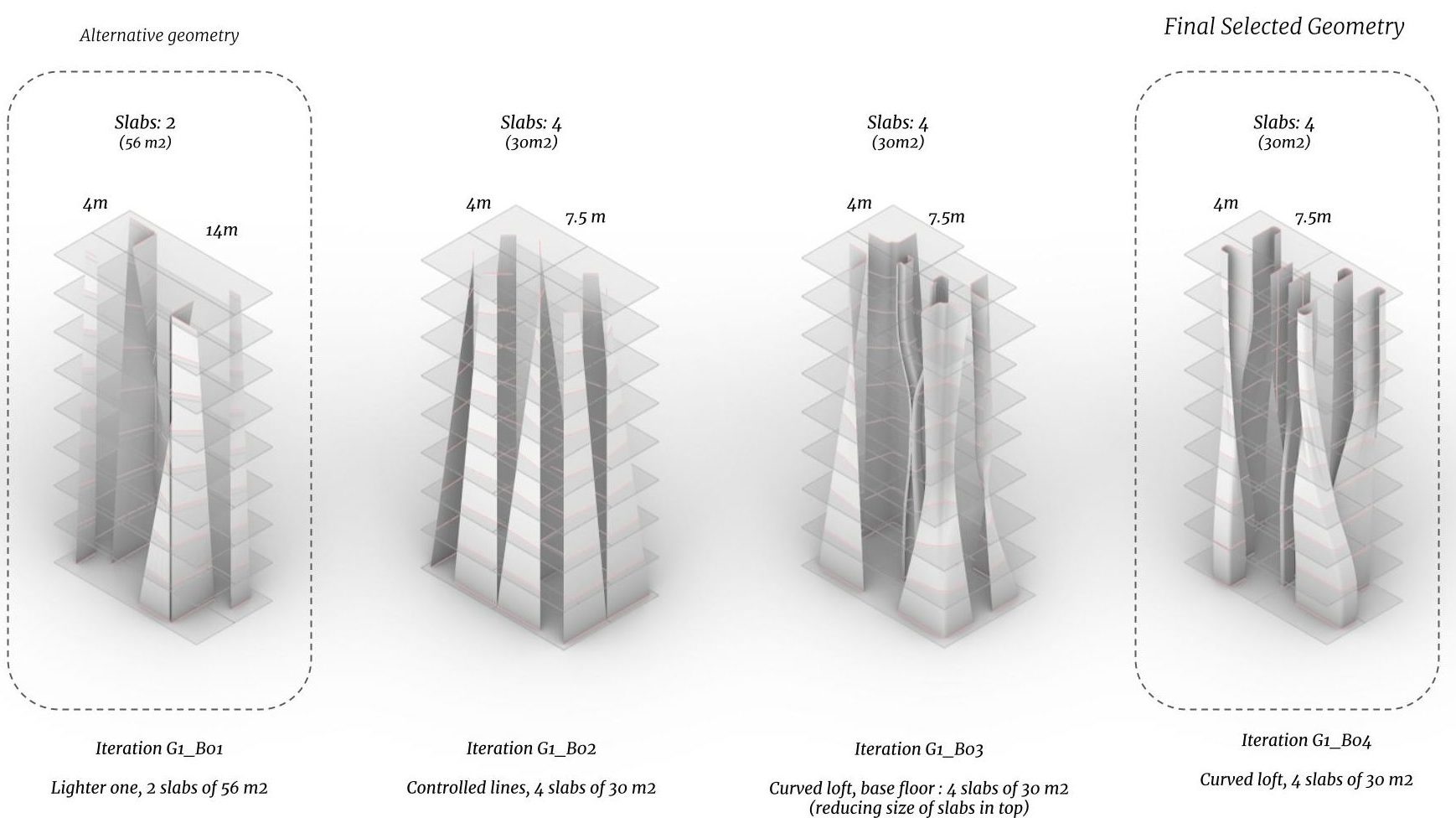

Options of lines, curves, and/ or shapes were explored for building form generation. The selected geometry was inverted and its geometry was subdivided into the plan drawings used to derive slabs. A void was planned as a condition, and the slabs were developed in a way that made that achievable through all the building storeys.

Bifurcation or Twist Walls + ‘TOVA’ Infill Pattern

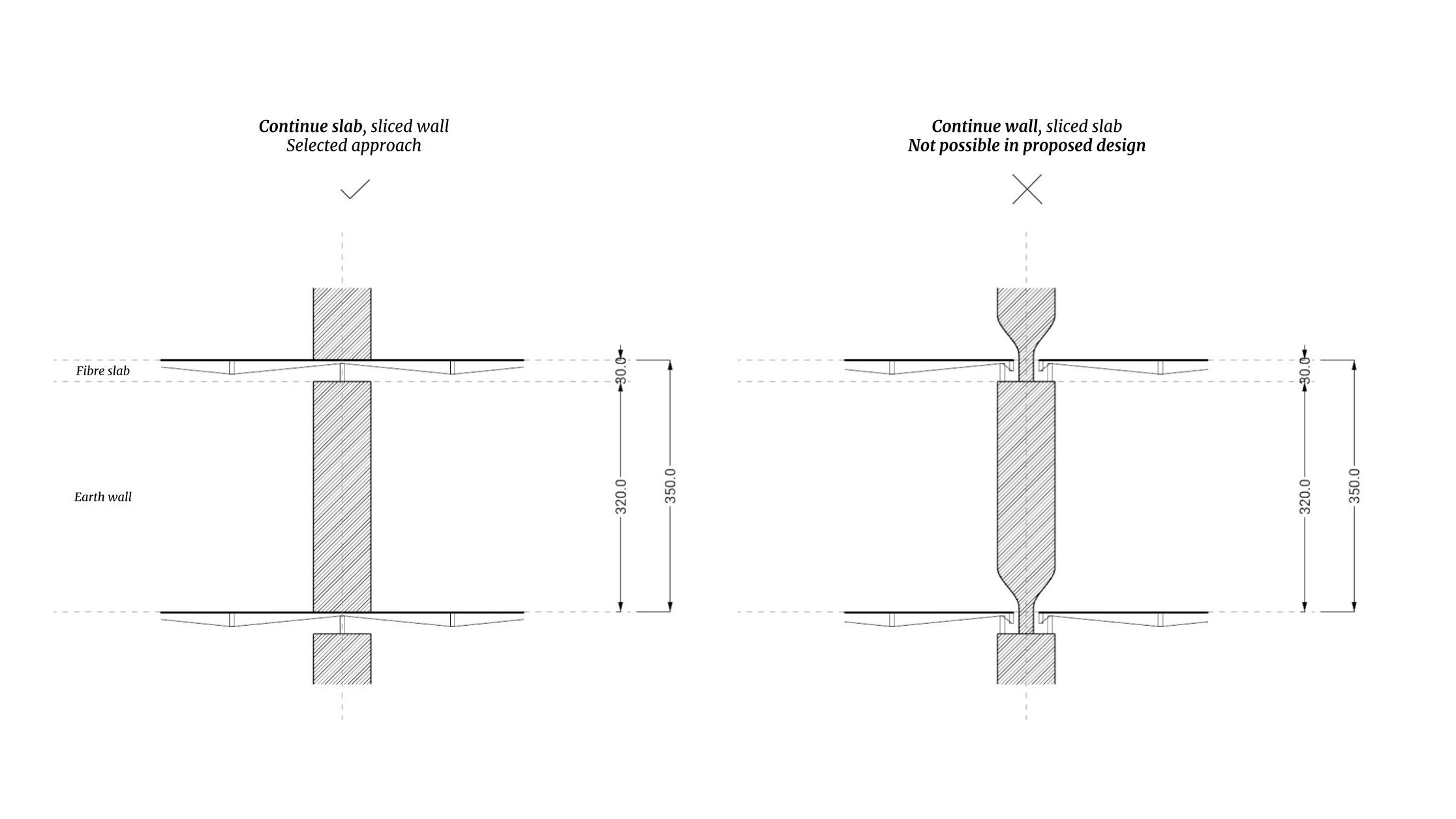

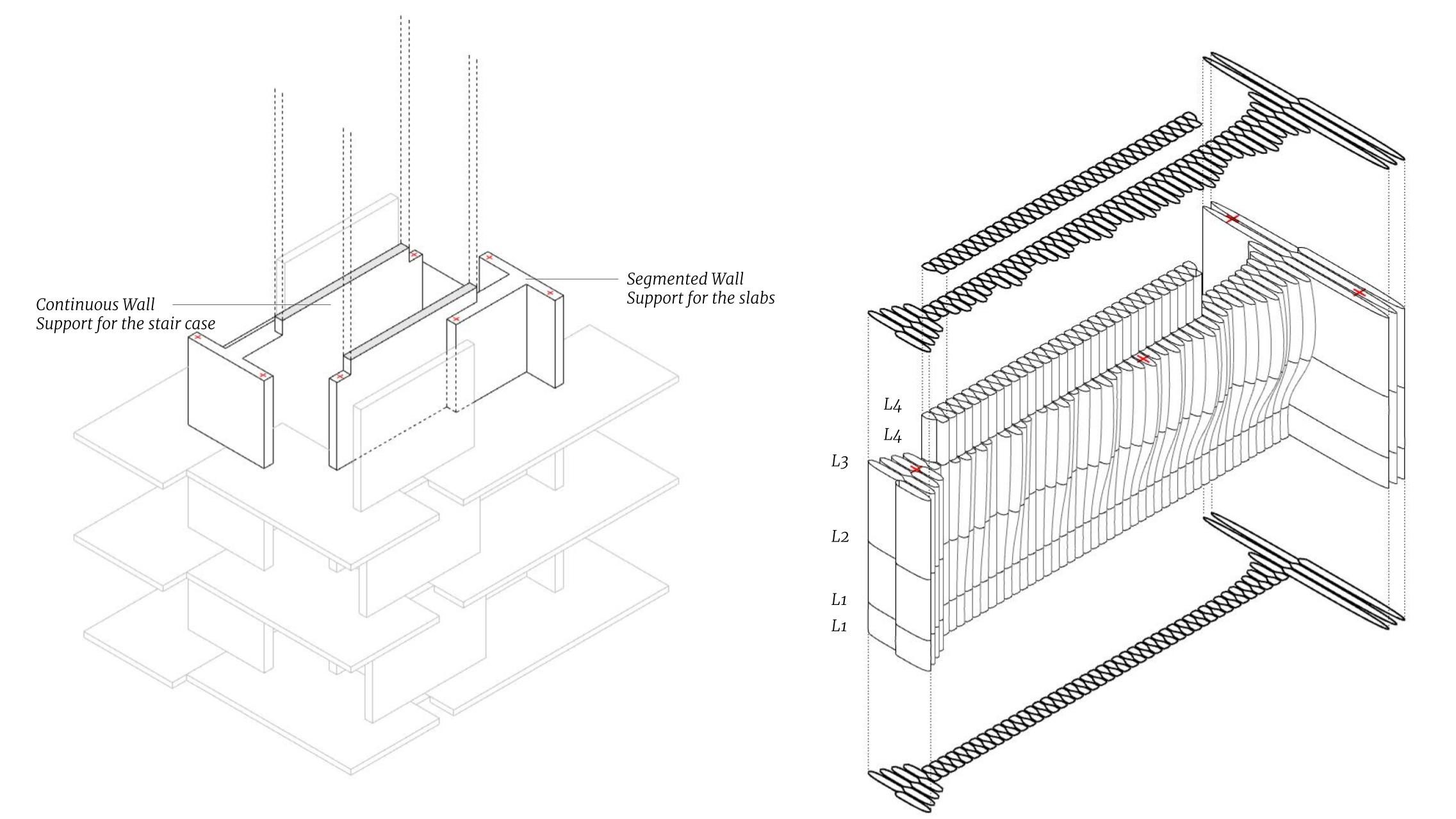

The criteria for building typology selection revolved around the capacity to expose the advantages of fiber and earth systems, the capacity to be built and withstand itself structurally and in printability, and the spatial performance and the flexibility of the program and experience. The continuous wall of the building that interrupts the slabs was not chosen because it was not feasible for the choice of building design. Therefore, the choice of a discontinuous clay wall and a continuous fiber slab was made.

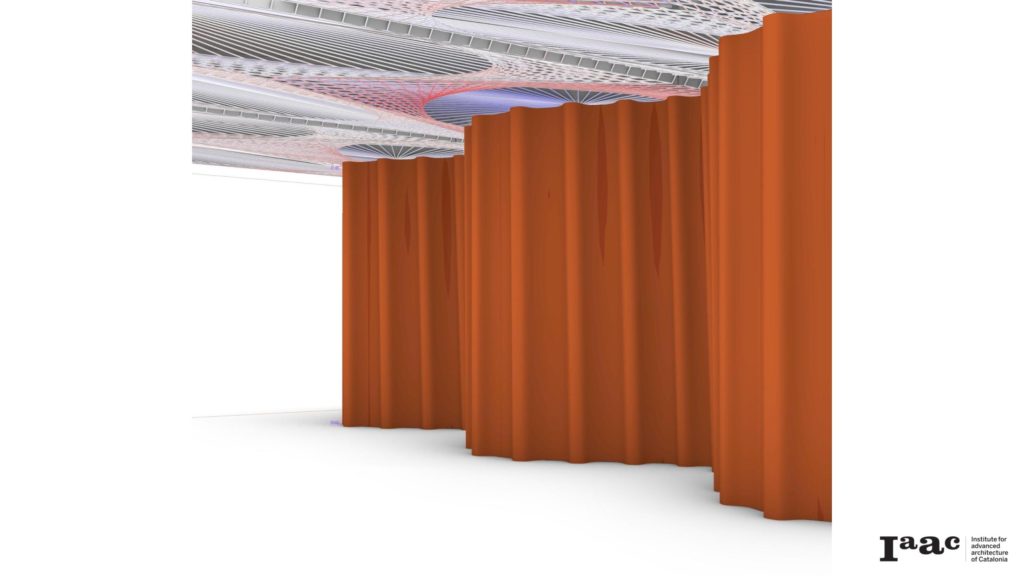

The external facade was characterized by a bumpy texture that was significant for the resistance to erosion from water and has benefits for shading. Internal wall facades were flat.

Orthogonal Walls + ‘Living Prototype’ Infill Pattern

The walls from the lowest floor to the highest move inwards towards one another hence tapering the profile of the building. Periods of wall infills were explored manually and they varied between interior spaces that had textured walls of different depths/ thicknesses, flat exterior facades, and varying depths on both the interior and exterior facades.

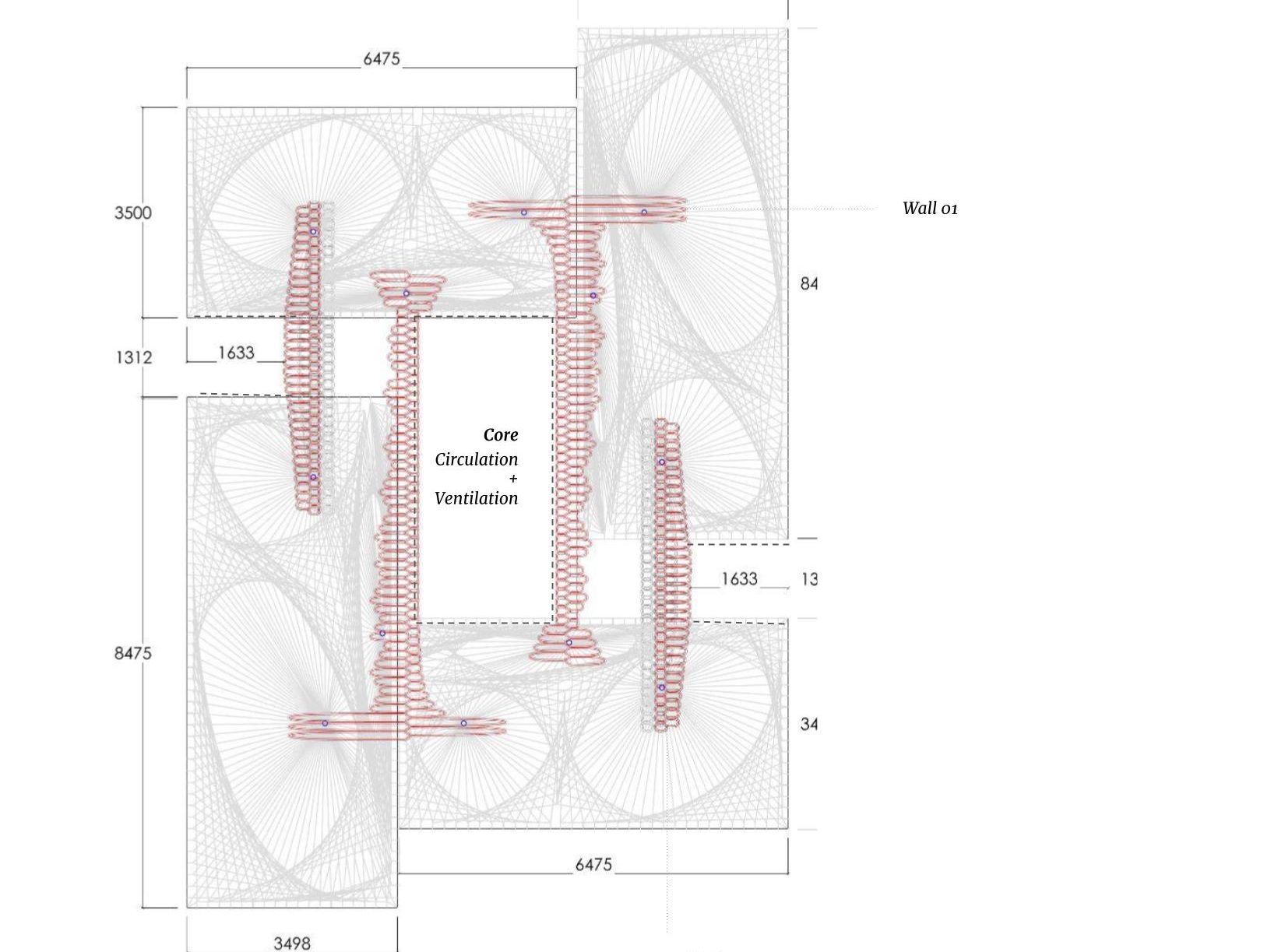

A continuous wall from the lowest to the highest level supports a staircase, and wall segmentation is used to host support points for the fiber slabs. A voided core in the building is dedicated for circulation and ventilation. The slabs allow this void to take place in the midst of them.

Orthogonal Walls + ‘TOVA’ Infill Pattern

Floor plan organization, which has an impact on overall structure, mass, usability, and other attributes, were experimented using assessments. The same exploration and assessment takes place on the exterior wall texture in order to achieve a non-interrupted clay-wall building profile. A vertical multiplier was involved alongside a randomness factor.

The generated support points’ locations overlap with the wall projections.

An uninterrupted wall that assists the fiber slabs allows a continuous clay wall building profile.