Framework

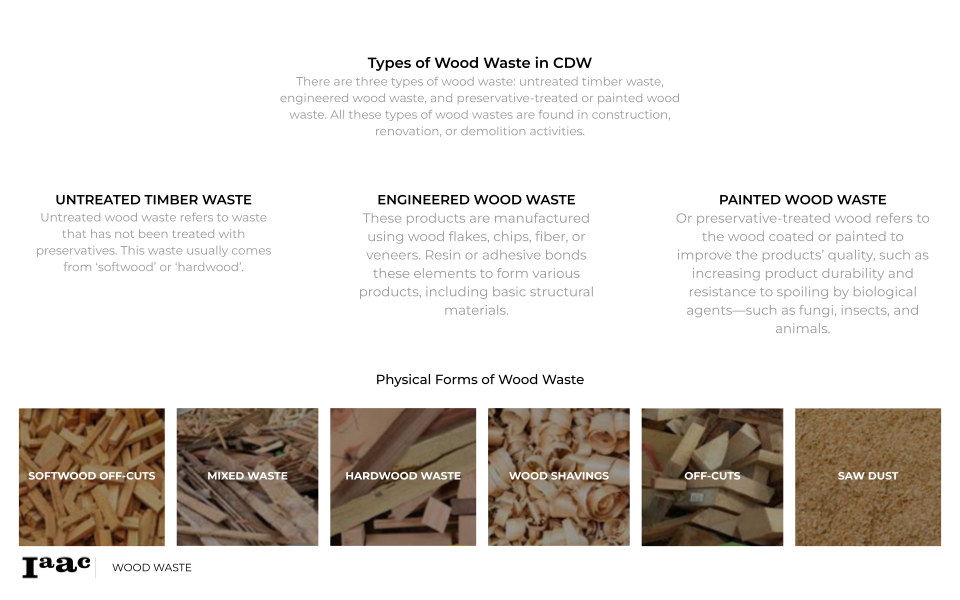

In the year 2018, 28 European Union countries produced 50.2 million tons of wood waste. Unveiling the specifics, timber waste constitutes a substantial 20-30% of the total Construction and Demolition Waste (CDW) stream. 10-15% of the timber used in new construction projects finds its way into the waste stream, contributing to the concerning statistic that approximately 10% of all waste material is dumped into landfills. Timber waste further underscores the complexity of the issue, standing as the second leading element in the Construction and Demolition Waste spectrum. Beyond this, CDW generates a substantial yearly amount of wood waste and disposable solid wood materials. Adding to the environmental impact is the fact that wood, as an organic material, undergoes anaerobic decomposition when landfilled, releasing significant amounts of greenhouse gases (GHG) such as carbon and CH4 into the environment.

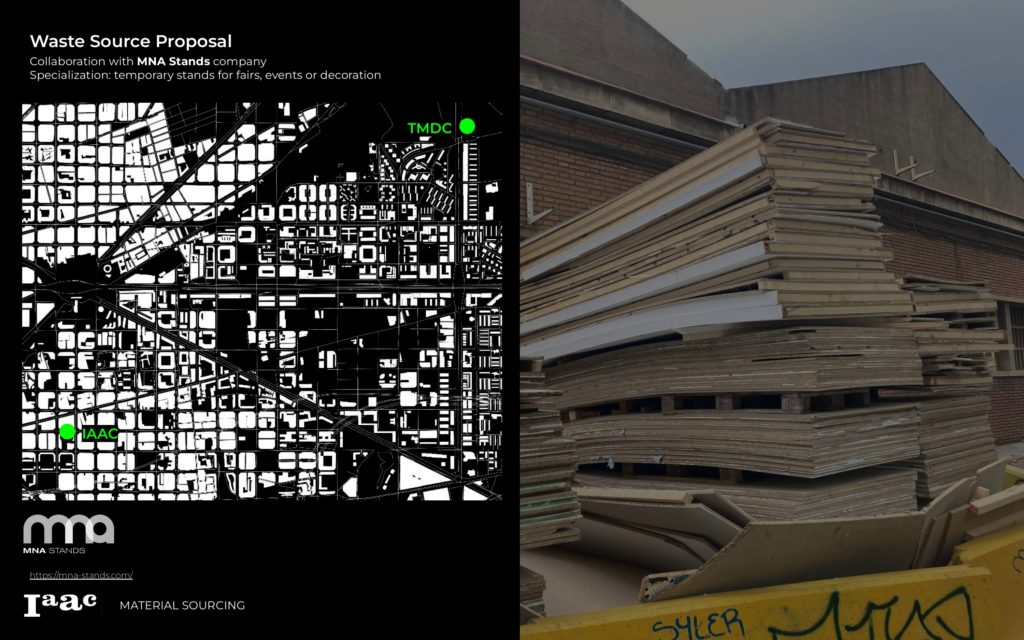

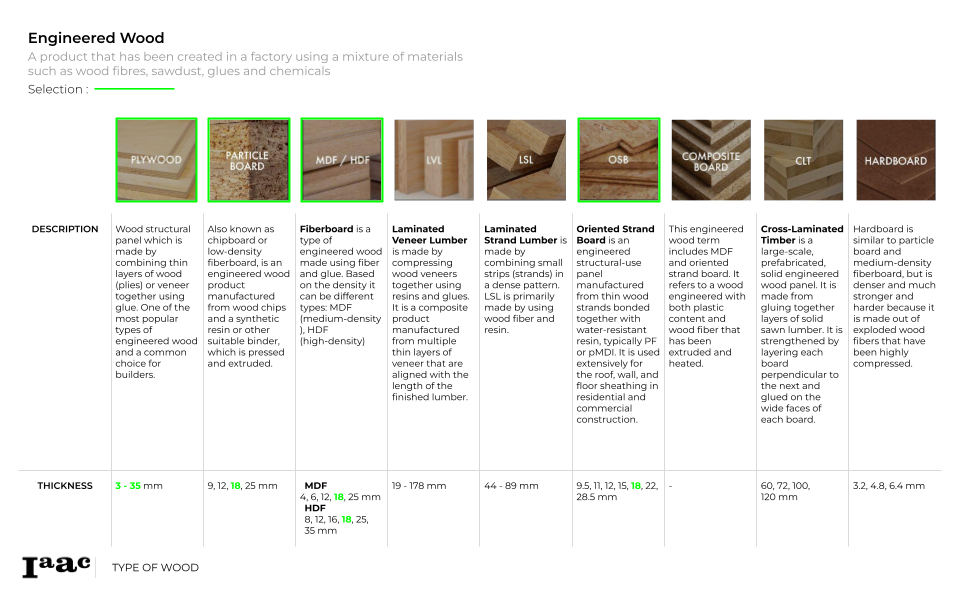

Wood waste manifests in three distinct types: untreated timber waste, engineered wood waste, and preservative-treated or painted wood waste. These varieties of wood waste are commonly encountered in construction, renovation, or demolition endeavors. For our project, we have opted to focus specifically on engineered wood waste as the primary material.

Engineered wood is a composite product crafted from various layers of wood veneers, strands, or fibers bonded together with adhesives under heat and pressure. Unlike traditional solid wood, engineered wood boasts enhanced structural stability and resistance to warping and cracking. Engineered wood products come in various forms, including plywood, oriented strand board (OSB), and laminated veneer lumber (LVL), each tailored to specific applications. In construction and design, engineered wood finds widespread use for its dimensional stability and strength. It is employed in framing, flooring, and structural elements.

We chose various types of engineered wood as potential materials for our project due to their consistent standard thickness, a critical feature aligning with our design requirements.

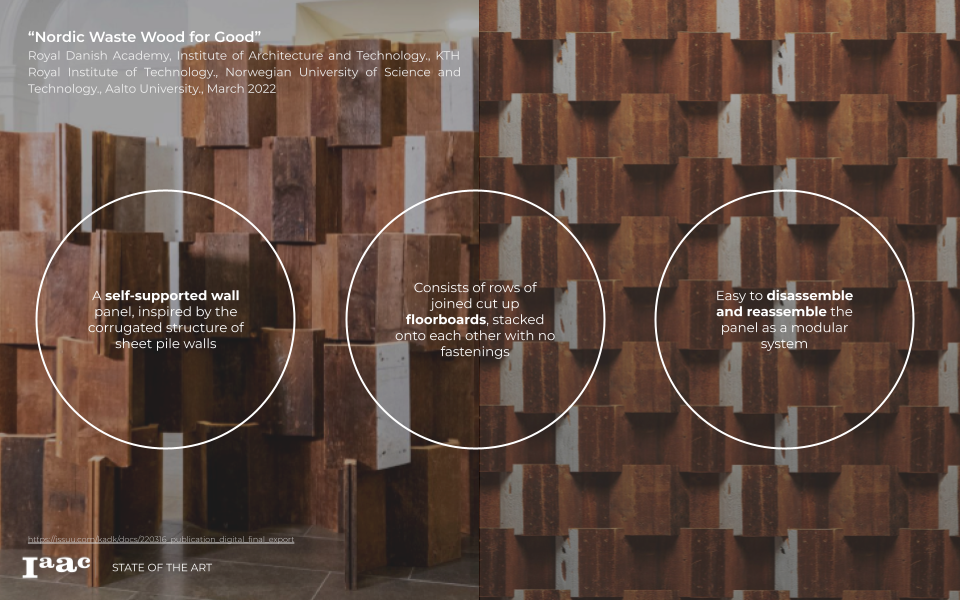

State of the Art

DESIGN

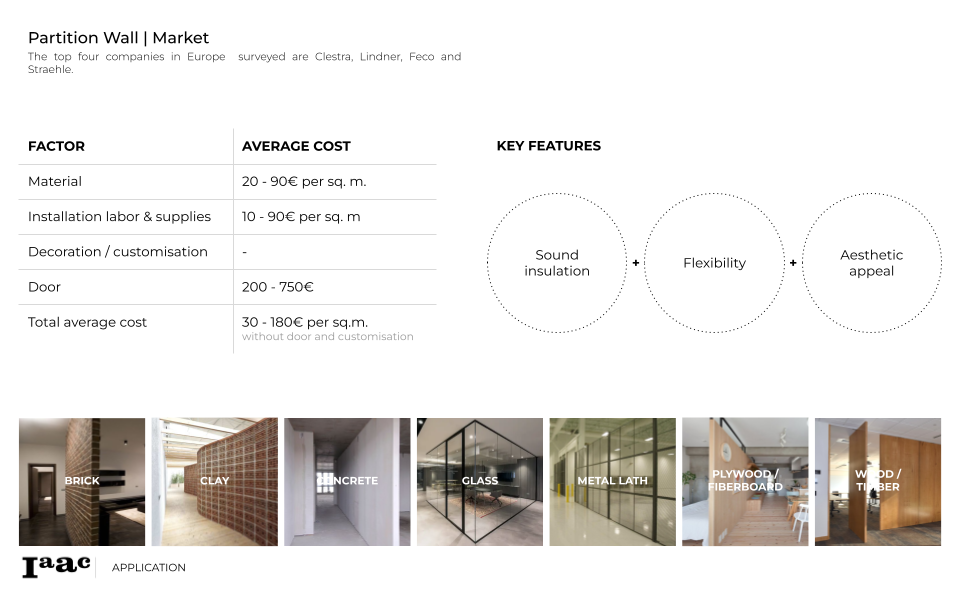

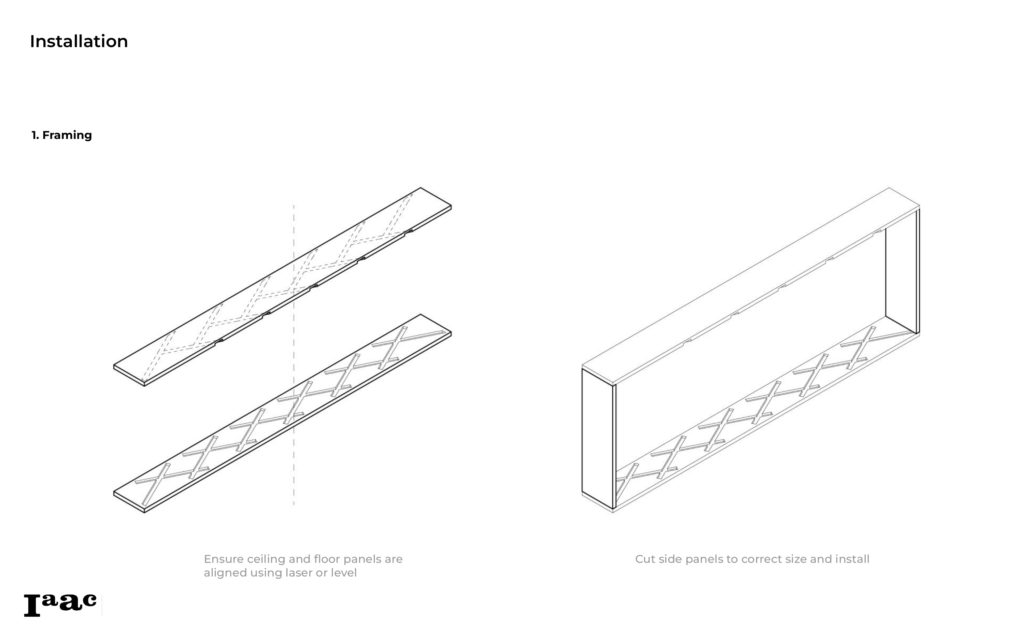

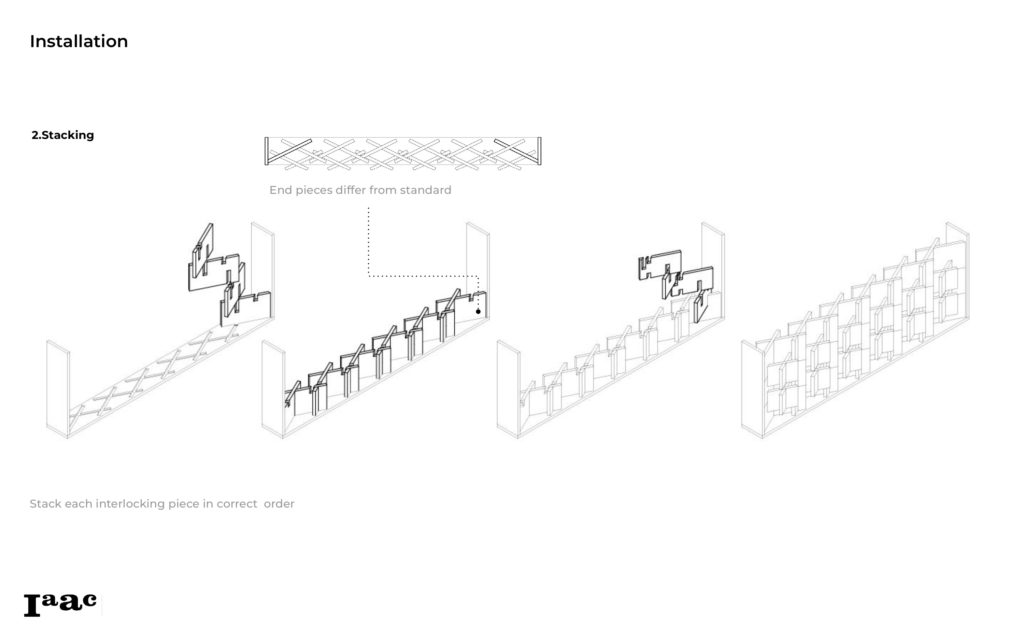

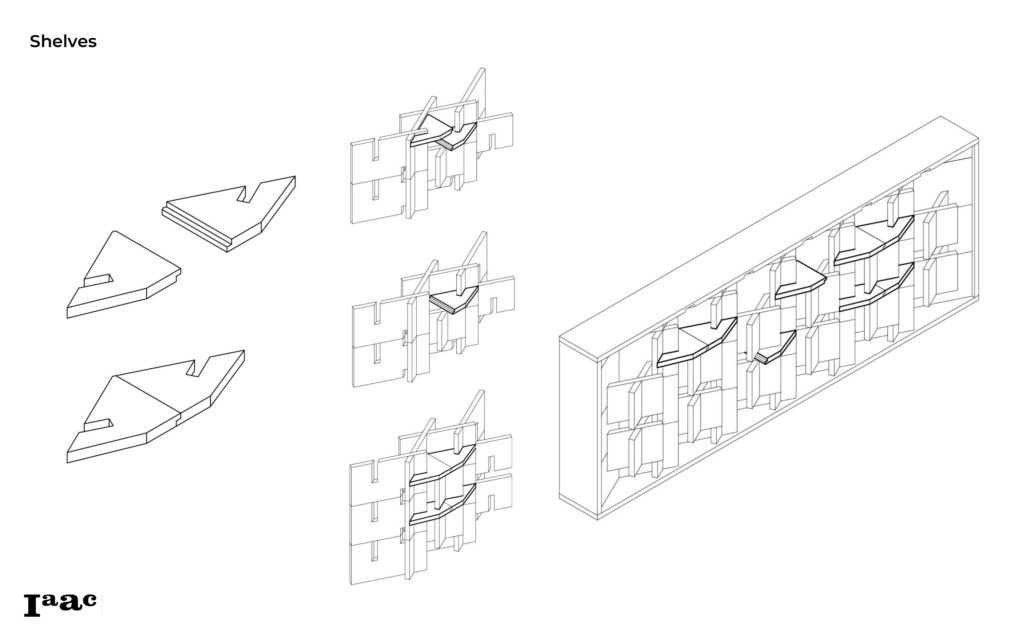

A partition wall is an interior design element, serving both functional and aesthetic purposes. Partition walls come in various materials, finishes, and configurations. Key features of a partition wall include sound insulation to enhance privacy (the best soundproof wood types are Acoustic Plywood, Medium Density Fiberboard (MDF), and Oriented Strand Board (OSB), flexibility, allowing for versatile space utilization and an aesthetic appeal that complements the overall design scheme.

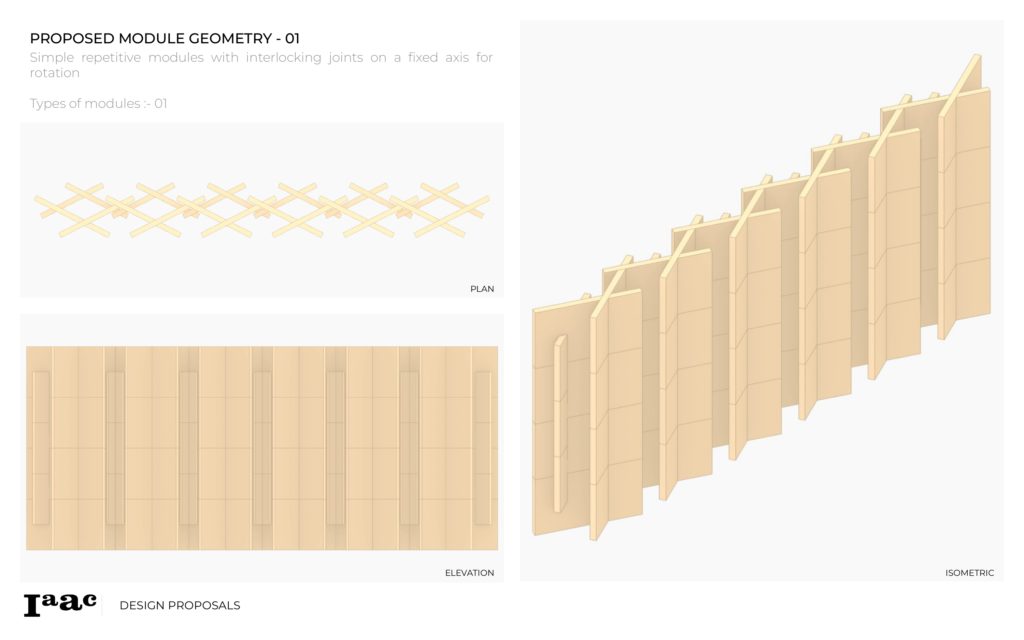

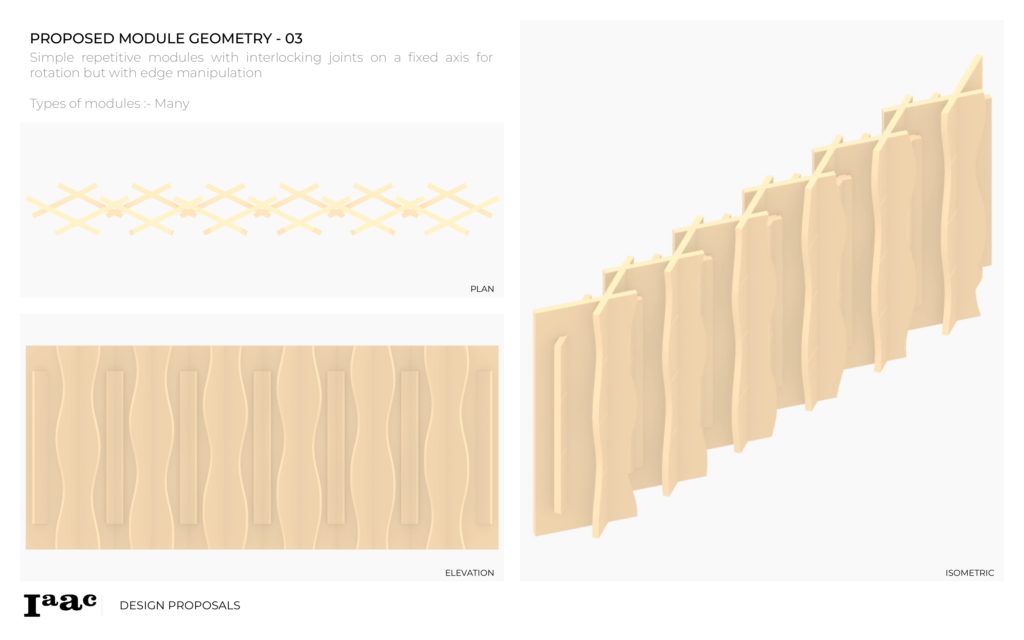

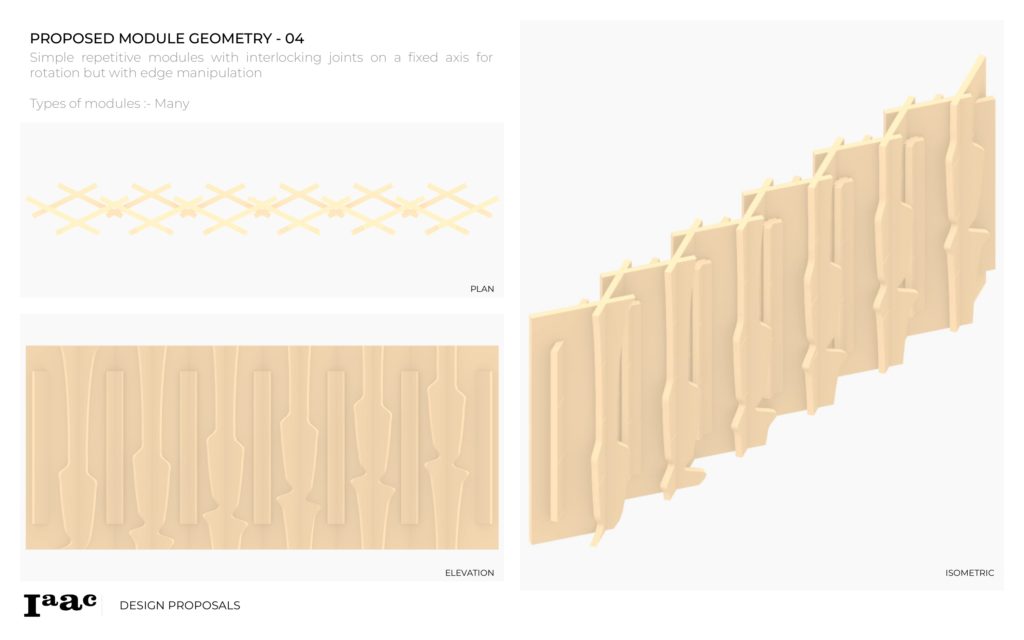

Design logic

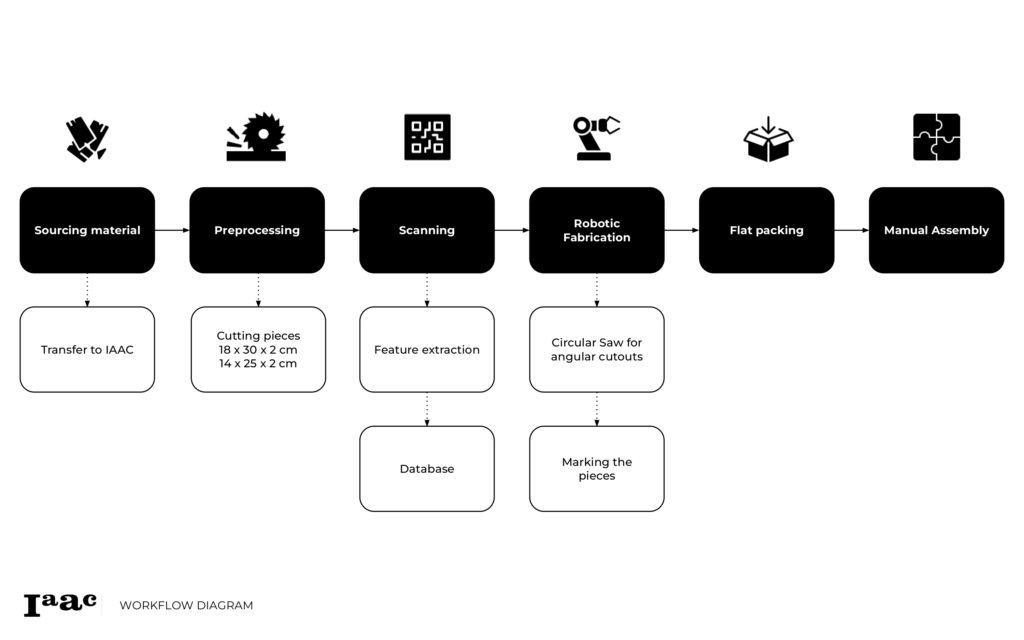

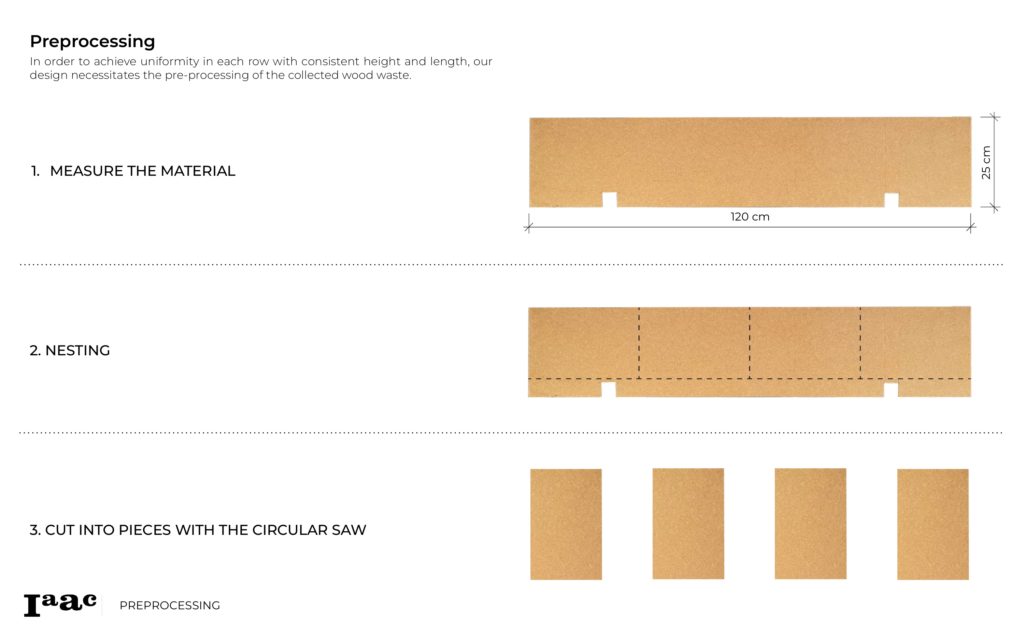

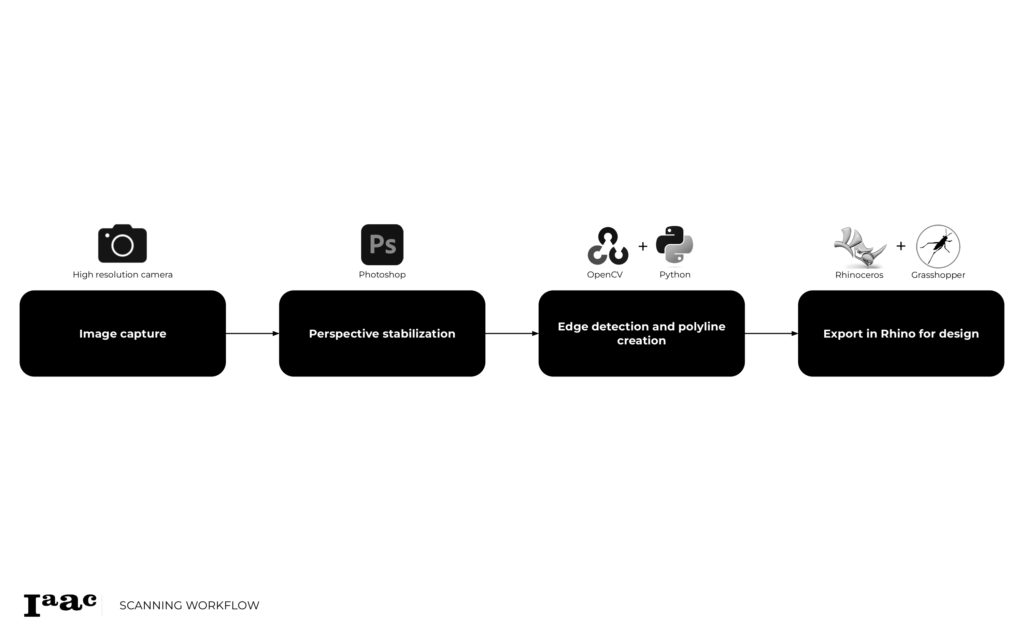

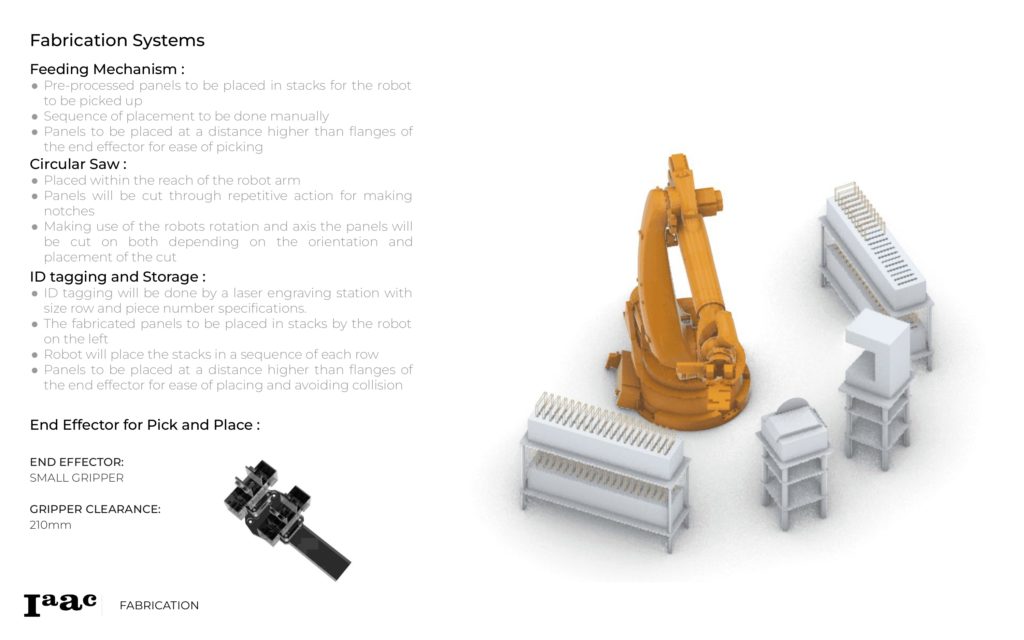

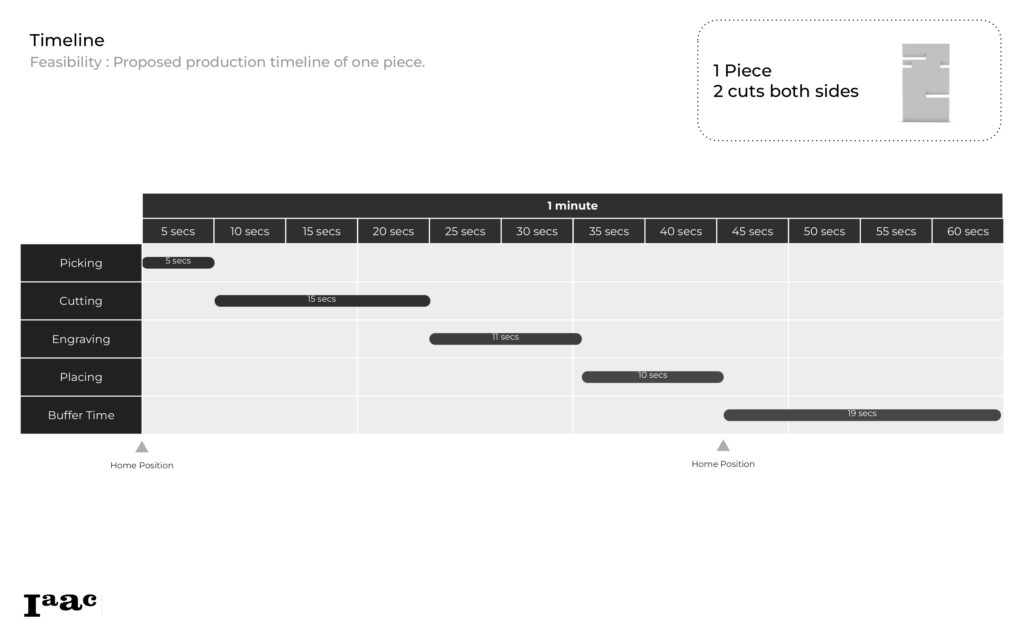

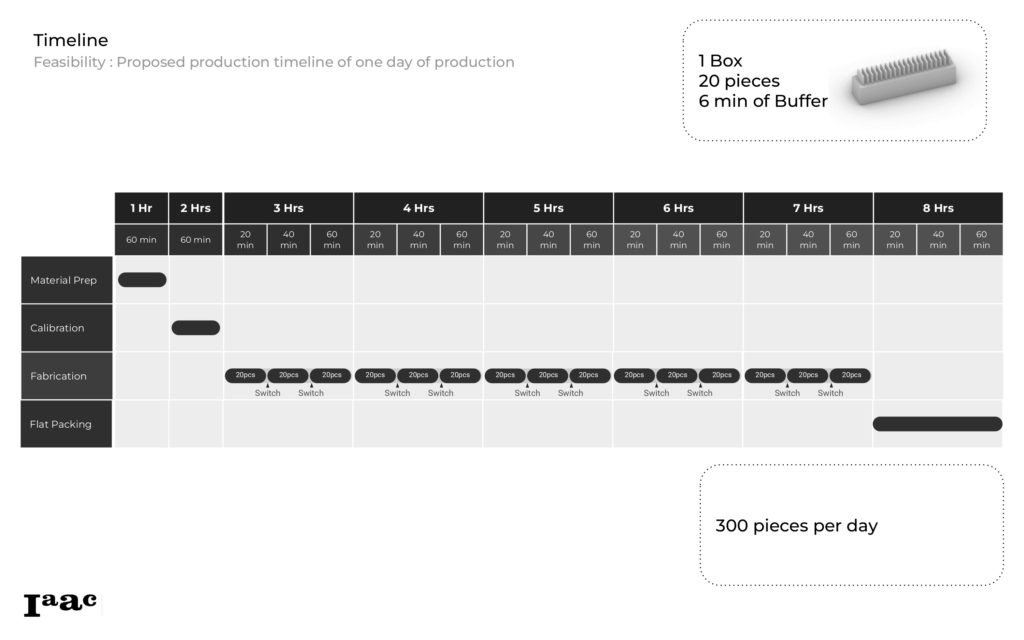

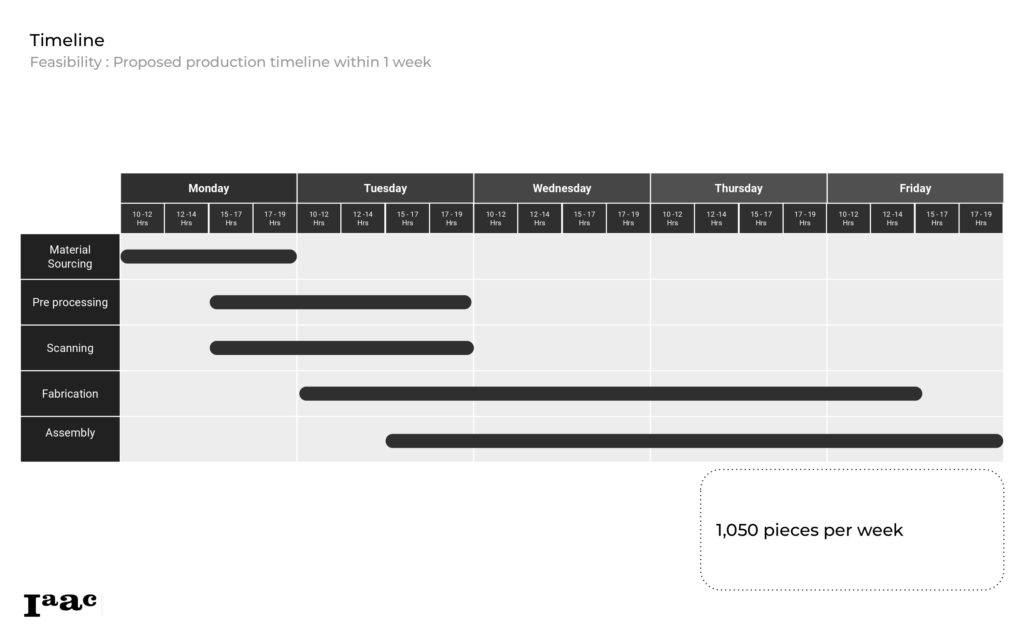

Workflow