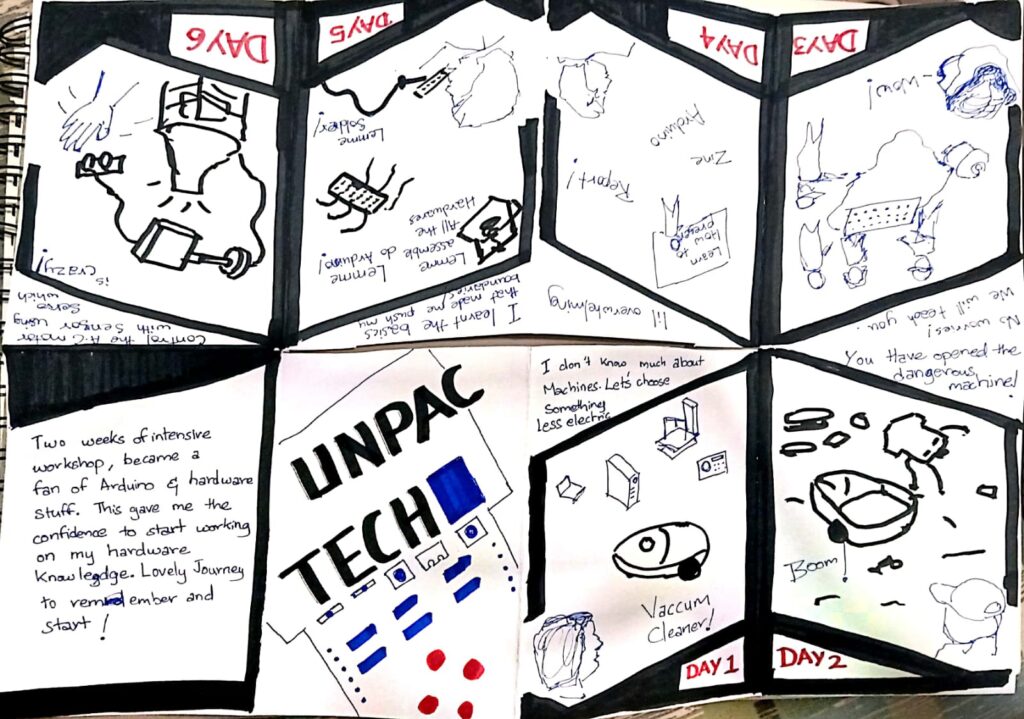

Starting from unpacking a machine, exploring the machines functionality, critically reporting and creating a machine paradox. In our first week, we were introduced to a bunch of scrap in our backyard.

We choose to unpack a vacuum cleaner which was not fully functional.

╭────────────────────────────────────────────╮

│ FORENSIC REPORT: UNPACKING TECHNOLOGY │

╰────────────────────────────────────────────╯

Reporting Agency: MACT, MAA, MDEF

Case Identifier: Forensics of the Obsolescence

Submitters: Lakshmi Narayanan, Sakshi Advani, Nina Avdalyan, Aishwarya Kaur, Amon

Date of Receipt: 20/11/2025

Date of Report: 20/11/2025

══════════════════════════════════════════════

OBJECT

══════════════════════════════════════════════

Brand: Rowenta Compact Cyclonic Vacuum Cleaner

Model: VC21VW0

Serial: R0346301 / RO346301

Color: ORANGE (plastic), BLACK (plastic & resin)

Made In: Germany, Romania, Spain, China, France, International

Forensic Questions

1. WHAT DOES IT DO?

The Rowenta Compacte Cyclonic is a bagless household vacuum cleaner that uses cyclonic separation to collect dust without disposable bags.

KEY ABILITIES

• Cyclonic dust separation

• Multi-surface cleaning

• HEPA filtration

• Compact and portable form

• Adjustable reach via telescopic tubes

• Suitable for mixed household surfaces

INTENDED USE CASES

• Daily floor cleaning

• Carpet & rug maintenance

• Hard floor cleaning

• Upholstery & furniture

• Crevice and corner dust removal

2. HOW DOES IT WORK?

OPERATING STEPS

Step 1: Power Generation

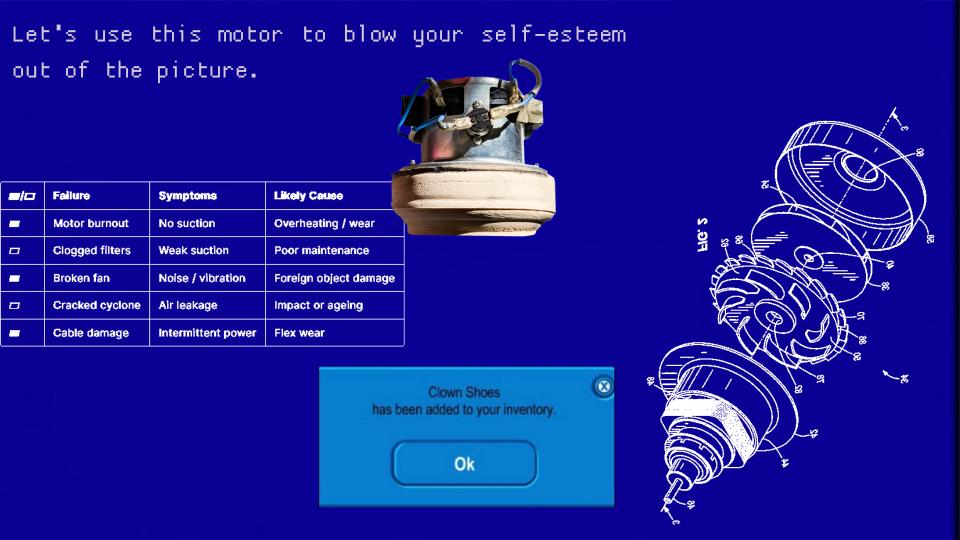

The 1700W universal motor spins at high RPM to create suction.

Step 2: Air Intake

Air + debris enter through the nozzle → hose → tube → cyclone.

Step 3: Cyclonic Separation

Debris spins rapidly; heavier particles drop into the dust bin.

Step 4: Multi-Stage Filtration

- Primary cyclone → coarse particles

- Pre-motor foam filter → protects motor

- HEPA filter → captures fine particles

Step 5: Clean Air Exhaust

Filtered air exits via rear exhaust vents.

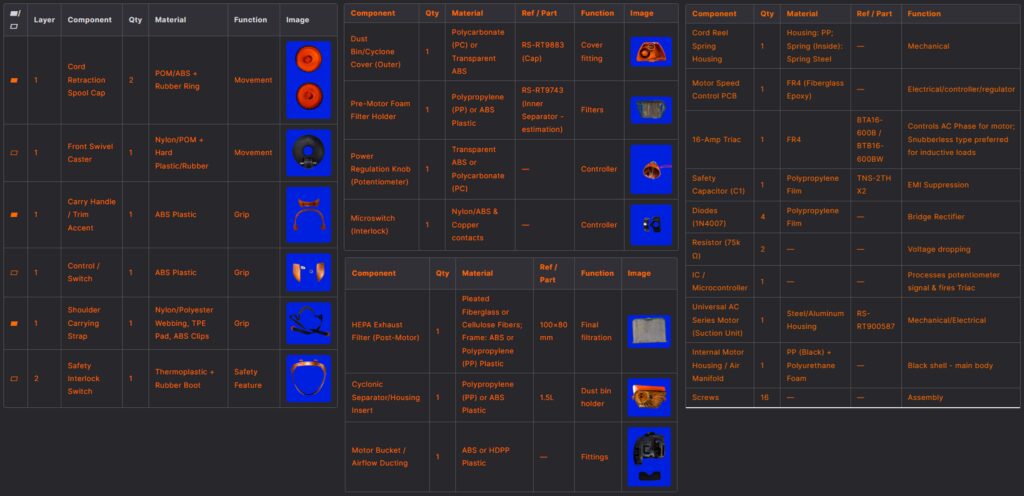

3. HOW IS IT BUILT?

SUBSYSTEMS

• Motor assembly — universal motor + impeller

• Cyclone system — transparent dust chamber

• Filtration — foam + HEPA filters

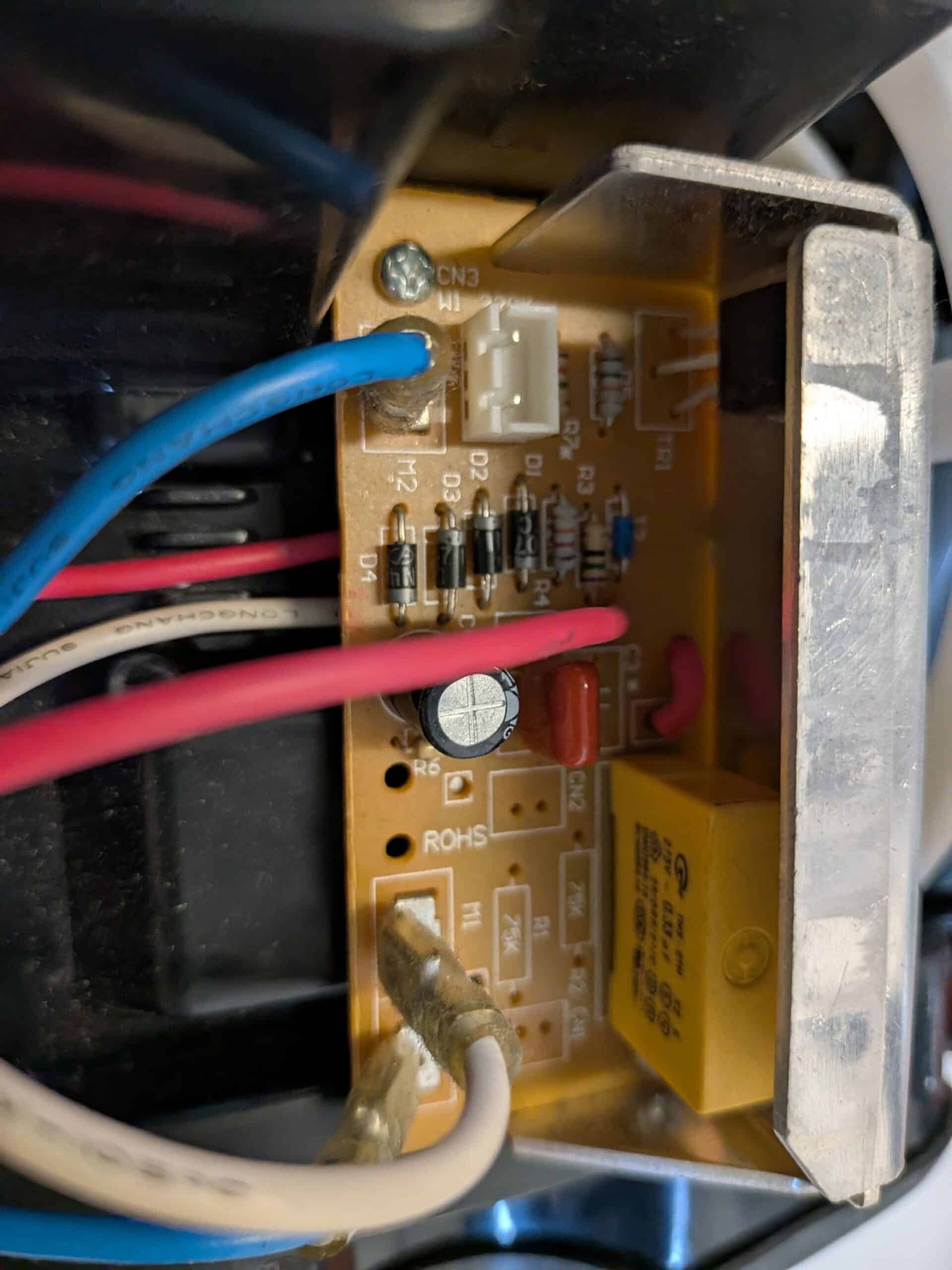

• Electronics — PCB speed/triac control

• Cable system — retractable 5 m power cord

• Mobility — rear wheels + front swivel caster

• Accessories — nozzle, tubes, brushes

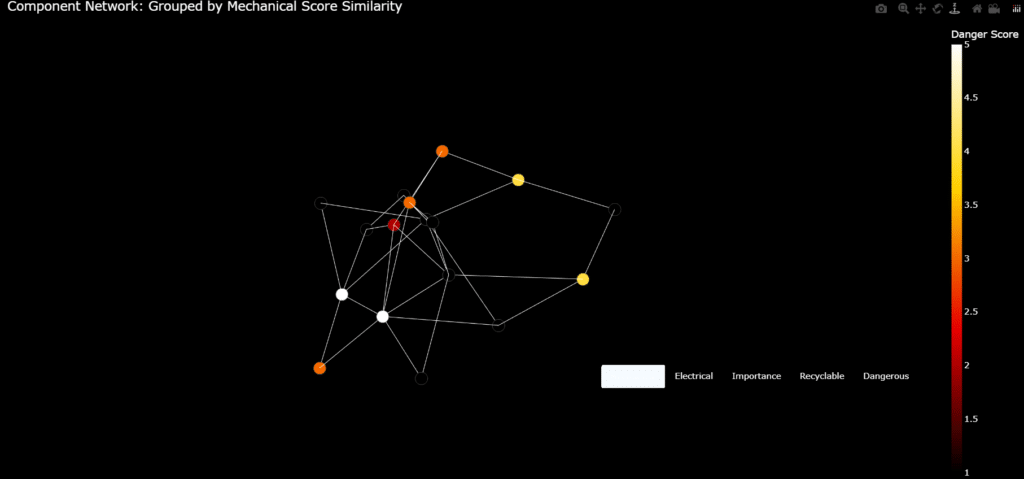

We created a network graph using python where each item in the machine was values individually based on scores given by our analysis. The following are the parameters: Electrical, Mechanical, Importance of the component in the machine, Recyclable factor and Danger?

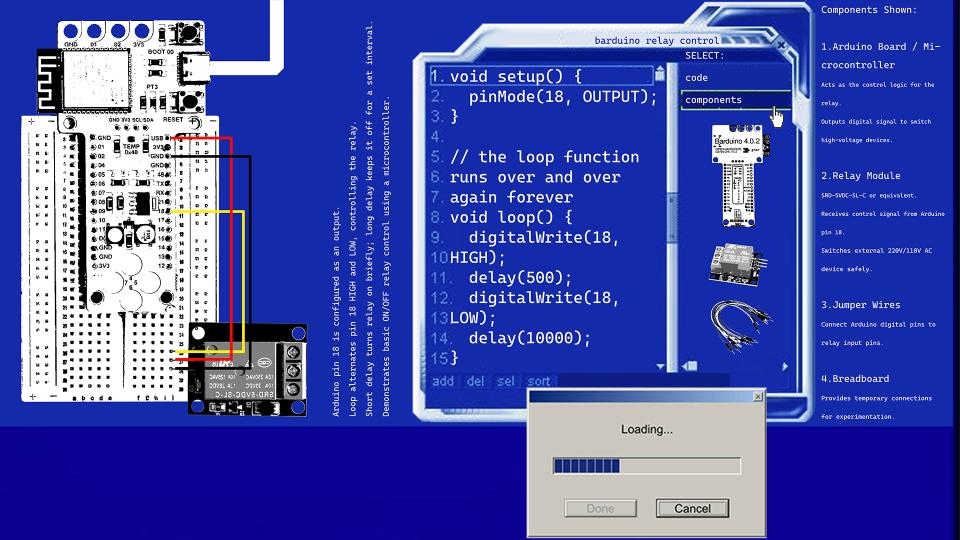

At last, we tried to switch on the motor for just 0.30 second since it was a dangerous AC motor. In order to do that, we used a basic arduino blink code.

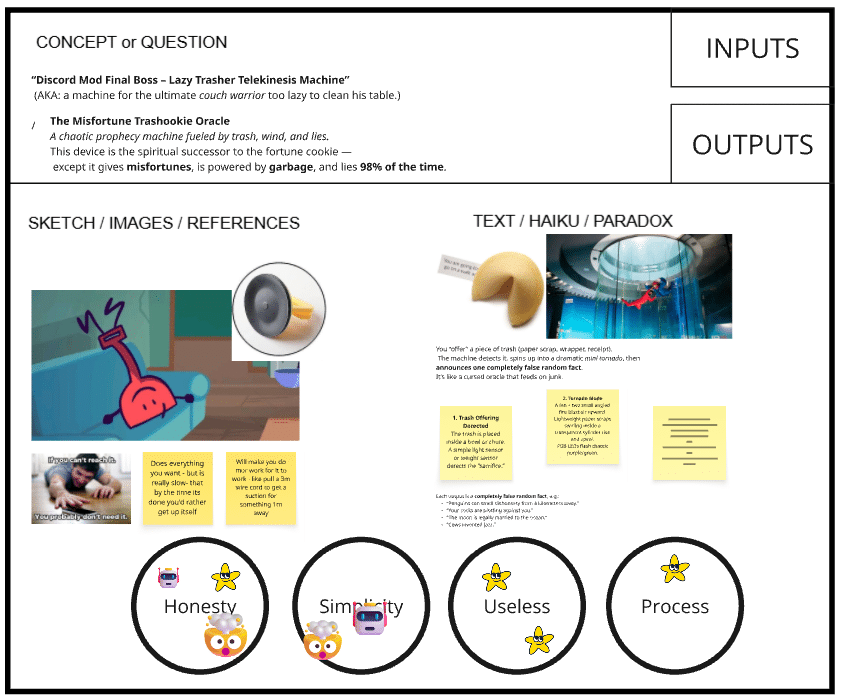

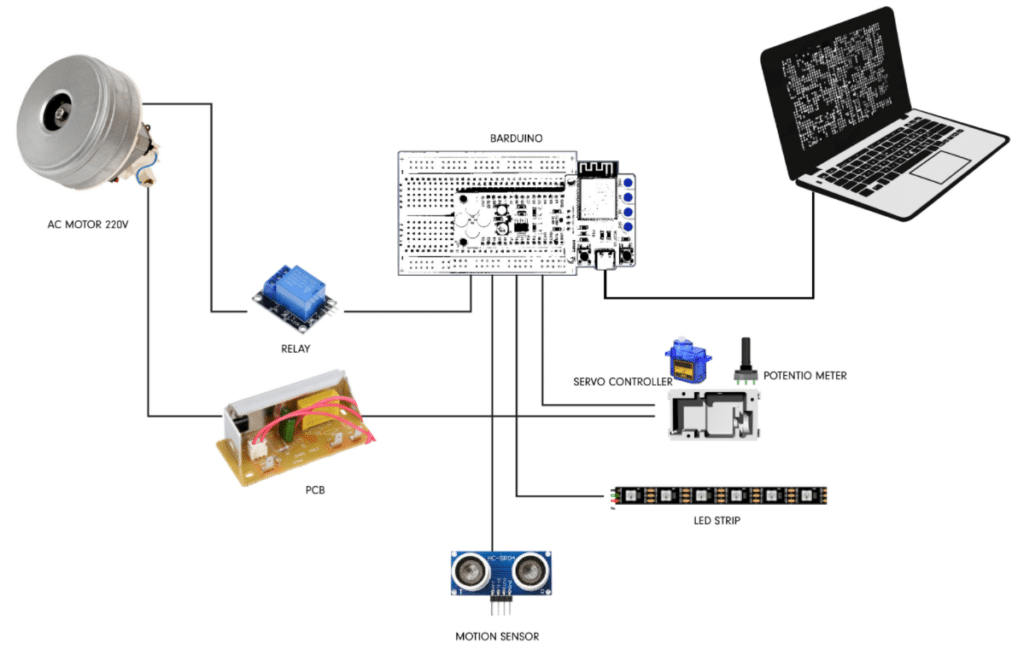

In our second week, “Machine Paradox” we aimed to create useless machine but using the components that we dismantled from our first week. Using the AC motor that sucks and throws air, we came up the idea to make a goblet of fire.

We decided to use the Universal A.C motor but one of the most challenging part is to control it using arduino. Since the arduino and sensors work on a D.C current, controlling the AC motor or even touching it was more dangerous as getting short circuited.

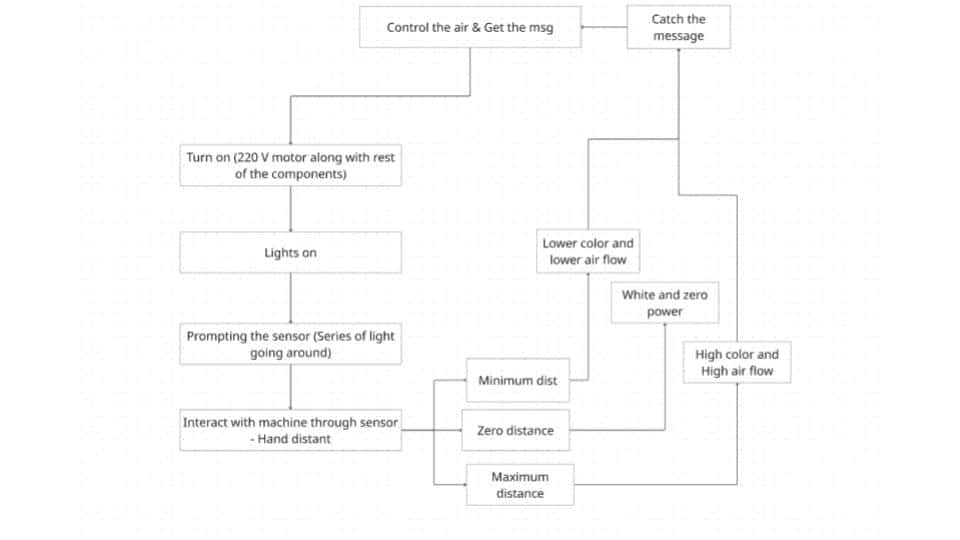

We used arduino code with the below given logic flow chart. Since there were multiple functions happening at a same time, the flow chart helped us to figure out the hierarchy of commands to be executed in the machine.

- Turning on the lights to prompt the sensor and blowers.

- When user brings the hand closer to the ultra sonic sensor, it first changes color.

- The Distance between the hand to the sensor is turned into data feed for the Servo motor to turn from 0 to 180 degrees.

- The Servo motor is connected with the 220v potentiometer which controls the power of the A.C motor.

- Finally, when the hand is closer to the Ultra sonic sensor, the motor runs in full potential thus blowing the magic chits out of the blower, holding messages that can change your life.

Personal reflection: Lakshmi Narayanan