Theory of Structural Materials:

Commercial 3D printing in concrete

Faculty: Prof Jane Burry

Faculty Co-presenter: Dr Sascha Bohnenberger

Thesis

Technological innovation has always been an important part in the advancement of architecture, allowing new tools to solve current problems in the design industry. The 20th century showed us the great mechanical properties that concrete is capable of achieving when it works in conjunction with steel. In the same way, the continuation of this material in the world of digital manufacturing represents a promising future that could renew the construction industry through the investigation of 3D printing techniques.

Currently there are multiple ways to deal with layer printing on concrete, which depends on the construction system, the chemical properties and the scale of the printing. There are certainly not many examples of effective building applications, while it is true that new Chinese companies are emerging in the market of 3D printing dwelling, meaning that it has not been fully exploited. The objective of this article is therefore to disclose the most promising techniques / applications derived from additive printing.

01 INTRODUCTION

First examples of digital fabrication in concrete

Printing on concrete is part of a process called Additive Manufacturing (AM), by which the object is built solely with the extrusion material by adding successive layers and, in some cases, with the help of supports printed with the same material. In the last decade, there has been a development of large scale AM processes in fields such as design, construction, and architecture, using various materials such as polymers, metals, and stones. The deposition process introduced in this paper is designed for cement-based 3D printing.

There are 3 main approaches for printing that are important to mention:

1- Contour crafting, based on the extrusion of two parallel layers of cement that generates a form-work for interior fillings, which only allows to extrude flat geometry [1].

2- Concrete printing, very similar 3D printing in plastic and therefore, with the option to achieving any 3D shape [2].

3- D-Shape printing [7], where a large-scale bed of sand is solidified in certain areas by deposition of a binding agent, which is distributed using a print head mounted on an overhead crane.

Outside temperature: -35º, https://apis-cor.com/

02 STATE OF THE ART

Recent building systems for concrete 3D printing

The problem of actual implementation in the construction industry has not been fully addressed and two main approaches of such technologies can be gleaned from the literature. One, printing a whole building directly on the site, and the other, to use innovative processes to manufacture more valuable building components to be assembled during the construction phase. The innovative potential of both options is obvious, but the way in which the printing process should be implemented in large-scale building systems remains to be resolved.

Next classifications [4] are intended to shed light on other processes present nowadays in the field:

SCALE

a) Objects smaller than one meter, usually building connections

b) Constructive element around 1–4 m, typically a beam, column or slab.

c) Object around 5–10 m, typically a dwelling unit.

EXTRUDER SCALE

It characterizes the size of what is extruded at each moment, and can vary from the thickness of the diameter of the head to the thickness of the final piece, as is the case of slip forms.

PRINTING PLACE

Regarding the control of the printing environment, there are another 3 possibilities:

a) fixed impression; b) controlled printing; c) pre-made print;

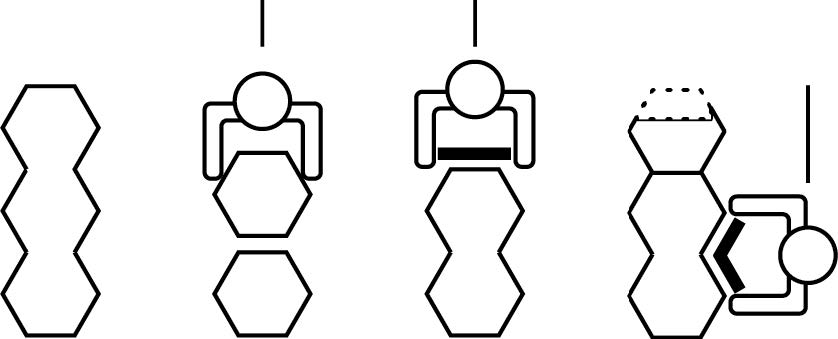

ASSEMBLY

This work is understood to be carried out by people, machinery or a second robot, following the proposed classification by Pedro Filipe Martins (Table 2) Digital Fabrication in Concrete Architecture – Developments in Research [5]:

a) without assembly;

b) assembly of pieces in a single one;

c) external parts after printing;

d) external parts during printing

SUPPORTS

With this term we refer to each rigid (or semi-rigid) surface on which the extruded material is deposited and which has a beneficial effect on its stability.

CONCRETE MIXTURE

Controlling the rheological properties, expressed in practical terms as workability, is important as it will determine the efficiency of the pouring process during construction. These are the main factors implied according to the research by Delphine Marchona [3].

a) Superplasticizers: used in cementitious materials to reduce the yield point, the viscosity and therefore, decreasing the porosity of the concrete for a higher printing quality.

b) Viscosity Modifying Agents (VMAs): used in industrial practice to control water transport and pore structure in both the fresh and hardened states.

c) Thixotropic agents : Fresh cement-based materials exhibit thixotropy, a continuous decrease in viscosity. Inorganic additions of clays and organic inclusions, such as polymer fibers, can also be effective rheology modifiers.

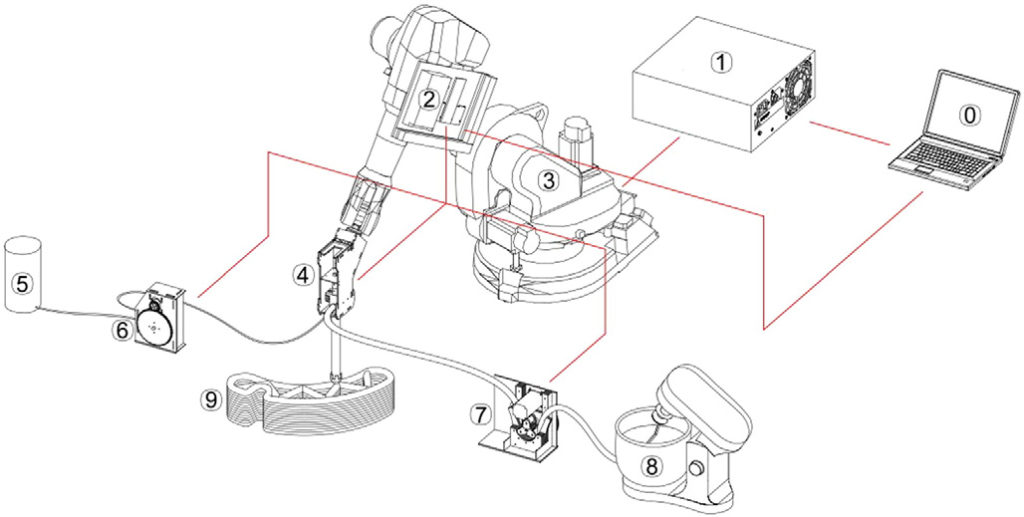

Robotic system

Today, most of the research dedicated to printing concrete makes use of 3-axis robotics but recent advances are oriented to secondary devices that bring external elements to a directly printed building.

0. System command; 1. Robot controller; 2. Print driver; 3. Robotic arm; 4. Print head; 5. Accelerator agent; 6. Peristaltic pump for agent accelerator; 7. Bomb peristaltic for premix; 8. Premix mixer; 9. Printed object

Following the 3 main points for robotic construction (geometric complexity, size and collaboration) this are the types of robots in use [6]:

• 3-axis robot

They are already well developed and make it possible to focus on secondary robotic devices such as print nozzles.

• 6-axis robot:

With the use of 6-axis robots, the set of printable shapes can be expanded since the layers can easily vary in thickness and orientation. Helps solve the problem of overhanging printed structures and layer-to-layer adhesion besides easier robot-human collaboration.

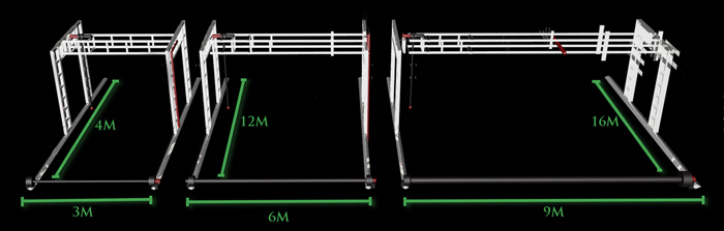

• 6-axis robot on rail:

One way to increase the printable size of a device is to place a 6-axis robot on a rail.

• Collaboration of 6-axis robots:

Robots capable of working with each other can bring great innovation to current construction techniques, mixing printing and assembly, in a fast and precise way.

• 6-axis robot on 3-axis robot:

This step represents an additional challenge for robotics: being able to maintain precision while moving a robot on a large scale and in three dimensions.

03 CONCLUSIONS

The most successful case in the concrete printing market could be the case of WinSun, when in 2014 the company achieved the construction of 10 houses in one day. The vertical and horizontal walls were prefabricated and put on site in record time, but without a real economic or labor advantage.

The reality is that the in-situ impressions have not yet exceeded 2 stories in height since the current robotic arms do not allow easy movement of place or a great reach. Added to this, the impossibility of building horizontal roof surfaces without the help of another system/material, seems to be the most unfavorable problem when it comes to standardizing 3D printing.

REFERENCES:

[1] Behrokh Khoshnevis, DJ Epstein Department of Industrial & Systems Engineering, University of Southern California, Los Angeles, CA 90089-0193, USA –Automated construction by contour crafting—related robotics and information technologies– 12 August 2003 – publisher: Elsevier B.V. https://doi.org/10.1016/j.autcon.2003.08.012

[2] S. Lim*, R. A. Buswell, T. T. Le, S. A. Austin, A. G. F. Gibb, and T. Thorpe, Civil and Building Engineering, Loughborough University, Loughborough, LE11 3TU, UK –Developments in construction-scale additive manufacturing processes– 2019 – publisher: Elsevier B.V. http://dx.doi.org/10.1016/j.autcon.2011.06.010

[3] Delphine Marchona,?, Shiho Kawashimab, Hela Bessaies-Beyc, Sara Mantellatod, Serina Ng, –Hydration and rheology control of concrete for digital fabrication: Potential mixtures and cement chemistry– 15 May 2018- publisher: Elsevier B.V. https://doi.org/10.1016/j.cemconres.2018.05.014

[4] R. Duballeta,c., O. Baverela, J. Dirrenberger – Classification of building systems for concrete 3D printing – 17 August 2017 – publisher: Elsevier B.V. http://dx.doi.org/10.1016/j.autcon.2017.08.018

[5] Pedro Filipe Martins1, Jose Pedro Sousa -Digital Fabrication Technology in Concrete Architecture- 2014 – publisher: Elsevier B.V. https://sigarra.up.pt/flup/pt/pub_geral.pub_view?pi_pub_base_id=107807

[6] C. Gosselin a,b, R. Duballet a,b, Ph. Roux a,b, N. Gaudillière a,b, J. Dirrenberger a,c,?, Ph. Morel -Large-scale 3D printing of ultra -high-performance concrete – a new processing route for architects and builders- 25 March 2016 – publisher: Elsevier B.V. http://dx.doi.org/10.1016/j.matdes.2016.03.097

[7] Giovanni Cesaretti, Enrico Dini, Xavier De Kestelier, Valentina Colla, Laurent Pambaguian, -Building components for an outpost on the Lunar soil by means of a novel 3D printing technology- 8 August 2013 – publisher: Elsevier B.V. https://doi.org/10.1016/j.actaastro.2013.07.034