Credits: Fab.AR Seminar Final Presentations, MAA01 2021/22

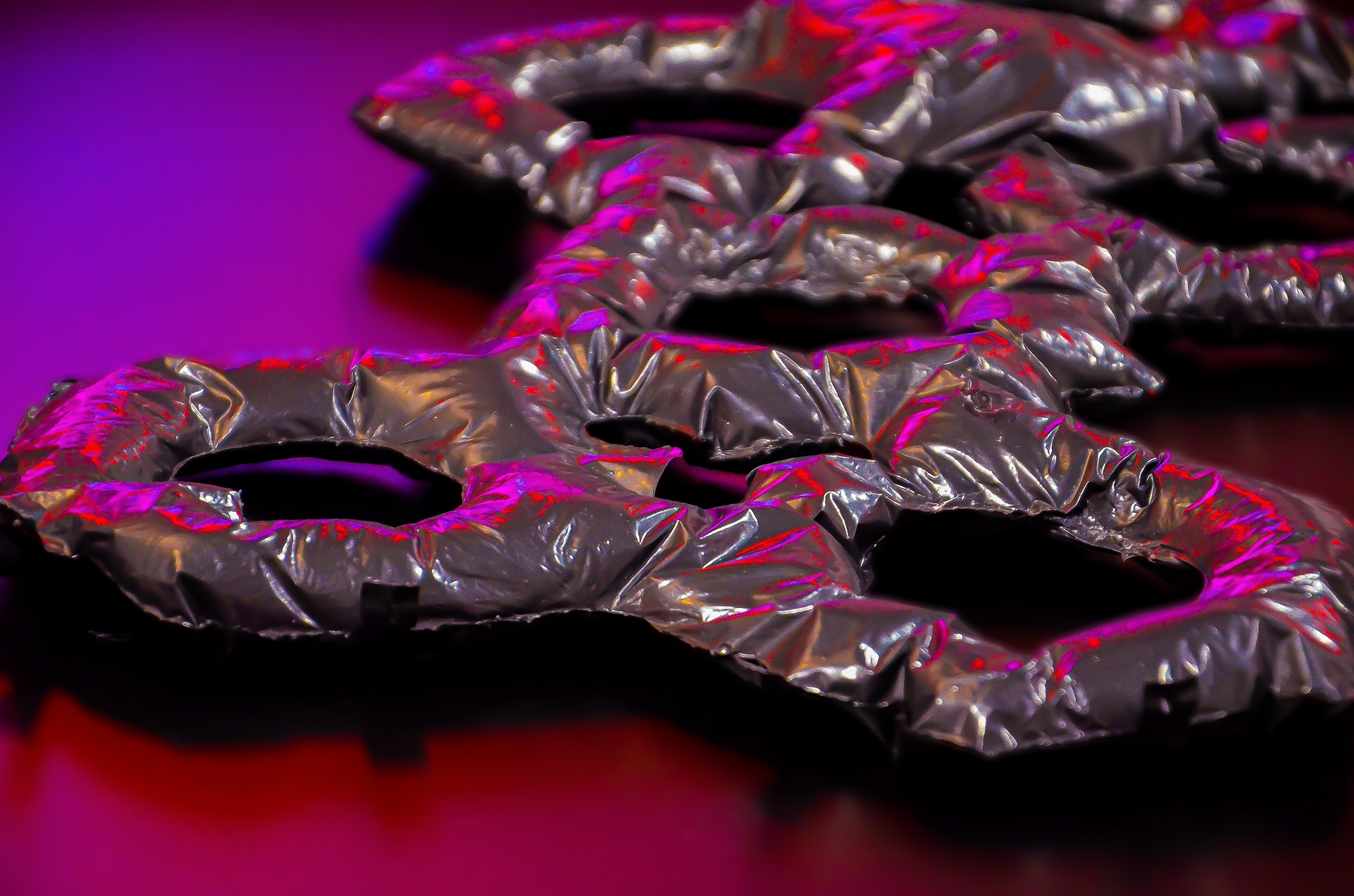

Digital fabrication allows architects to achieve high precision and extreme variability of designs. Computational design tools further expand the ability to simulate natural processes, express complex geometries, interface with fabrication machines, and further involve the target audience in various stages of design. However, often behind the race for automation, certain cratsmanship qualities are being left behind. For one, certain material properties are inherently hard to express quantitatively. Moreover, for us as advanced architects a common challenge with algorithmic workflows is lack of aesthetic control and disconnection from the target user, whereby a design definition acts as a black box.

The advances in Mixed Reality (MR) technologies have opened up possibilities to overlap digital information on top of physical spaces. Out of the full spectrum of MR technologies, Augmented Reality (AR) provides a vast range of applications on all stages of the creative process: from design, to idea communication, from visualisation, to assistance in fabrication or assembly. Democratisation of the technology made it extremely accessible leaving the realm of technological experiments into fully integrated real-world use cases. Thus, MR at its current state provides a unique opportunity to create custom interfaces and tools facilitating our expression. Indeed, architecture has been increasingly absorbing knowledge from related fields and architects and designers are pushed to consider even more facets for the projects, while keeping the core ideas reachable.

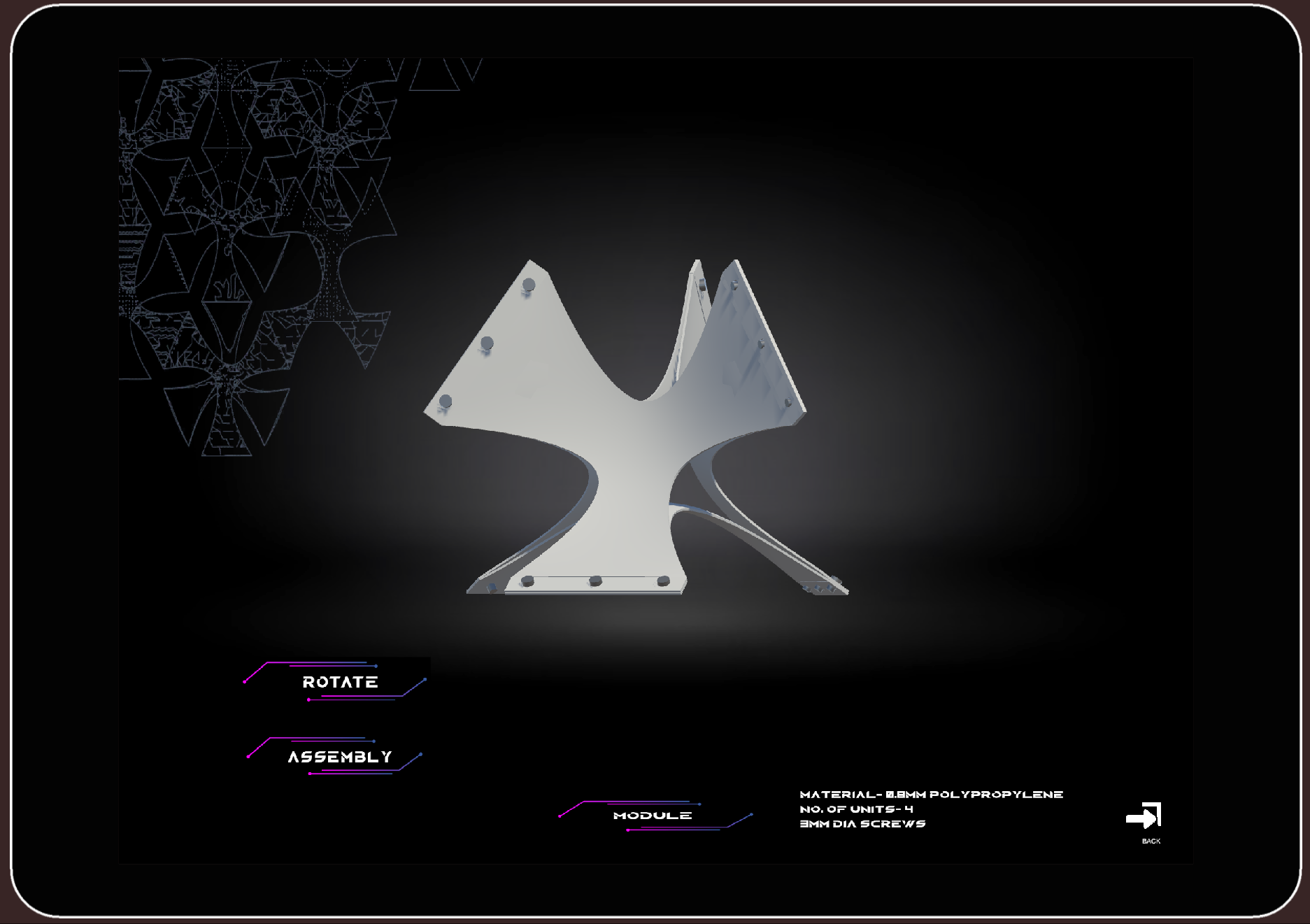

Within the seminar students are invited to explore the toolchain of Augmented Reality when applied to fabrication related scenarios, combining physical prototyping, material testing, computational design and augmented reality, in order to bridge the gap between the physical and digital realm and propose new ways for guided manual fabrication. Around this core objective, students will isolate a target stage of the design process they want to extend, develop custom tools for it and explore new possibilities for communication these tools can bring

Credits: BloomShell / Bartlett BPro Research Cluster 9 2017-18 / Directed by: Soomeen Hahm & Alvaro Lopez Rodriguez / Students: Yi Lin, Yushi Gao, Yang Song, Jiayi Liu

Learning Objectives

At course completion the student will:

- Know how to work with Unity & Vuforia & MRTK;

- Know how to create prototype interfaces in augmented and mixed reality applications;

- Develop a workflow for assisted fabrication through the use of AR;

- Develop a case study applying it to a materials system and fabrication/assembly technique that is guided / assisted by AR;

- Expand the possibilities of manual fabrication process by overlaying them with digital models in AR

- Bridge the gap between the digital and physical worlds within the architectural applications.