The evolution of digital fabrication has transitioned from rapid prototyping toward the sophisticated integration of multi-platform manufacturing workflows. This report examines the technical implementation of Additive Manufacturing (AM), Subtractive Computer Numerical Control (CNC), and Robotic Automation within a controlled laboratory environment. By synthesizing these diverse technologies, the project explores the precision, scalability, and material efficiency required in contemporary architectural and engineering paradigms.

Digital fabrication represents a fundamental shift in the relationship between design intent and physical production. At its core, this discipline leverages computational logic to drive hardware, ensuring that complex geometries are translated into tangible artifacts with minimal deviation. This study focuses on the tripartite synergy between 3D Printing, Laser Cutting, and CNC Milling, complemented by the implementation of Robotic Arms to facilitate automated handling and assembly.

.

Flexfirng: Laser Cutting

Laser Cutting (Light Amplification by Stimulated Emission of Radiation) is a non-contact, subtractive fabrication technology that utilizes a high-power, concentrated coherent light beam to melt, burn, or vaporize material with extreme precision. In an automated fabrication workflow, this process is governed by Computer Numerical Control (CNC), which translates vector-based geometries into precise Cartesian coordinates.

Concept and Reference

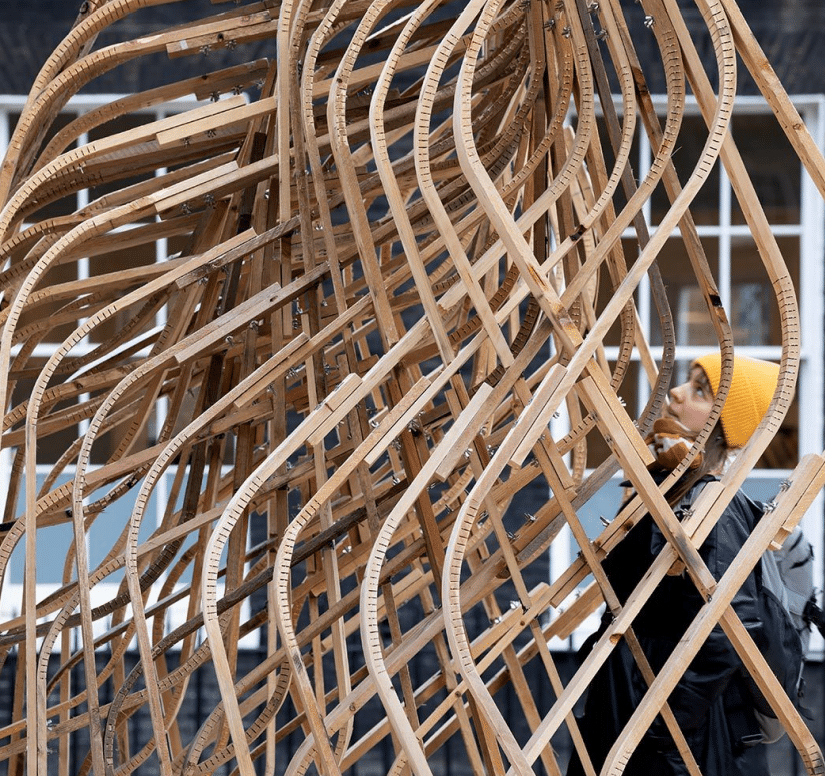

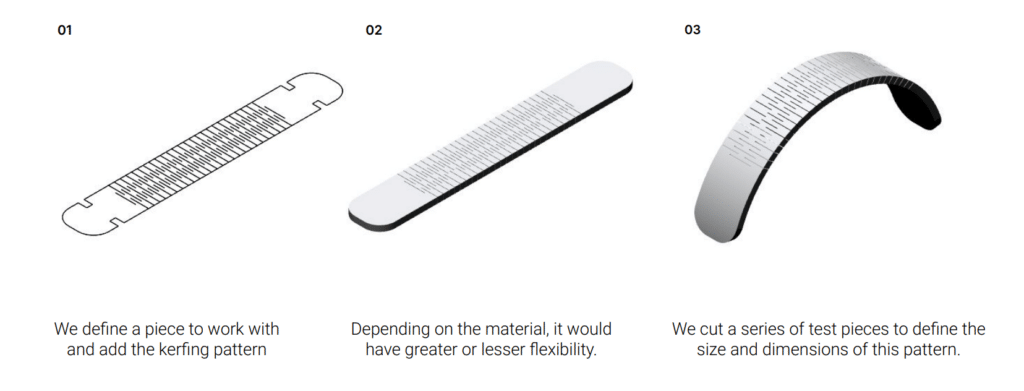

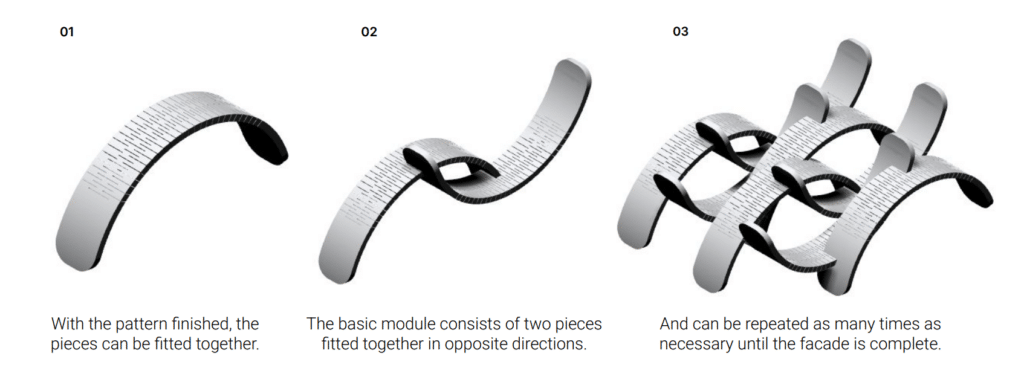

This exploration focuses on transforming flat materials into spatial structures through interlocking and kerf-bending techniques. Working with plywood and

acrylic, we conducted a series of tests to understand tolerance behaviour, minimum bending radio, and material failures under repeated stress. These studies informed the development of an undulating vertical element composed of interlocking ribs that acquire curvature through calibrated kerf patterns.

Final Model

This exploration focuses on transforming flat materials into spatial structures through interlocking and kerf-bending techniques. Working with plywood and

acrylic, we conducted a series of tests to understand tolerance behaviour, minimum bending radio, and material failures under repeated stress. These studies informed the development of an undulating vertical element composed of interlocking ribs that acquire curvature through calibrated kerf patterns.

Twines: 3D printing

Additive Manufacturing (AM), commonly referred to as 3D printing, represents a paradigm shift in fabrication by synthesizing three-dimensional objects through the incremental deposition or polymerization of material layers. Unlike subtractive methods, AM processes allow for the realization of topologically optimized geometries and internal lattice structures that are otherwise impossible to manufacture. The integration of 3D printing within this project serves as a bridge between digital complexity and physical functionality.

Concept and Reference

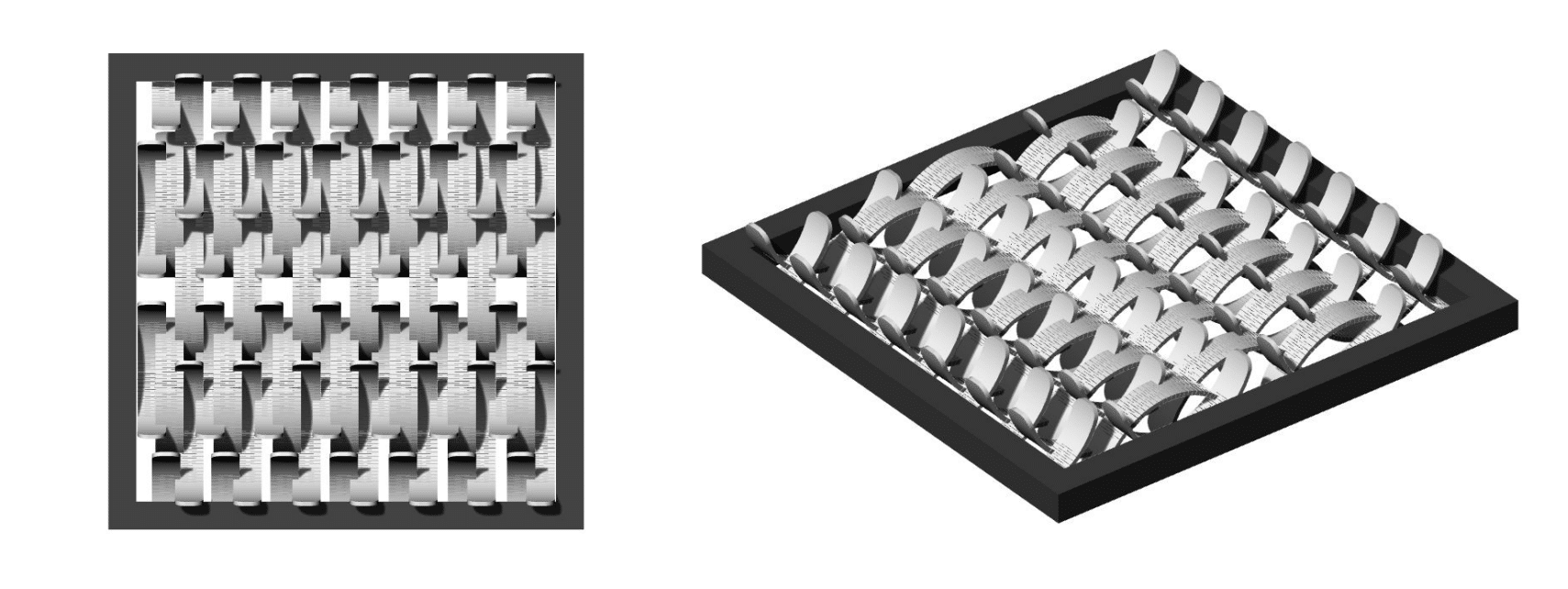

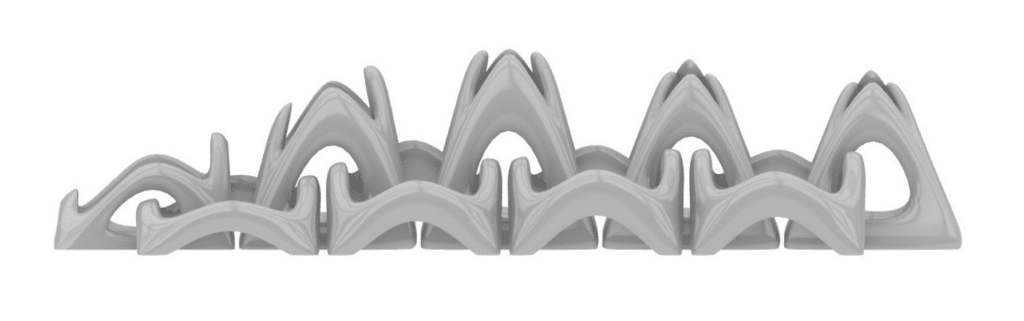

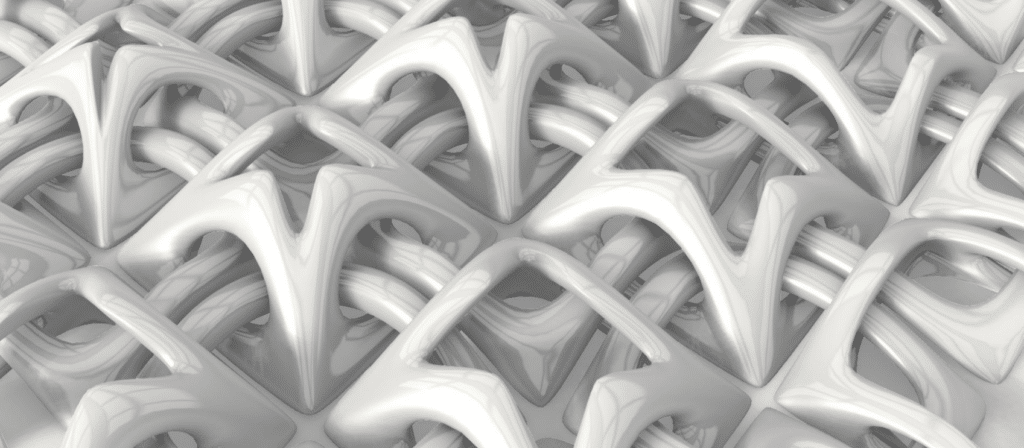

This project investigates additive manufacturing as a tool for producing modular façade components with controlled porosity and light performance. Using PLA and FDM printers, we developed a family of interlocking elements generated through a parametric subdivision logic that allowed each module to vary its aperture size. The geometry was engineered to print without supports, adhesive, or post-processing, relying instead on a chain-mill-like continuity where each part locks directly into the next.

FINAL MODEL

This exploration focuses on transforming flat materials into spatial structures through interlocking and kerf-bending techniques. Working with plywood and

acrylic, we conducted a series of tests to understand tolerance behaviour, minimum bending radio, and material failures under repeated stress. These studies informed the development of an undulating vertical element composed of interlocking ribs that acquire curvature through calibrated kerf patterns.

Flexfirng: Laser Cutting

Laser Cutting (Light Amplification by Stimulated Emission of Radiation) is a non-contact, subtractive fabrication technology that utilizes a high-power, concentrated coherent light beam to melt, burn, or vaporize material with extreme precision. In an automated fabrication workflow, this process is governed by Computer Numerical Control (CNC), which translates vector-based geometries into precise Cartesian coordinates.

Concept and Reference

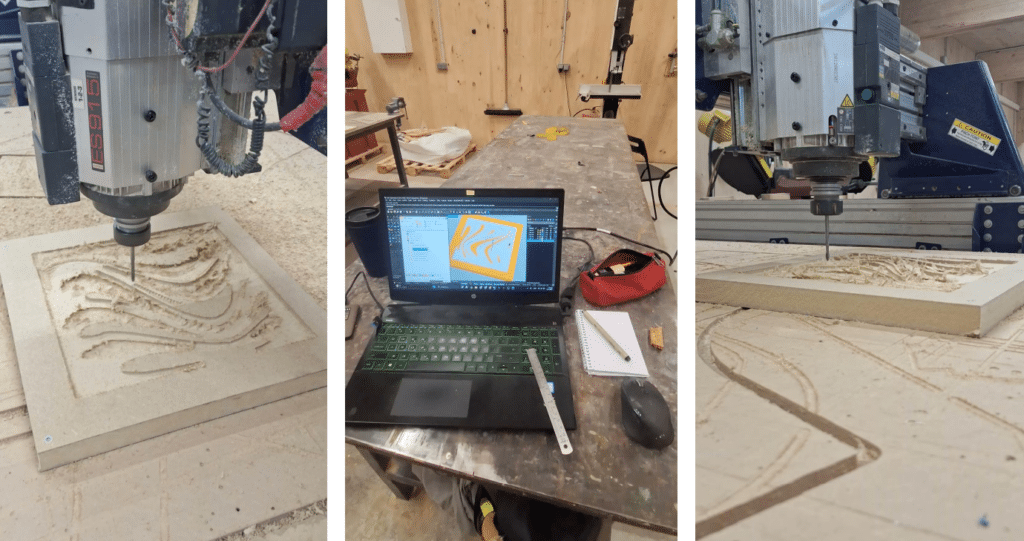

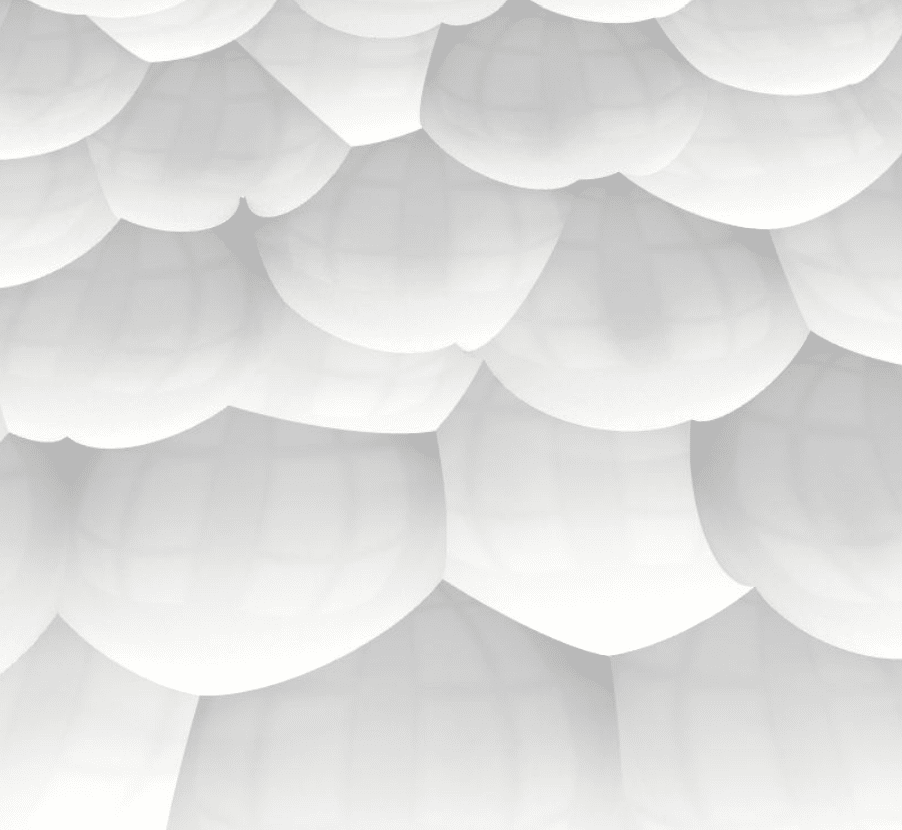

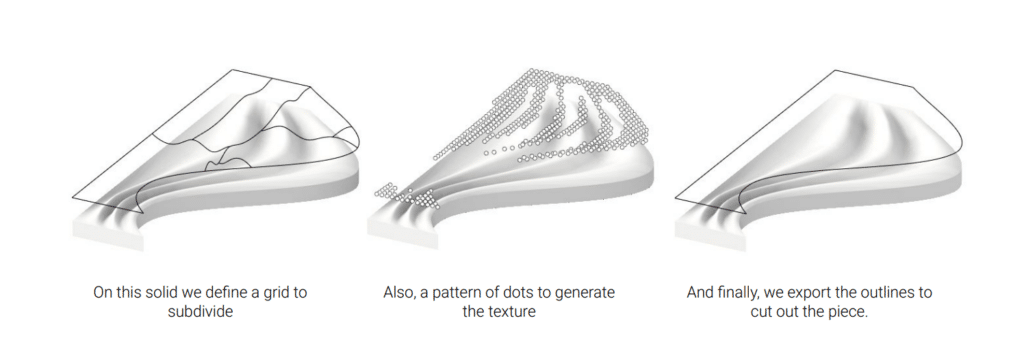

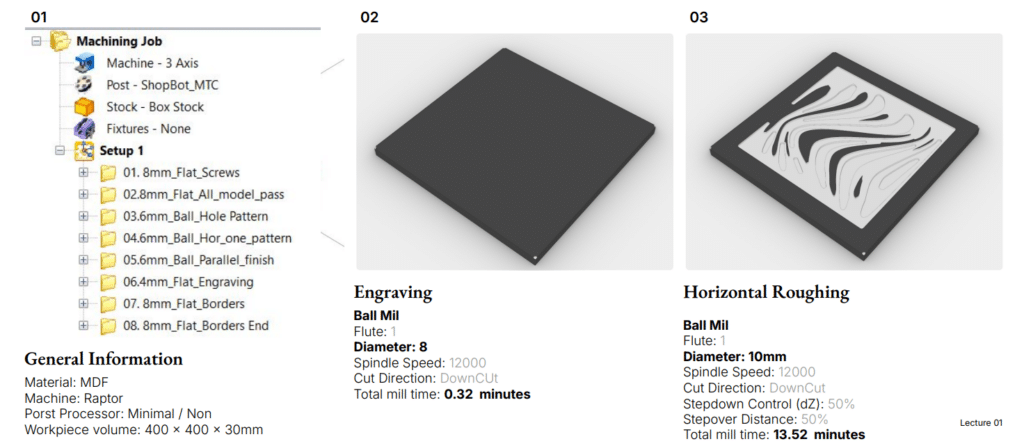

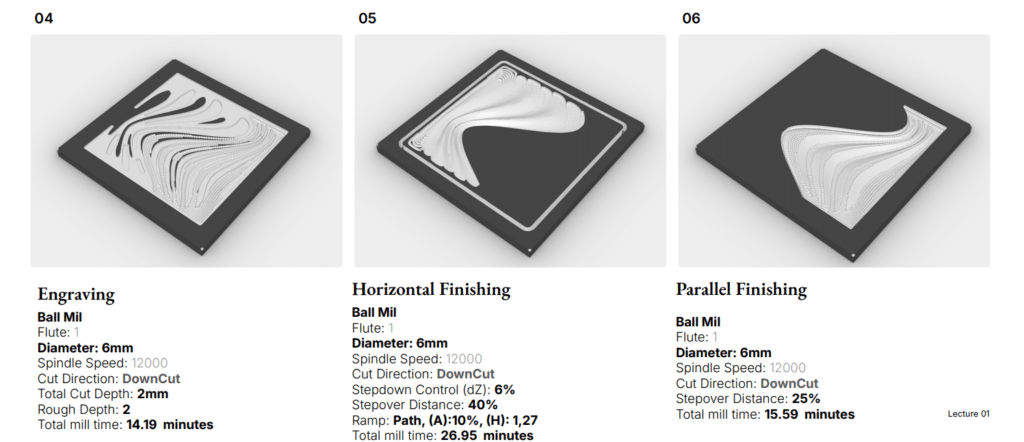

This CNC milling study examines how tool choice, machining strategy, and material behaviour converge to define the texture and performance of architectural

surfaces. Using MDF as a uniform substrate, we developed a panel integrating six distinct toolpath operations—including roughing, horizontal and parallel finishing, dot-pattern texturing, engraving, and contour cutting.

Fabrication Processes

Final Model

This exploration focuses on transforming flat materials into spatial structures through interlocking and kerf-bending techniques. Working with plywood and

acrylic, we conducted a series of tests to understand tolerance behaviour, minimum bending radio, and material failures under repeated stress. These studies informed the development of an undulating vertical element composed of interlocking ribs that acquire curvature through calibrated kerf patterns.