Processes and Products in the contemporary AEC sector

Syllabus

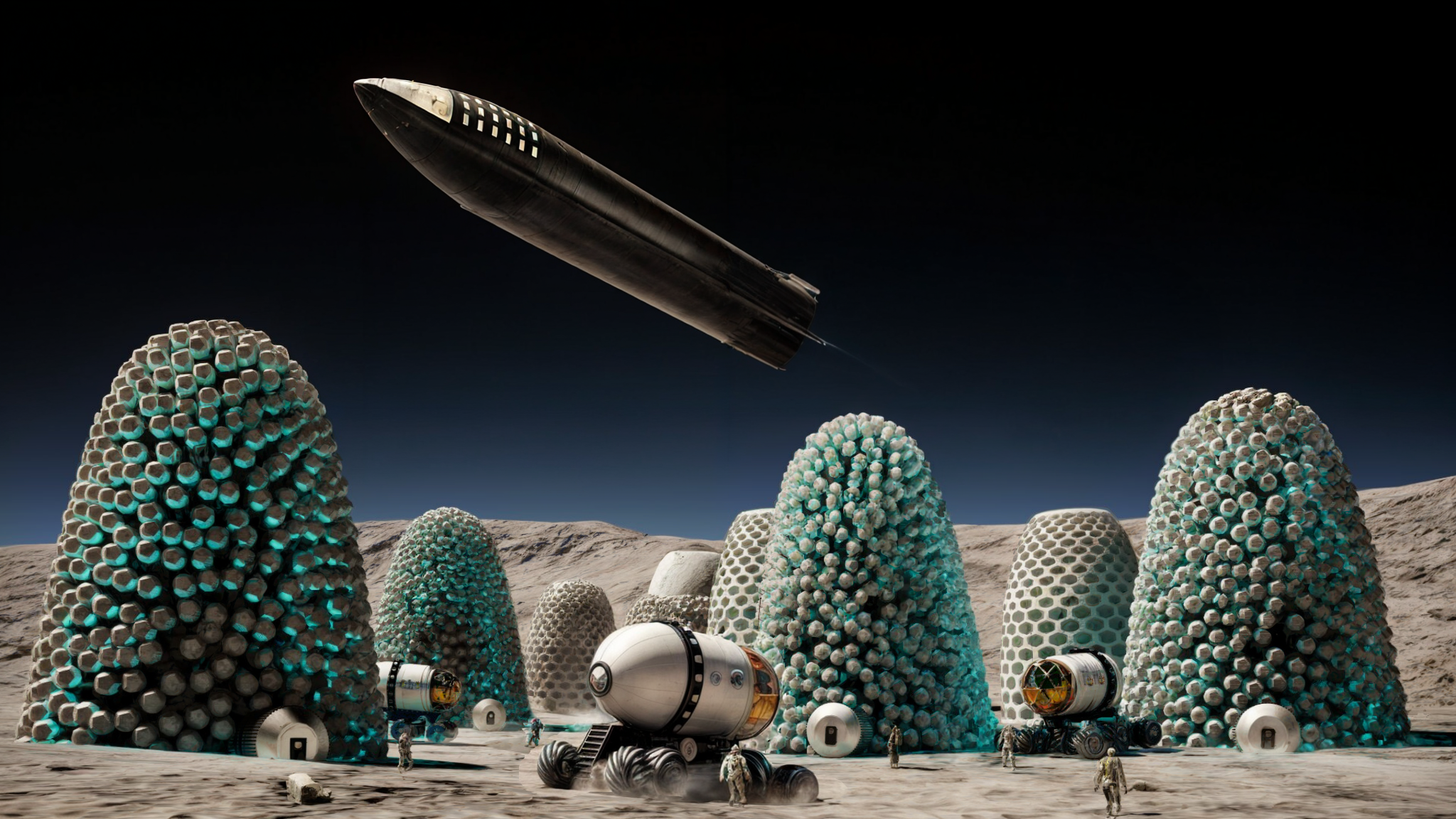

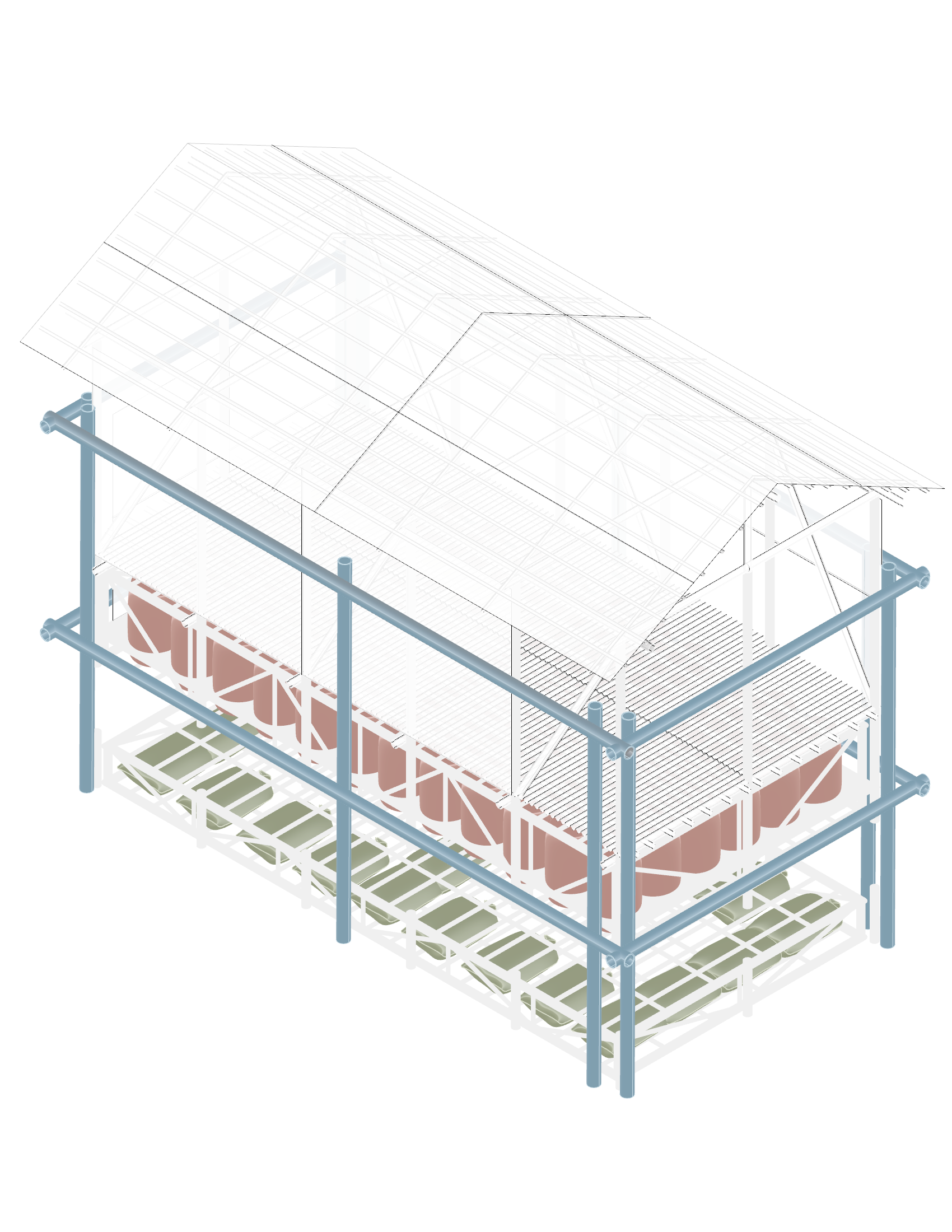

Photo Credit: Xylem: Wood Composite by Alex Ferragu. Advanced Manufacturing Thesis Cluster MAA02 22/23

Intro Description

Advanced manufacturing encompasses the use of innovative technologies and methodologies to enhance the production and design of products or processes. In the AEC (architecture, engineering, & construction) sector, it specifically refers to the integration of cutting-edge fabrication technologies and methodologies into the design and construction of built environments. This offers new solutions for construction methods, design processes, and components, among other examples that involve contemporary fabrication methods. This approach leverages digital fabrication, additive manufacturing, and automation to create precise, customized and often more sustainable architectural components and construction systems.

The implications of advanced manufacturing in the AEC sector go beyond the physical act of construction. It introduces a new paradigm in how professionals approach design and fabrication, problem-solving, and collaboration between agents and technology. As these technologies profoundly influence design capabilities, they also challenge traditional roles within the industry, prompting architects, engineers, and builders to embrace more interdisciplinary roles.

With the increasing adoption of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, architects, engineers, and builders can transition from design to production seamlesly. This enables now the realization of complex geometries, innovative material formulations, and structures that were previously challenging to construct. The integration of these technologies with the current architecture and construction reality will remain a fundamental aspect of the construction industry’s future, and an important aspect of the cluster.

Learning Objectives

MAA02 marks the first time students are faced with the challenge of research with their own agendas, besides the required knowledge of the state-of-the-art that frames their individual research projects and common practices in research studios, students of the advanced manufacturing cluster will be required to gain knowledge and expertise in the following areas:

- Fundamentals of the research frame: Gain knowledge of the principles and methodologies of advanced manufacturing and its relevance to contemporary architectural practice, linking and aglutinating them in a coherent framework.

- Digital Proficiency: Expand previous knowledge in computer-aided design (CAD) and computer-aided manufacturing (CAM) tools for developing digital workflows and simulations and a general understanding of their role in the design-to-fabrication workflows.

- Material Exploration: Investigate and understand the properties, potentials, and limitations of the materials that will be used in their research projects.

- Design for Manufacturability: Learn to design architectural components with manufacturability in mind, considering factors like material constraints, fabrication methods, and assembly logistics and transport.

- Sustainability and Efficiency: Recognize the potential of advanced manufacturing for sustainable architectural practices, including waste reduction, efficient use of resources and recycling and repurposing of architectural components.

- Fabrication Problem-Solving: Develop the ability to leverage fabrication techniques to address complex challenges posed by the design and manufacturing of components.

- Future Trends and Research: Create a research framework that will have the ability to evolve and expand according to present and future research.

Structure of the course

During the first term, students will be required to study and understand the state of the art that best aligns with their research projects. The goal is to identify a research gap and/or a market niche that validates their initial white paper intentions, ensuring that the market gap is evident and the problem they aim to address is clearly defined. By the end of the term, students should also produce a series of prototypes to validate an MVP (minimum viable product).

The second term will focus on applying the product/process in a relevant environment to test the feasibility of the proposal. Students’ efforts will be centered on refining the state of the art while simultaneously conducting larger-scale experiments to broaden the potential of the MVP. It is expected that the material research from the first term is redefined and expanded aswell.

The third term will concentrate on scaling up and tailoring the proposals to the realities of the AEC sector and its current technologies and challenges. In the last month, students should identify an industry that could benefit from their research, and envision the possibilities of the projects in reality. A series of future trends and applications will be also required as a concluding part of the thesis.

Faculty

Faculty Assistants

Projects from this course

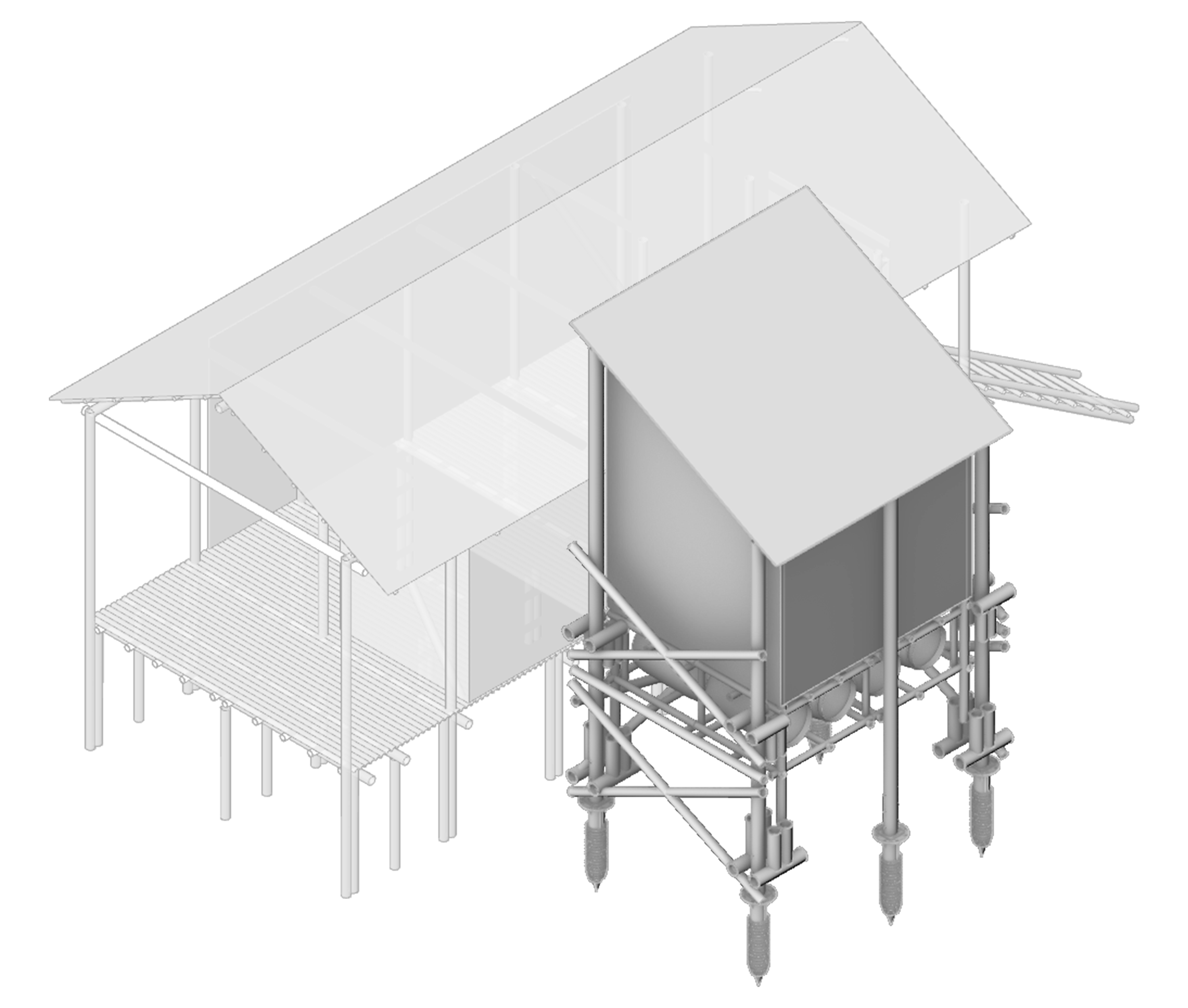

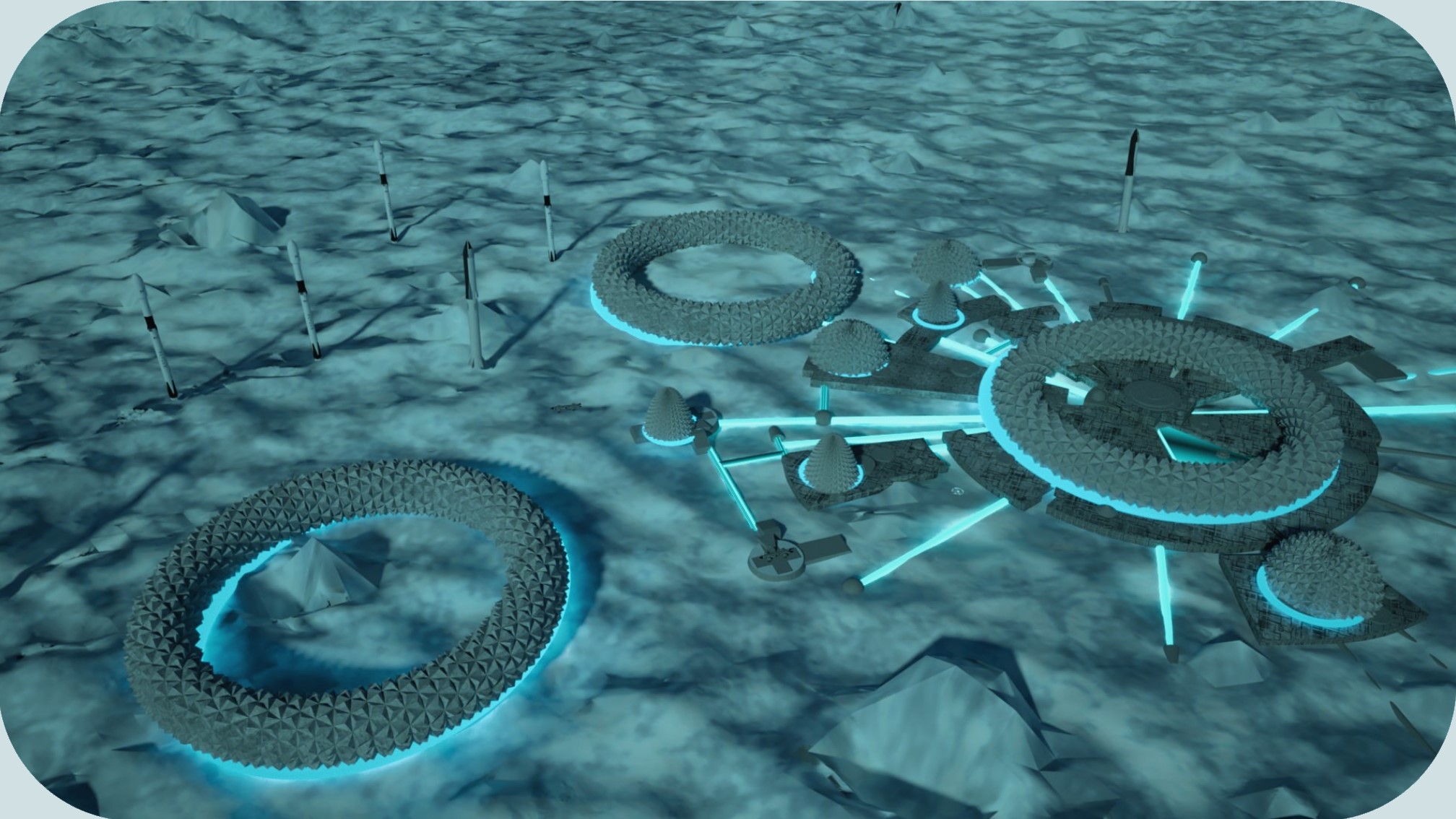

The Adjunct Amphibian

Amphibious attachment systems for existing stilt houses to counteract flash floods along the Brahmaputra river plains in Assam, India Context The river Brahmaputra, with one of the largest tributary systems in the world, divides the state of Assam into almost two halves. This means that a large geographical area in Assam is prone to floods and … Read more

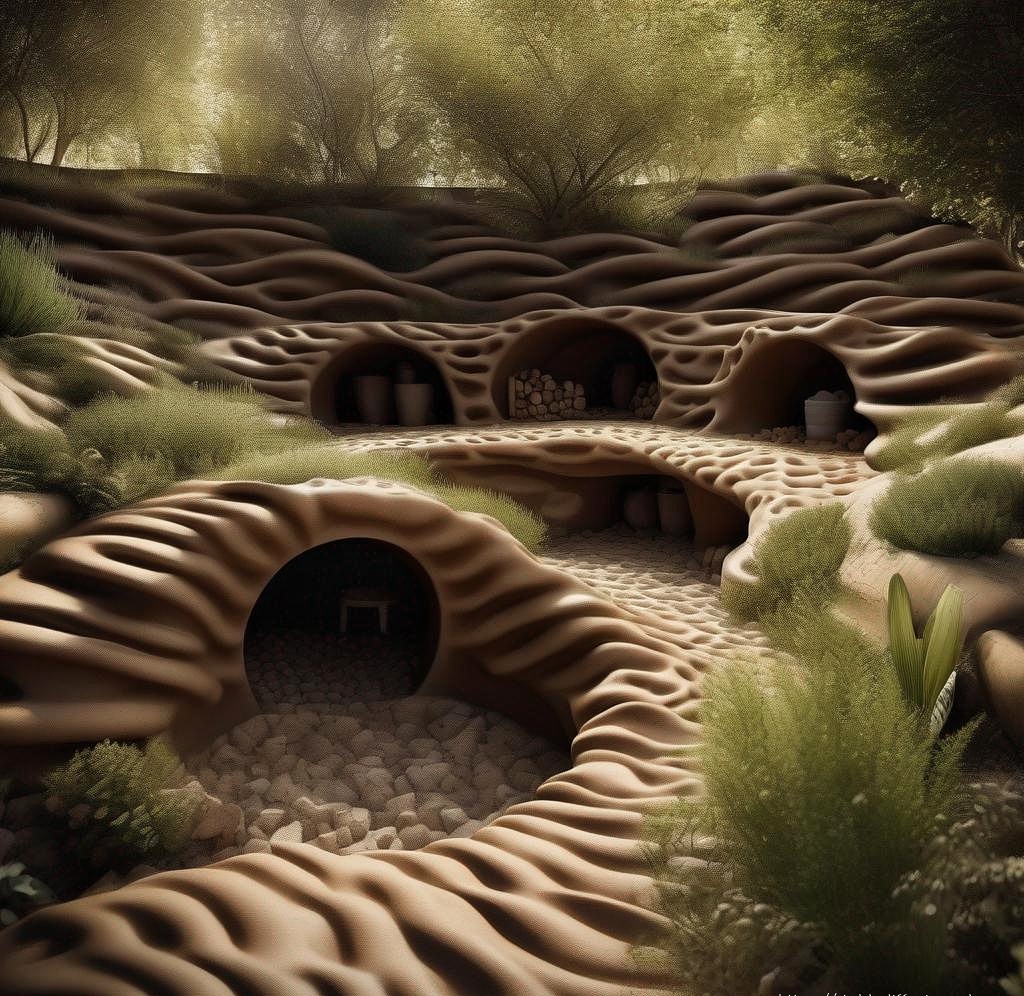

Bionook

This blog describes and showcases the second-term research and prototyping for Bionook. Research Topic: Investigating the Synergistic Potential Between Additive Manufacturing Methods and Engineered Timber in Reshaping Urban Design Paradigms. This research delves into precisely integrating sawdust and orange peels as industrial by-product additives for Soil Additive Manufacturing and locally sourced Engineered Timber, synergizing them … Read more

The Hugging Amphibian

Amphibious attachment systems for existing stilt houses to counteract flash floods along the Brahmaputra river plains in Assam, India Context In India, about 40 million hectares, or one-eighth of the country’s geographical area, is flood prone. Assam receives more rainfall than most parts of India. In 2022, floods affected around 5.5 million people across 32 … Read more

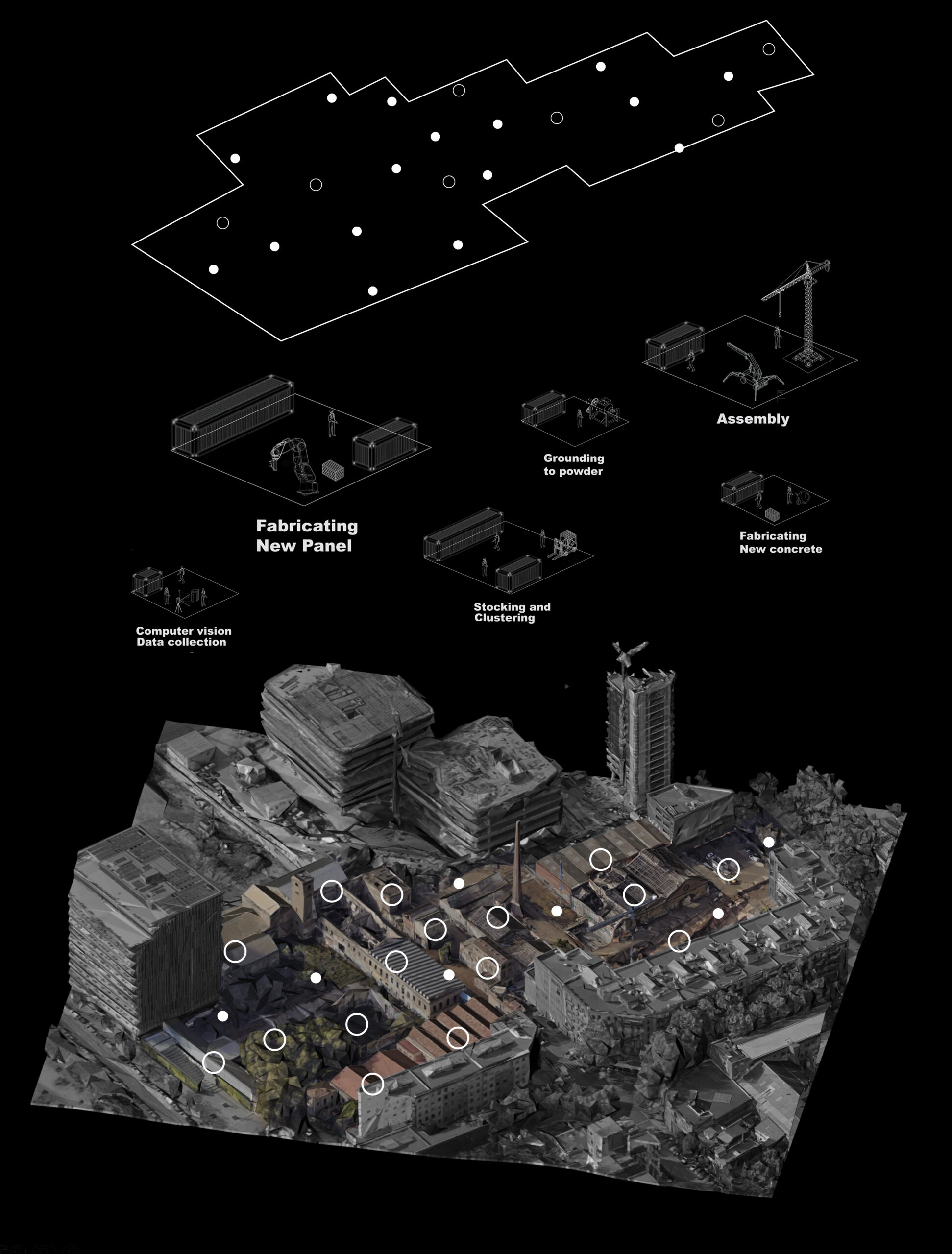

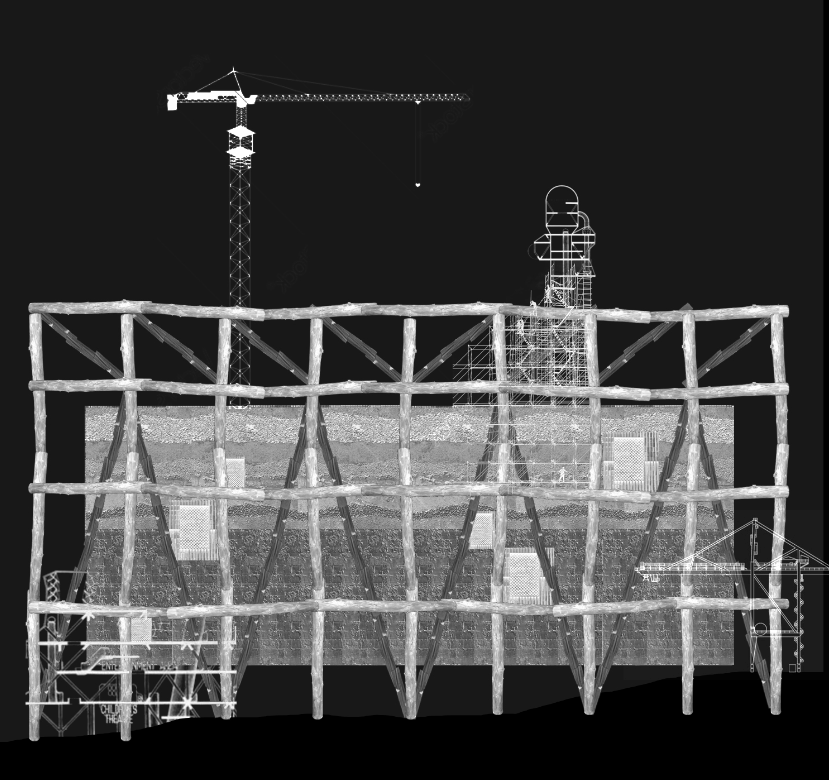

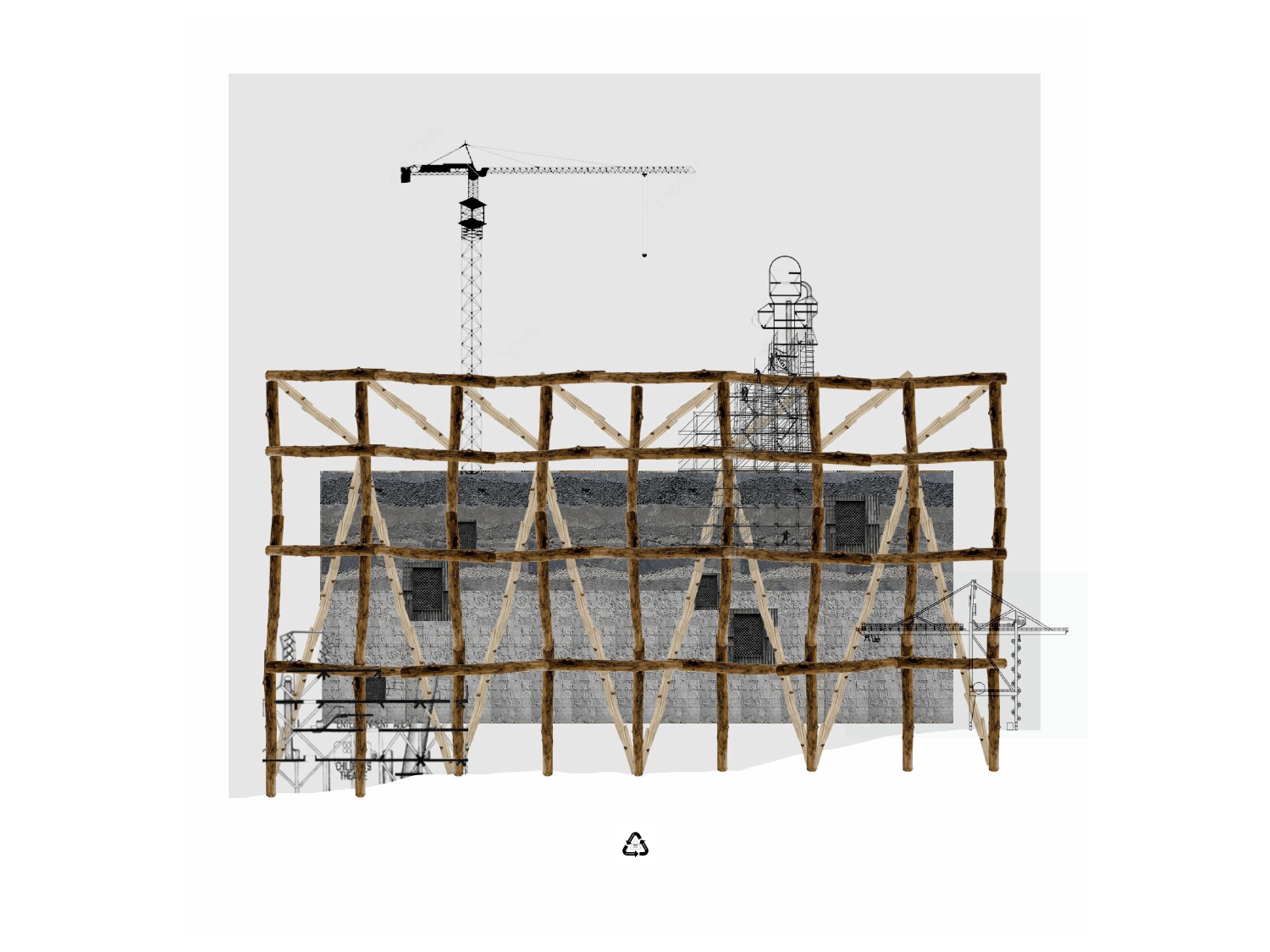

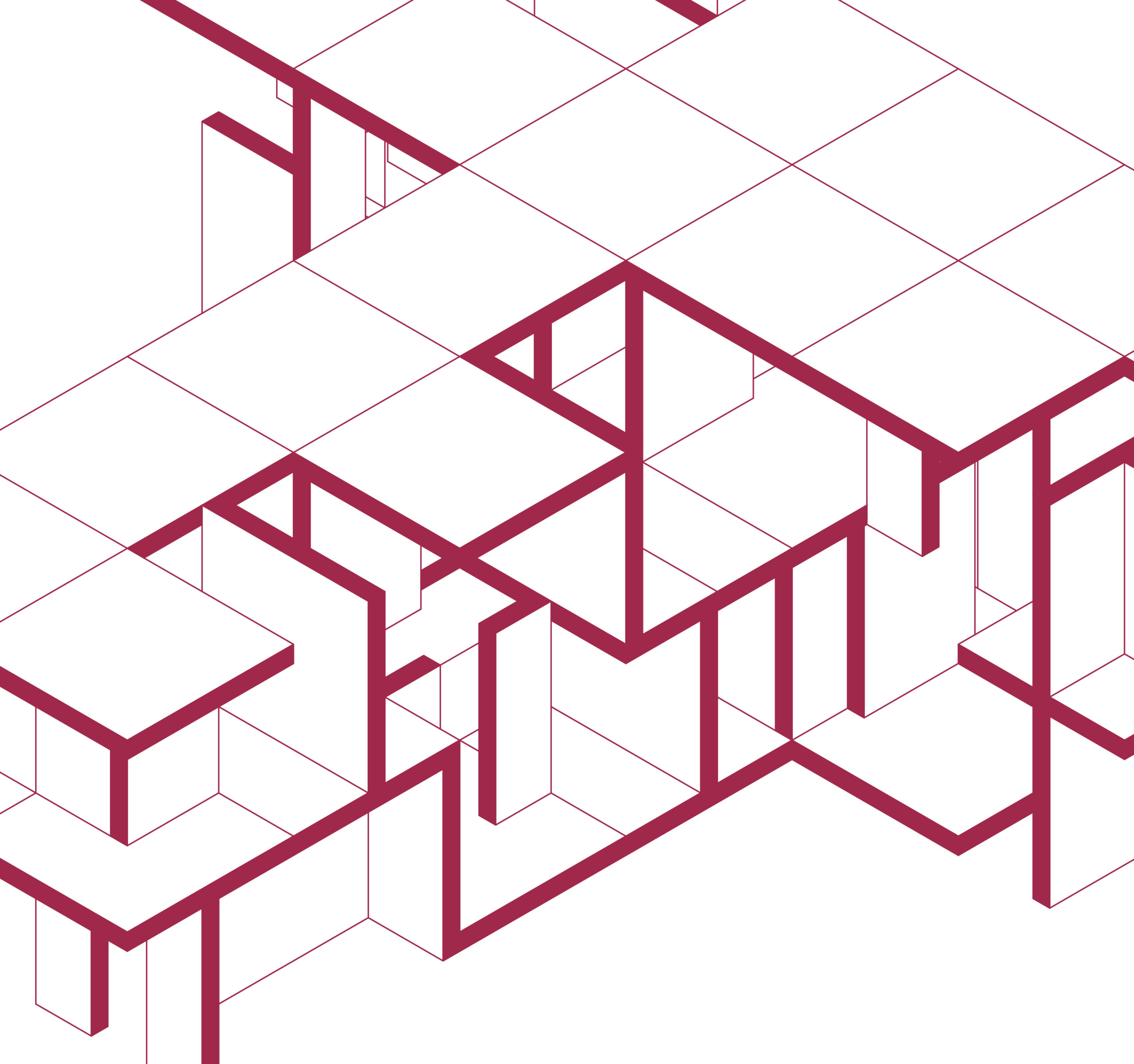

AFTER DEMOLITION : A general methodology for recycle buildings

This project provides design-to-fabrication workflow for upcycling building before the demolition of architecture. Rather than down cycling concrete into low value aggregate, redirected steel back into the furnace or grinding up timber into OSB board, methods are shown for this material to be indexed, re-matching and rearranged into new assemblies. These assemblies are conceived of … Read more

Introducing need for Bionook

Abstract In response to urgent carbon mitigation challenges and biodiversity loss, a paradigm shift toward manufacturing symbiosis and circular bio-economy is crucial for ecologically sensitive design in urban ecosystems. This study explores the transformative potential of a 3D-printed urban Bionook, incorporating layers of Cross-Laminated Timber (CLT) with a natural-locally sourced soil admixture, to enhance strength, … Read more

To float or not, that is the question!

Amphibious retrofit systems for existing stilt houses to counteract floods along the Brahmaputra river plains in Assam, India Abstract Imagine a situation in life, where you were periodically afraid of your house getting washed away by intense floods, and always had to be alert and prepared! The fear of losing everything you have. Not a … Read more

Generative housing system

•The global prefabricated construction market was valued at $117.62 billion in 2022, and is expected to reach $269.02 billion by 2032, growing at a CAGR of 8.70% during the forecast period, 2023-2032. •Soon the prefab market will be projected 5% growth until 2030 whereas the construction industry will be targeting 2.3% growth overall.