Syllabus

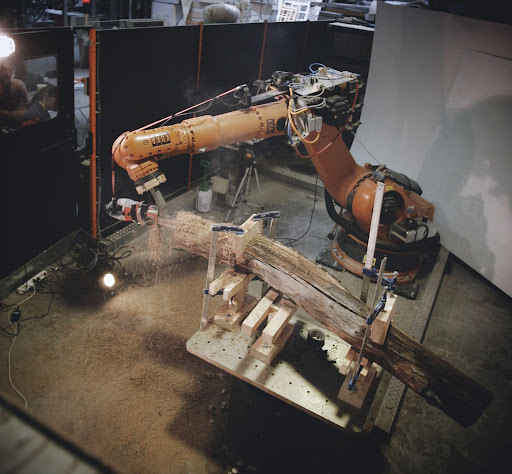

Photo Credits: Robotic ChainSaw © IAAC

Description

In a context of demographic explosion, resource scarcity and global warming, the construction sector needs to evolve towards faster, cleaner, more efficient and more customisable building systems. On the other hand, the current trend of Industry 4.0 promises groundbreaking technologies: robotics, accurate sensors, computational design, AI and cyber physical systems that could potentially transform the way we design, build and inhabit tomorrow.

Focusing on the wood industry, huge quantities of leftover pieces from sawmill and manufacturing are considered waste, often used for energy recovery by burning it, or worth, just discarded in landfills. On the other hand, computer vision could catalogue this “waste” and allow it to be integrated in flexible digital production systems such as robotic ones. This extra sense allows for automated design and manufacturing processes to adapt to each material input, resulting in a system that can handle otherwise unused material, to produce products that are each one different, yet adapted to their function. Towards robotic craftsmanship.

This seminar proposes to explore the design potential lying in an heterogeneous stock of recycled wood that could be upcycled into a constructive project using computer vision, computational design and robotic fabrication ; creating an automated process that adds value to a material normally considered as waste.

Students can expect to learn and practice technology necessary to execute such project : computer vision algorithms, stock nesting, computational design of wood assembly, Robotic path planning and wood process that can be automated

The seminar is structured in two phases. In the first term students will work in small groups and explore different design to fabrication options, concluding each with a possible project proposal, in a competition-like format (with render, detail, budget and calendar). In the second term students will work as one collective toward the engineering and production of one large scale prototype.

Learning Objectives

At course completion the student will learn to :

- Manage an architectural project from design to construction, incorporating digital data flows and automated processes.

- Apply Computational design principles to create mass-customised products based on material inputs.

- Apply Computer vision algorithm into a specific application of fabrication

- Apply Robotic fabrication process in an architectural project.

- Develop design and technology for a circular economy.

Faculty

Faculty Assistants

Projects from this course

Shingles

This project repurposes live-edge wood waste for shingle facade elements, enabling diverse spatial configurations. The goal is a flexible system accommodating varied thickness, length, and geometry of live-edge wood waste. Advanced robotic fabrication and scanning ensure adaptability in design. The focus is on an easily constructed, flexible system utilizing scanning to match live-edge wood, resulting … Read more

LOG-LIVE

MASTER IN ADVANCED ARCHITECTURE ROBOTIC WOODCRAFT FACULTY: Alexandre Dubor, Marielena Papandreou, Huanyu Li STUDENT: Praneeth Aashwinay Basavraju, Anish Hatekar, Bora Cobanoglu, Sunny Manish Chopda

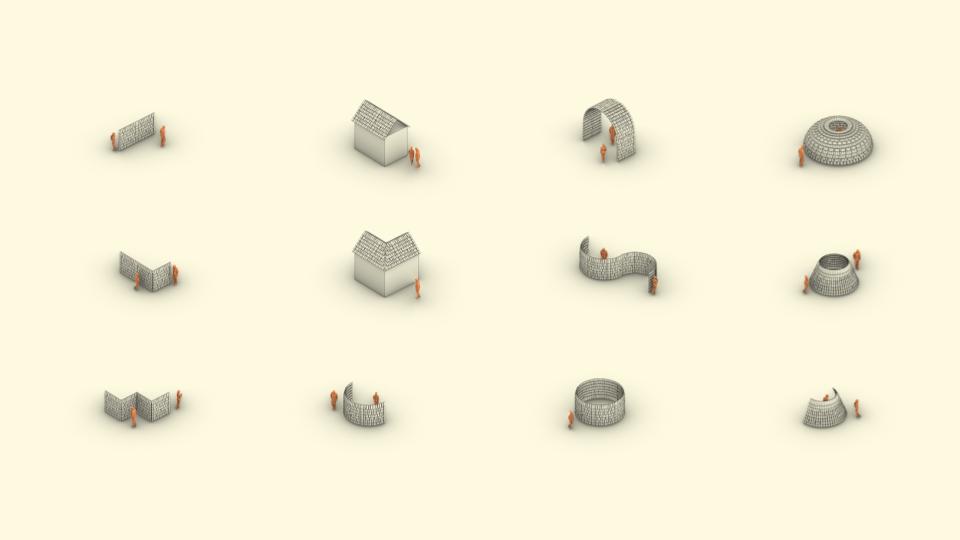

Crafted Configurations

Framework In the year 2018, 28 European Union countries produced 50.2 million tons of wood waste. Unveiling the specifics, timber waste constitutes a substantial 20-30% of the total Construction and Demolition Waste (CDW) stream. 10-15% of the timber used in new construction projects finds its way into the waste stream, contributing to the concerning statistic … Read more