This blog describes and showcases the second-term research and prototyping for Bionook.

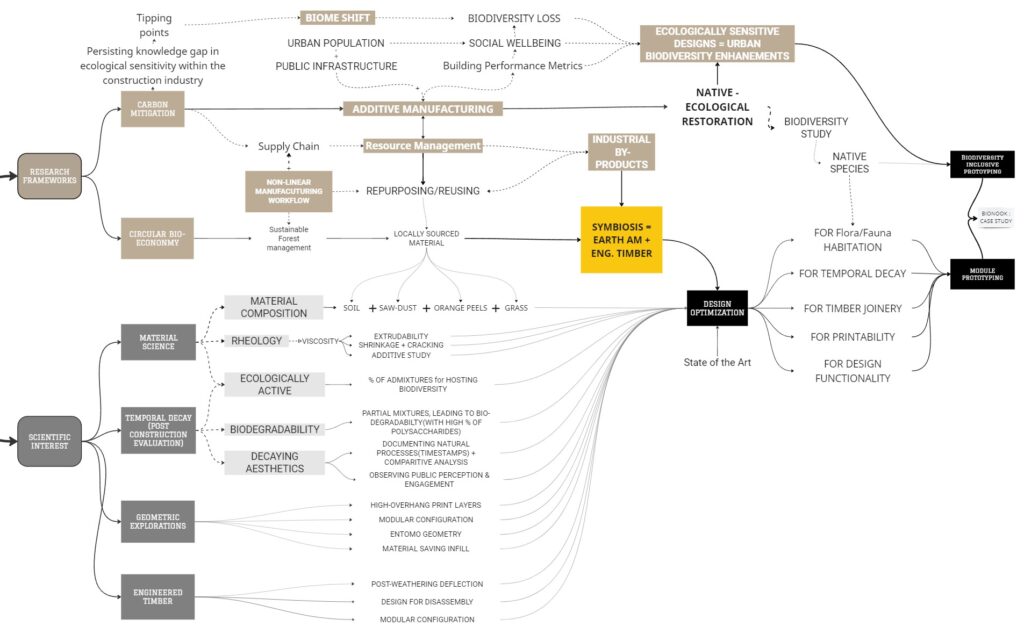

Research Topic: Investigating the Synergistic Potential Between Additive Manufacturing Methods and Engineered Timber in Reshaping Urban Design Paradigms. This research delves into precisely integrating sawdust and orange peels as industrial by-product additives for Soil Additive Manufacturing and locally sourced Engineered Timber, synergizing them for ‘Manufacturing Symbiosis.’ Bionook as a proof of concept, signifies applicable research on ‘circular bio-economy principles’ and ‘Nature-Based-Solutions’ integration within Urban Ecoregions, thereby demonstrating a deep-rooted commitment to ecological intelligence.

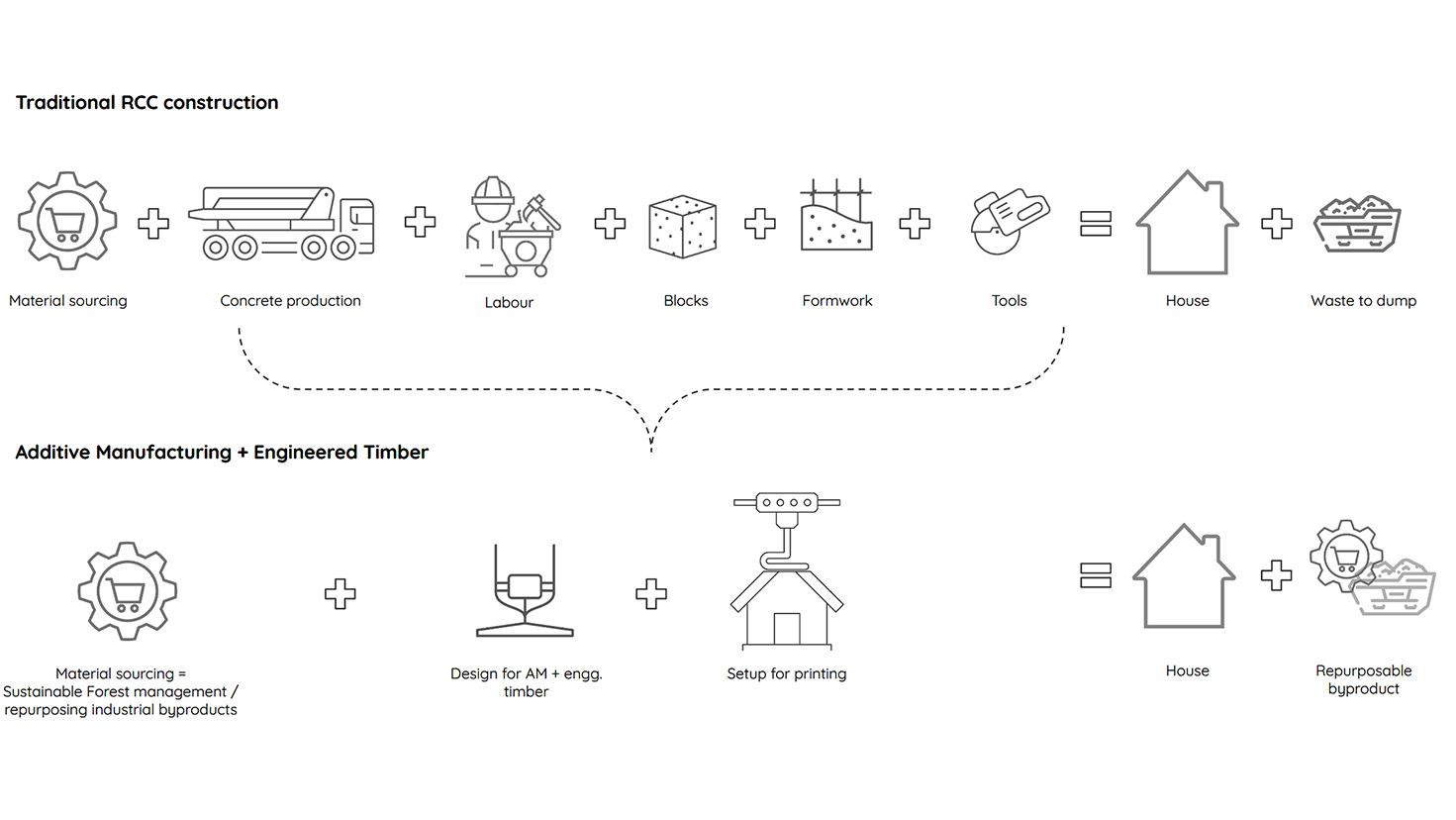

Problem Statement: ‘How can the symbiosis between additive manufacturing and engineered timber technology be harnessed for effective carbon mitigation? And in what ways can circular bioeconomy principles guide the development of an ecologically sensitive material admixture utilizing natural, locally sourced resources including industrial waste/ by-products, to further close the loop and complement the material science to overlap with technological advancements in terms of design for printing to further advance this symbiotic manufacturing processes?’

Introduction and background study: Deriving the need

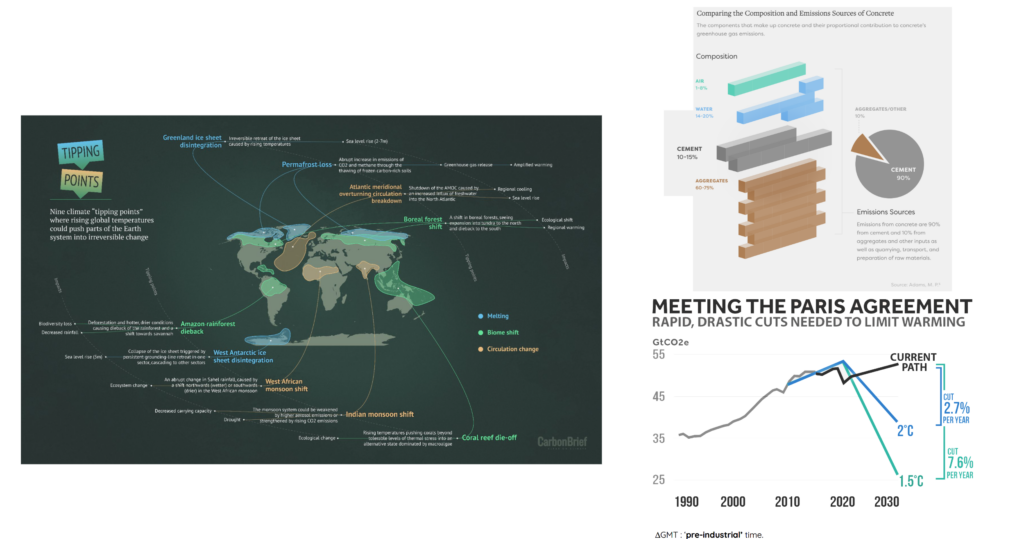

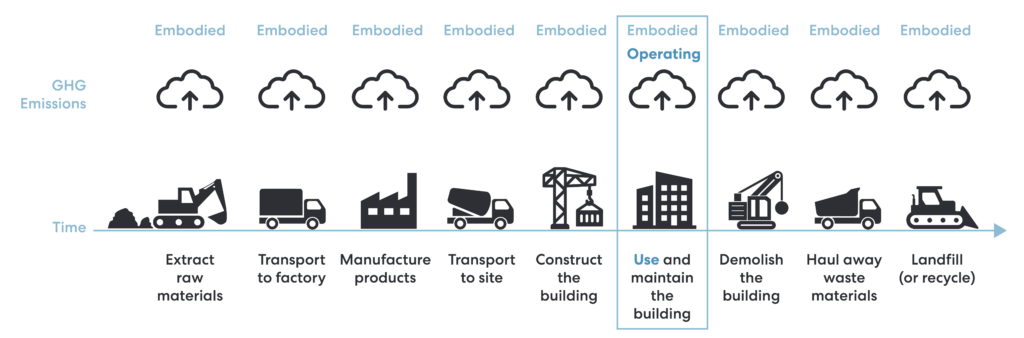

Need for Carbon Mitigation

Need for Manufacturing Symbiosis

The convergence of Soil additive manufacturing (SAM) and engineered timber within the framework of the circular bioeconomy represents a paradigm shift towards sustainable and innovative manufacturing practices with multifaceted benefits. SAM, characterized by its layer-by-layer paste-extrusion fabrication process via digital design, enables precise customization and intricate geometries in production. Engineered timber, on the other hand, harnesses advanced manufacturing techniques to optimize wood’s structural properties, durability, and dimensional stability

Research Framework (Grant Influence on Research)

The grant opportunity is a vital step that not only supported my academic pursuits but also contributed to advancing my knowledge and addressing real-world challenges. As part of the research process, efforts were dedicated to adapting to applicable grants, leading to the shortlisting of “EIT Connect” NEB open call grants closely aligned with my research inclination.

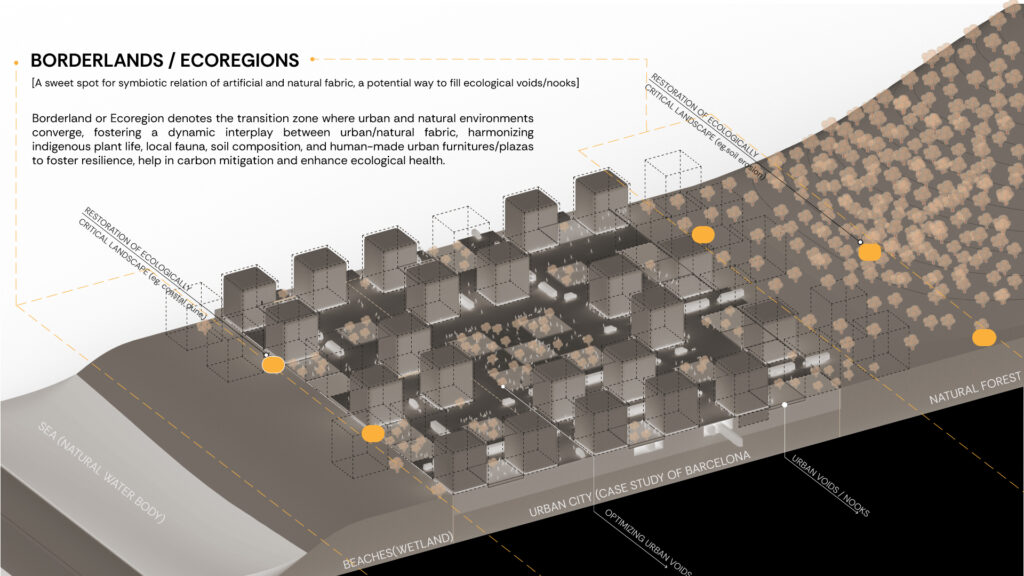

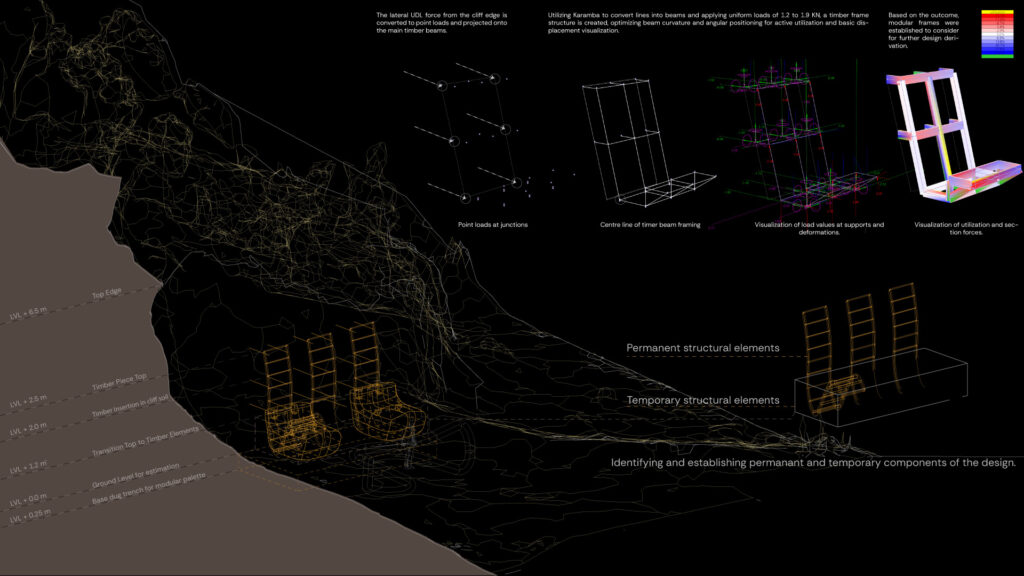

Need for Site Section: Consequently, my research alignment with EIT NEB OPEN CALL, led to the selection of a site, which could give the ‘proof of concept’, a real dimension. In the context of selecting potential locations, which integrate additive manufacturing (AM) and engineered timber within the circular bioeconomy framework, ‘Borderland Ecoregions’ play a crucial role. The grant requirements, converged my site selection to font del gos, based on earlier OPEN NATURE project experience.

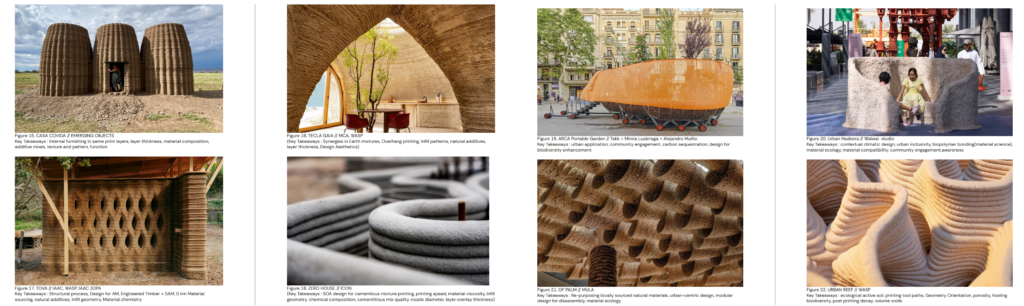

State-of-the-Art

Proof of Concept: Bionook

Bionook [noun phrase]

Bionook embodies an innovative design concept, which refers to a small, strategically placed, and designed green space or ecological pocket/corner(nook) within an ecoregion. These nooks are intended to be crafted in a way to support biodiversity, often incorporating natural elements, such as native plants, soil mixes, and habitat features, while also considering human interaction and usability.

The final prototype of Bionook showcases a harmonious blend of modular engineered timber elements seamlessly integrated with non-structural printed components, embodying both aesthetic appeal and ecological functionality. This innovative design not only exemplifies the capabilities of Additive Manufacturing (AM) and Engineered Timber (ET) symbiosis but also serves as a testament to the potential of Bionook as a Nature-Based Solution (NbS) within the urban fabric. As I envision a cyborganic future, this prototype stands as a proof of concept, highlighting the need for further exploration in design thinking and the application of such technological synergies.

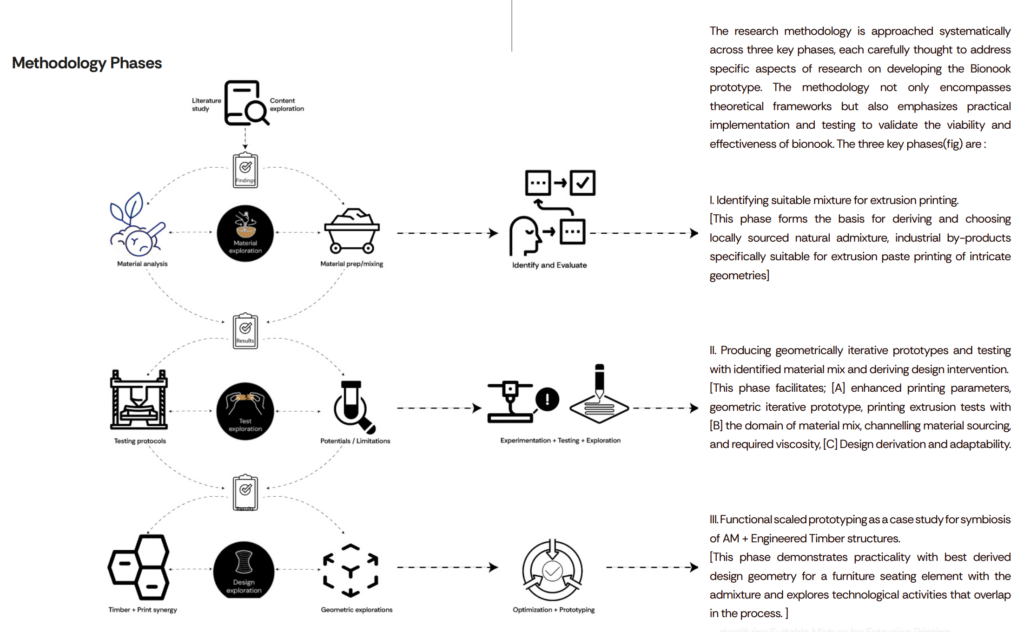

Research and Design Methodology

Methodology Overview (Mind Map)

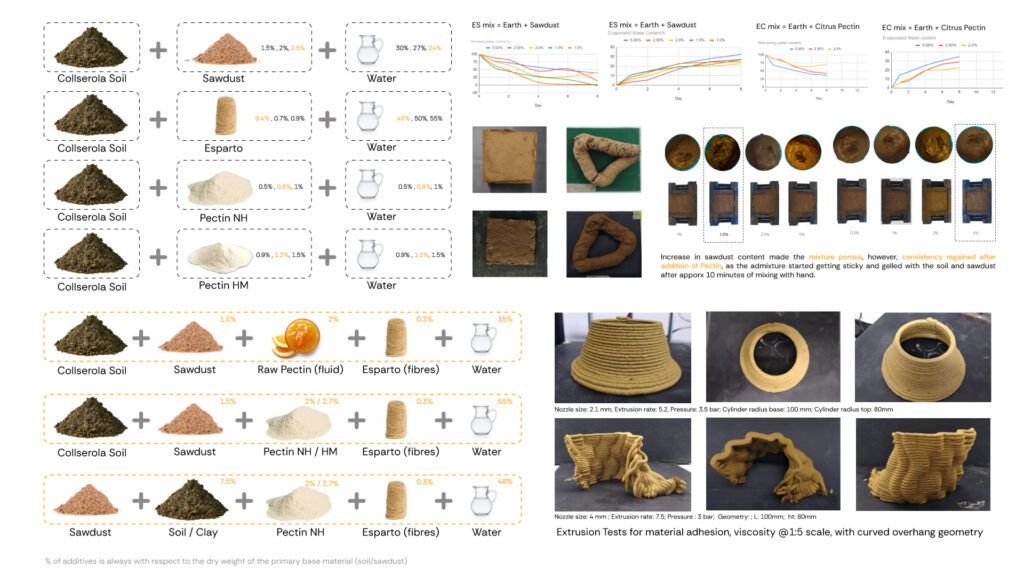

A. Sourcing and Identification of Suitable mixture for printing

The initial phase of this methodology focuses on identifying a suitable mixture for extrusion printing. This involves extensive research and experimentation to derive a locally sourced natural admixture, including industrial by-products, specifically tailored for extrusion paste printing of intricate geometries. By analyzing material

properties, printing feasibility, and environmental impact, the aim is to select a sustainable and functional material mix for subsequent phases.

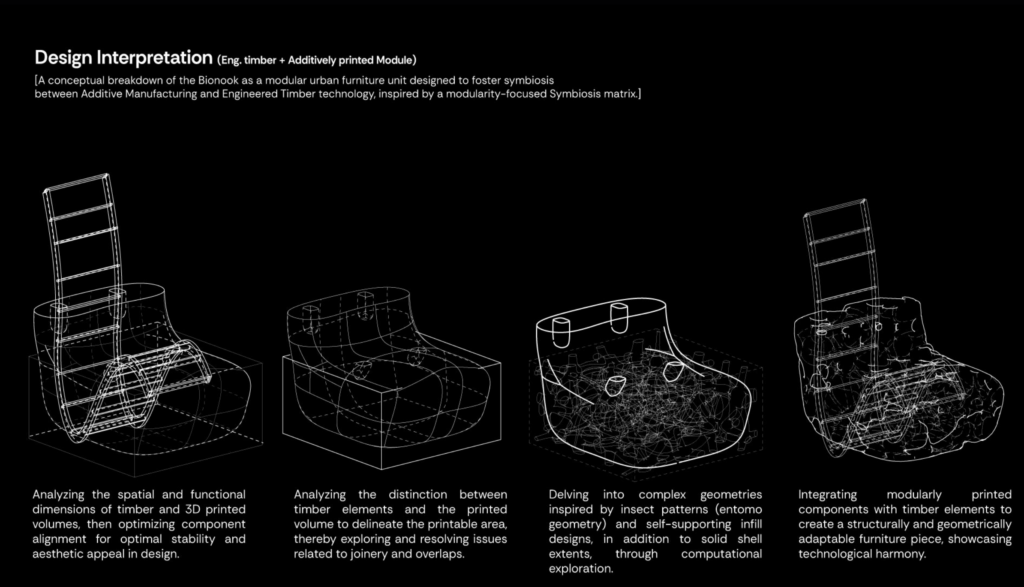

B. Producing geometrically iterative prototypes and Design Interpretation (Symbiosis Matrix)

This next phase of the methodology centers on producing geometrically iterative prototypes and testing them with the identified material mix to derive design interventions. This phase facilitates: -Enhanced printing parameters through iterative testing and optimization; -Conducting printing extrusion tests with a focus on the domain of material mix, ensuring proper channeling of material sourcing, and achieving required viscosity for printing. ; -Deriving design variations and assessing adaptability based on printing results and structural considerations; -Exploring Printing technologies and understanding the suitable one.

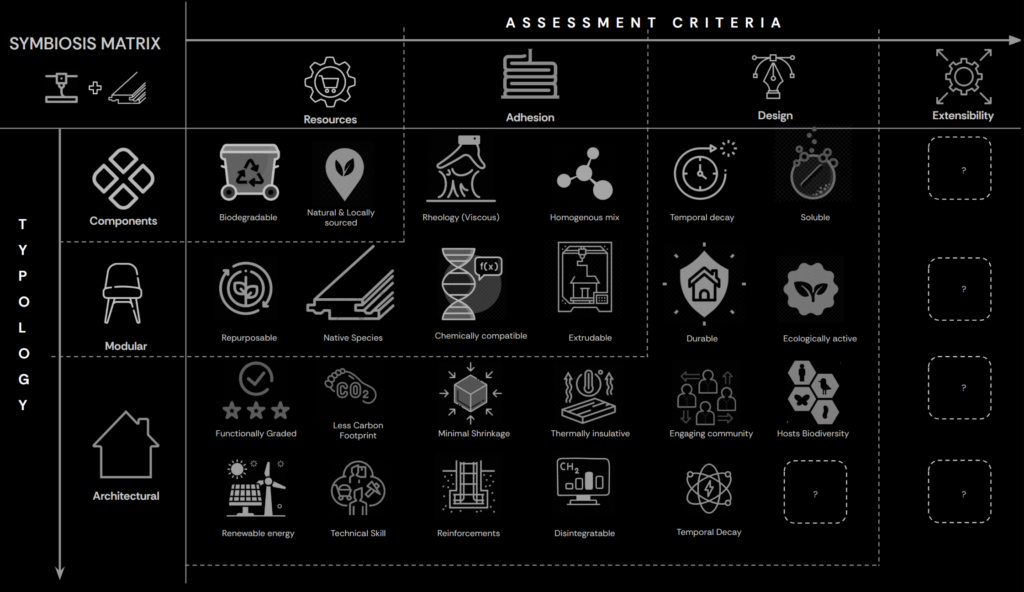

Alongside iterative printing for design, there was an exploration into the broader applicability of these findings. An Open-ended Matrix, termed as: “Symbiosis

Matrix” was developed to assess the technological relevance, design interpretation, and applicability, particularly in determining the symbiosis of Additive Manufacturing (AM) with engineered timber., This “Symbiosis Matrix” includes a section dedicated to extensibility, focusing on how these technologies can seamlessly integrate into existing business ecosystems without significant disruptions or changes to current systems. This approach ensures practicality and real-world feasibility, aligning technological advancements with sustainable and seamless implementation within established frameworks

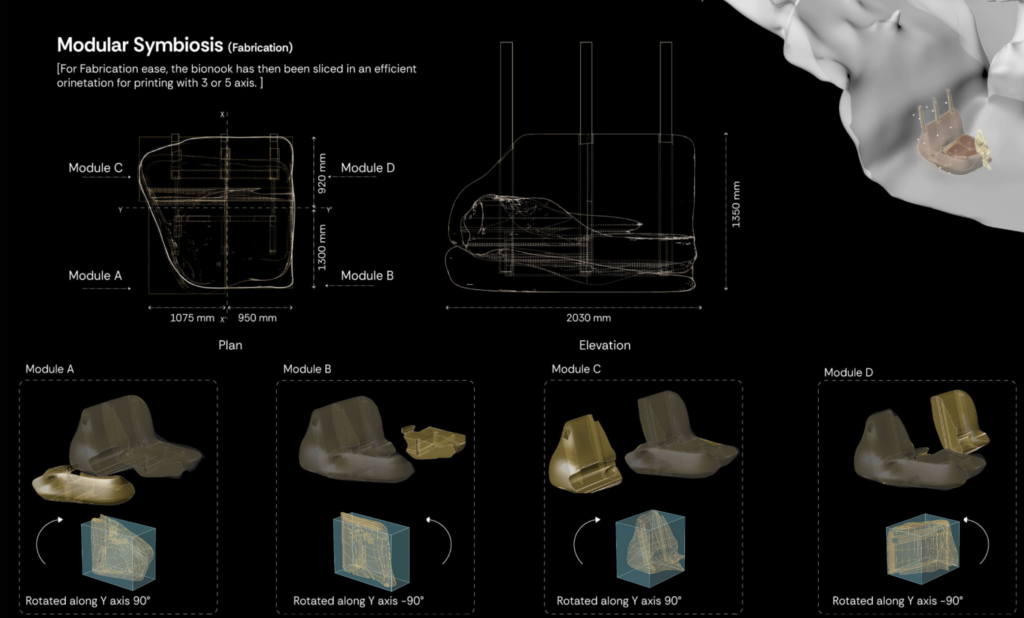

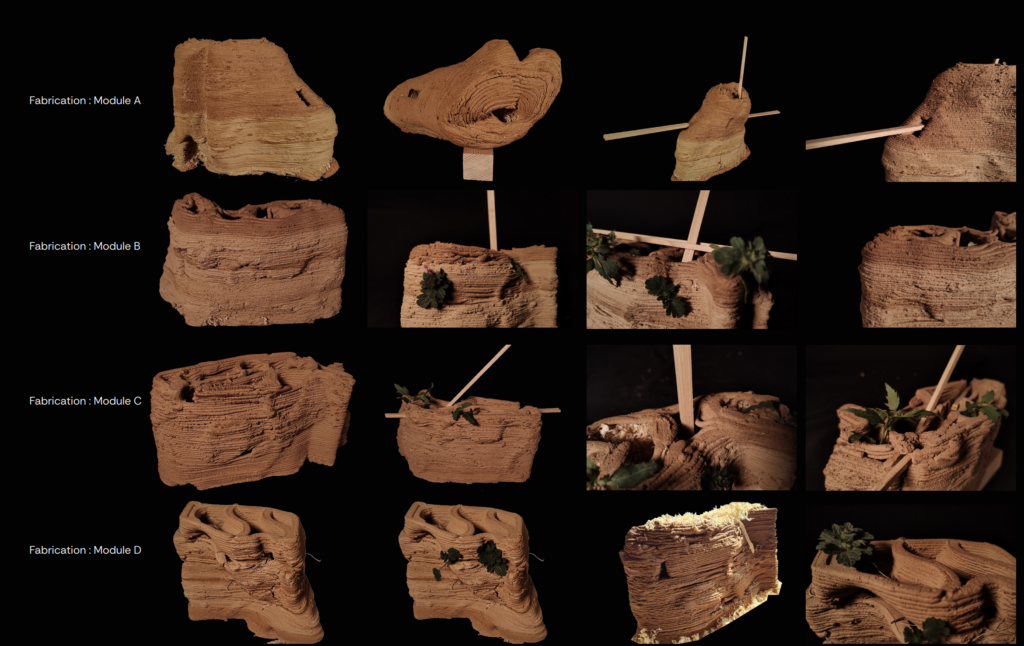

C. Functional scaled prototyping and Fabrication

At the core of this synergy lies the modular nature of engineered timber elements, meticulously crafted to serve as robust structural modules. These scaled modules, encapsulated within a bounding box of 2 meters by 2 meters by 2 meters(in 1:1 scale), showcase versatility and durability, promising longevity in urban environments. Eventually, as the printed elements naturally degrade over time, the engineered timber remains steadfast, ensuring continued functionality and structural integrity. The non-structural printed elements, carefully wrapped and placed around the timber modules, contribute not only to the aesthetic finesse of the design but also serve ecological purposes.

These elements, designed with ergonomic precision and futuristic vision, harmonize with the environment while fostering biodiversity and environmental resilience within urban pockets/nooks. This modular symbiosis is not just a juxtaposition of materials but a thoughtful fusion that leverages the strengths of each component. The technology-driven approach ensures that the design is not only visually captivating but also functionally efficient, catering to the dynamic needs of urban spaces.

Furthermore, the design interpretation for prototyping involved functional scaled prototyping, serving as a case study to showcase the symbiosis of Additive Manufacturing (AM) and Engineered Timber (ET) structures. This includes: -Understanding the modularity at (1:5), which was decided based on the scope and limitations of time and equipment. ; -Demonstrating practicality by implementing the best-derived design geometry into a furniture seating element using the identified admixture. ; -Exploring technological activities that overlap in the process, such as AM techniques, material sourcing strategies, and structural considerations for engineered timber integration.

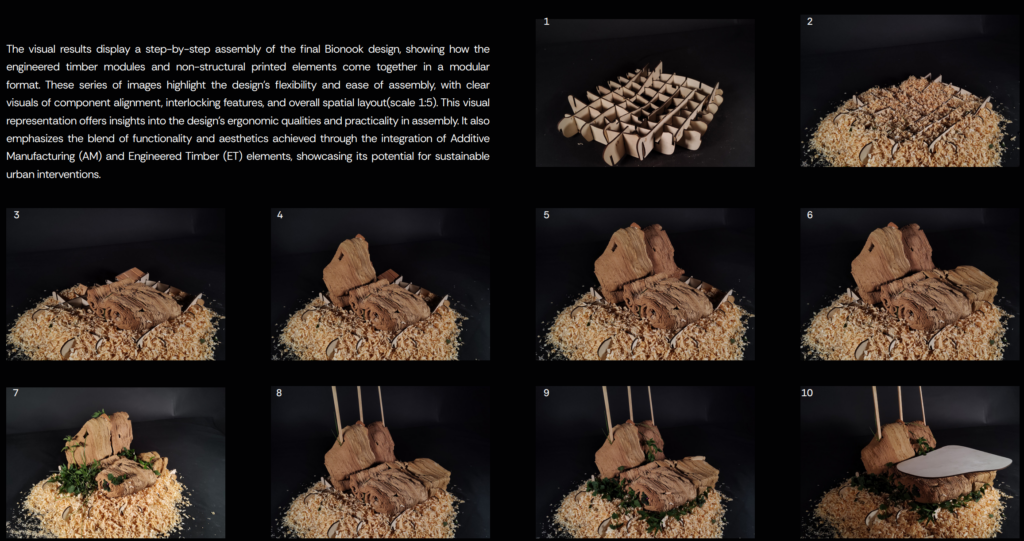

Modular Fabrication

Modular Fabrication is a step-by-step assembly of the final Bionook design, showing how the engineered timber modules and non-structural printed elements come together in a modular

format. These series of images highlight the design’s flexibility and ease of assembly, with clear visuals of component alignment, interlocking features, and overall spatial layout(scale 1:5). This visual

representation offers insights into the design’s ergonomic qualities and practicality in assembly. It also emphasizes the blend of functionality and aesthetics achieved through the integration of Additive Manufacturing (AM) and Engineered Timber (ET) elements, showcasing its potential for sustainable urban interventions

Fabrication Phases (Design for Disassembly)

In conclusion, through thorough literature reviews and grant influence, I developed a methodology focusing on integrating Additive Manufacturing (AM) and Engineered Timber (ET) for urban intervention. Material studies highlighted the potential of repurposing industrial by-products within a circular bioeconomy framework. The creation of modular Bionook prototypes demonstrated structural integrity and aesthetic appeal, aligning with Nature-Based Solutions (NEB) principles. This approach addresses urban voids while enhancing resilience and reducing post-construction carbon impacts, paving the way for further research into regenerative urbanism.