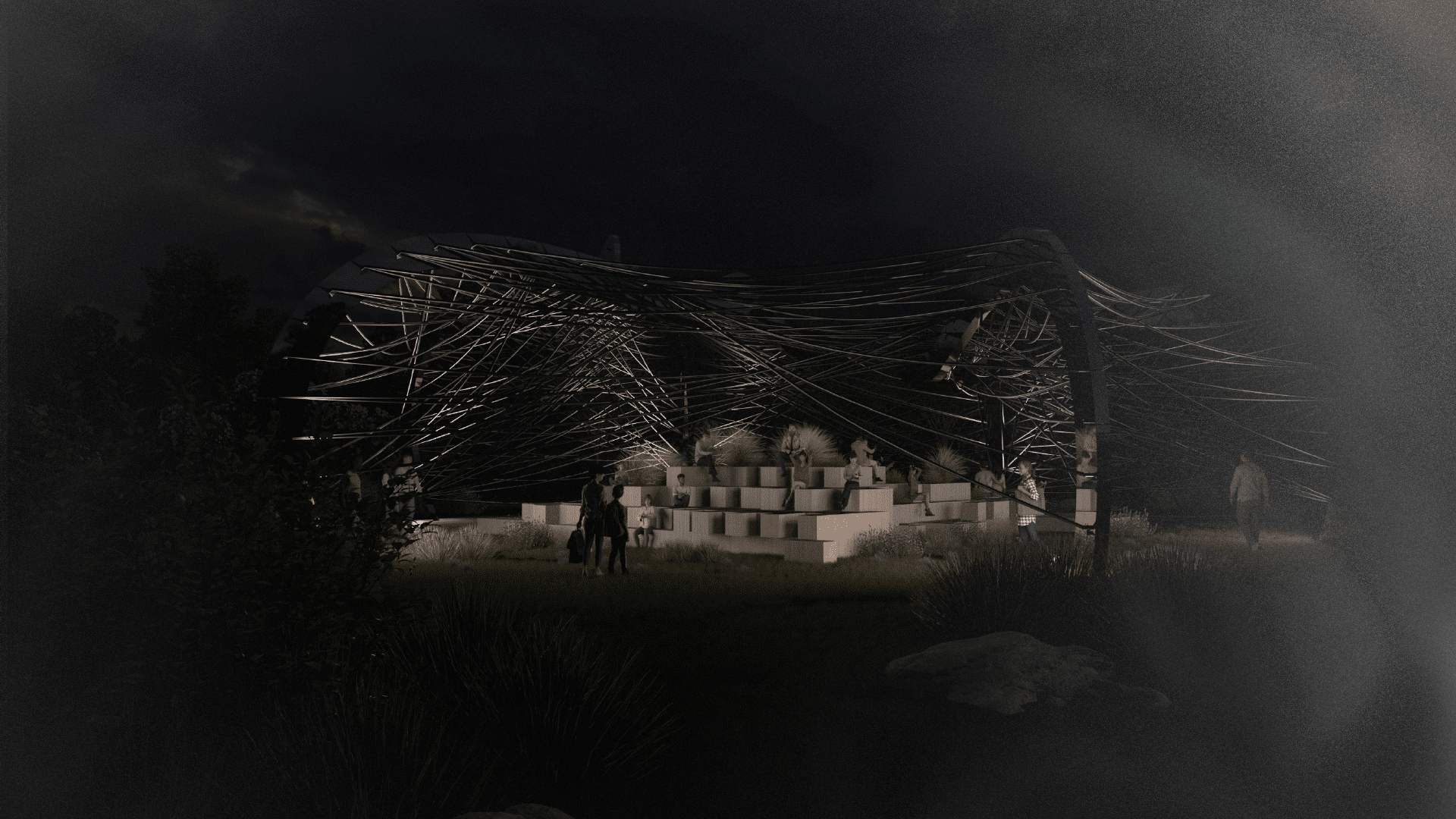

Credits: Fab.AR Seminar Final Presentations, 2022

As with most aspects of modern-day reality, design has radically shifted to embrace the potential of the digital. Computational design opened up new possibilities to explore up-until-recently unimaginable geometries, simulate nature, optimize for a wide range of constraints, and facilitate easier integration of digital fabrication processes, to achieve high precision and mass customization. During this shift, professions such as architecture and design have absorbed responsibility for the tight integration of often conflicting specialty knowledge from related fields. Moreover, lost within the wide range of possibilities and design solutions that computational design offers, it is becoming harder and harder to convey the full reasoning behind design solutions. However, while our technical capacity to implement these solutions has increased with the use of the universal tools, a trade-off in craftsmanship, flexibility of expression, and sometimes excessive difficulty of automation has been introduced.

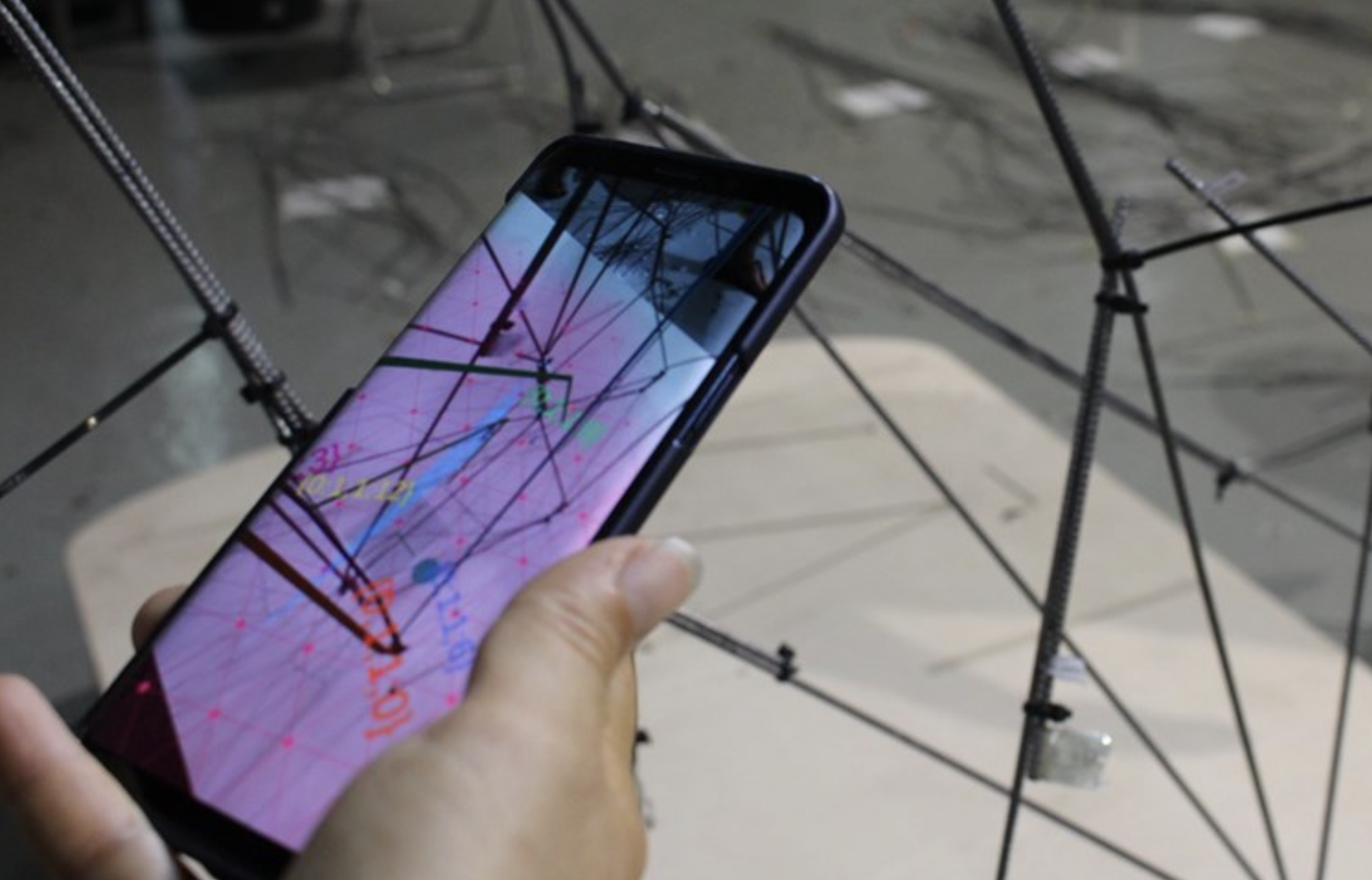

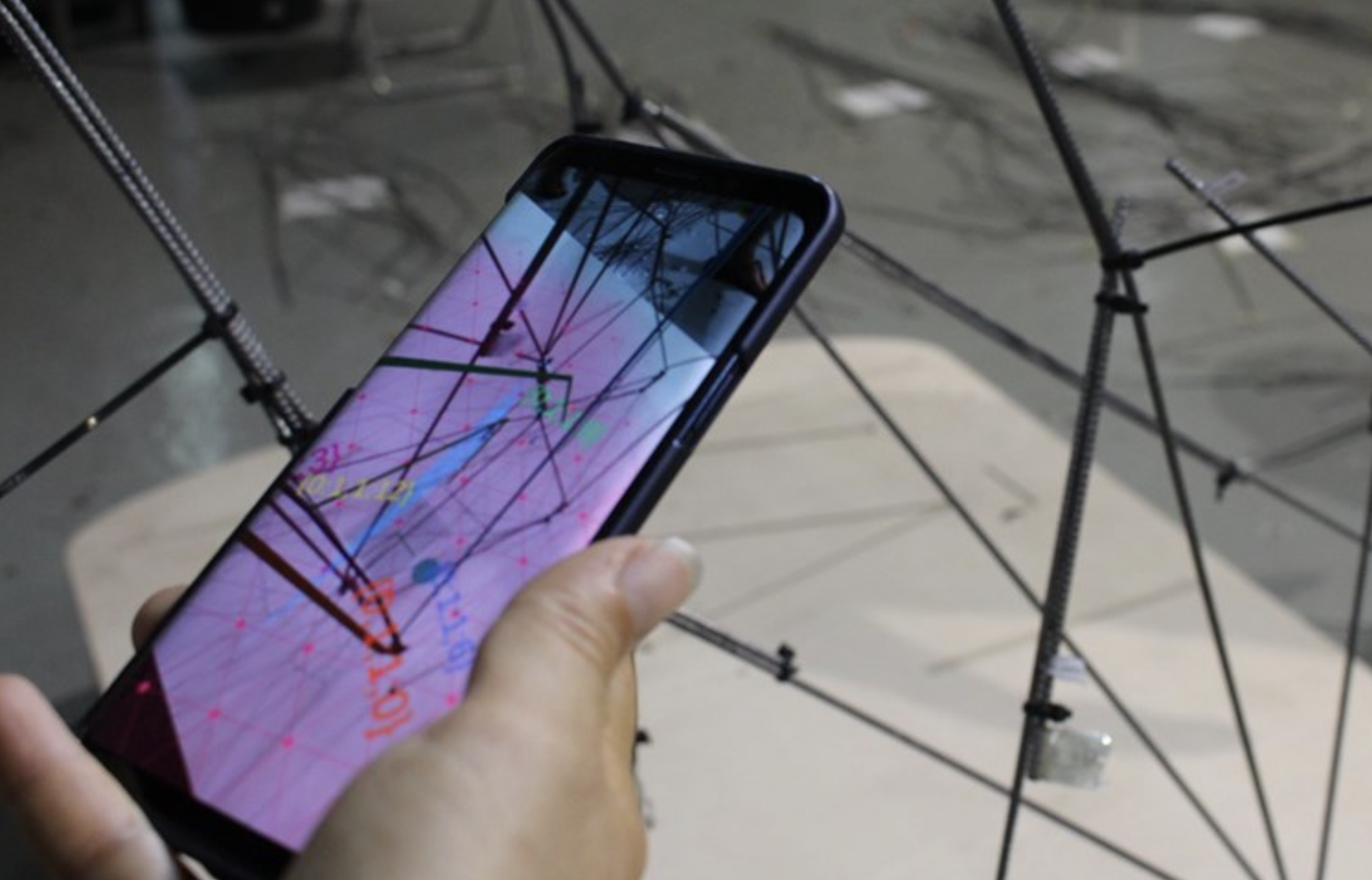

To tackle these challenges, students are invited to explore Mixed Reality (MR) applications in their workflows. Recent advancements in MR technologies allow digital information to be seamlessly integrated within physical spaces. Among MR technologies in the context of architecture, Augmented Reality (AR) offers a wide range of possibilities across all stages of the creative process: from ideation to design, visualization to communication, assisting in fabrication and assembly, and monitoring and usage. The democratization of computing power has made it highly accessible, moving beyond experimental or recreational applications into integrated, practical tools for real-world use. This seminar focuses on leveraging AR’s unique ability to create custom interfaces and tools that empower creative expression and facilitate innovative workflows.

Credits: Steampunk Pavilion by Gwyllim Jahn & Cameron Newnham (Fologram), Soomeen Hahm Design & Igor Pantic, 2019

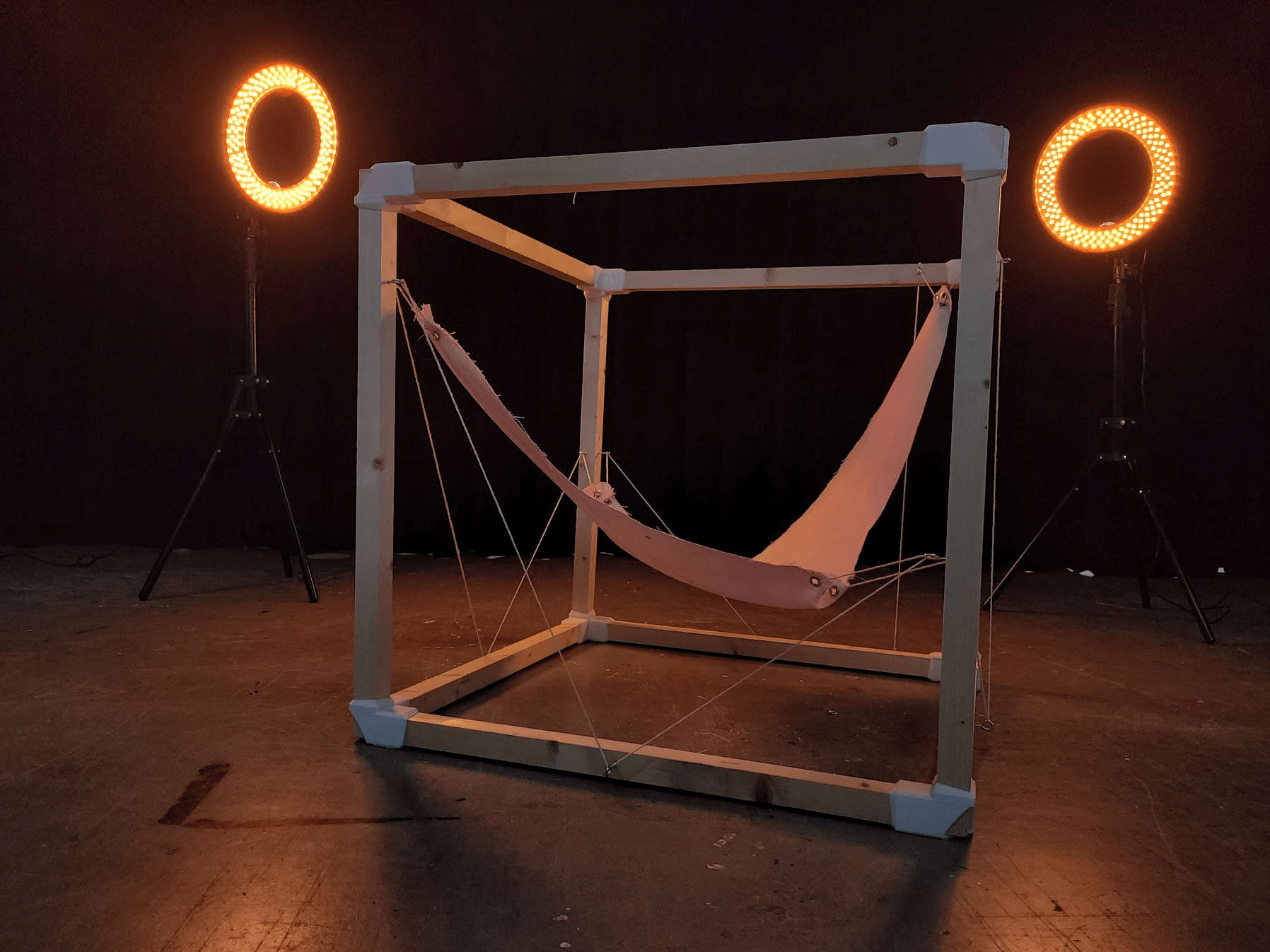

Within this seminar, students will explore the AR toolchain as it applies to fabrication-related scenarios, integrating physical prototyping, material testing, and computational design – developing innovative methods for assisted manual fabrication, effectively bridging the gap between the physical and digital aspects of the profession. This approach aims to introduce students to the mindset of creating custom digital tools to fit their design scenarios and uncover new possibilities for enhanced communication and collaboration.

Credits: HoloFab by Ardeshir Talaei, Daniil Koshelyuk & Armin Akbari, 2018

Learning Objectives

At course completion the student will:

- Understand the role of Augmented Reality in fabrication: Demonstrate an understanding of how AR technologies can enhance various stages of the design and fabrication process.

- Know how to work with Unity: Create, develop, and collaborate within Unity projects to create custom tools.

- Develop functional AR/MR applications: Design and implement proof-of-concept AR/MR applications.

- Create custom user interfaces and experiences: Build intuitive and interactive AR-based user experiences tailored to specific project-related usability and functionality.

- Bridge the gap between the digital and the physical worlds: Identify and critically analyze a fabrication methodology to be enhanced with AR/MR.

- Communicate technical concepts and design decisions: Present and articulate the purpose, design and development process, and functionality of the AR/MR applications, demonstrating the ability to explain complex ideas to both technical and non-technical audiences.

- Evaluate and reflect on AR/MR’s Impact: Critically assess the effectiveness of their AR solutions, considering their potential impact on the design and fabrication workflow and identifying areas for further improvement.