As the world continues to develop rapidly, the problem of noise pollution, especially in metropolitan cities, cannot be eliminated. Not only outside but also inside the old houses. “Corteza” is an experimental design proposal to tackle the noise pollution problem inside Barcelona’s buildings with 3d printed natural cork furniture.

What is noise pollution? And what are the effects of noise pollution?

Noise pollution is considered to be any unwanted or disturbing sound that affects the health and well-being of humans and other organisms. And World Health Organization considers decibels over 65 dB noise pollution. Noise pollution is affecting everyone. For some people its just an annoyance, but for other its a serious health issue.

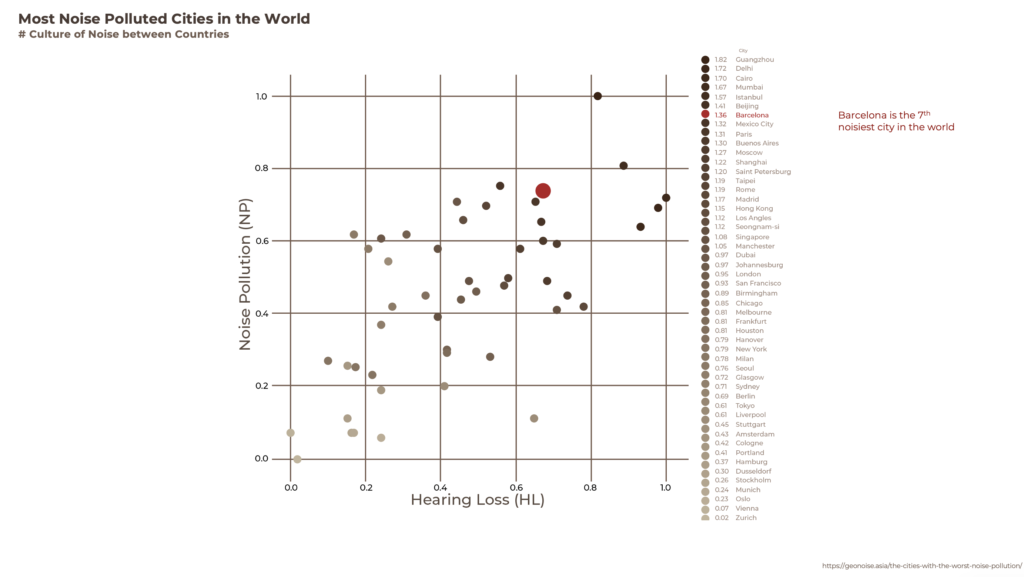

There a lot of cities that are poluted with noise pollution. And Barcelona it the 7th noisiest city in the world.

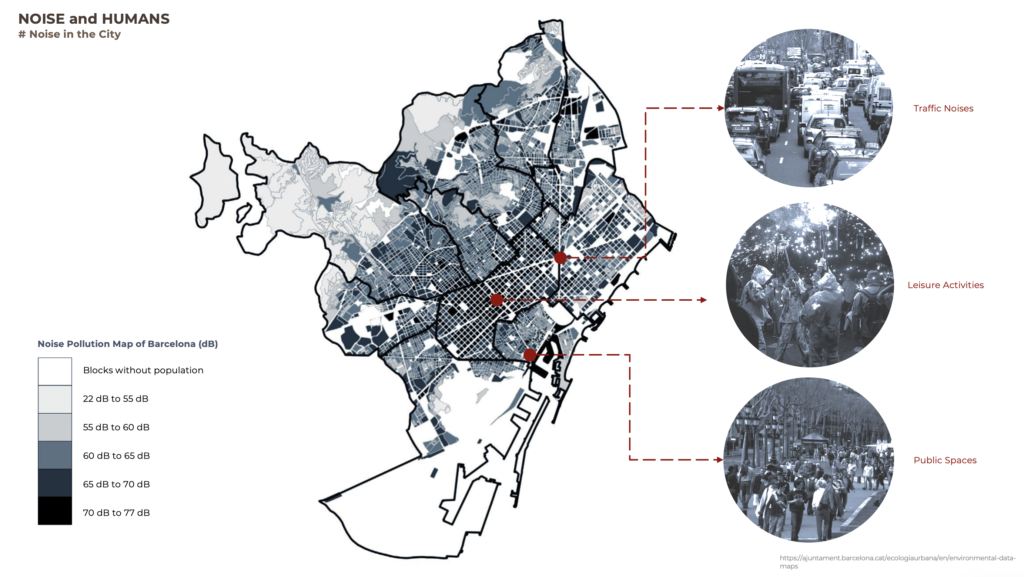

And inside Barcelona, there are 3 main noise reasons traffic noise, leisure activities and public spaces. The traffic noises are mostly through avinguda diagonal, gran via etc. Although the leisure activities such as protests, marches, and festivals are in Passage de Gracia, in Ramla etc.

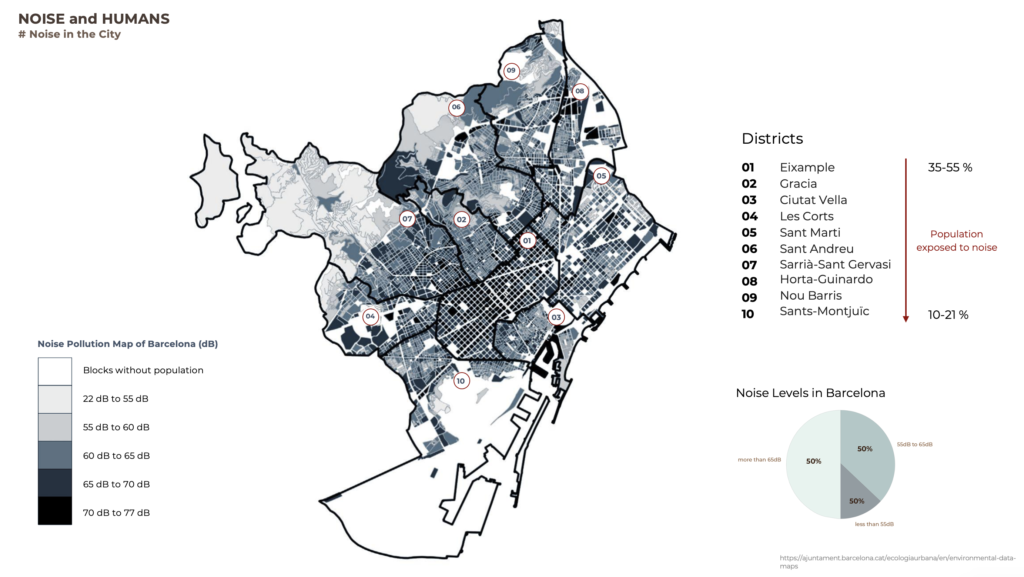

Eixample district is one of the highest districts exposed to noise pollution, around 35 to 55 per cent. Whereas Sants Monjuic is the lowest, around 10-21 percent.

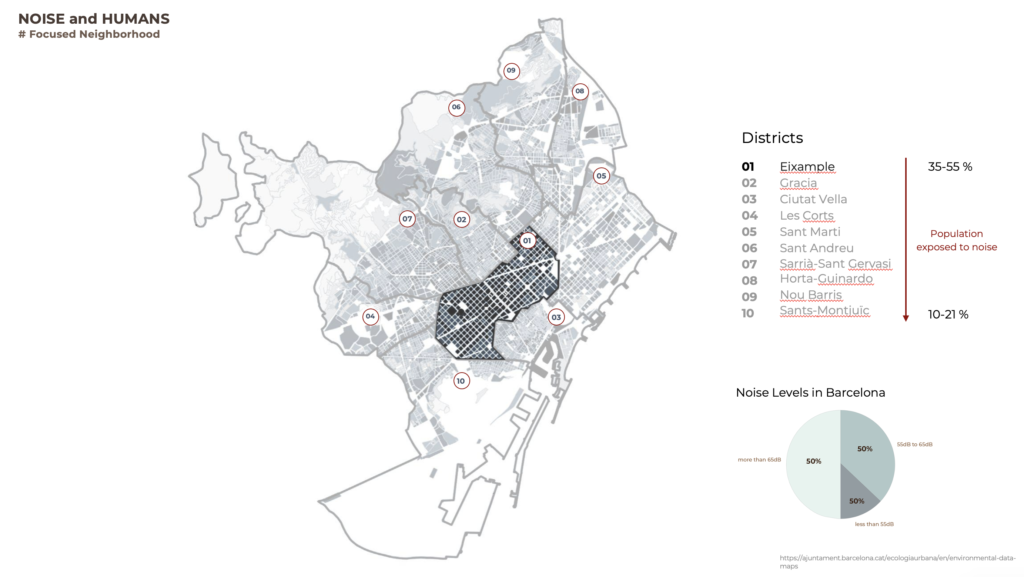

Through out this thesis, we will be focusing on the Eixample district.

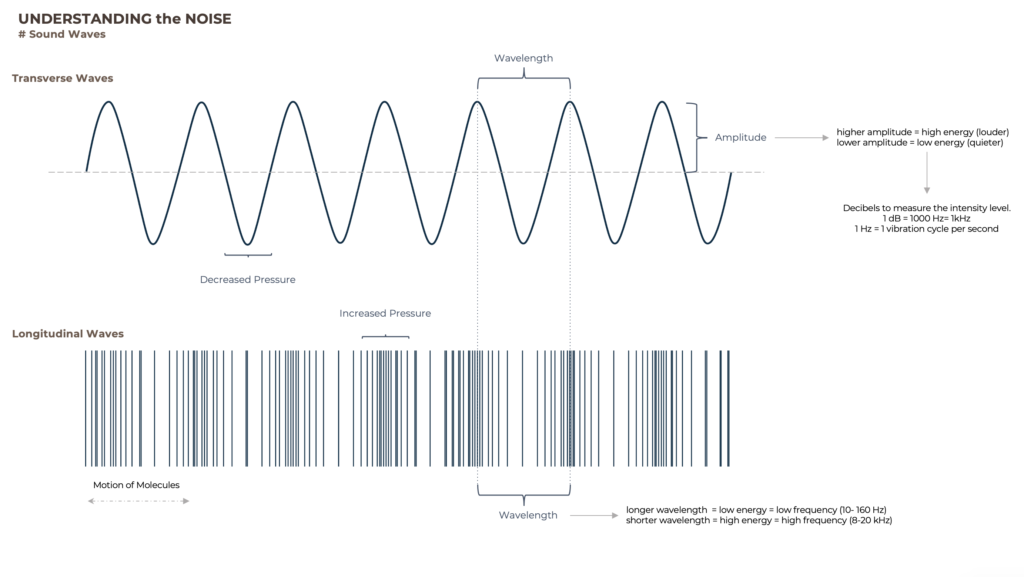

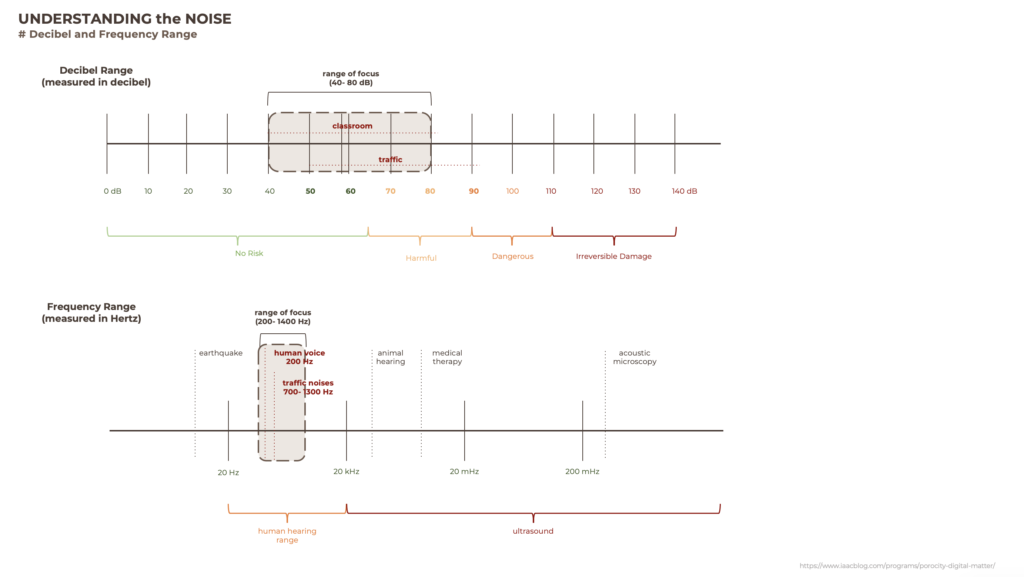

The sound is measured by The decibel and frequency. Frequency is the number of vibrations or cycles of sound per second measured in hertz. Decibels measure the strength of these vibrations, which is the amplitude. So the higher the amplitude is, the higher energy is and the louder you would hear. And the lower the amplitude is, the lower energy is and the quieter the sound is.

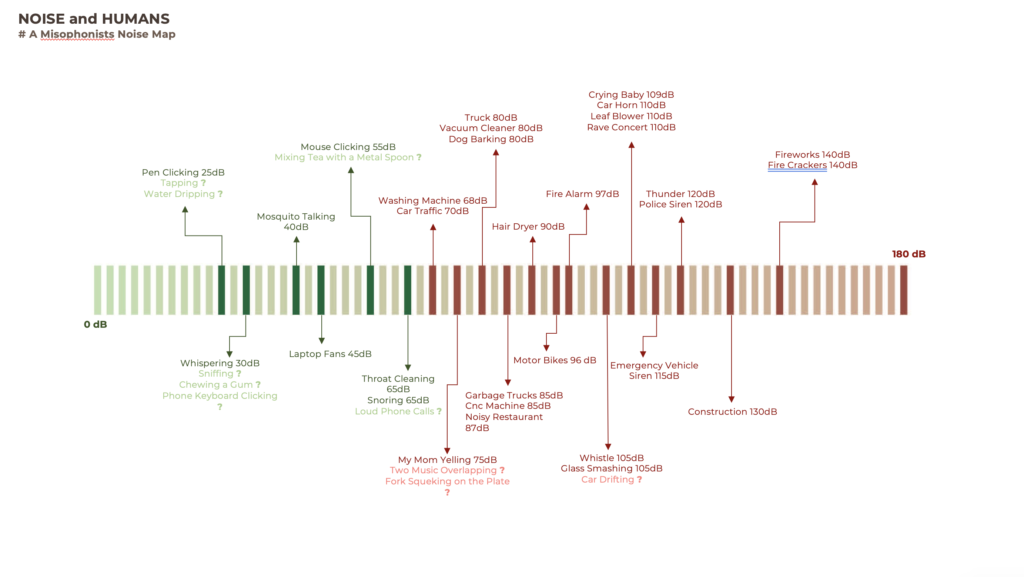

One of the main reasons I was dragged to this topic was that I’m a bit sensitive person when it comes to noise. And there are specific sounds that really do drive me crazy! And to understand the noise more personally, I wanted to make a chart of the noises that annoy me with their decibels. Such as pen clicking, which is 25 dB or crying baby, which is 109dB etc.

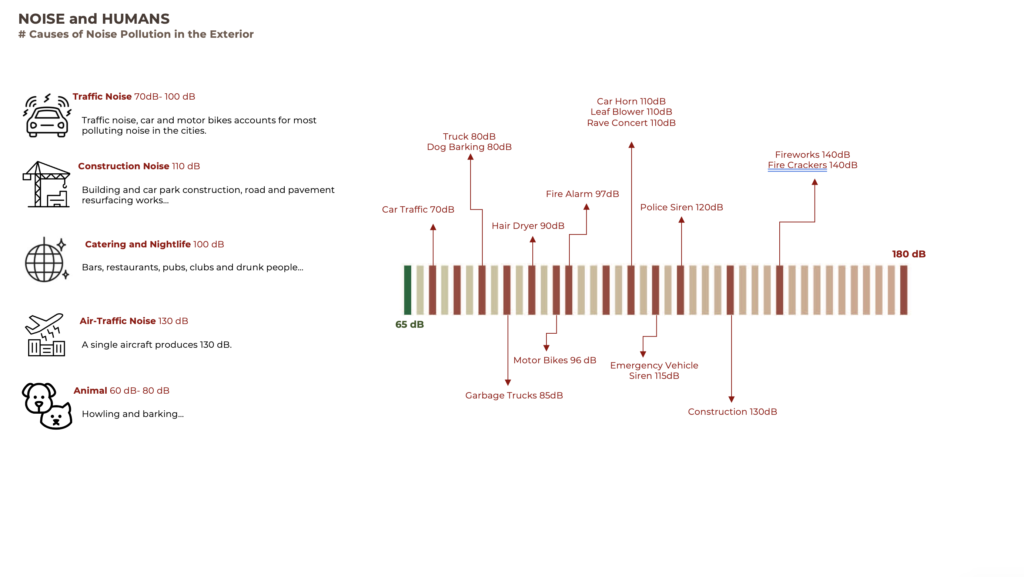

The main cause of noise pollution in exterior, in the outside is that mainly traffic noises that comes from cars and motor bikes such as around 70-100db, construction noises around 110db, catering and nightlife, in clubs in bars is around 100 db, air traffic130db and animals, such as barking howling is around 60- 80db

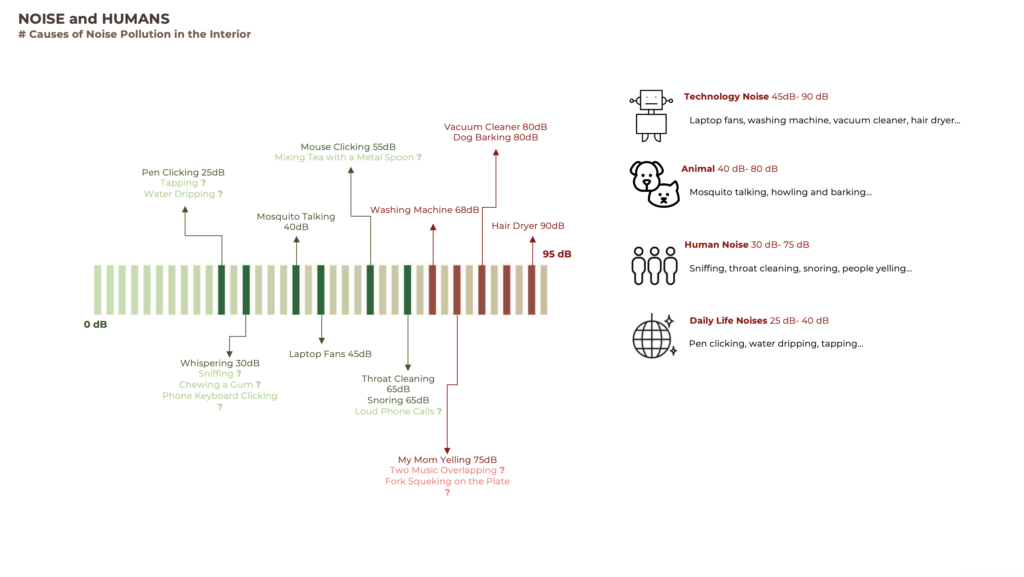

However, inside our homes, it’s totally different. The main causes we have in our homes are the technological noises that come from washing machines, vacuum cleaner or even hairdryers that are around 45 to 90 dB. Or such as human noises, yelling, and snoring that is around 30 to- 75 db

Therefore the range of focus for this project is traffic noises and the human voice, which ranges between 50 and 90 decibels or 200 to 1300 Hertz.

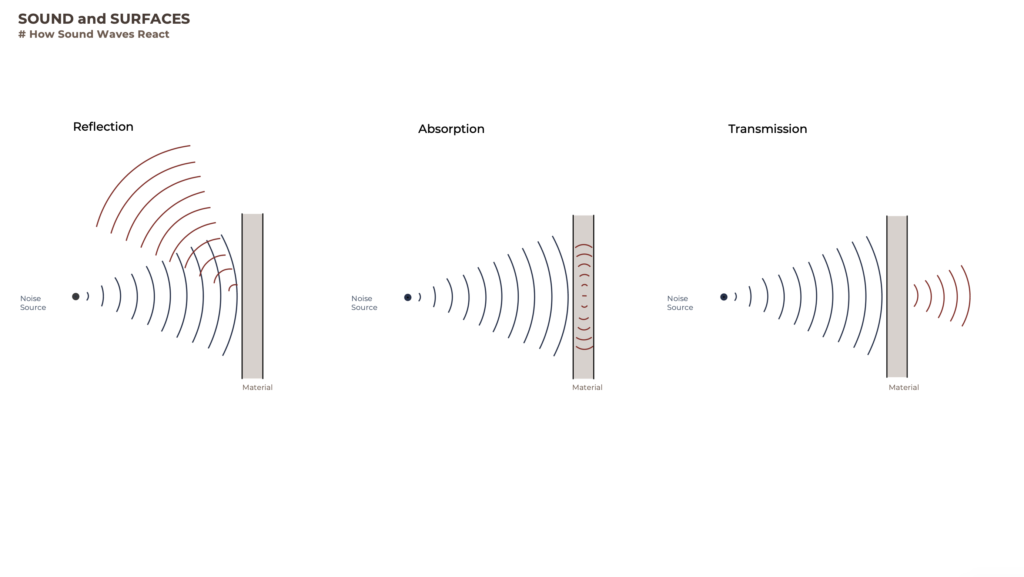

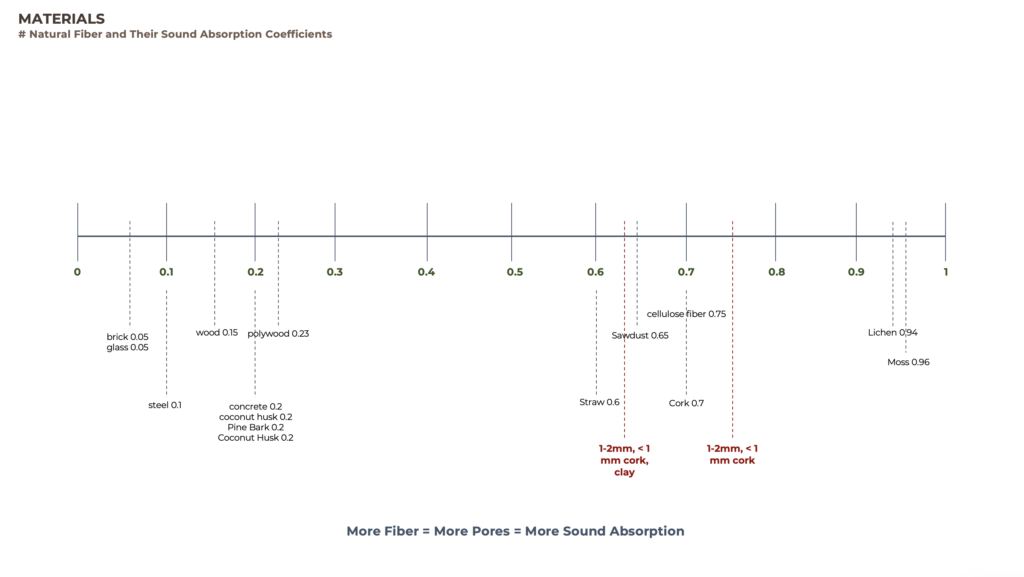

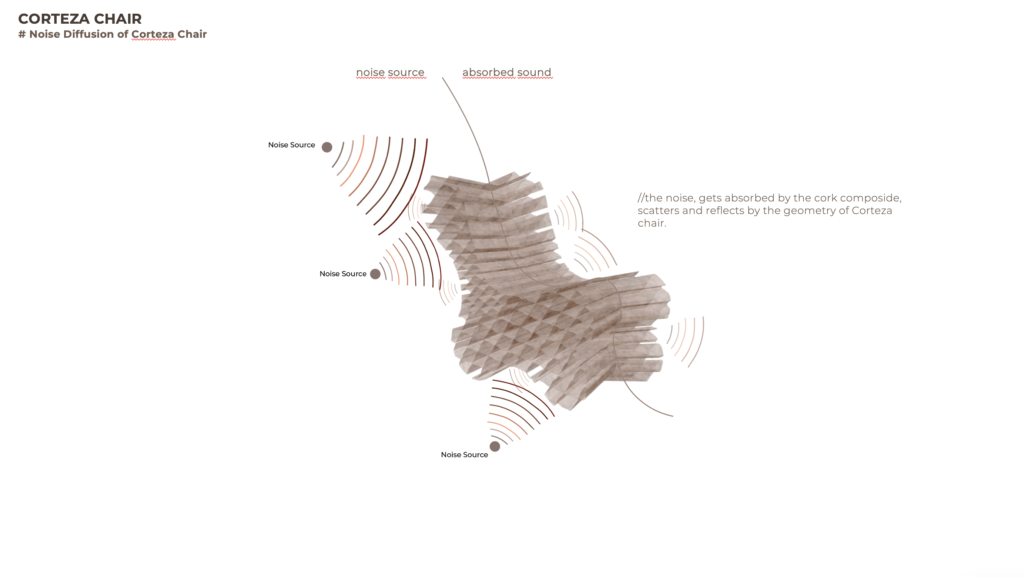

And when we look at how they react on different types of surfaces, is that on straight and corner surfaces, it reflects. On convex surfaces is it scatters in opposite directions. On concave surfaces, it concentrates the sound waves by reflecting them to a common point. And on porous surfaces, it diffuses the sound.

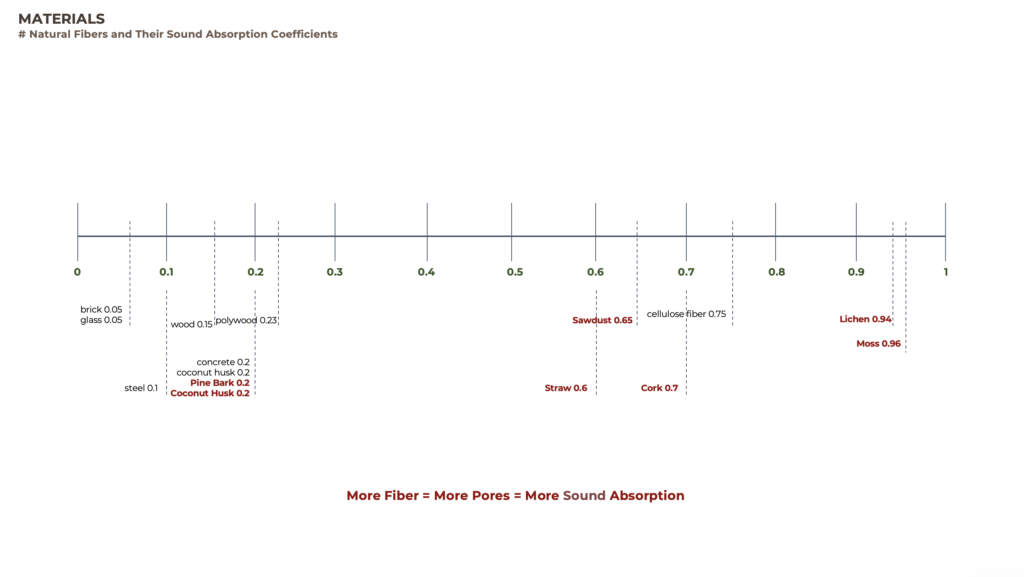

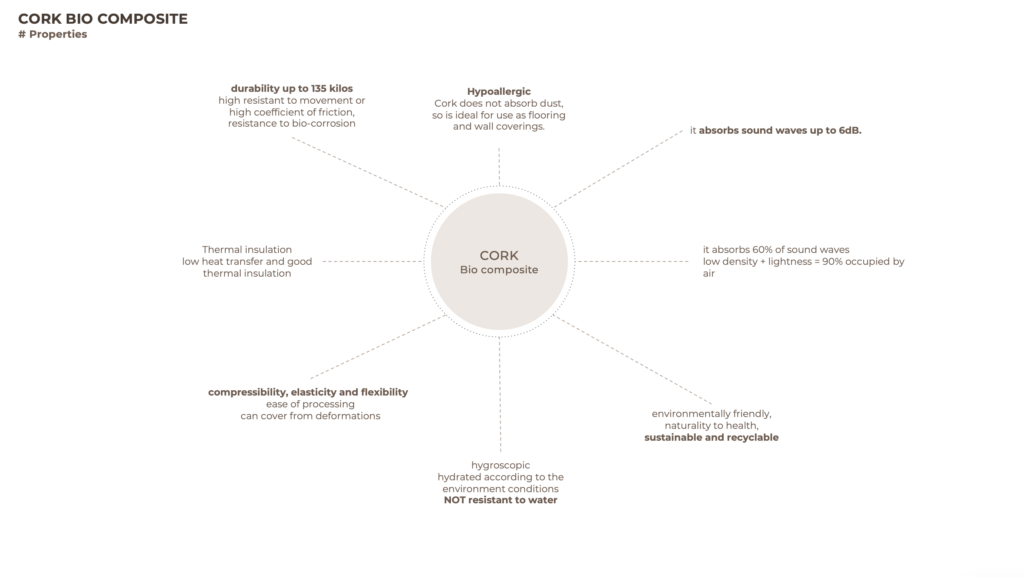

Therefore according to those properties, the more smoother the surface is, the more reflective they become. For instance, in glass, its sound absorption coefficient is 0.05, which is almost zero. Although cork is 0.7, which is quite high. So the more fibre or pores they have, the more absorbent they become.

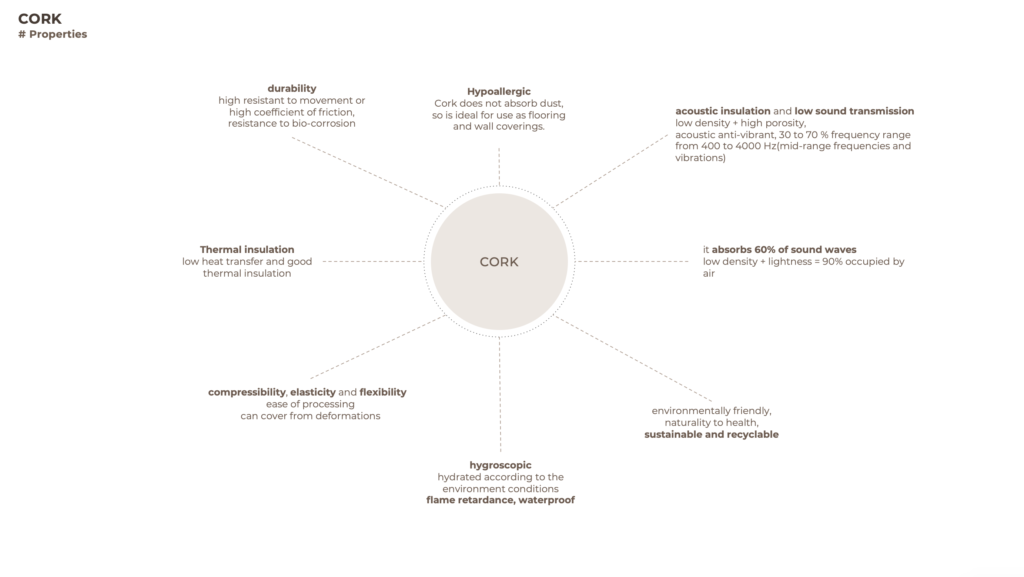

Cork is not only good in sound absorption but also durable, hypoallergic, water and fire-resistant and flexible.

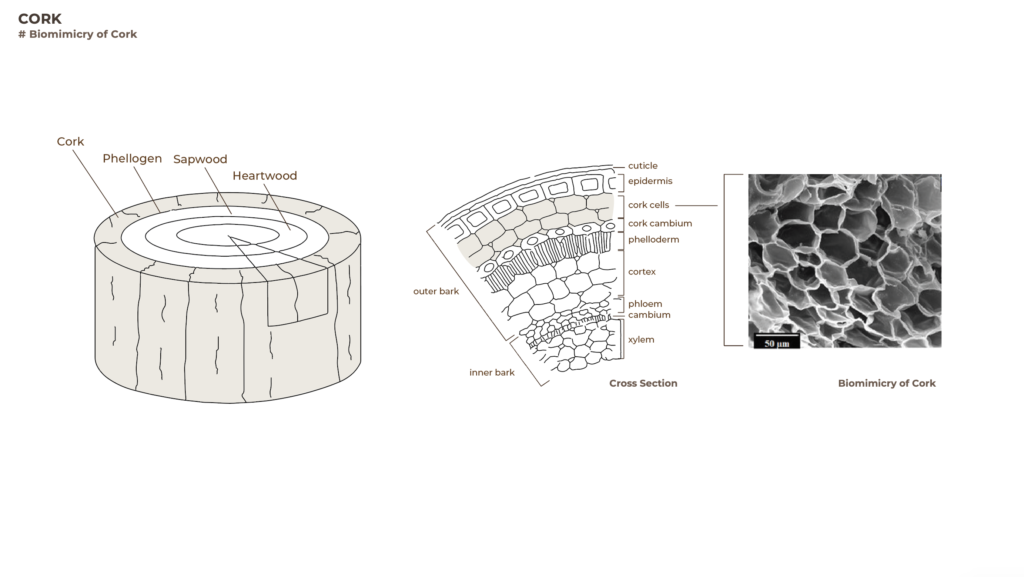

Cork also has its own unique features. Harvests happen every 10 years or so from tree bark. However, since only use the outer bark, the tree continues living unharmed. And It’s a continuous cycle. It has simple biomimicry to absorb the sound and trap it inside.

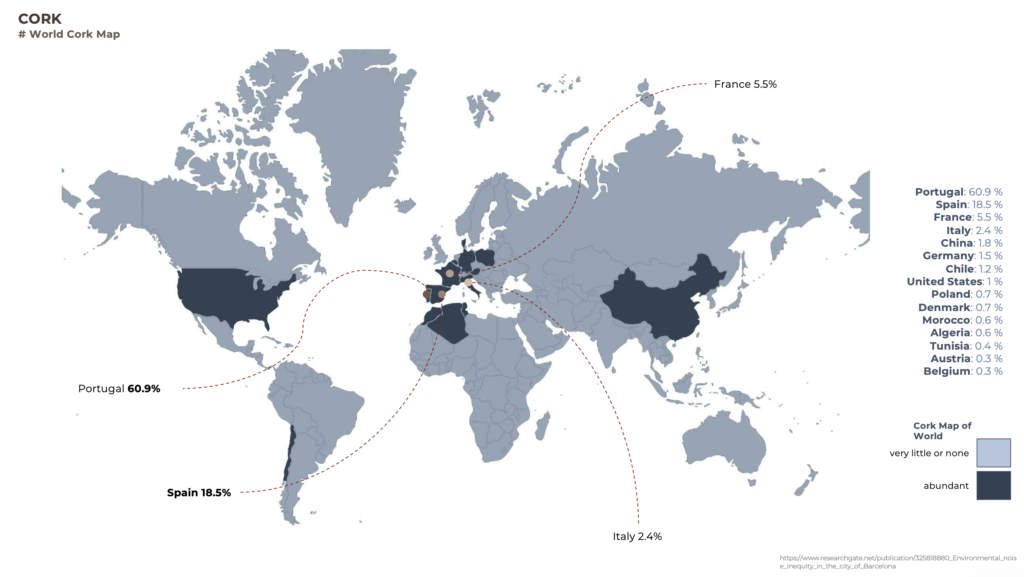

However, cork doesn’t grow everywhere. It has 2 main distributors of cork, and they are Portugal and Spain.

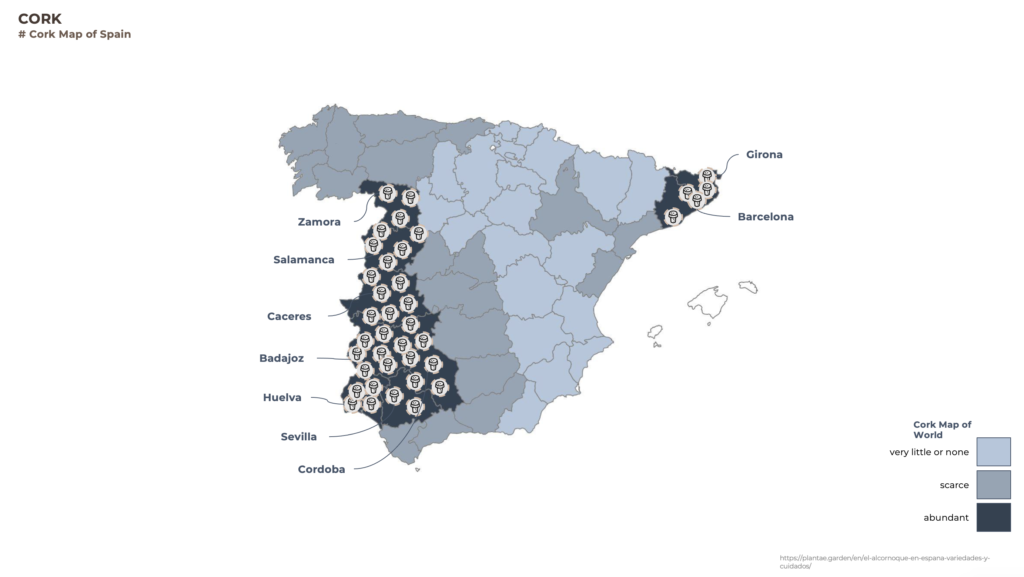

And here in Spain, the cork oak tree mainly grows in the Extremadura region. In Catalonia, Andalusia

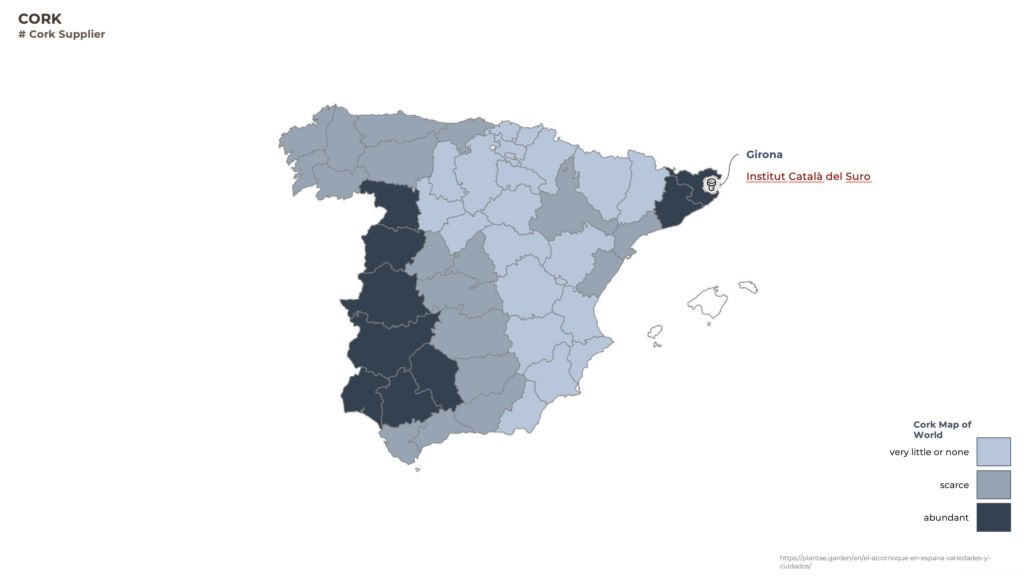

Throughout my thesis, Icsuro supported me with the granules.

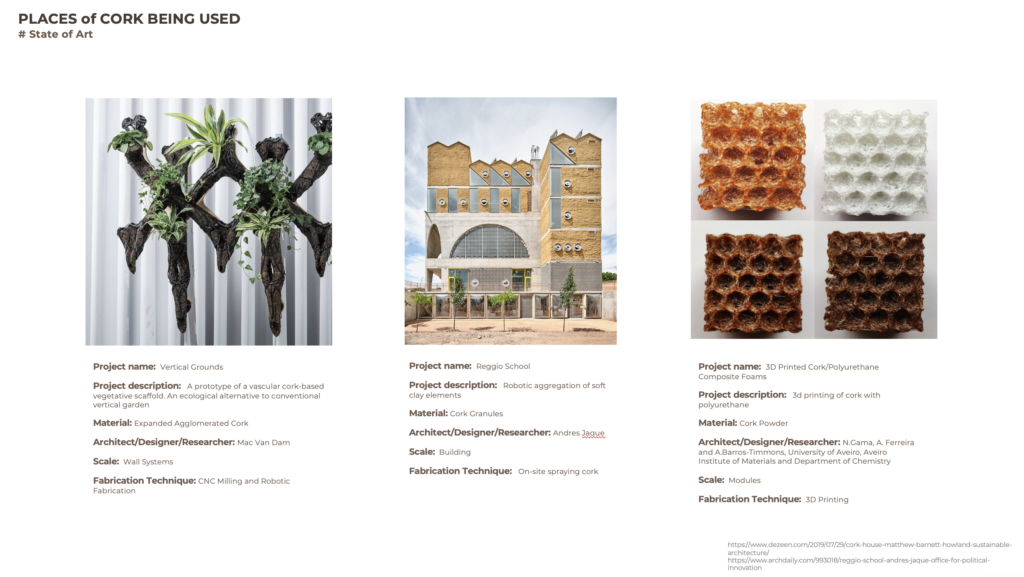

Cork is being used in many ways. And could go through many processes. Such as CNC milling, spraying or 3d printing. However, so far, most of the procedures, especially in 3d printing, include plas. So far, no one has been able to 3d print cork with natural binders.

With Corteza, we are aiming to 3d print with natural binders.

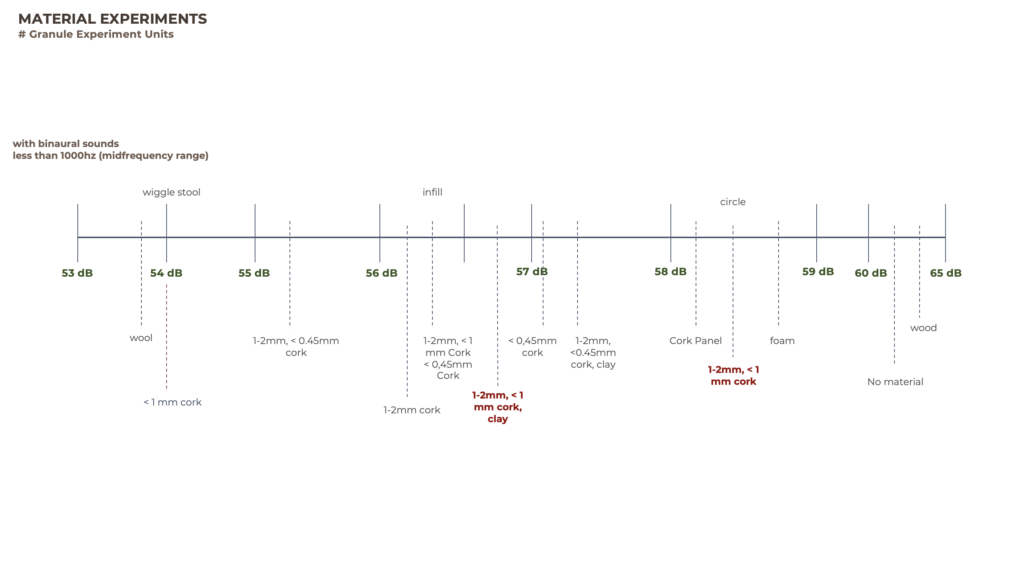

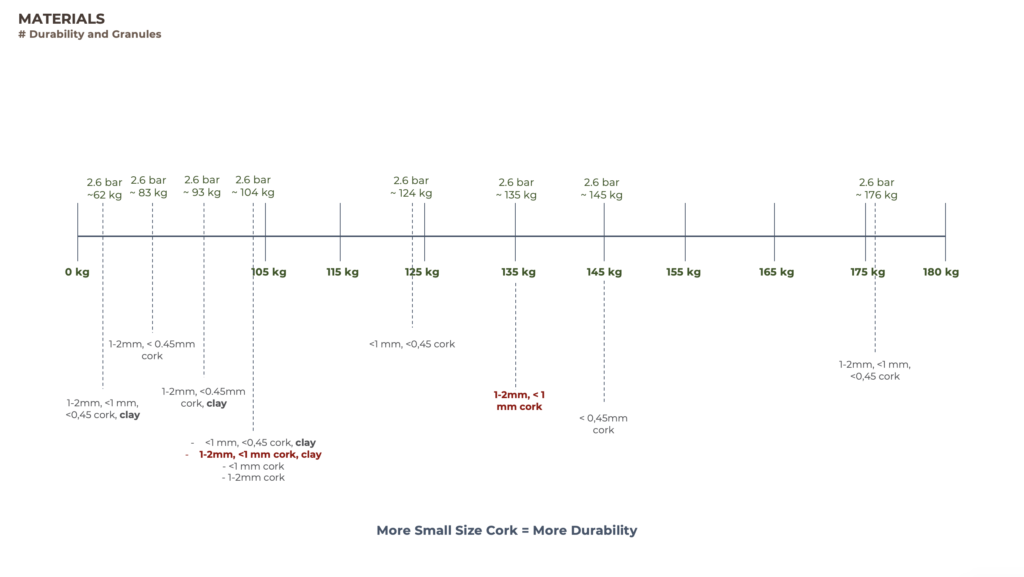

Having a cork bio composite has negative and positive impacts. With our cork bio composite, we were able to absorb sound up to 6 decibels, and durability is up to 135 kilos. However, it’s not water resistant. Therefore it’s also recyclable.

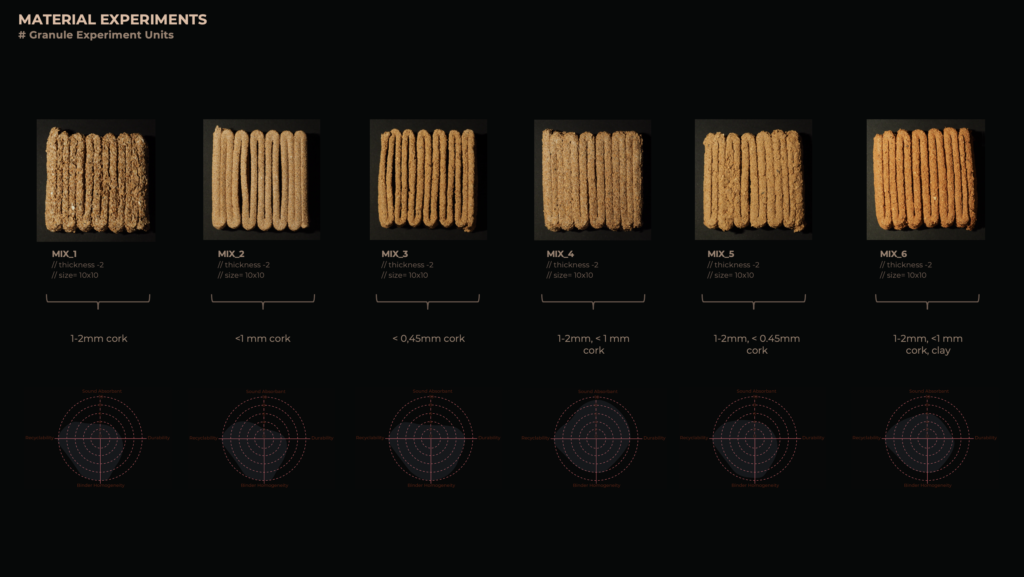

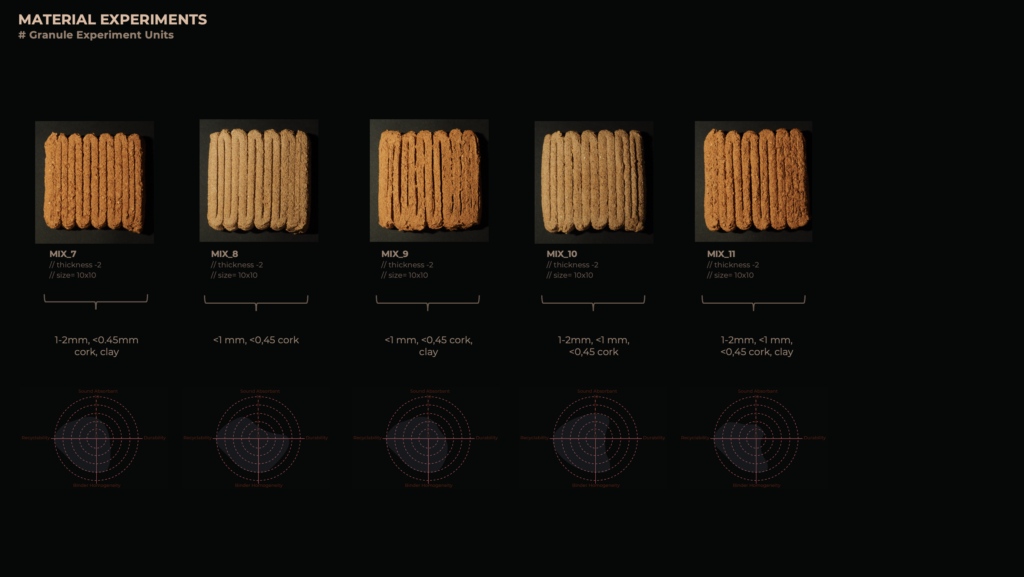

From Icsuro, we were able to get 3 different types of cork sizes.

We go through 11 different types of mixtures.

Therefore they reacted differently in sound absorbent and durability.

The best performance came from 1-2mm and less than 1 mm cork. And the worst was less than 1 mm mixture. Our mixture can absorb maximum of upto 5.5 db

And if we need to compare it with other materials, that cork biocomposite is even better than a cork panel in the market.

However, in if we check the durability, even though clay gives weight, we see the clay effect negatively in the durability. And the more small sizes of granules have more durability.

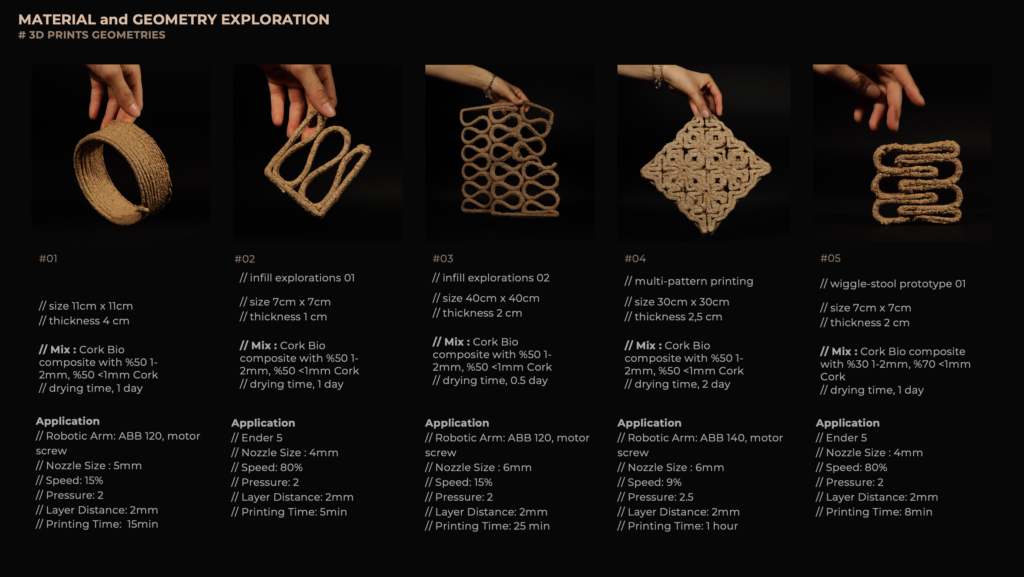

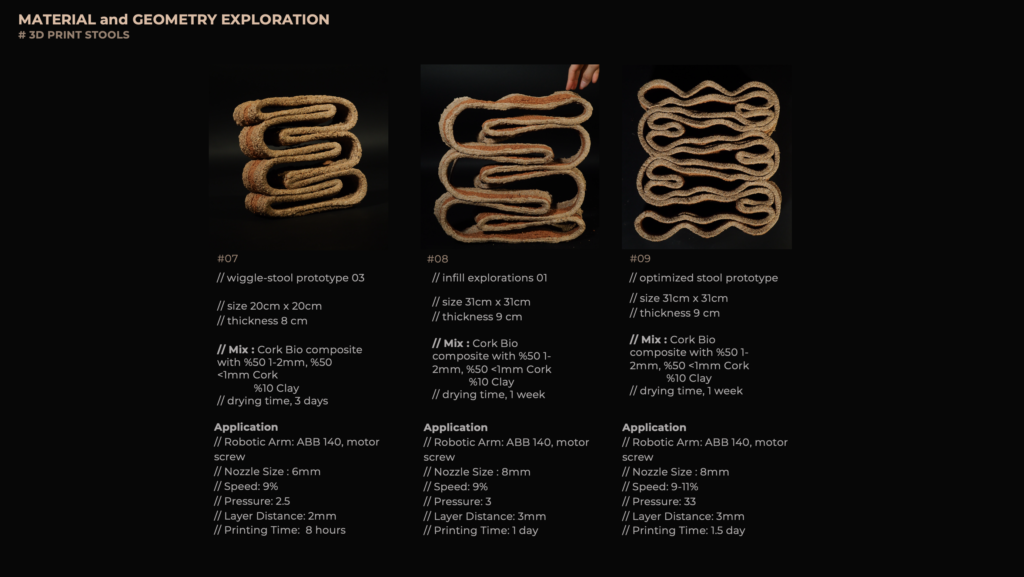

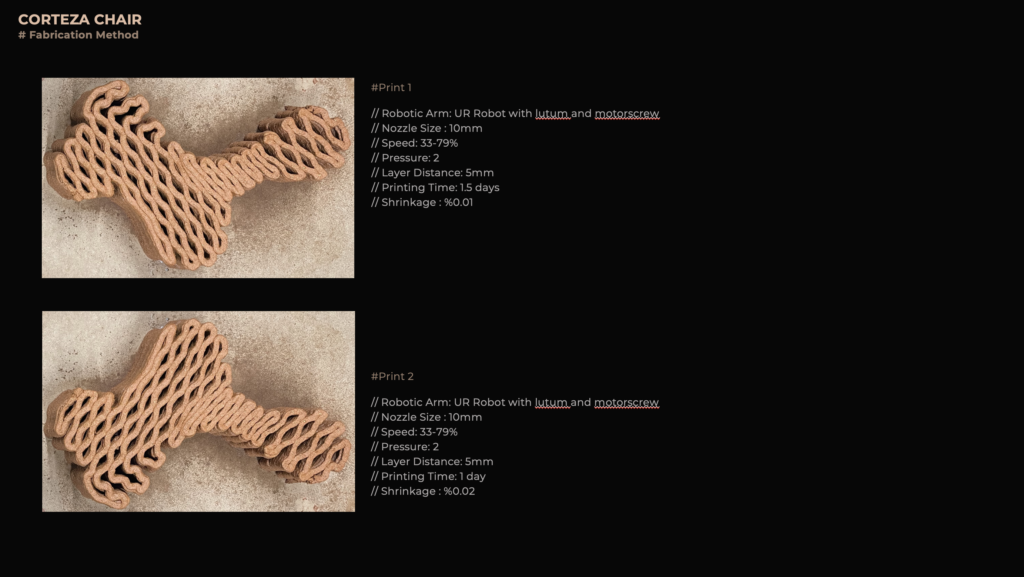

Before going into furniture. We go over some printing tests. To test the materials and printing.

Throughout the rest, we used 3 different types of machines. For small prototypes, We used abb 120 and abb 140 with motor screws between the nozzle sizes of 5mm to 6mm. Since the model sizes were small, it didn’t require too much drying time.

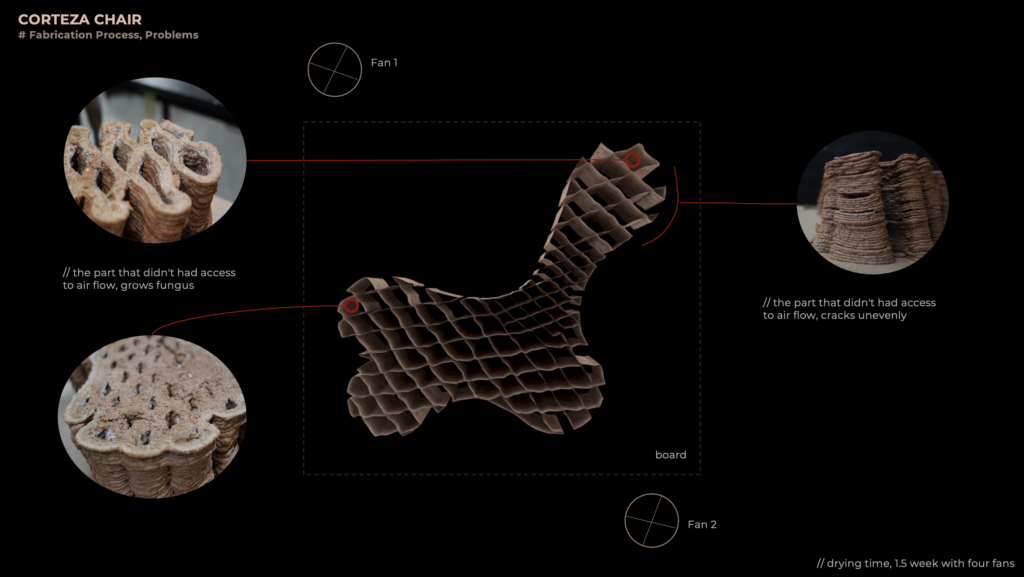

However, the bigger scale we went more difficulties we started to face. For the bigger prototypes, we used robot arm abb 140 with motor screw and with 6 to 8 mm nozzle size. Since we were printing with abb and because of the mixture, we needed to go really slow with 9 per cent speed. Therefore it took so long to print the pieces. And it took 3 days up to 1 week of drying time.

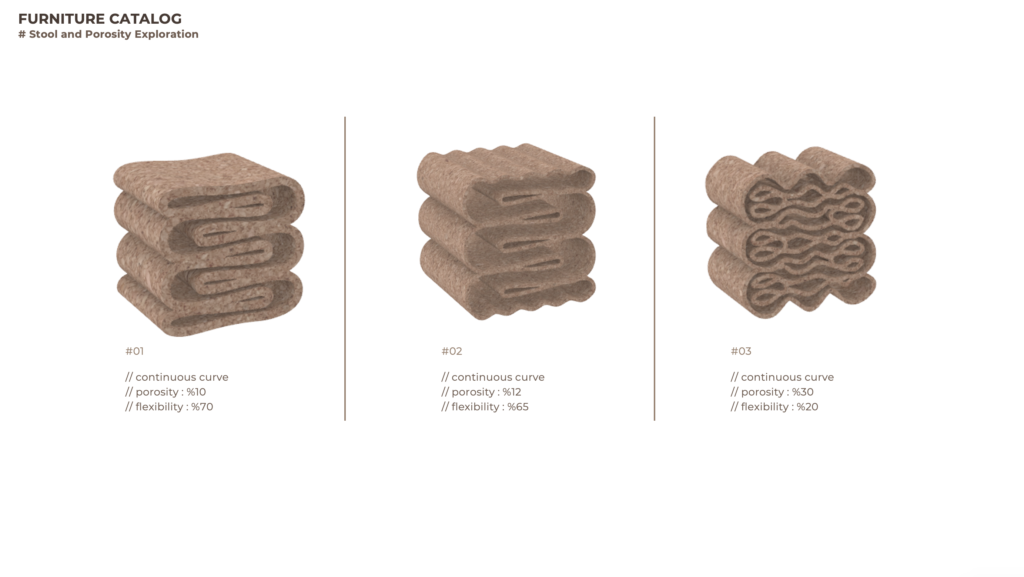

Throughout the experiment, 2 of the models showed quite a lot of flexibility. Therefore to explore more flexible infills, we went through some furniture catalogues with flexible, porous structures to absorb the sound.

First, we started with small stools with 10 to 30 per cent porosity. With these, we saw that the less porous it is, the more flexible it gets.

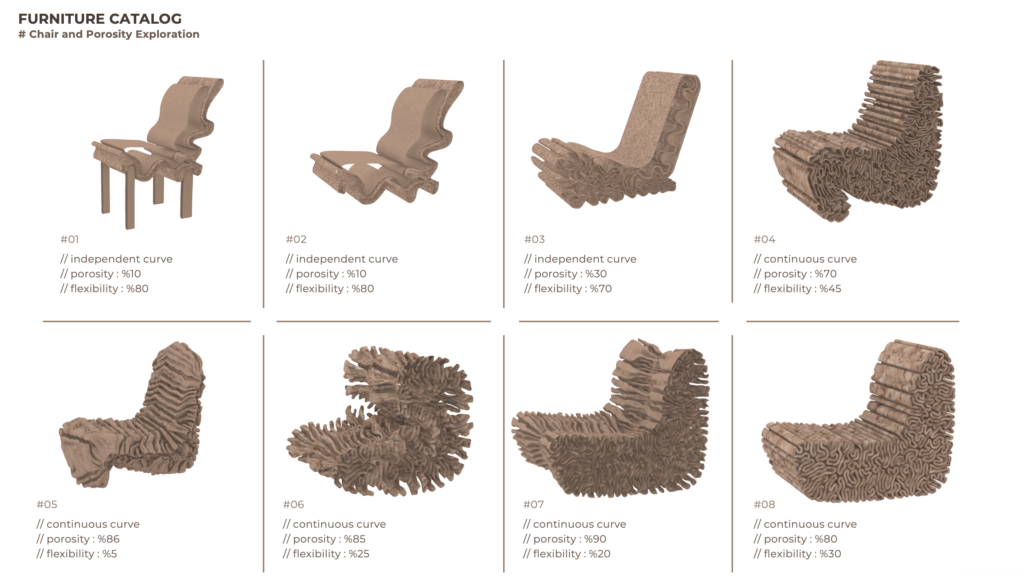

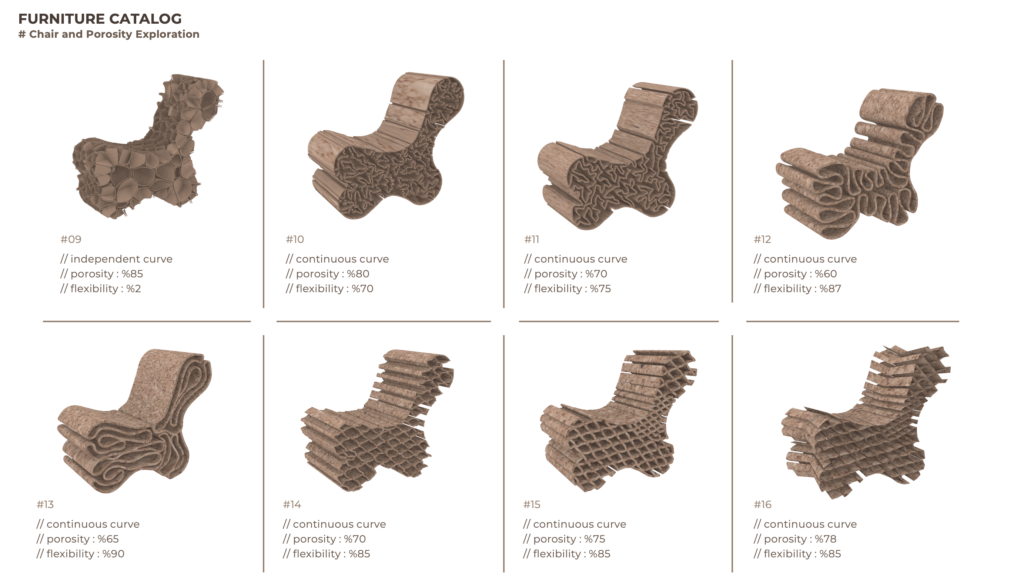

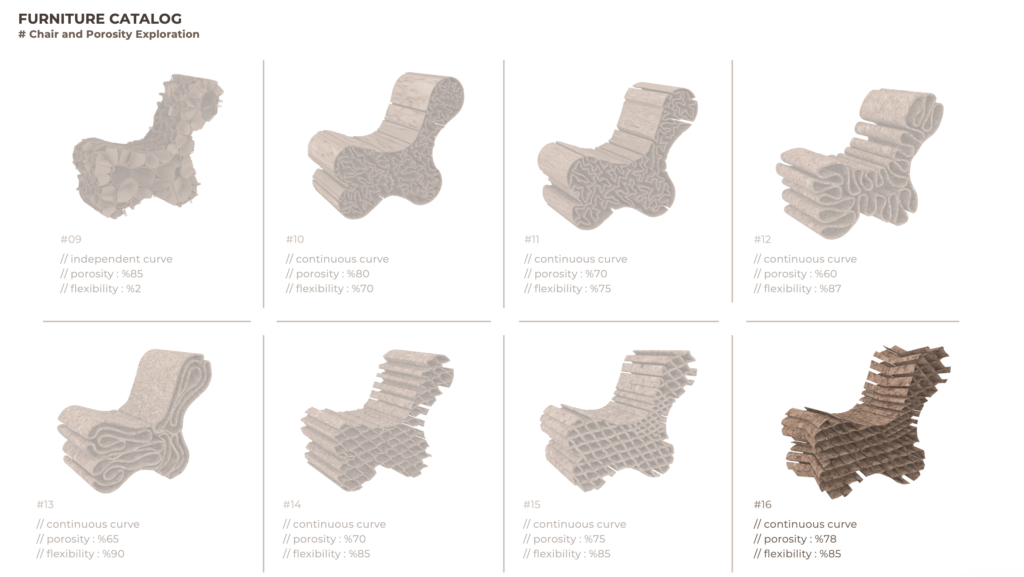

Afterwards, we went through some chair explorations with again different porosity and flexibility.

With test 9, the Voronoi structure, we achieved the most porosity but the least flexibility. Since most of them weren’t really achieving what we wanted.

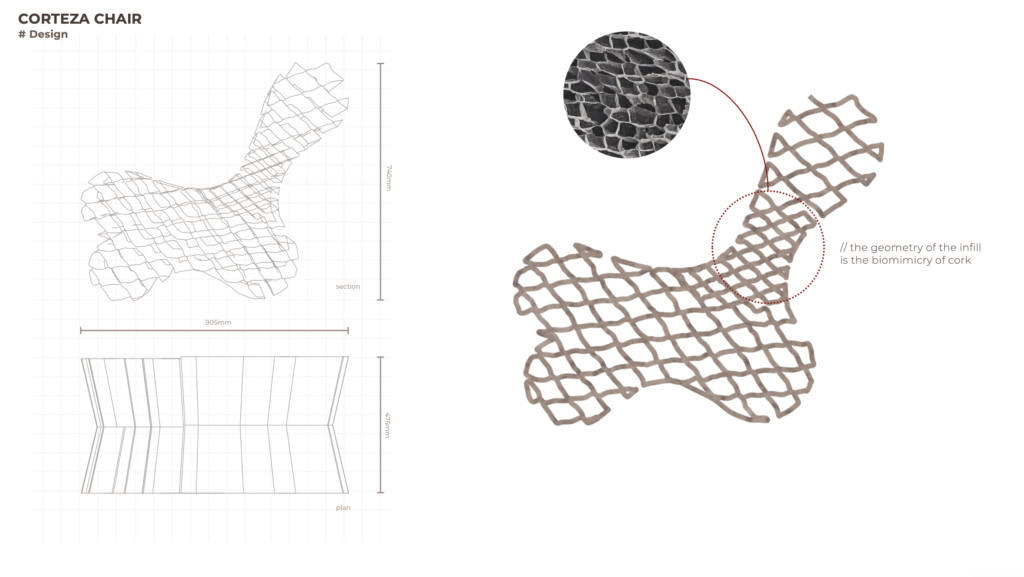

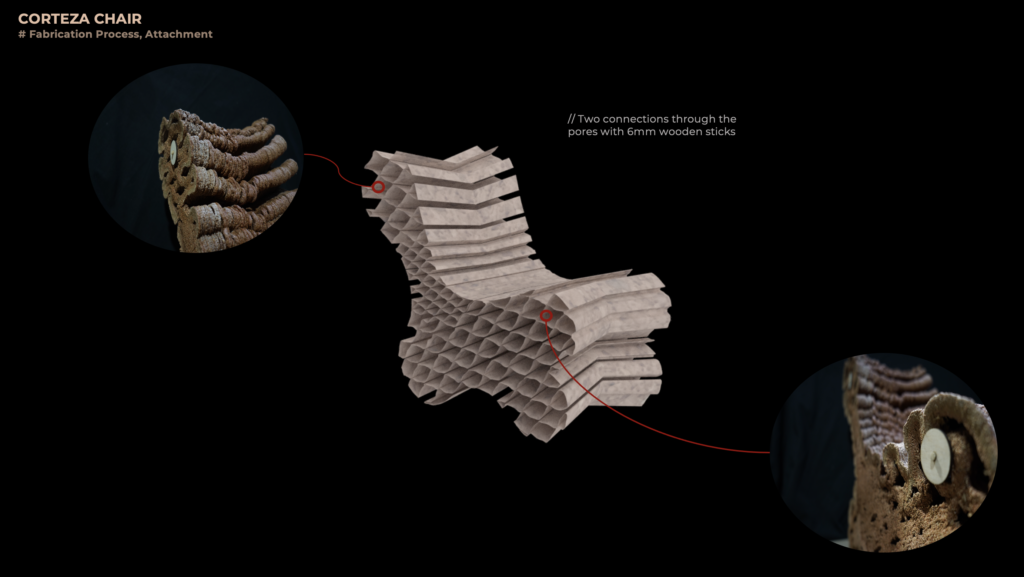

We went through the basic of corks biomimicry. And started the replicate it through a chair module.

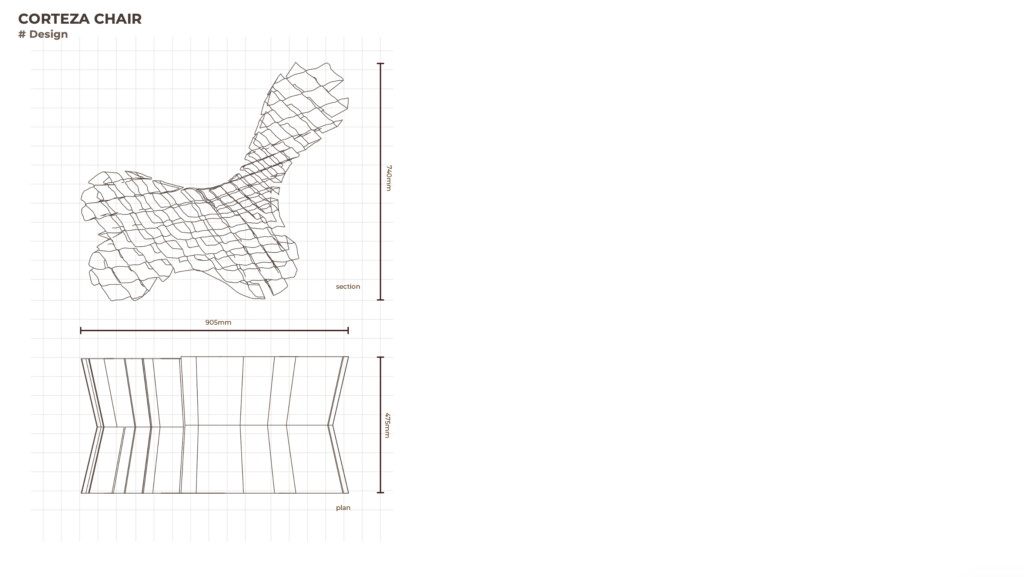

We created a baby chair with 90, 47, and 74 dimensions.

And through it, we tried to replicate the infills inside the chair geometry with biomimicry of cork

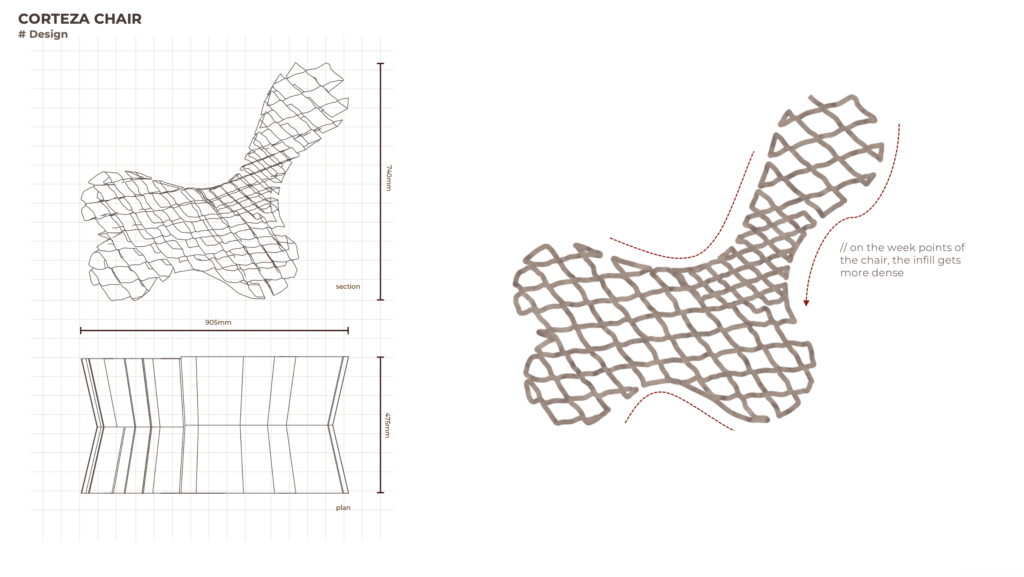

On the weaker points of the chair infill gets denser, and because of the rotation of the infills, it gives the cushion effect.

With the cork composite, the noise gets absorbed, and its porous surface scatters and reflects the sound

For the final model, we used an ur printer motors-crew with lutum cartridge and with 10mm nozzle size. Printing took 2.5 day

We always think that it is a chair in a house that you can use or put as art to absorb sound.

However, a single chair won’t absorb all of the unwanted sounds. Therefore maybe with a room full of cork furniture, maybe we can bring back the silence.