Additive manufacturing technology opens the possibility to carefully design the material distribution over geometries, taking advantage of the wide pallet of material available to build architecture. MACHINE is the introductory workshop to introduce technologies , techniques and materiality on deposition modeling and its implication in the design.

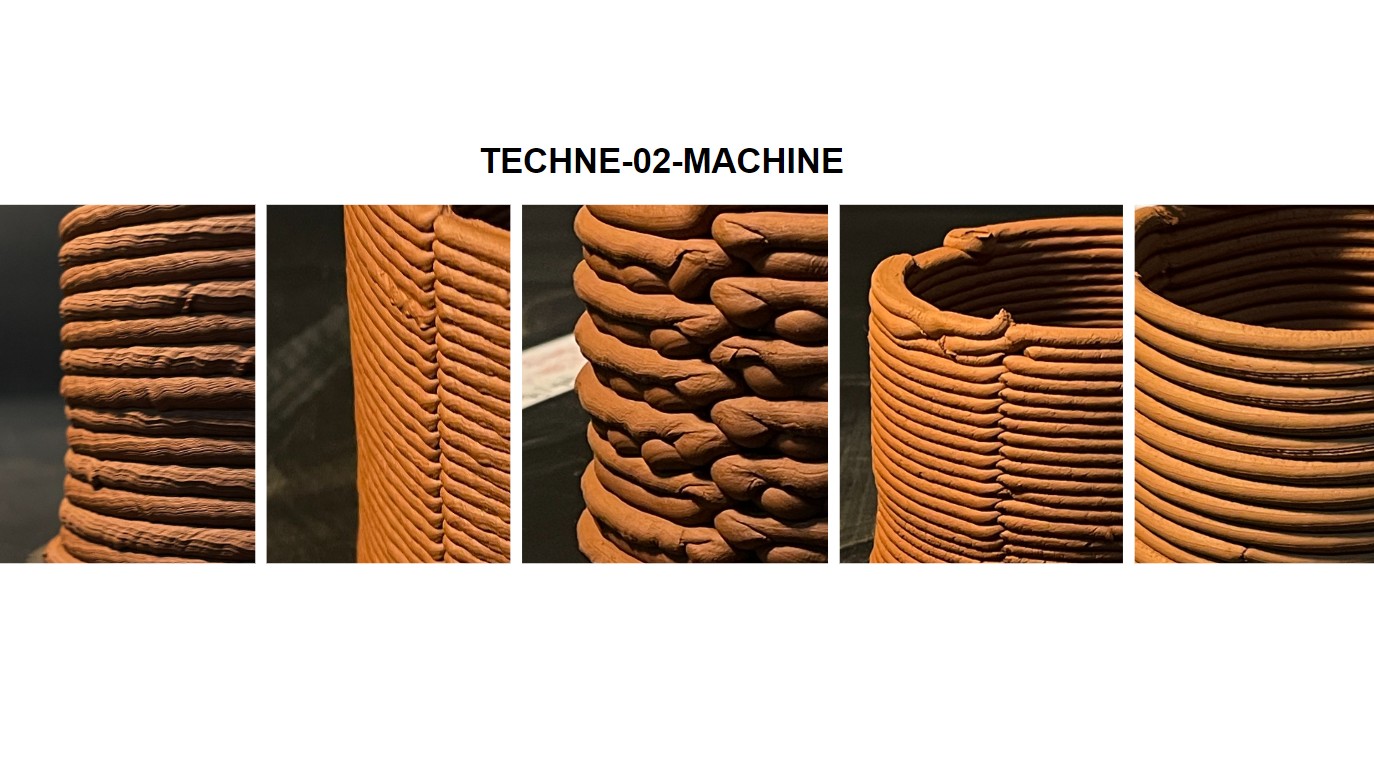

Materiality directly informs the technology and the methodology of fabrication, needing to adapt the process to characteristics and peculiarities of the material itself. This workshop will examine the implications of paste extrusion, in particular clay on the 3d printing process and how it modifies the traditional printing methodologies. Needing to adapt kinematic movements to its characteristics .

The students will be introduced to 3d printing technology and how the mechatronics behave, control systems, firmware and possible outcome on multiple configurations , understanding the limits and future improvement possibilities.

Finally, the workshop will conclude with a series of prints based on methodological assumptions. The systems built along this workshop will work as fast small scale rapid prototyping platforms along all the courses.

Learning Objectives

- Understanding principles and workflow of clay 3D printing from Design to Production

- To understand the mechanism of a 3D printer and its controller interface(repetiter host)

- mounting and calibration of paste deposition extruding system on the desktop 3D printer

- Getting familiar with wasp crane gcode generator and its controlling interface

- Large scale and small scale clay printing with desktop printers and wasp crane

During the workshop, the students are expected to work in groups of 3 and 4, test and calibrate the whole 3D printing system to be able to become independent to prototyping along the course of the program.