The widespread use of Additive Manufacturing technologies has brought a significant revolution in the field of design and fabrication, both in domestic and industrial settings. Designers today are much closer to the actual process of manufacturing and production, as was promised when these technologies arise. Despite the numerous challenges that come with the idea of 3D printing buildings, this technology is progressively finding its way into the architecture, engineering and construction (AEC) sector.

The TECHNE W2 MACHINE aims to provide students with a comprehensive understanding of paste-based additive manufacturing and the technologies and methodologies we use in 3DPA. We will examine the technology, techniques and materials required for clay-based 3D printing. Students will develop a solid foundation of the principles, gaining knowledge and skills necessary to work independently with the Ender platform, as it will be the tool of choice during the rest of the course stages.

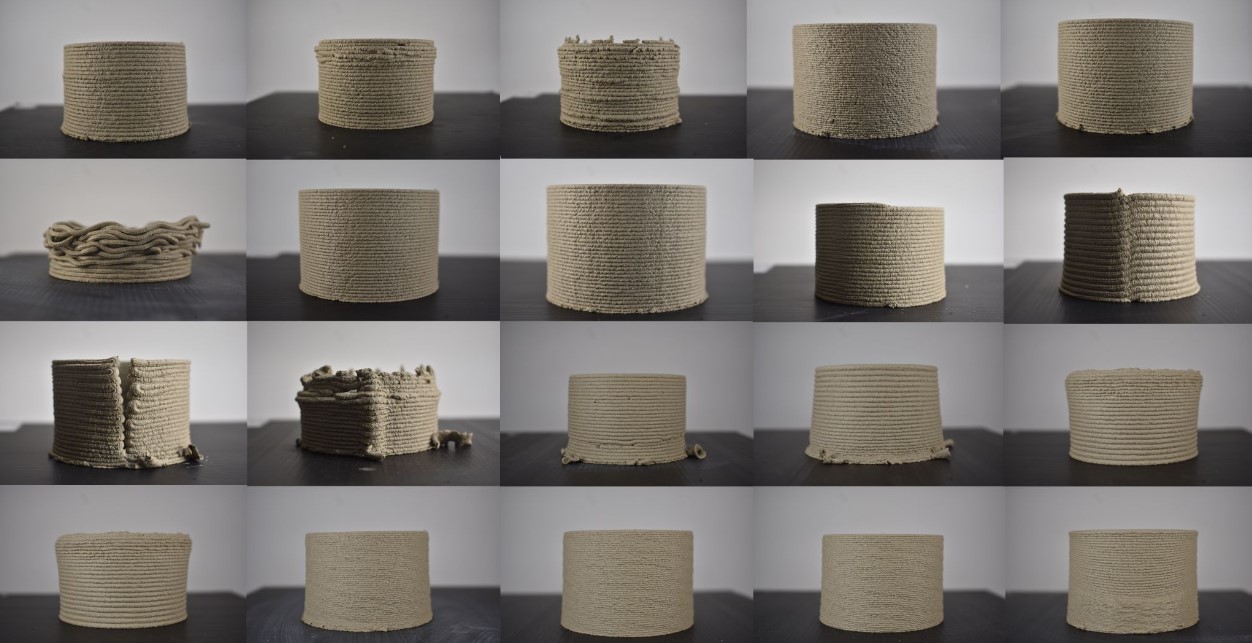

Students will have access to previous works, enabling them to progress faster and deeper in their understanding of the machine protocols and operation parameters. Test prints will still need to be conducted to validate and refine previous findings.

Learning Objectives

The workshop has a clear hands-on and learning-by-doing directive, intended to force students to solve problems as they occur. At the completion of the it, students will:

- Understand the principles and workflow for clay 3D printing:

- Define a Design-to-Production scenario.

- Be able to generate Gcodes for the printer and run them.

- Control the variables and parameters of operation.

- Gain knowledge of the mechatronics of the Ender platform:

- Mounting and calibration of paste extruding systems.

- Assembly and general maintenance of the printer.

- Understand the cartesian movement mechanics and its controller interface.

- Understand the principles and workflow of 1:1 earth-based 3D printing:

- Assembly of the WASP crane. General idea of a Construction Site 4.0

- Getting familiar with the design to production workflow in 1:1.

- Understand the production requirements for large-scale printing.

- Get familiar with the WASP Crane Gcode generator.

- Understand the polar movement mechanics and the controller interface of the WASP crane.