Introduction

The Parametric Nexus project represents a forward-thinking approach to high-rise construction, where sustainability is at the forefront. With its use of advanced materials like glass, steel, and concrete, the project aims to minimize environmental impacts through a comprehensive Life Cycle Impact Assessment (LCIA). This blog explores the rationale, methods, and key findings of this impactful study.

Why Choose LCIA for Parametric Nexus?

The LCIA methodology was chosen to address the project’s primary challenge: balancing the massive material requirements of a high-rise with environmental responsibility.

- Comprehensive Evaluation: LCIA assesses the environmental impact of materials across their entire lifecycle—from extraction to end-of-life. This ensures all phases, including production, construction, and use, are evaluated.

- Data-Driven Decisions: The analysis supports material selection using measurable data, identifying hidden environmental costs, and reducing embodied carbon.

- Sustainability Focus: Glass, steel, and concrete, the core materials for this project, are assessed not just for use but for their potential to be recycled and reused, making them integral to sustainable design goals.

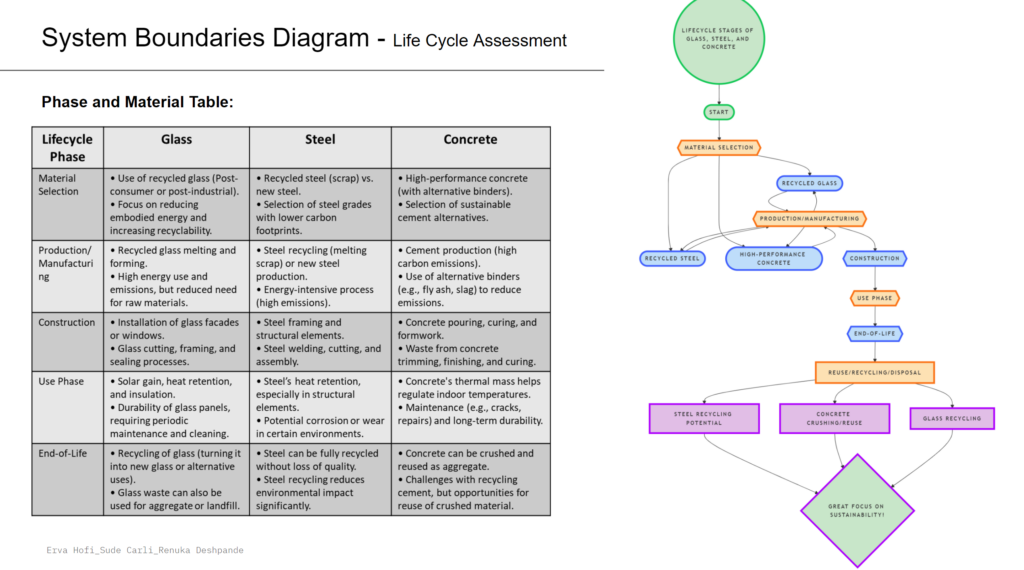

System Boundaries Diagram

The system boundaries of this LCIA encompass five lifecycle phases for each material:

- Material Sourcing: Energy use and emissions during raw material extraction.

- Production: Environmental impacts of manufacturing, including CO2 emissions and energy intensity.

- Construction: Waste generation and energy use during assembly.

- Use Phase: Maintenance and long-term durability of materials in operation.

- End-of-Life: Recycling and waste reduction opportunities.

Each phase is crucial in understanding the full environmental footprint of glass, steel, and concrete.

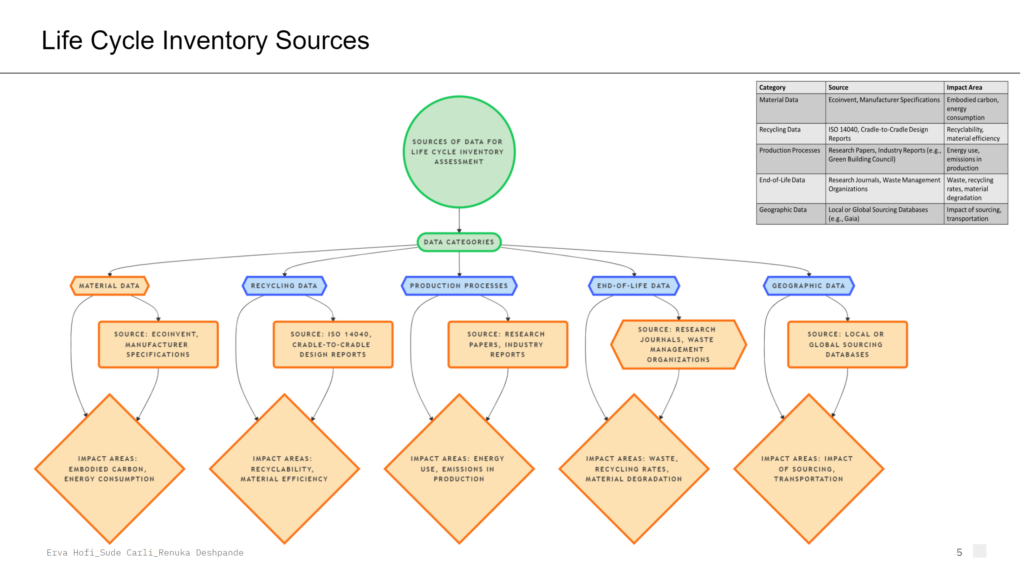

Life Cycle Inventory (LCI): Data Sources and Methodology

To ensure accuracy, the study relied on reputable sources:

- Ecoinvent Database: For material-specific embodied carbon and energy data.

- ISO 14040 Standards: For recycling efficiency metrics.

- Research Publications: Studies on reinforced concrete, steel recycling, and glass reuse.

- Industry Reports: Green Building Council data on energy use and emissions during production.

These sources provided the foundation for analyzing material impacts across all lifecycle stages.

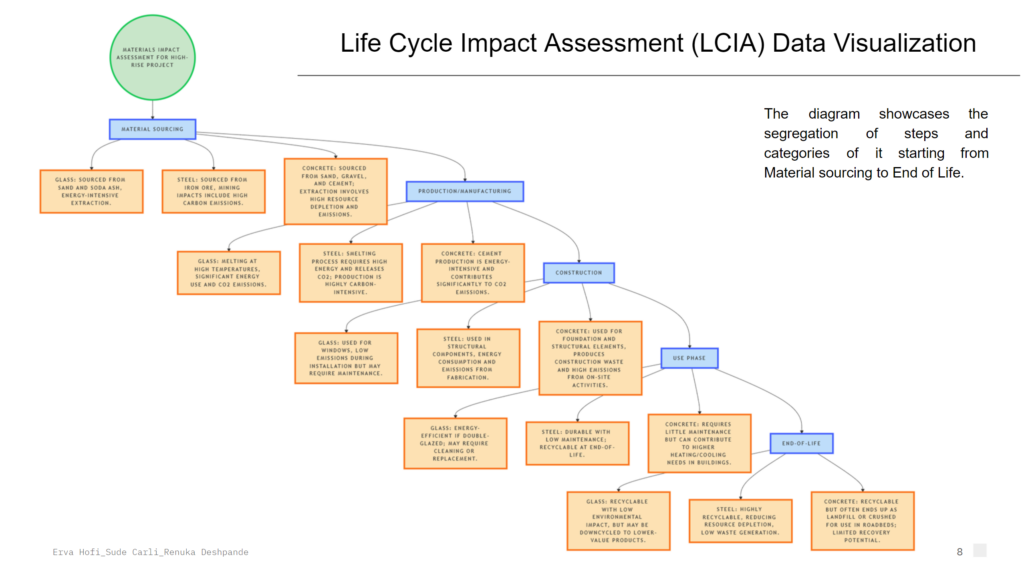

Data Visualization of Results

The study revealed significant insights through visual representation:

- Embodied Carbon and Energy Use:

- Glass: 300 kg CO2e/ton (new), 100 kg CO2e/ton (recycled).

- Steel: 1500 kg CO2e/ton (new), 800 kg CO2e/ton (recycled).

- Concrete: 700 kg CO2e/ton (traditional), 400 kg CO2e/ton (with fly ash).

- Recyclability and End-of-Life Impact:

- Glass: 100% recyclable with minimal degradation.

- Steel: 90% recyclable with a significant reduction in carbon emissions.

- Concrete: Reusable as aggregate but with limited recycling options for cement.

These findings underscore the need to prioritize recycled materials and innovative production techniques to reduce the project’s environmental footprint.

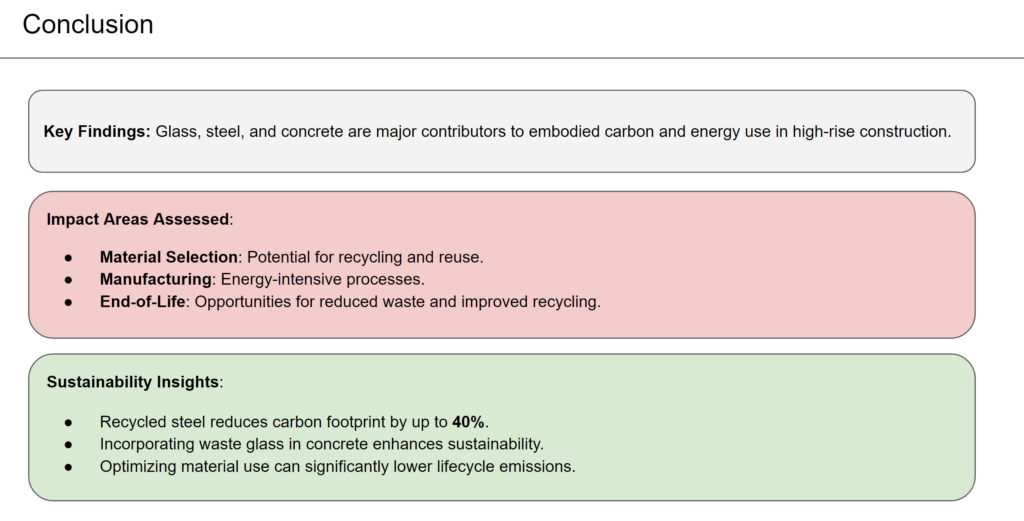

CONCLUSION

Conclusion: Building a Sustainable Future

The LCIA of the Parametric Nexus project highlights the environmental burden of glass, steel, and concrete while offering actionable insights to mitigate their impacts.

- Key Findings:

- Recycled steel reduces the carbon footprint by up to 40%.

- Incorporating waste glass into concrete enhances sustainability.

- Alternative binders for concrete (e.g., fly ash) reduce CO2 emissions by 30%.

This study demonstrates how parametric design, coupled with lifecycle thinking, can revolutionize high-rise construction by embedding sustainability at its core. The Parametric Nexus serves as a blueprint for future designs that harmonize innovation with environmental responsibility.